You are building a ship that will carry thousands of tons of cargo across oceans for 25 years. Would you trust its hull to uncertified steel? Using non-certified plates is a gamble with safety, legal liability, and the vessel’s entire economic life.

Shipbuilding steel plates must be certified to guarantee they meet the strict chemical, mechanical, and toughness requirements set by classification societies like ABS, DNV, or CCS. This certification, documented in a Mill Test Certificate (MTC), provides traceability and proof that the steel can withstand the extreme stresses and corrosive environment of the sea, which is non-negotiable for safety, insurance, and regulatory compliance.

Certification is not a luxury or a paperwork exercise. It is a fundamental part of the ship’s safety system. To understand why it’s mandatory, we first need to understand what makes shipbuilding steel special in the first place.

What are the steel plates for shipbuilding?

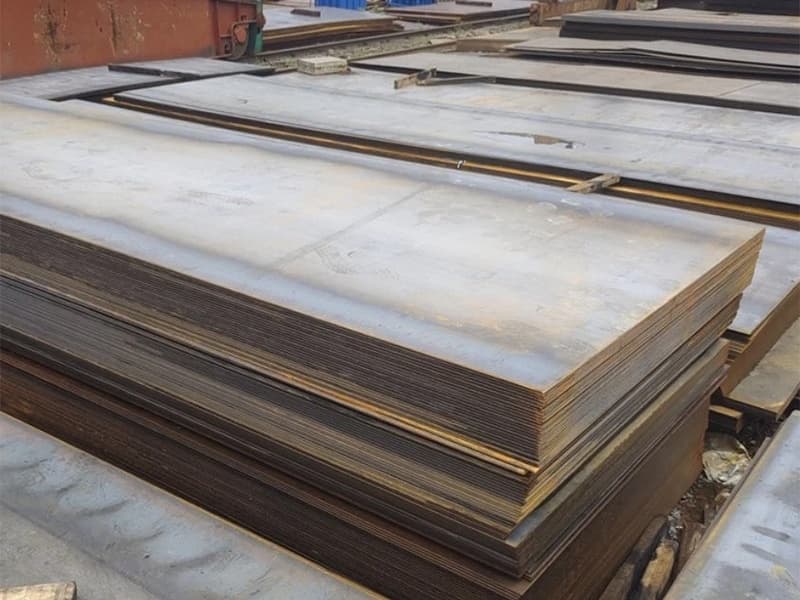

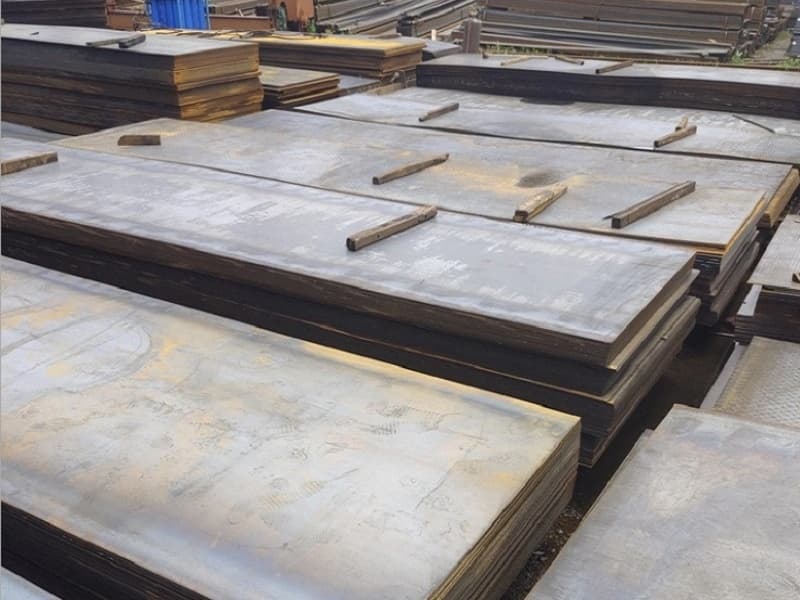

Shipbuilding plates are not ordinary construction steel. They are high-performance materials engineered for a specific, hostile environment. Their entire design prioritizes a combination of properties that general-purpose steel lacks.

Shipbuilding steel plates are hot-rolled flat products made from specially formulated grades of steel. They are designed to provide high strength, excellent weldability, and most critically, guaranteed toughness1 (resistance to brittle fracture) at low temperatures. They form the hull, decks, and bulkheads of vessels.

Imagine the forces on a ship’s hull: constant water pressure, the pounding of waves, the massive bending stress as the ship rides over swells, and the impact loads from cargo or ice. The plates must handle all this, often in seawater that is near freezing.

Key Design Drivers for Marine Plates

Three properties are paramount in their design:

- Strength: The steel must have a high yield strength2 (e.g., 235 MPa for normal strength, 355 MPa for high strength like AH36) to resist permanent deformation under load.

- Toughness: This is the most critical differentiator. The steel must be tough, meaning it can absorb significant energy and deform plastically before fracturing. More importantly, it must maintain this toughness1 at low temperatures to prevent brittle fracture in cold seas. This is tested via the Charpy V-notch impact test.

- Weldability: Ships are primarily welded structures. The steel’s chemical composition must allow for reliable, high-quality welding without pre- or post-heat treatment in most cases, to keep construction efficient and sound.

These properties are achieved through tight control of chemistry (low carbon, specific manganese, micro-alloys like niobium) and specialized rolling processes like Normalizing or Thermo-Mechanical Controlled Processing (TMCP).

The Certification Link

A steel mill can produce a plate that looks right. But how do you, the shipbuilder or owner, know it truly has the required toughness1 at -20°C? You cannot tell by looking at it. The only way is through testing and certification3. The certification process validates that the plate is not just "steel," but the specific, performance-guaranteed shipbuilding steel your design requires. Without this proof, you are building on an assumption, not a guarantee.

What grade of steel is used in shipbuilding?

Shipbuilders use a defined family of steel grades, not a single type. The grade is a code that specifies a precise set of mechanical properties and toughness levels. Choosing the correct grade is a critical engineering decision.

Shipbuilding primarily uses grades defined by classification societies. These include normal strength grades (A, B, D, E)1 and high-strength grades (AH, DH, EH, FH). The letter indicates toughness (E is tougher than A), ‘H’ indicates higher yield strength, and the number (e.g., 36 in AH36) denotes the minimum yield strength in ksi (approx. 355 MPa).

The system, standardized by the International Association of Classification Societies (IACS), is logical and global. It allows a designer in Europe, a shipyard in Asia, and a steel mill in the Americas to all refer to the same material expectations.

The Two Main Families and Their Application

The selection of grade is strategic, based on the structural importance of the ship part.

- Normal Strength Steel (Grades A, B, D, E): Yield strength ~235 MPa.

- Grade A/B: Used for internal structures, non-critical areas. Grade B requires impact testing at 0°C.

- Grade D/E: Used for more critical parts of the hull. Grade D is tested at -20°C, Grade E at -40°C. They are used in locations subject to higher stress or colder waters.

- High Strength Steel (Grades AH, DH, EH, FH)2: Yield strength 315 MPa (32), 355 MPa (36), 390 MPa (40) and above.

- AH32/DH36/EH40: These grades combine higher strength (for weight saving) with good toughness. They are used in decks, upper hull sides, and critical areas like the sheer strake.

Why Grade Selection Demands Certification

A designation like "DH36" is a promise of performance: "This plate will have a yield strength of at least 355 MPa and will absorb a minimum amount of energy in a Charpy test at -20°C."

Anyone can stamp "DH36" on a plate. Certification is the proof that this promise is kept. The Mill Test Certificate (MTC)3 is the legal document that provides this proof. It lists the actual test results for the specific batch (heat) of steel:

- Chemical Analysis: Confirms the recipe is correct for weldability and toughness.

- Tensile Test Results: Shows the actual yield and tensile strength meet or exceed 355 MPa.

- Charpy Impact Test Results4: Provides the numerical energy values (in Joules) from tests conducted at the specified temperature, proving toughness.

If you use an uncertified plate labeled "DH36," you have no evidence of its toughness. In a regulatory audit or after a structural failure, this lack of proof can have severe consequences. The grade system only works when paired with the certification system that validates it.

What is the difference between EH36 and DH36?

Both EH36 and DH36 are common high-strength shipbuilding grades. They share the same minimum yield strength (355 MPa), but they have a crucial difference that dictates where on the ship they can be used.

The key difference between EH36 and DH36 is the required impact toughness temperature1. DH36 steel must pass Charpy impact tests2 at -20°C, while EH36 must pass at -40°C. EH36 offers superior resistance to brittle fracture3 in colder environments, making it mandatory for vessels operating in Arctic waters or for the most critical structural members.

This difference seems small—just 20 degrees—but in material science, it represents a significant leap in alloy design and processing capability. It directly impacts safety in extreme conditions.

The Implications of the Toughness Difference

Brittle fracture is a shipbuilder’s nightmare. It is a rapid, catastrophic crack propagation with little warning, often initiated at a notch or weld defect in cold, high-stress conditions.

- DH36 Application: This is the workhorse high-strength grade for most ocean-going vessels (tankers, bulk carriers, container ships) operating in temperate to cool waters. It is used for the main hull, decks, and other high-stress areas.

- EH36 Application: This grade is specified for:

- Ships trading in Arctic or very cold regions (Ice Class vessels).

- The most critical zones of large ships, such as the sheer strake (the topmost run of hull plating) and the keel, even if the ship isn’t an icebreaker. These areas are subject to the highest stresses, so extra toughness is a safety buffer.

- Offshore structures in cold environments.

Certification as the Critical Differentiator4

You cannot visually distinguish an EH36 plate from a DH36 plate. The difference is locked in its microstructure and is only revealed through standardized impact testing.

This is where certification is absolutely vital. The MTC for an EH36 plate will explicitly state that the Charpy tests were conducted at -40°C and that the results exceeded the minimum requirement (e.g., 41 Joules average). The MTC for a DH36 plate will show tests at -20°C.

If a supplier provides an uncertified plate and claims it is "EH36," you have zero evidence that it meets the -40°C requirement. You might be paying an EH36 price for a DH36 (or worse) material, and you are installing it in a location where its inability to perform at the lower temperature could lead to failure. The certification is not just paperwork; it is the only objective guarantee that you are getting the specific, higher-performance grade you paid for and that your design relies upon.

Are steel plates safe to use?

This is the ultimate question that certification answers. "Safe" in shipbuilding means the material will perform predictably under all design conditions throughout the ship’s life. For steel plates, safety is not inherent; it is demonstrated and documented1.

Steel plates are safe for shipbuilding only when they are certified to prove they meet the specific grade requirements. Uncertified plates pose a significant safety risk because their properties—especially toughness and weldability—are unknown and unverified. This can lead to unpredictable brittle fracture, poor weld integrity, and catastrophic structural failure at sea.

Safety in engineering is about managing and mitigating risk. Using uncertified steel introduces a huge, unnecessary, and invisible risk into the very foundation of the vessel.

The Risks of Uncertified Steel Plates

Several failure modes become possible with uncertified material:

- Brittle Fracture2: As discussed, this is the top risk. An uncertified plate may have poor toughness, especially at low temperatures. A small crack from fabrication or service can propagate rapidly through the brittle material, potentially causing the ship to break apart.

- Incorrect Strength: The plate may not meet the minimum yield strength. This can lead to overloading and permanent deformation (yielding) of the hull under normal operating loads.

- Poor Weldability3: Uncontrolled chemistry (high Carbon Equivalent) can lead to hard, crack-prone welds and Heat-Affected Zones (HAZ). These cracks become initiation points for fatigue or brittle fracture.

- Lack of Traceability: If a problem is discovered years later, there is no way to trace the material back to its production batch, understand its properties, or identify if other parts of the fleet use the same faulty material.

How Certification Ensures Safety

Certification is a systematic risk control process. It ensures safety through:

- Verified Material Properties4: The MTC provides objective, numerical proof of strength and toughness.

- Manufacturing Process Control: To gain classification society approval, the mill must demonstrate strict control over its entire production process, from melting to rolling.

- Independent Oversight5: Classification society surveyors conduct periodic audits of the mill and may witness tests. Third-party inspectors (like SGS) provide an additional layer of verification for the buyer.

- Legal and Insurance Compliance6: Maritime law and insurance contracts require ships to be built to class rules. Using uncertified materials voids these agreements, leaving the owner fully liable in case of an incident.

For a client like a project contractor or shipyard, demanding certified plates is the most basic duty of care. Our client Gulf Metal Solutions specifically sought suppliers who support SGS inspection for this exact reason—they needed that third-party verification to de-risk their supply chain. When you choose certified steel, you are not just buying a product; you are buying verified safety, reduced liability, and peace of mind. That is why certification is not optional; it is the bedrock of safe shipbuilding.

Conclusion

Certification is the non-negotiable link between a steel plate’s specified grade and its real-world performance. It provides the documented proof of strength, toughness, and traceability that ensures a ship’s structural safety, regulatory compliance, and long-term reliability at sea.

-

Understanding this concept is crucial for ensuring the safety and reliability of steel plates in shipbuilding. ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring the causes of brittle fracture can help you understand the risks associated with uncertified steel plates. ↩ ↩ ↩ ↩

-

Learning about weldability issues can provide insights into the structural integrity of shipbuilding materials. ↩ ↩ ↩ ↩

-

This knowledge is essential for ensuring that steel plates meet safety standards in shipbuilding. ↩ ↩ ↩

-

Understanding independent oversight can help you appreciate the importance of third-party verification in material safety. ↩

-

This information is vital for shipbuilders to avoid liability and ensure adherence to maritime laws. ↩