I still remember my first shipbuilding project where we used the wrong flat steel size. The entire structural frame had to be redesigned, costing us valuable time and resources.

This guide provides complete bulb flat steel dimensions and weight charts according to international standards. Bulb flats typically range from 100x7mm to 450x22mm, with weights from 3.5kg/m to 84.5kg/m. The exact dimensions depend on the specific profile and marine classification requirements.

Getting the right dimensions and weights is crucial for any marine project. Let me walk you through the essential size information you need for successful ship construction.

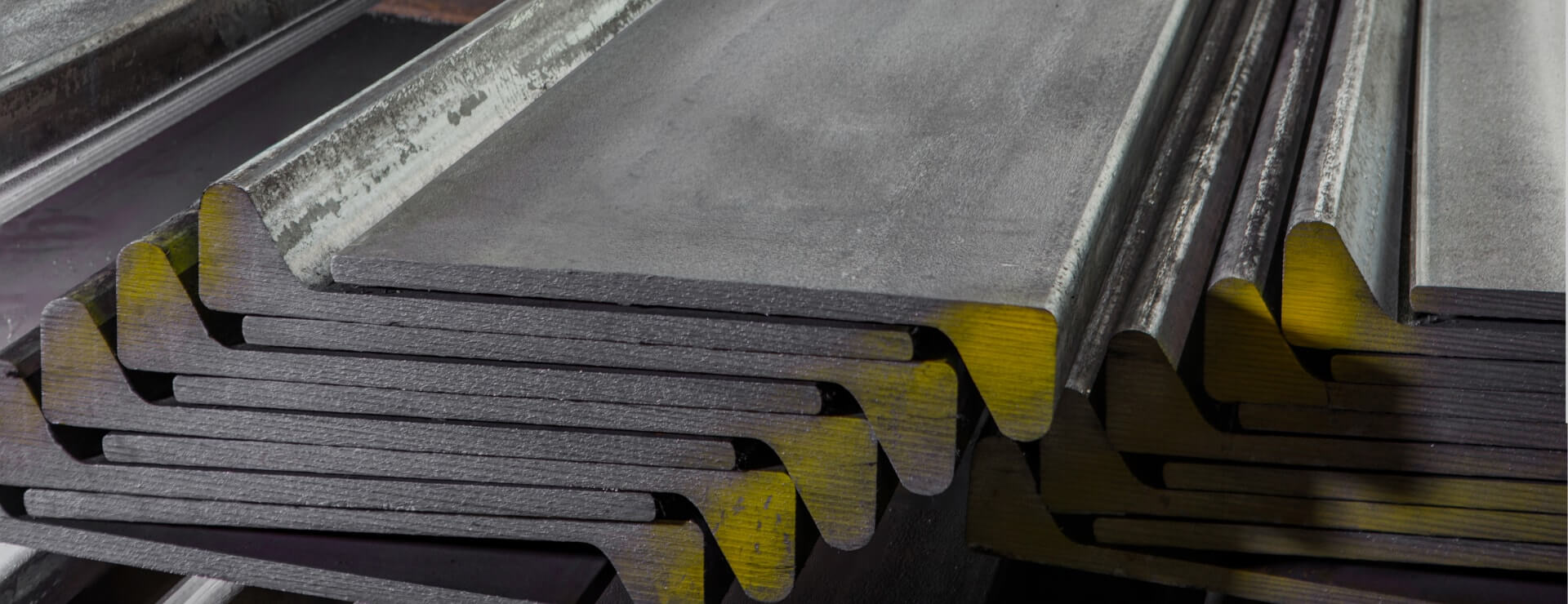

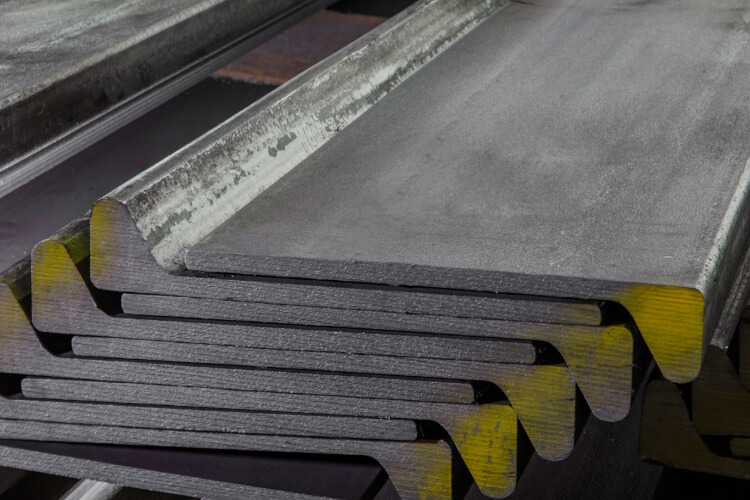

What sizes does flat steel come in?

Many shipbuilders struggle with flat steel sizing1. They often order the wrong dimensions, leading to project delays and increased costs. I’ve seen this happen too many times in our industry.

Standard flat steel comes in widths from 20mm to 300mm and thicknesses from 3mm to 60mm. Marine-grade flat steel follows specific classification society standards like ABS, DNV, and LR, with sizes tailored for shipbuilding applications and structural requirements.

Understanding Flat Steel Size Variations

Flat steel sizing isn’t as simple as it seems. Different applications require different size ranges, and marine applications have the strictest requirements.

Flat Steel Size Classification Table

| Application Type | Width Range | Thickness Range | Standard Length | Common Uses |

|---|---|---|---|---|

| General Purpose | 20-150mm | 3-20mm | 6m, 12m | Brackets, supports |

| Structural | 150-300mm | 20-40mm | 12m | Beams, frames |

| Marine Grade | 100-450mm | 7-22mm | 12m, 15m | Ship framing, stiffeners |

| Heavy Duty | 300-600mm | 40-60mm | Custom | Bridge components |

General purpose flat steel is the most common type. It’s used across various industries for basic structural applications. The sizes are relatively small because these pieces don’t need to carry heavy loads. In shipbuilding, we use them for non-critical components like small brackets and support plates.

Structural flat steel handles heavier loads. The wider dimensions and greater thickness provide more strength and stability. Construction projects use these sizes for beam connections and structural framing. However, they’re not optimized for marine environments without proper coating and treatment.

Marine-grade flat steel follows specific classification society requirements. Organizations like American Bureau of Shipping (ABS) and Det Norske Veritas (DNV) set strict standards for marine steel sizes. These standards ensure the steel can withstand harsh ocean conditions. The sizes are carefully calculated to provide optimal strength-to-weight ratios for ship structures.

Heavy-duty flat steel serves specialized applications. The extra-large dimensions handle extreme loads in bridges, offshore platforms, and large industrial structures. These sizes often require custom ordering and special handling during fabrication and installation.

In our work with Gulf Metal Solutions, we learned that having the right size chart readily available prevents costly mistakes. Their project managers now keep our dimension tables handy for quick reference during material planning and ordering.

What is the standard size of MS flats?

Mild steel flats1 come in standardized sizes, but many buyers don’t realize these standards vary by region and application. Choosing the wrong standard can derail your entire project timeline.

Standard MS flat sizes typically range from 20x3mm to 200x25mm in metric measurements. Common lengths are 6 meters for easier handling. Imperial sizes include 1"x1/4" to 8"x1" for markets using inch measurements, with standard lengths of 20 feet.

MS Flat Size Standards Explained

Understanding MS flat standards helps you select the right material for your specific needs and avoid compatibility issues during fabrication.

MS Flat Standard Size Reference Table

| Standard System | Width Range | Thickness Range | Length Options | Tolerance Standards |

|---|---|---|---|---|

| Metric (ISO) | 20-200mm | 3-25mm | 6m, 12m | ISO 9445 |

| Imperial (ASTM) | 1"-8" | 1/4"-1" | 20ft, 40ft | ASTM A36 |

| British (BS) | 25-200mm | 3-25mm | 6.1m, 12.2m | BS 970 |

| Japanese (JIS) | 25-250mm | 3-26mm | 5.8m, 11.8m | JIS G3101 |

Metric MS flats follow International Organization for Standardization (ISO) specifications. These sizes are most common in Europe, Asia, and other metric-using regions. The dimensions progress in logical increments, making calculations straightforward. Most shipbuilding projects use metric measurements for global compatibility.

Imperial MS flats adhere to ASTM standards2, primarily used in the United States and some Middle Eastern markets. The fractional inch measurements can be challenging for international projects. We always double-check measurement systems with clients to prevent ordering errors that could halt production.

British Standard (BS) MS flats combine metric and imperial influences. The sizes are similar to ISO standards but with slight variations in available dimensions and tolerances. These are common in Commonwealth countries and former British territories.

Japanese Industrial Standards (JIS) govern MS flats in Asian markets. The sizes are compatible with metric systems but have unique length options and tolerance requirements. Many of our clients in Vietnam and Thailand prefer JIS-compliant materials for their regional projects.

Tolerance standards ensure consistency across batches. ISO 9445 specifies dimensional tolerances for hot-rolled steel flats, while ASTM A36 covers structural steel requirements. Understanding these tolerances helps fabricators plan their machining and welding processes accurately.

What is a bulb flat1?

Many people in the steel industry confuse bulb flat1s with standard angles or tees. This misunderstanding can lead to improper applications and structural weaknesses in marine projects.

A bulb flat1 is a specialized steel profile with a flat plate and a rounded bulb at one edge. This unique shape provides superior strength and stiffness compared to regular flat steel. The bulb acts as a natural reinforcement, making it ideal for ship frames and longitudinal stiffeners.

Bulb Flat Anatomy and Applications

The bulb flat1‘s design may seem simple, but its engineering principles are quite sophisticated for marine environments2.

Bulb Flat Component Analysis Table

| Component | Function | Design Features | Manufacturing Process |

|---|---|---|---|

| Web Plate | Main load-bearing surface | Consistent thickness, flat surface | Hot rolling |

| Bulb Edge | Provides stiffness | Rounded profile, gradual taper | Controlled forming |

| Transition Zone | Distributes stress | Smooth curvature, no sharp edges | Precision rolling |

| Surface Finish | Corrosion protection | Mill scale, optional treatments | Descaling, coating |

The web plate forms the main body of the bulb flat1. It carries most of the tensile and compressive loads in ship structures. The plate thickness determines the profile’s basic strength capacity. In shipbuilding, we select web thickness based on the specific hull location and expected loads.

The bulb edge is the defining feature of this profile. The rounded shape concentrates material where it provides maximum stiffness against bending forces. The bulb’s size relative to the web varies by profile size, following optimized ratios developed through naval architecture research.

The transition zone3 between the web and bulb is critically important. A smooth, gradual transition prevents stress concentration that could lead to cracking. Poorly manufactured bulb flat1s with sharp transitions can develop fatigue cracks under repeated loading from wave action.

Surface finish requirements depend on the application. Most bulb flat1s come with natural mill scale, which provides some corrosion protection. For harsh marine environments2, we often recommend additional coatings or treatments to extend service life.

Our production process ensures consistent bulb formation and proper transition geometry. We work with certified mills that maintain tight control over rolling temperatures and forming pressures to produce reliable, high-quality bulb flat1s for marine applications.

How much does a steel flat bar weigh?

Weight calculation errors can cause serious problems in shipbuilding. I’ve seen projects where miscalculated steel weights led to stability issues and required expensive rework.

Steel flat bar weight depends on dimensions and steel density. The formula is: Weight (kg/m) = Width (mm) × Thickness (mm) × 0.00785. For example, a 100mm x 10mm flat bar weighs 7.85 kg/m. Actual weight varies slightly based on steel grade and manufacturing tolerances1.

Comprehensive Weight Calculation Guide

Accurate weight calculations require understanding multiple factors beyond basic dimensions.

Steel Flat Bar Weight Reference Table

| Width (mm) | Thickness (mm) | Weight (kg/m) | Weight for 12m (kg) | Common Applications |

|---|---|---|---|---|

| 50 | 6 | 2.36 | 28.3 | Small brackets, supports |

| 100 | 10 | 7.85 | 94.2 | Medium frames, stiffeners |

| 150 | 12 | 14.13 | 169.6 | Structural beams, braces |

| 200 | 16 | 25.12 | 301.4 | Heavy frames, base plates |

| 250 | 20 | 39.25 | 471.0 | Main structural members |

| 300 | 25 | 58.88 | 706.6 | Primary ship components |

The basic weight calculation formula2 uses the theoretical density of steel. The constant 0.00785 comes from the density of steel (7850 kg/m³) converted to practical units. This formula provides a good estimate for most planning purposes, but actual weights may vary slightly.

Width and thickness are the primary factors in weight calculation. Doubling either dimension doubles the weight per meter. This linear relationship makes calculations straightforward but requires precise measurement input. We always verify actual dimensions against ordered specifications.

Length considerations affect total project weight. While weight per meter is useful for calculations, total weight matters for shipping, handling, and structural design. Longer lengths generally mean fewer connections but require special handling equipment.

Steel grade influences actual weight slightly. Different alloying elements change steel density marginally. High-strength steels might be slightly denser than mild steel, but the difference is usually negligible for weight calculation purposes.

Manufacturing tolerances cause weight variations. Hot-rolled steel flats can have dimensional variations within allowed tolerance ranges. These small differences can accumulate in large orders, so we recommend adding a 2-3% contingency for weight-sensitive applications.

In our export business, accurate weight calculations are essential for shipping cost estimates and customs documentation. We provide detailed weight certificates with each shipment to ensure our clients have precise information for their logistics planning.

Conclusion

Understanding bulb flat steel dimensions and weights ensures proper material selection and project success in shipbuilding applications.

-

Learning about manufacturing tolerances can help you anticipate weight variations and improve project accuracy. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring the weight calculation formula helps ensure precision in weight estimates, essential for various applications. ↩ ↩ ↩ ↩

-

Learn about the critical role of the transition zone in preventing stress concentrations and enhancing durability in steel profiles. ↩