Hidden defects in bulb flat steel can lead to project delays and safety risks. As a supplier, I see how these issues cause major headaches for shipyards and contractors. Catching problems early is crucial.

Common defects in bulb flat steel include surface imperfections like scale, rust, and pitting; dimensional inaccuracies in the bulb or web; and internal flaws like laminations or poor chemistry. To avoid them, buyers must source from certified mills, insist on proper Mill Test Certificates (MTCs), and conduct pre-shipment inspections like SGS to verify quality and specifications before the steel leaves the factory.

You can’t fix a defective bulb flat on the job site. Prevention happens during sourcing and purchasing. The next sections will break down the key risks and give you a clear checklist to protect your project.

What damages galvanized steel?

Galvanized bulb flats are chosen for extra corrosion protection. But the zinc coating1 is not invincible. Seeing rust on a new "protected" steel delivery is a frustrating and costly surprise.

Galvanized steel is damaged by chemical exposure2, physical abrasion3, and moisture traps4. Acids, alkalis, and saltwater can break down the zinc coating1. Scratches, cuts, and heavy impact expose the base steel. Constant wetness or contact between dissimilar metals also speeds up corrosion, defeating the purpose of galvanization.

Understanding the Enemies of Your Galvanized Coating

The zinc layer on galvanized steel is a sacrificial shield. It corrodes first to protect the iron underneath. But several factors can destroy this shield faster than expected. Knowing these factors helps in proper storage, handling, and application.

1. Chemical and Environmental Attack

The coating reacts with its environment. Some reactions are slow, others are fast.

- Acidic Conditions: Rainwater in industrial areas can be acidic. Soils with low pH (acidic soils) aggressively attack zinc. Chemical splashes in industrial plants are a major threat.

- Alkaline Conditions: Fresh concrete and mortar are highly alkaline. When wet concrete touches galvanized steel, it can dissolve the zinc, leading to "white rust" (zinc hydroxide) and then base steel rust.

- Salt Exposure: Marine environments are the toughest. Salt (chlorides) breaks down the protective zinc carbonate layer that forms on the surface. This leads to rapid, localized pitting and rust.

2. Physical and Mechanical Damage

The coating is a layer bonded to the steel. It can be removed by force.

- Abrasion and Wear: During transport, if steel bars rub against each other without proper dunnage, the coating wears off. Dragging steel on rough surfaces has the same effect.

- Cutting and Welding: Any operation that heats or cuts the steel will destroy the coating at that point. The heat from welding vaporizes zinc, leaving an uncoated heat-affected zone that rusts immediately if not re-protected.

- Impact Damage: Heavy objects dropped on the steel can chip or crack the zinc layer.

3. Design and Installation Flaws

Sometimes, the damage is built into the design.

- Moisture Traps: If sections are designed where water can pool and sit (like in crevices or capped sections), the constant wetness accelerates corrosion. This is worse if debris like leaves or sand traps the moisture.

- Galvanic Corrosion: When galvanized steel is in direct electrical contact with a more "noble" metal like copper or stainless steel in a wet environment, the zinc corrodes much faster. Proper insulation is needed.

Here is a table to identify common damage causes and their signs:

| Damage Cause | What Happens | Visible Sign | How to Prevent It |

|---|---|---|---|

| Acid Rain / Pollution | Zinc layer chemically dissolves. | Dull, whitish film (zinc salts) leading to patchy bare spots and rust. | Specify thicker coatings for harsh environments. Rinse surfaces if possible. |

| Saltwater Spray | Chlorides penetrate and break down the coating. | Rapid formation of red rust, often in streaks or patches. | Use marine-grade galvanizing with specified thickness. Implement regular wash-downs. |

| Abrasion in Transit | Rubbing removes the zinc coating1. | Shiny, bare steel streaks along the length of the bar where contact occurred. | Use proper wooden dunnage and separators. Avoid over-tightening straps. |

| Cutting/Welding | Heat destroys the zinc. | A clear line of rust along cut edges or welds, while the rest is intact. | Recoat cut edges and welds with zinc-rich paint immediately after work. |

| Contact with Wet Concrete | High alkalinity dissolves zinc. | White, flaky deposits (white rust) followed by base steel corrosion. | Use protective barriers or sleeves where steel is embedded in concrete. |

For a buyer, the lesson is this: specify the correct galvanizing standard (e.g., ASTM A123 for hot-dip) and coating thickness for your environment. Then, ensure your supplier packs the steel properly to prevent transit damage. We learned this with a client in the Philippines. Their previous shipments arrived with abrasion damage. We solved it by using more dunnage and edge protectors, ensuring the zinc shield arrived intact at the job site.

What is a bulb bar?

Before we can talk about its defects, we need to be clear on what a "bulb bar" is. Confusion over the name itself can lead to ordering the wrong product, which is the most basic defect of all.

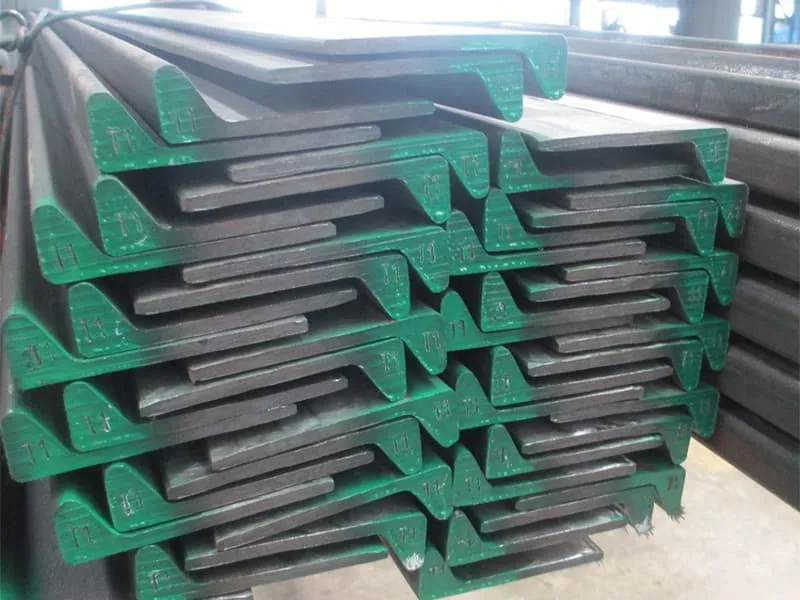

A bulb bar is another common name for bulb flat steel1. It is a specialized steel profile used mainly in shipbuilding. Its cross-section looks like a flat bar with one edge thickened into a rounded, bulb-like shape. This bulb adds extra strength and stiffness, making it ideal for ship frames and stiffeners where high resistance to bending is required.

More Than Just a Name: The Identity of a Bulb Bar

The term "bulb bar" is industry shorthand. Understanding its full identity—its design purpose, standards, and exact geometry—is the first step in recognizing when something is wrong with it.

1. The Design Logic Behind the Shape

The bulb is a brilliant piece of engineering efficiency. The goal is to increase the section modulus2 (a measure of bending strength) without adding a lot of weight. By placing extra metal in the bulb, far from the center of the beam, it acts like a small, continuous flange. This gives the bar much greater resistance to bending forces compared to a simple flat bar of the same height and weight. In a ship, these forces come from waves, cargo, and water pressure.

2. Standards and Specifications

Bulb bars are not generic. They are manufactured to precise dimensional standards set by international ship classification societies3. These include:

- Lloyd’s Register4 (LR)

- Bureau Veritas (BV)

- Det Norske Veritas (DNV)

- American Bureau of Shipping (ABS)

Each society publishes standard profiles (like HP for "hot rolled bulb flats"). Common sizes are designated by their height and web thickness, such as 200×10, 250×12, or 300x13mm. The first number is the total height (including the bulb), and the second is the thickness of the flat "web" part.

3. Key Identification Features

When you inspect a bulb bar, you should check for these defining features:

- The Bulb: A smooth, rounded thickening along one edge. Its size is proportional to the overall profile.

- The Web: The flat, vertical part connecting the bulb to the other edge. It has a uniform thickness.

- The Toe: The thin, flat edge opposite the bulb. It is usually square or slightly rounded.

- Length: Supplied in standard lengths, often 6m, 12m, or as per customer requirement.

Here is a table to clarify the standard naming and key checks:

| Aspect | What It Means | Why It Matters for Quality |

|---|---|---|

| Name: "Bulb Bar" | Industry term for Bulb Flat Steel. | Ensures you and your supplier are talking about the same product. |

| Standard Profile (e.g., HP 200×10) | Defines the exact shape and dimensions per a classification society. | The mill must roll steel to this precise profile. Any deviation is a defect. |

| Material Grade (e.g., AH36, DH36) | Specifies the steel’s yield strength, toughness, and chemistry. | Must match the Mill Test Certificate5. Wrong grade means the steel is unfit for its purpose. |

| Primary Application | Ship frames, longitudinals, stiffeners in marine structures. | Defects here compromise vessel integrity. Quality is non-negotiable. |

| Certification | Must come with a valid Mill Test Certificate5 (MTC). | The MTC is the product’s birth certificate. No MTC, no verification of quality. |

For buyers like Gulf Metal Solutions, getting the right "bulb bar" starts with a clear specification in the purchase order: "Bulb Flat Steel, Profile HP 250×12 per LR standards, Grade AH36, with MTC and third-party inspection." This clarity eliminates confusion and sets a clear benchmark for inspecting the product. A defect could be as simple as receiving a 240×12 bar when you ordered 250×12—a dimensional error6 that starts with a misunderstanding of the product itself.

What is a bulb flat?

"Bulb flat" is the formal term. Knowing its exact definition helps you spot deviations that qualify as defects. A vague understanding leads to accepting substandard material.

A bulb flat is the official name for the hot-rolled steel profile characterized by a flat web and a bulb at one edge. It is a standardized structural shape, primarily governed by shipbuilding rules. The term "flat" refers to the main web, and "bulb" refers to the thickened edge. Together, they create a profile optimized for unidirectional bending strength in marine frameworks.

Deconstructing the Bulb Flat: Anatomy of a Standard

To inspect for defects, you must know the perfect specimen. Let’s break down the bulb flat into its components and understand the tolerances allowed for each. This knowledge turns you from a passive buyer into an informed inspector.

1. The Components and Their Roles

- The Bulb: This is the reinforcing element. Its round shape is designed for efficient rolling at the mill and good stress distribution. The bulb’s size (height and radius) is critical. An undersized bulb reduces strength. An oversized bulb can mean the mill used an incorrect roll pass.

- The Web: This is the vertical plate that connects the bulb to the toe. Its primary function is to provide height and connect to the ship’s hull plate via welding. The web thickness must be consistent. Variations, known as "waisting" or "barreling," are defects.

- The Toe: The opposite edge from the bulb. It is usually flat and provides a welding edge or a reference surface. The toe should be straight and square to the web.

- The Length and Straightness: The entire bar must be straight within defined limits. Excessive curvature (camber or sweep) makes fabrication difficult and can induce unwanted stresses.

2. Tolerances: The Line Between Acceptable and Defective

No manufacturing process is perfect. Standards define allowable tolerances. Anything outside these limits is a defect.

- Dimensional Tolerances: These cover the height (overall and bulb height), web thickness, bulb radius, and width of the toe. For example, the web thickness on a 10mm bulb flat might have a tolerance of ±0.5mm.

- Shape Tolerances: This includes straightness (camber), flatness of the web, and the angle of the toe. A twisted bulb flat is very difficult to use.

- Mass Tolerance: The weight per meter should be within a certain percentage of the theoretical weight. Significant deviation suggests a major dimensional error.

3. The Importance of the Mill Test Certificate (MTC)

The MTC is the quality report for that specific production batch. It lists the actual chemical composition and mechanical properties (yield strength, tensile strength, elongation, Charpy impact values). The numbers on the MTC must meet the ordered grade (e.g., AH36). If they don’t, the steel is defective, even if it looks fine.

Here is a table of common bulb flat defects linked to their components:

| Component | Potential Defect | What Causes It | Consequence |

|---|---|---|---|

| Bulb | Underfilled / Flat Bulb | Worn mill rolls, incorrect rolling temperature. | Reduced section modulus, lower bending strength. |

| Bulb | Overfilled / Asymmetric Bulb | Misaligned rolls, uneven heating. | Fits poorly in designs, may indicate internal stress. |

| Web | Variation in Thickness | Roll deflection, uneven wear. | Weak points in the structure, unpredictable strength. |

| Web | Surface Scales or Pitting | Poor descaling during rolling, rusty slab. | Creates stress concentrators, weakens weld areas, promotes corrosion. |

| Entire Bar | Excessive Camber (Curvature) | Improper cooling, handling after rolling. | Hard to fit and weld, creates alignment problems in the frame. |

| Internal | Laminations or Inclusions | Impurities in the steel slab, rolling defects. | Hidden internal weakness that can cause sudden failure under load. |

When a buyer understands this anatomy, they can create a targeted inspection checklist. They don’t just look at the steel; they measure the bulb, check the web thickness with a caliper, review the MTC chemistry, and verify straightness. This is the process we support for all our clients. It transforms quality assurance from a hope into a verified fact before the steel ever leaves our warehouse.

What are the characteristics of a bulb?

The bulb is the defining feature. Its characteristics directly determine the performance of the entire bar. If the bulb is wrong, the bulb flat fails its purpose, regardless of other qualities.

The key characteristics of a bulb on bulb flat steel are its shape, size, and consistency. The bulb should have a smooth, rounded contour. Its height and radius must conform to the standard profile’s specifications. Most importantly, the bulb must run straight and consistent along the entire length of the bar, with no flat spots, underfilling, or asymmetrical deformation.

A Deep Dive into Bulb Quality: The Make-or-Break Details

The bulb is not just a bump. Its quality is a direct reflection of the mill’s manufacturing precision and process control. Evaluating the bulb requires looking at specific geometric and material attributes.

1. Geometric Characteristics: Shape and Dimensions

- Bulb Height (B): This is the distance from the toe edge to the top of the bulb. It is a primary dimension in the profile code (e.g., in a 250×12 profile, 250mm is the total height, which includes the bulb height and web height). An incorrect bulb height changes the all-important section modulus.

- Bulb Radius (R): The bulb is not a perfect semicircle, but it has a defined radius of curvature. This radius affects how the stress flows through the section. A sharp or irregular radius creates stress concentration points.

- Bulb Symmetry: The bulb should be centrally located on the edge of the web. An off-center or "lopsided" bulb indicates the steel was not centered in the rolling mill, which can lead to uneven mechanical properties and twisting.

- Bulb-to-Web Transition: The area where the bulb meets the web should be smooth and continuous, without notches or abrupt changes. A poorly blended transition is a potential crack initiation site.

2. Material and Surface Characteristics

- Surface Finish: The bulb surface should be free of rolling defects like seams, rolls marks, or deep scratches. These can act as fatigue crack starters in the high-stress bulb area.

- Consistency: The bulb’s shape and size must be uniform from one end of the 12-meter bar to the other. Tapering or "fading" of the bulb is a serious rolling defect. You can check this by measuring the bulb height at both ends and the middle of the bar.

- Internal Soundness: While not visible, the integrity of the steel within the bulb is critical. The bulb undergoes significant deformation during rolling. Internal defects like shrinkage cavities or inclusions from the original ingot can be stretched into dangerous planar flaws within the bulb.

3. The Impact of Bulb Defects on Performance

A defective bulb compromises the bar’s core function:

- Reduced Strength: An undersized bulb directly lowers the moment of inertia and section modulus. The beam will bend more easily under load.

- Poor Weldability: If the bulb surface is rough or scaled, it can trap contaminants and lead to poor-quality welds when attaching brackets or other members.

- Fatigue Failure: Notches or asymmetries in the bulb create points where stress concentrates. Under the cyclic loading of a ship at sea, these points can develop cracks over time.

Here is a table to help inspect the bulb’s key characteristics:

| Characteristic | Good Quality Sign | Defect Indicator | Inspection Method |

|---|---|---|---|

| Shape & Contour | Smooth, continuous rounded curve. | Flat spots, underfilling (flat top), overfilling (mushrooming), sharp angles. | Visual inspection and using a profile gauge or template. |

| Consistency Along Length | Uniform shape and size from end to end. | Tapering bulb, bulb that "disappears," variable radius. | Measure bulb height at multiple points (ends and center). |

| Symmetry | Bulb is centered on the web edge. | Bulb is shifted to one side (asymmetric). | Visual check against a square, or measure from bulb center to web faces. |

| Surface Finish | Clean, metallic surface free of deep flaws. | Heavy mill scale, deep roll marks, seams, or cracks. | Visual and tactile inspection. Grind a small area if in doubt. |

| Transition to Web | Smooth, flowing blend with no notch. | A visible notch, lap, or crease at the junction. | Visual inspection, run a finger along the transition. |

For a project contractor, accepting bulb flats with poor bulb characteristics is a major risk. It transfers the mill’s quality problem onto their project’s structural integrity. That’s why our quality control includes checking bulb dimensions against profile drawings. For a buyer, the action is simple: include bulb dimension checks in your third-party inspection scope. Don’t assume the bulb is correct just because the profile looks roughly right. Measure it.

Conclusion

Preventing defects in bulb flat steel is a proactive process. It starts with clear specifications, relies on sourcing from certified mills, and is secured by rigorous documentation review and pre-shipment inspection. Knowing what to look for—from the galvanized coating to the precise shape of the bulb—is your best defense against costly failures.

-

Explore this link to understand the significance of bulb flat steel in enhancing ship structural integrity. ↩ ↩ ↩ ↩

-

Learn about section modulus to grasp its critical role in engineering design and material selection. ↩ ↩

-

Discover the standards set by ship classification societies to ensure safety and quality in marine construction. ↩ ↩

-

Explore Lloyd’s Register’s impact on shipbuilding standards and safety regulations. ↩ ↩

-

Understand the importance of Mill Test Certificates in verifying the quality and specifications of steel products. ↩ ↩

-

Understand the implications of dimensional errors to avoid costly mistakes in procurement and construction. ↩