Choosing the wrong steel profile can cause delays and increase costs. This is a common headache in shipbuilding and heavy construction. I see many clients struggle with this basic but critical decision.

Bulb flat steel and flat bar steel are both flat, elongated steel products, but they serve different structural purposes. The key difference is that bulb flat steel has a thickened "bulb" along one edge, providing superior strength and stiffness for specific applications like ship framing, whereas a standard flat bar is a simple, uniform rectangle of steel used for general fabrication, bracing, and brackets.

Understanding this difference is more than academic. It directly impacts the safety, performance, and budget of your project. Let’s break down the details so you can choose with confidence and avoid costly mistakes.

What are the different types of flat steel?

You might think "flat steel" is just one simple product. That’s not true. The term covers a range of shapes, each engineered for a unique job. Picking the wrong type can lead to structural weakness or wasted money.

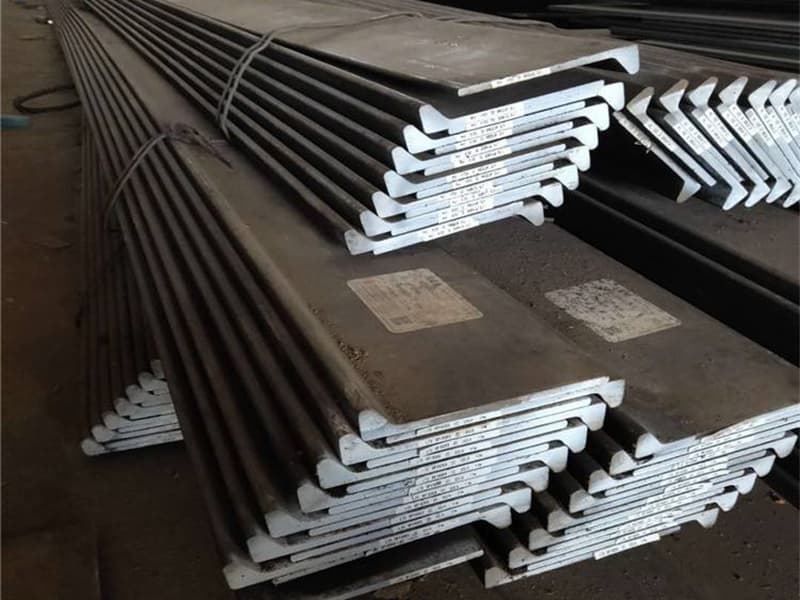

Flat steel primarily refers to products with a rectangular cross-section, and the main types include standard flat bars, bulb flat bars, and plates. They are categorized by their dimensions, with flat bars and bulb flats being long, narrow sections, while plates are much wider. Each type has distinct mechanical properties1 and standard specifications for different industrial uses.

A Closer Look at Flat Steel Varieties

To make an informed choice, we need to look beyond the basic shape. The world of flat steel is defined by specifications, standards, and intended use cases. Here is a structured breakdown of the primary types you will encounter in marine and industrial projects.

1. Standard Flat Bar (Flat Bar Steel)2

This is the most basic form. It is a solid, rectangular bar with sharp or slightly rounded corners. Its strength is uniform across its width. We supply these in various grades like AH36, DH36 for marine use, or standard S235JR, S355JR for construction. The key parameters are width, thickness, and length. They are versatile but lack specialized strength characteristics.

2. Bulb Flat Steel (Bulb Bar)3

This is a specialized profile. One edge is thickened into a rounded bulb. This design concentrates material where it’s needed most to resist bending. It’s a profile born from shipbuilding. The bulb provides extra strength and stiffness along one axis without adding excessive weight. Sizes are standardized (e.g., 200×10, 250×12) where the first number is the height including the bulb, and the second is the web thickness.

3. Steel Plate4

While technically "flat," plates are a different category due to their size. They are defined by their thickness and can be cut into any shape. We supply marine plates (e.g., A, B, D, E grades) in thicknesses from 6mm to over 100mm. Plates are the raw material for fabricating larger structures, or they can be used as they are for hull plating.

4. Cut Plate from Coil5

For some applications, flat steel is sheared from large rolled coils. This is efficient for high-volume production of strips with consistent thickness but limited width. It’s common for lighter fabrication work.

Here is a table to compare their core characteristics:

| Type | Key Feature | Primary Standard | Typical Application | Main Advantage |

|---|---|---|---|---|

| Standard Flat Bar | Uniform rectangular cross-section | ASTM A36, EN 10025, JIS G3101 | Brackets, frames, bracing, general fabrication | Simple, versatile, readily available |

| Bulb Flat Steel | Bulb (thickened edge) along one side | GL, BV, DNV, ABS shipbuilding rules | Ship frames, stiffeners, marine structures6 | High strength-to-weight ratio, excellent bending resistance |

| Steel Plate4 | Wide, flat surface with specified thickness | ABS A/B/D/E, EN 10025 S355 | Hull plating, pressure vessels, structural bases | Can be fabricated into complex shapes, provides large surface area |

| Cut Plate (from Coil) | Consistent thickness, slit from coil | ASTM A1011, A569 | Automotive parts, light structural components, panels | Cost-effective for mass production of simple strips |

Choosing between them starts with your design requirements. For a simple brace, a flat bar is perfect. For a ship’s frame that must handle constant stress, the bulb flat is the engineered solution. For the hull itself, you start with a plate. Knowing these differences helps you speak precisely with your fabricator and ensures you get the material that truly fits your design.

What is another name for a flat bar?

Searching for materials can be confusing when different names are used for the same product. This confusion can waste your time and lead to ordering errors, especially in international trade.

A flat bar is most commonly also called a "flat bar steel1," "mild steel flat bar2," or "rectangular bar3." In technical drawings and older standards, you might see it referred to as "bar stock4" or simply "flat." In some regions or specific industries, terms like "strap5" or "batten" are used for particular sizes or applications.

Decoding the Terminology: Why So Many Names?

The variety of names isn’t random. It often reflects the industry, the country, the historical context, or the specific use of the product. As a supplier dealing with global clients like those in Vietnam, Saudi Arabia, and Mexico, I hear all these terms. Understanding them prevents miscommunication.

1. Industry-Specific Jargon

In shipbuilding, a long, narrow flat bar might be called a "stiffener6" or a "batten," especially if it’s used to reinforce a plate. In construction and general fabrication, "flat bar" or "rectangular bar3" is standard. In machining and tooling, it might be called "bar stock4" or "flat stock," indicating it’s a raw material to be cut and shaped.

2. Material and Standard References

The name often includes the material grade. For example, "Mild Steel Flat Bar" points to low-carbon steel (like S235). "Alloy Flat Bar" specifies a higher grade (like S355). In purchase orders, you’ll see precise designations like "EN 10025-2 S275JR Flat Bar", which defines the exact European standard.

3. Regional and Historical Terms

In some markets, influenced by British standards, you might hear "flat section." In very specific contexts, a thin, wide flat bar could be called a "strap5," often used for binding or tying. These terms are less common in modern technical specifications but still appear in older blueprints or regional colloquialisms.

Here is a table to clarify where you might encounter these different names:

| Common Name | Typical Context | What It Usually Means | Example Use Case |

|---|---|---|---|

| Flat Bar | Global, general industrial | The standard term for a solid rectangular steel section. | "We need 100 pieces of 50x10mm flat bar for brackets." |

| Mild Steel Flat Bar | Construction, general fabrication | Specifies low-carbon steel, easy to weld and form. | "Fabricate the gate frame from mild steel flat bar2." |

| Rectangular Bar | Technical drawings, engineering | Emphasizes the geometric shape precisely. | "Material: Rectangular Bar, 30mm x 5mm." |

| Bar Stock / Flat Stock | Machining, workshops | Raw material supplied in lengths for cutting. | "Cut the gears from this flat stock." |

| Stiffener / Batten | Shipbuilding, structural engineering | A flat bar used to add rigidity to a plate or panel. | "Weld the vertical stiffener6s to the bulkhead plate." |

| Strap | Packaging, light structural tying | A thinner, often narrower flat bar for securing items. | "Use steel strap5s to bundle the pipes." |

My advice is simple. In your requests and orders, use the most precise term possible. Say "S355JR Flat Bar, 100mm x 12mm" rather than just "flat steel." This clarity is what helped us build trust with clients like Gulf Metal Solutions. They valued our fast, accurate responses, which started with understanding exactly what they meant, regardless of the term they used initially. Clear names prevent delays and ensure you get the right material delivered to your port.

What is a bulb bar?

If you’re not in shipbuilding, you might never have heard of a bulb bar. But in marine construction, it’s a fundamental component. Ignoring its specific role is like building a house without knowing what an I-beam does.

A bulb bar, formally called bulb flat steel1, is a specialized steel profile with a unique cross-section. It looks like a flat bar with one edge thickened into a rounded, bulb-like protrusion. This bulb is the key feature, designed to add significant strength and stiffness to the edge, making it ideal for use as a stiffener or frame in ships and offshore structures.

The Engineering Behind the Bulb: More Than Just a Shape

The bulb isn’t for decoration. It’s a highly efficient engineering solution to a common problem: how to make a beam stiffer without adding too much weight or material cost. Let’s dive into why this specific shape is so important for marine applications.

The Core Principle: Section Modulus

The strength of a beam in bending depends on its section modulus2. This is a geometric property of its cross-section. By adding mass (the bulb) far from the beam’s neutral axis (the center of bending), engineers dramatically increase the section modulus2. Think of it like using a long wrench instead of a short one—you get more leverage. The bulb acts like a small, continuous flange, providing that leverage against bending forces from waves, cargo loads, and hull pressure.

Standardization and Sourcing

Bulb flats are not arbitrary. They are produced to strict international ship classification society3 standards, such as Lloyd’s Register (LR), Det Norske Veritas (DNV), American Bureau of Shipping (ABS), and Germanischer Lloyd (GL). Common sizes include 200×10, 220×11, 250×12, 300×13, and so on. The number before the ‘x’ is the total height (in mm), and the number after is the web thickness. Sourcing the correct certified grade (like Grade A or AH32) is critical for approval in shipyards.

Comparison with Similar Profiles

It’s useful to compare a bulb flat to other profiles:

- vs. Flat Bar: A flat bar of the same height and weight would be much weaker in bending. The bulb flat is smarter engineering.

- vs. Angle Bar (L-shaped steel): An angle bar also has material away from the center, but the bulb flat often provides a better strength-to-weight ratio for one-directional bending and offers a flatter surface for welding to hull plates.

- vs. T-Bar: A T-bar has a more pronounced flange. A bulb flat is sometimes considered a "light" or asymmetrical T-bar, often more economical for certain frame sizes.

Here is a table summarizing the bulb bar’s key aspects:

| Aspect | Description | Importance for Buyers |

|---|---|---|

| Primary Function | Acts as a stiffening frame or longitudinal. | It is a dedicated structural component, not general-purpose steel. |

| Key Advantage | High section modulus2 and bending resistance4 per unit weight. | Saves weight on the ship, improving fuel efficiency5 and cargo capacity. |

| Manufacturing | Hot-rolled to specific profiles from shipbuilding-grade steel. | Must come from certified mills to meet classification rules. Our long-term mill partnerships ensure this. |

| Certification | Supplied with Mill Certificate (MTC)6 and often third-party inspected (e.g., SGS). | Non-negotiable for shipbuilding. We provide full documentation support. |

| Common Applications | Ship hull frames, deck stiffeners, offshore platform braces7, port structures. | Defines its use case—ideal for marine/offshore environments with dynamic loads. |

For a project contractor or shipyard, choosing the right bulb bar means looking at the structural design specs, the required classification society approval, and the total cost-in-place. Our role as a supplier is to provide the certified material that meets these precise needs, just as we did for our client in Saudi Arabia who moved from plates to ordering bulb flats for their next project phase. The bulb bar is a perfect example of how a simple shape change creates a product that is essential for modern, efficient marine engineering.

What is a flat bar used for?

Flat bars are the unsung heroes of metal fabrication. Their simplicity is their greatest strength. But if you only use them for one or two things, you’re missing out on their full potential to solve construction challenges.

Flat bar steel1 is a versatile, general-purpose material used primarily for fabrication, support, and framing. Its most common uses include making brackets, braces, frames, supports, and trim. It is also widely used for constructing ladders, gates, railings, machinery guards, and as a stiffener for steel plates in various industrial and construction projects.

The Workhorse of Industry: Endless Applications

The use of flat bar is limited only by the fabricator’s imagination. Its uniform shape makes it easy to cut, drill, weld, and bend. Let’s explore its applications across different sectors, which also highlights why we keep a wide range of sizes and grades in stock for our wholesale clients.

1. Structural and Fabrication Uses

This is the largest category. Flat bars are the "go-to" for creating strong, simple connections and supports.

- Brackets and Gussets2: The most frequent use. A piece of flat bar cut and drilled becomes a perfect corner brace to join two beams at a right angle, transferring load effectively.

- Frames and Chassis3: They form the perimeter of machine guards, equipment frames, and cart bases. Their straight edges make alignment easy.

- Stiffeners and Braces: Welded onto larger plates or sections (like in storage tanks or trailer beds), they prevent buckling and add rigidity, similar to but more general than a bulb flat.

2. Architectural and Construction Uses

Here, flat bars often combine function with a simple aesthetic.

- Gates, Fences, and Railings4: Flat bars are used for horizontal rails, vertical pickets, and decorative elements. They can be powder-coated for durability.

- Trim and Edging5: A thin flat bar can provide a clean, finished edge on a concrete step, a wooden workbench, or a composite panel.

- Ladder Rungs and Steps: Flat bar provides a strong, slip-resistant surface for industrial ladders and platform steps.

3. Marine6 and Industrial Specific Uses

Even in specialized fields, the humble flat bar has its place alongside premium products like bulb flats and marine angles.

- Marine6: While bulb flats are for primary framing, standard flat bars are used for secondary brackets, equipment mounts, and non-critical stiffening inside a ship’s superstructure.

- Machinery: They are used as straps, clamps, and machinery guards. Their predictability makes them safe for creating protective barriers around moving parts.

- Tool Making7: Flat bar stock is the starting point for making custom jigs, fixtures, and tools in a workshop.

To understand its role better, here is a table comparing its use to other common steel sections:

| Application Need | Why Flat Bar is a Good Choice | When Another Section Might Be Better |

|---|---|---|

| Making a Support Bracket | Easy to cut to length, drill holes, and weld. Provides strong, direct support. | For very heavy loads, an angle bar or channel might offer more leverage. |

| Building a Simple Frame | Straight edges allow for easy square assembly. Clean, simple look. | For a heavier duty frame subject to twisting, square or rectangular hollow sections are more rigid. |

| Adding Stiffness to a Plate | Can be welded directly along its length. Effective and economical. | For critical, high-load stiffening (e.g., ship hull), a bulb flat is specifically designed and far stronger. |

| Creating a Guardrail | Provides a solid hand-grip surface. Easy to attach posts. | For high-traffic public areas, a pipe is often preferred for comfort and a different aesthetic. |

The key is to match the material to the demand. For Gulf Metal Solutions, our reliable supply of flat bars for their fabricator clients meant they could fulfill orders for everything from construction braces to industrial furniture frames without delay. The flat bar is not glamorous, but it is indispensable. It’s the foundational building block that enables more complex structures to come together, proving that in steel, simplicity often equals reliability.

Conclusion

Choosing between bulb flat and flat bar steel is a fundamental decision. It hinges on understanding their distinct shapes and engineered purposes. The bulb flat is your specialist for marine strength, while the flat bar is your versatile workshop all-rounder. Making the right choice ensures your project is built on a foundation of safety, efficiency, and cost-effectiveness.

-

Explore the advantages of flat bar steel, a versatile material essential for various construction applications. ↩ ↩ ↩ ↩

-

Learn how brackets and gussets enhance structural integrity, making them crucial in construction and fabrication. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover how frames and chassis are constructed and their importance in machinery and equipment. ↩ ↩ ↩ ↩ ↩

-

Find out why flat bars are a popular choice for durable and aesthetic gates, fences, and railings. ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the role of trim and edging in providing a clean finish and enhancing the overall look of projects. ↩ ↩ ↩ ↩ ↩ ↩

-

Understand how flat bars are utilized in marine applications, ensuring safety and structural integrity. ↩ ↩ ↩ ↩ ↩ ↩

-

Discover how flat bar stock serves as a foundation for creating custom tools and fixtures in workshops. ↩ ↩