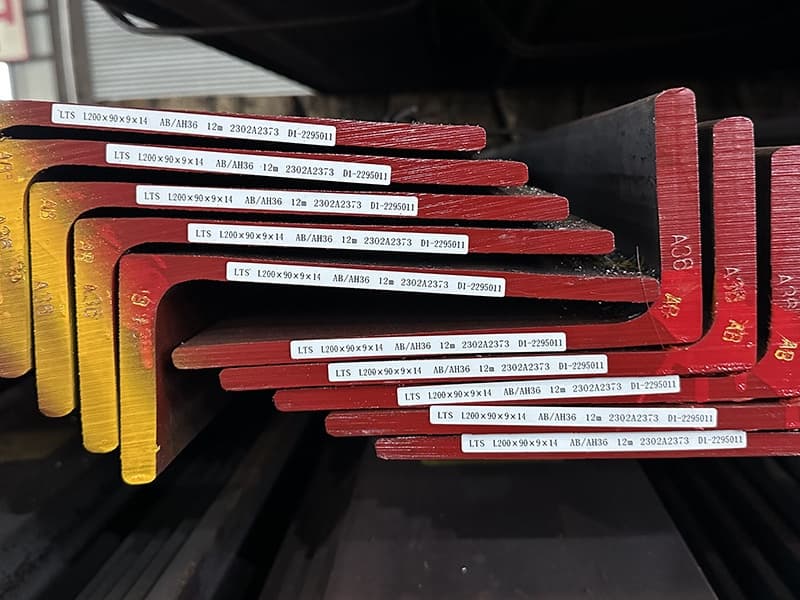

You see two L-shaped steel samples. One is hot rolled, one is cold formed. For a ship’s frame, the choice is clear and critical. The wrong process can compromise the entire vessel’s integrity in harsh seas.

Shipbuilders prefer hot-rolled marine L-shaped steel because it offers superior toughness and impact resistance at low temperatures, better weldability due to a normalized microstructure, and dimensional suitability for heavy structural frames. These properties are essential for a ship’s safety and longevity, making it the best choice over cold-formed sections.

The preference isn’t about tradition; it’s about physics and performance. Hot rolling does more than shape the steel; it defines its internal structure and capabilities. Let’s examine the advantages that make it the undisputed choice for building ships that must survive decades at sea.

What are the advantages of hot rolled steel?

You need steel that can absorb energy, not just resist bending. In a collision or a rogue wave, the steel must deform, not shatter. This ability is rooted in the hot rolling process.

Hot-rolled steel’s key advantages are better toughness and ductility, a more favorable microstructure for welding, and typically higher yield strength for structural grades. It is also more cost-effective for producing large sections like L-angles, I-beams, and plates used in shipbuilding.

The Metallurgical Edge: How Heat Shapes Performance

The advantages of hot-rolled steel are not just a list of features. They are direct consequences of the manufacturing process. Steel is shaped at temperatures above 1700°F (925°C), which is above its recrystallization temperature. This high heat changes everything.

1. Superior Toughness and Ductility

This is the most critical advantage for marine applications.

- The Process: During hot rolling, the steel’s grain structure (the arrangement of its microscopic crystals) is broken down and reformed into a finer, more uniform grain structure as it cools. A finer grain size is the single most important factor for improving toughness—the ability to absorb impact energy.

- The Result: Hot-rolled steel has a lower Ductile-to-Brittle Transition Temperature (DBTT). This means it stays ductile (able to bend and deform) at much lower temperatures. For a ship in the North Atlantic, this property prevents catastrophic brittle fracture.

2. Excellent Weldability

A ship is a welded structure. The quality of every weld is vital.

- The Process: The hot-rolling and subsequent cooling (often controlled or normalized) produces a relatively soft, uniform microstructure with low residual stress. It also results in a lower Carbon Equivalent Value (CEV) for a given strength level compared to some cold-worked alternatives.

- The Result: This microstructure is less prone to cracking in the Heat-Affected Zone (HAZ) during welding. It requires less pre-heat, simplifies welding procedures, and produces more reliable, crack-free joints. This directly translates to faster construction and higher structural integrity.

3. Favorable Mechanical Properties for Structural Use

Hot-rolled structural steels (like S355, AH36) are engineered for construction.

- The Process: Alloying elements like manganese and niobium are used in combination with controlled rolling and cooling to achieve high yield strength (e.g., 355 MPa) while maintaining good toughness.

- The Result: You get a material with a well-defined yield point, good elongation (ductility), and guaranteed minimum impact values. These are published, certified properties that designers can rely on.

4. Economic Production of Large Sections

It is virtually impossible to cold-form a large L-angle like 200x200x20mm. Hot rolling is the only practical and economical method to produce the heavy sections required for ship frames, stiffeners, and brackets.

This comparison highlights why these advantages matter at sea:

| Advantage of Hot-Rolled Steel | Why It Matters in Shipbuilding | Consequence of Using an Inferior Process |

|---|---|---|

| High Toughness / Low DBTT | The hull must resist impact from ice, collision, or heavy seas without brittle fracture. | Risk of sudden, catastrophic crack propagation in cold water. |

| Good Weldability | A ship has kilometers of welds. Reliable welding is essential for watertight integrity and strength. | Increased risk of weld cracks, leading to leaks or structural failure. More complex/expensive welding procedures. |

| Certified Mechanical Properties | Naval architects design based on guaranteed yield strength and impact values. | Unpredictable performance. The structure may not meet the designed safety margin. |

| Availability in Large Sections | Ship frames and longitudinals require massive, long sections. | Design compromise, needing built-up sections, increasing weight and fabrication time. |

For a shipbuilder, these are not optional benefits. They are mandatory requirements for building a classed vessel that will receive insurance and operate safely. When we supply hot-rolled marine L-shaped steel, we are delivering this complete package of certified performance.

What is the best steel for ship building?

"Best" is a dangerous word if not defined. For shipbuilding, the best steel is not one type, but a family of materials chosen for a balance of specific properties that guarantee safety, durability, and efficiency over a 25-year life in saltwater.

The best steel for shipbuilding is hot-rolled, normalized high-strength low-alloy (HSLA) steel with guaranteed toughness at low temperatures, such as grades AH36/DH36/EH36. It is produced to strict classification society rules (ABS, DNV, LR) to ensure consistent weldability, strength, and corrosion performance for hull structures.

The Hierarchy of Needs: Selecting the "Best" for Each Part

There is no single "best" steel for an entire ship. The best steel is the one that most precisely meets the requirements of each specific location, balancing performance, cost, and constructability. Let’s build this hierarchy from first principles.

The Non-Negotiable Core Requirements:

Any steel used in the primary hull structure must have:

- Adequate Strength: To withstand global hull bending moments and local pressures.

- Guaranteed Toughness: To prevent brittle fracture, especially in colder waters.

- Excellent Weldability: To allow for efficient and sound construction.

- Consistent Quality: Batch-to-batch uniformity is critical for predictable fabrication and performance.

- Classification Society Approval: This is the formal certification that the steel meets all the above.

The "Workhorse" Grade: AH36 / DH36

For the majority of a commercial vessel’s hull—the bottom, side shell, decks, and major frames—the best and most common choice is Grade AH36 or DH36.

- AH36: ‘A’ grade for general areas, ‘H’ for high strength, ’36’ for ~355 MPa yield strength. Often supplied in the as-rolled condition.

- DH36: ‘D’ grade indicates guaranteed impact toughness at -20°C. This is the standard for most ocean-going vessels. It is often normalized (heat-treated) to ensure this toughness.

- Why it’s the best balance: It provides high strength (allowing for thinner, lighter plates), proven toughness for most routes, good weldability, and is widely available at a competitive cost.

Specialized Grades for Special Areas:

- Higher Strength (EH40/FH40): Used in the sheer strake, keel, and upper deck of large container ships to manage higher stresses. Grades E and F offer toughness down to -40°C and -60°C for ice-class vessels.

- Extraordinary Toughness (Arctic Grades): For icebreakers, steels with added nickel (e.g., 3.5% Ni, 5% Ni) are used to maintain toughness below -50°C.

- Corrosion-Resistant Steels: For chemical tankers or specific areas, stainless clad steel or specially alloyed steels are used.

The Critical Role of Hot Rolling in Delivering the "Best"

The "best" steel grade specifications (like DH36) are achieved through the hot-rolling process. The controlled thermomechanical rolling or subsequent normalizing treatment is integral to developing the required fine-grained microstructure that delivers both strength and toughness.

This selection matrix shows how the "best" steel is chosen:

| Ship Area / Component | Primary Requirement | Typical "Best" Steel Choice | Key Reason |

|---|---|---|---|

| Bottom Shell Plating | High strength, resistance to slamming, good toughness. | DH36 (Normalized) | Balanced strength & guaranteed -20°C toughness for most trades. |

| Side Shell (Amidships) | Strength, toughness, weldability. | AH36 or DH36 | Standard workhorse grade. |

| Sheer Strake (Upper Side) | Very high strength & toughness (high stress area). | EH36 or EH40 | Enhanced toughness (-40°C) and higher strength for critical zone. |

| Deck Plating (Midship) | High tensile strength to resist hull bending. | AH36/DH36, or higher grades for large ships. | Resists tensile stresses from hull sagging. |

| Frames & Stiffeners (L-Shaped Steel) | Good strength-to-weight, excellent weldability, toughness. | Hot-rolled AH36/DH36 L-Angles. | Can be easily welded to plate; provides required structural performance. |

| Ice Belt | Extreme impact resistance and low-temperature toughness. | FH-grade or Arctic Ni-steel. | Must withstand ice impact at extremely low temperatures. |

Therefore, the best steel is a hot-rolled, class-approved HSLA steel in the appropriate grade. For L-shaped sections used in frames and brackets, this means hot-rolled marine angles in grades like AH36 or DH36. It is the combination of the right material, the right process, and the right certification that makes it "best."

Which is better, CR or HR?

Cold-rolled (CR) steel has a smooth, shiny finish. Hot-rolled (HR) steel has a rough, scaled surface. For a ship’s interior panel, CR might be better. For the ship’s main frame, the question isn’t about looks—it’s about survival, and HR is definitively better.

For structural applications in shipbuilding, Hot-Rolled (HR) steel is better than Cold-Rolled (CR). HR offers superior toughness, weldability, and is available in the thick, large sections needed for frames and hulls. CR is better for non-structural applications requiring precise dimensions and a smooth surface, like panels or furniture.

A Process Comparison, Not a Simple Ranking

"Better" depends entirely on the application. CR and HR are different tools for different jobs. Comparing them directly requires understanding their processes and resulting properties. For load-bearing marine structures, HR’s advantages are overwhelming.

The Cold Rolling (CR) Process and Its Niche

Cold rolling takes hot-rolled steel and passes it through rollers at room temperature.

- What it does: It compresses the steel, making it thinner, harder, and stronger through "strain hardening." It also produces a very smooth, precise surface finish.

- Key Properties: Higher yield strength (from work hardening), excellent surface finish, tight dimensional tolerances.

- The Major Drawback for Structure: Cold working reduces ductility and toughness. The steel becomes harder but more brittle. It also increases residual stresses.

- Marine Application: CR steel is used for non-structural elements: interior wall panels, cabinet-making, furniture, decorative trim, or appliances on a ship. It is never used for primary hull frames, brackets, or plating.

The Hot Rolling (HR) Process and Its Dominance

As detailed before, hot rolling shapes steel above its recrystallization temperature.

- What it does: It shapes the steel while maintaining a soft, ductile, and tough microstructure. It produces a mill-scaled surface and has wider dimensional tolerances.

- Key Properties: Excellent toughness and ductility, good weldability, favorable microstructure.

- Marine Application: This is the exclusive process for all primary and secondary structural members: hull plates, deck plates, bulb flats, and L-shaped steel for frames.

Why HR is the Only Choice for Structural L-Shaped Steel

Let’s be explicit: You cannot make a Class-approved marine L-angle from cold-rolled steel. Here’s why:

| Property/Requirement | Hot-Rolled (HR) L-Shaped Steel | Cold-Rolled (CR) Steel (General) | Why HR Wins for Ship Frames |

|---|---|---|---|

| Toughness / Impact Resistance | High. Fine-grained structure ensures low DBTT. | Low. Work hardening makes it brittle. | A frame must absorb impact energy without cracking. Brittleness is unacceptable. |

| Weldability | Excellent. Low residual stress, uniform microstructure. | Poor. High residual stress and hardened structure promote weld cracks. | Frames are welded continuously. Poor weldability creates immediate failure points. |

| Ductility | High. Can undergo significant deformation. | Low. Prone to cracking if bent. | The structure needs to yield and deform as a warning before failure. |

| Availability in Size | Produced in large sections (up to 300mm+ legs). | Limited to thinner, smaller sections (typically from sheet/coil). | Ship frames require large, heavy angles. CR cannot produce them. |

| Surface Finish | Mill scale, requires blasting before painting. | Smooth, shiny, often ready for painting or plating. | Irrelevant. Structural steel is always blasted and painted. The surface is prepared. |

| Cost for Structural Sections | Lower cost per ton for large shapes. | Higher cost, suitable for finished products. | More economical for the massive tonnage required. |

For a shipbuilder, the choice is clear and binary. Hot-rolled steel is for structure. Cold-rolled steel is for finish. Attempting to use CR for a structural frame would violate every classification society rule and create an unsafe vessel. Our supply chain is built around providing the correct HR structural products, like L-shaped steel, that meet these fundamental requirements.

What are the three types of hot rolled steel?

Hot-rolled steel isn’t one product. It’s a category. Knowing the three main types helps you understand what you’re buying and ensures you get the right material for brackets, frames, or hull plates.

The three primary types of hot-rolled steel are: 1) Hot-Rolled Structural Shapes1 (beams, channels, angles like L-shaped steel), 2) Hot-Rolled Plate2, and 3) Hot-Rolled Sheet/Strip/Coil3. They differ in their cross-section, thickness, and primary uses in shipbuilding and construction.

The Product Family: From Coils to Massive Shapes

All three types start as a hot slab, but their journeys through the rolling mill differ, resulting in distinct product forms. For shipbuilding, all three are essential, but they play very different roles.

1. Hot-Rolled Structural Shapes1 (Sections)

This category includes all the profile sections with a constant cross-section along their length.

- How it’s made: A heated billet is passed through a series of specially shaped rolls in a structural mill4 to progressively form the final profile (like an L, I, or U shape).

- Key Products: L-Shaped Steel5 (Angles), I-Beams (W-beams, H-beams), Channels, Tees, Bulb Flats, Z-sections.

- Typical Dimensions: Thick (e.g., 6mm to 100mm+), supplied in standard lengths (6m, 9m, 12m, 18m).

- Primary Shipbuilding Use: These are the bones of the ship. L-angles for frames and brackets. Bulb flats for longitudinal stiffeners. Large I-beams for deck girders and transverse frames.

2. Hot-Rolled Plate2

Plate is a flat product with a width-to-thickness ratio that distinguishes it from sheet.

- How it’s made: A thick slab is reduced to a specific thickness by passing it back and forth through a plate mill6 with horizontal rolls.

- Key Product: Flat steel plates.

- Typical Dimensions: Thickness typically > 3mm (1/8 inch) and can be over 300mm. Widths up to 5 meters. Sold in discrete sheets or cut-to-order.

- Primary Shipbuilding Use: This is the skin of the ship. Hull plating, deck plating, bulkheads. It is also the starting material for cutting and fabricating complex parts that are not standard sections.

3. Hot-Rolled Sheet/Strip/Coil3

This is the thin, flat product, often supplied in large coils.

- How it’s made: A slab is hot-rolled down to a thin gauge in a hot strip mill and then coiled for efficiency.

- Key Products: Hot-rolled coil (HRC), hot-rolled sheet (cut from coil).

- Typical Dimensions: Thickness generally from about 1.5mm (1/16") up to about 12-13mm. Very wide (up to 2 meters).

- Primary Shipbuilding Use: Limited in primary hull structure. May be used for non-critical, lighter applications like some interior partitions, ductwork, or temporary works. Its main industrial use is as feedstock for cold-rolling mills to make cold-rolled sheet, or for manufacturing pipes and tubes.

This table summarizes their roles in a shipbuilding project:

| Type of Hot-Rolled Steel | Example Products | Primary Role in Shipbuilding | Key Supplier Considerations |

|---|---|---|---|

| Structural Shapes | L 150x100x12, Bulb Flat 250×12, HP 310×12.7 | Primary & Secondary Structure: Frames, stiffeners, girders, brackets. | Must be from a mill certified for shape rolling to class society rules. Dimensional tolerances and straightness are critical. |

| Plate | Plate 15mm x 2000mm x 8000mm, Grade DH36. | Hull & Deck Plating, Fabricated Parts: The main envelope of the ship. | Must be from a mill certified for plate production. Thickness control, flatness, and internal soundness (UT tested) are vital. |

| Sheet/Coil | HR Coil, 4mm thick, 1500mm wide. | Ancillary & Non-Structural Uses: Ducts, covers, non-load-bearing linings. | Not typically supplied for critical marine structure. Focus is on price and basic mechanicals. |

For a buyer like Gulf Metal Solutions, who procures L-shaped steel (a structural shape) and plate, it’s crucial to understand they are buying two different types of hot-rolled products, potentially from different specialized mills within a steel complex. We manage this by partnering with mills that have strong capabilities in both plate and section rolling, ensuring both products meet the same marine-grade standards7. The preference for hot-rolled L-shaped steel is part of a larger ecosystem where hot-rolled structural shapes form the indispensable skeleton of every modern ship.

Conclusion

Shipbuilders prefer hot-rolled marine L-shaped steel for its unmatched toughness, weldability, and structural reliability—properties essential for safety at sea and inherent to the hot-rolling process.

-

Explore this link to understand the various applications and benefits of Hot-Rolled Structural Shapes in construction and shipbuilding. ↩ ↩

-

Discover the significance of Hot-Rolled Plate in shipbuilding and its role in creating complex parts. ↩ ↩

-

Learn about the applications of Hot-Rolled Sheet/Strip/Coil in various industries and its manufacturing process. ↩ ↩

-

Understand the role of a structural mill in producing various steel shapes and its importance in the industry. ↩

-

Find out how L-Shaped Steel is utilized in construction and shipbuilding, and its importance in structural integrity. ↩

-

Gain insights into the operations of a plate mill and how it produces high-quality hot-rolled plates. ↩

-

Learn about marine-grade standards and why they are crucial for ensuring safety and durability in shipbuilding. ↩