You receive a shipment of L-shaped steel, and the edges are cracked, or the surfaces are pitted. These defects compromise your entire fabrication project, leading to rework, delays, and safety risks.

Common defects in L-shaped steel include rolling defects (cracks, seams, scale), dimensional inaccuracies (uneven legs, bow, camber), surface imperfections (pitting, rust), and internal/metallurgical issues (laminations, poor toughness). Avoid them by sourcing from certified mills, specifying marine-grade standards, and implementing pre-shipment third-party inspection.

These defects don’t appear by chance. They have specific origins in the production process, handling, or material quality. Understanding their types and causes is the first step to prevention. Let’s explore the defect landscape systematically, from the mill to the job site.

What are the types of defects in steel structures?

A steel structure can fail not just from design error, but from defects hidden in the material itself. These defects act as stress concentrators, silently weakening the structure under load.

Defects in steel structures are categorized into material defects (from production), fabrication defects (from cutting/welding), erection defects (from assembly), and corrosion damage (from environment). For L-shaped steel, material and fabrication defects are most critical at the procurement stage.

A Lifecycle View of Defects: From Mill to Service

To manage quality, you must know where and when problems can occur. Defects are introduced at different stages. For an L-shaped steel buyer, your focus is on preventing material defects from entering your supply chain and avoiding fabrication defects through good practice.

1. Material Defects (Originating at the Mill)

These are present in the steel section when you receive it. They are our primary concern as a supplier.

- Internal/Metallurgical: Inclusions (non-metallic particles), laminations (internal separations), segregation (uneven chemical composition). These are often detected by ultrasound.

- Surface: Cracks, seams (linear folds), rolled-in scale (oxide pressed into surface), pits, excessive rust.

- Dimensional/Geometric: Incorrect leg lengths or thickness, excessive bow (curvature along the length), twist (torsion along the length), camber (curvature perpendicular to the web). For L-angles, leg straightness and the 90-degree angle are crucial.

2. Fabrication Defects (Introduced by the Workshop)

These occur when you process the raw steel.

- Cutting Defects: Notch-like cuts from torch cutting, excessive heat-affected zone (HAZ) from plasma cutting, inaccurate lengths.

- Welding Defects: Cracks (hot or cold), porosity (gas bubbles), lack of fusion, undercut (a groove at the weld toe), excessive spatter, distortion from weld heat.

- Drilling/Hole Making: Misaligned holes, burrs, torn edges.

3. Erection & Assembly Defects

These happen on site.

- Fit-up Problems: Members not aligning due to cumulative dimensional errors in multiple pieces.

- Improper Bolting: Incorrect torque, cross-threading, missing washers.

- Field Welding Issues: Poor conditions (wind, moisture) leading to defective welds.

4. In-Service Defects

- Corrosion: General rust, pitting, galvanic corrosion.

- Fatigue Cracks: Initiate from stress concentrators (like a sharp notch or a weld toe) under cyclic loading.

- Overload Damage: Permanent deformation from accidents or exceeding design load.

This table links defect types to their stage and impact on L-shaped steel:

| Defect Category | Typical Examples in L-Shaped Steel | Stage Introduced | Potential Consequence |

|---|---|---|---|

| Material: Surface | Longitudinal seam along leg, deep pitting, heavy mill scale. | Steel Mill (Rolling). | Acts as crack starter, reduces fatigue life, poor paint adhesion. |

| Material: Dimensional | Leg length mismatch, excessive bow (>spec), twist. | Steel Mill (Rolling/Cooling). | Fit-up problems during fabrication, misalignment in frame. |

| Material: Internal | Lamination at the root of the angle. | Steel Mill (Casting/Rolling). | Can delaminate under stress, creating a serious hidden flaw. |

| Fabrication: Cutting | Notched, irregular cut end from torch. | Fabrication Shop. | Creates a severe stress concentration point. |

| Fabrication: Welding | Crack at the weld joining an L-angle to a plate. | Fabrication Shop. | Immediate structural weakness; can propagate. |

| In-Service | Crevice corrosion in the inside corner of the angle. | Service Life (Maintenance). | Loss of cross-section, weakening. |

Your strategy is clear: Prevent Material Defects at source through supplier selection and inspection. Control Fabrication Defects through skilled workmanship and procedures. By partnering with a supplier that prioritizes mill quality and offers inspection support, you tackle the first and most critical category head-on.

What are the 4 rolling defects?

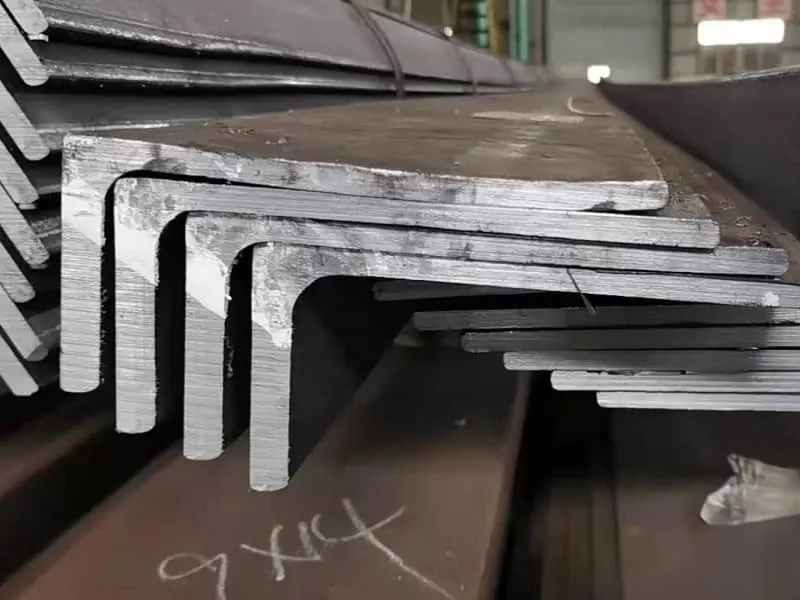

The hot-rolling process shapes red-hot steel into an L-section. If this process is not controlled, specific defects are baked into the profile. You cannot fix these later.

Four primary rolling defects are: seams (longitudinal surface folds), cracks (surface fissures), rolled-in scale (oxide layer embedded in surface), and dimensional inaccuracies (like uneven legs, bow, or twist). These occur due to issues with the raw billet, roll condition, temperature control, or rolling sequence.

The Mill Floor Perspective: How Rolling Creates (or Avoids) Defects

Rolling is a high-pressure, high-temperature forming process. Defects occur when the process variables go wrong. Understanding these four common ones helps you know what to look for during inspection.

1. Seams (or Rolled-in Scabs)

These are perhaps the most common and troublesome surface defects for angles.

- What it is: A long, linear groove or fold on the surface, usually running parallel to the rolling direction (along the length of the leg). It is formed when a crack or fissure on the original billet (from casting) gets elongated and folded over during rolling but does not weld shut.

- How to spot it: It can be visible as a thin, dark line. Sometimes it’s subtle and only revealed after shot blasting. Running a fingernail across it may catch.

- Why it’s bad: It acts as a natural crack, significantly reducing fatigue strength. It can also trap moisture, starting corrosion.

2. Cracks

These are more severe than seams. They are actual ruptures in the steel surface.

- What it is: Surface fissures, which can be transverse or longitudinal. They are caused by over-stressing the steel during rolling (if temperature is too low), improper chemical composition (making the steel "hot short" or "cold short"), or excessive cooling rates.

- How to spot it: Visible as jagged lines on the surface. Edge cracks on the leg tips are also common.

- Why it’s bad: Obvious stress concentrators and points of failure.

3. Rolled-in Scale (or Mill Scale)

Mill scale itself is normal—it’s the blue-black oxide layer that forms when hot steel meets air. The defect is when it becomes excessively thick or is mechanically rolled into the surface.

- What it is: During rolling, if the scale does not flake off properly, it can be forced into the steel surface, creating a rough, pitted appearance underneath.

- How to spot it: A very rough, irregular surface texture under the flaky scale layer. After blasting, deep pits may remain where scale was embedded.

- Why it’s bad: Creates a poor surface for paint adhesion. Paint over poorly adherent scale will blister and fail as the scale continues to detach in service.

4. Dimensional Inaccuracies (Bow, Camber, Twist, Uneven Legs)

These are geometric defects from uneven rolling forces or cooling.

- What it is:

- Bow: Curvature of the section along its length in the plane of the legs.

- Camber: Curvature perpendicular to the web (less common in angles).

- Twist: A torsional deformation where one end of the angle is rotated relative to the other.

- Uneven Legs/Thickness: One leg longer or thicker than specified.

- How to spot it: Lay the angle on a flat surface. Use a straight edge and a measuring tape. Check the 90-degree angle with a square.

- Why it’s bad: Causes major fit-up problems during fabrication. The structure will not assemble correctly, requiring forceful alignment (inducing stress) or costly rework.

The root causes and prevention strategies are tightly linked:

| Rolling Defect | Primary Cause | How a Quality Mill Prevents It | Your Action to Avoid It |

|---|---|---|---|

| Seams | Defects in the original steel billet (casting). | Strict quality control of incoming billets, surface conditioning (grinding) before rolling. | Source from mills with integrated billet production or strict billet QC. |

| Cracks | Incorrect rolling temperature (too low), poor steel chemistry. | Precise temperature control throughout the process, ladle metallurgy for correct chemistry. | Specify steel grade from a certified mill with process controls. |

| Rolled-in Scale | Inefficient descaling during rolling. | Using high-pressure water jets to blast scale off between rolling passes. | Inquire about the mill’s descaling equipment. Surface finish is a tell-tale sign. |

| Dimensional Issues | Worn or misaligned rolls, uneven cooling. | Regular roll maintenance and replacement, controlled cooling beds. | Specify compliance with tight tolerance standards (e.g., EN 10056, ASTM A6). Demand inspection for straightness. |

For a buyer, the lesson is to not just buy steel based on grade and price. Inquire about the mill’s rolling practices. When we work with clients, we specify mills that have modern, maintained rolling lines and strict process controls to minimize these exact defects from the start.

What are the common steel frame problems?

You’ve sourced good L-shaped steel, but the finished frame is weak, misaligned, or cracks appear. Often, the problem isn’t the material, but how it was turned into a structure.

Common steel frame problems include connection failures (poor welds/bolts), instability issues (buckling of members), excessive deflection (sagging), corrosion at joints, and fit-up difficulties due to cumulative dimensional errors in the raw sections. Many stem from fabrication and design, not the base material.

From Raw Material to Assembled Structure: The New Set of Risks

Once L-shaped steel leaves the mill, a new set of challenges begins. The most common frame problems often occur at the connections, where loads are transferred. Understanding these helps you specify fabrication requirements and conduct better site supervision.

1. Connection Problems1: The Weakest Link

The frame is only as strong as its connections.

- Welding Defects2: As mentioned earlier, cracks, lack of fusion, and porosity at welds are critical. For L-angles welded to plates, the sharp inside corner is a challenge. It requires a skilled welder to achieve proper penetration without undercutting the thin edge.

- Bolting Problems3: Using undersized bolts, incorrect grade bolts, insufficient torque, or missing nuts/washers. In slip-critical connections, failure to prepare faying surfaces properly.

- Eccentric Connections: L-angles are often connected through one leg only. This creates an eccentric load path, inducing secondary bending moments that the design must account for. Ignoring this causes unexpected stress.

2. Stability and Buckling

L-shaped sections are not ideal columns or beams due to their open cross-section.

- Lateral-Torsional Buckling4: When a beam bends, its top flange is in compression. An L-angle’s leg acting as a flange can buckle sideways and twist simultaneously if not properly restrained. This is a common failure mode for angles used as beams.

- Local Buckling5: The thin legs of an angle can buckle locally under compression before the overall member fails.

3. Excessive Deflection6 (Sagging)

Even if the frame doesn’t break, too much sag (deflection) can make it unusable or cause damage to attached elements. L-angles have a relatively low moment of inertia (I), making them less stiff than I-beams of similar weight. Using an angle where stiffness is critical is a design error.

4. Fit-Up and Alignment Problems7

This is where material defects (like bow or twist) directly cause frame problems.

- Cumulative Error8: If each piece of L-angle has a small bow, assembling many pieces into a large frame can lead to significant misalignment.

- Forced Fit-up: Fabricators sometimes use force (jacks, come-alongs) to make misaligned members fit for welding. This "pre-stresses" the frame in an unknown way, which can lead to early failure.

5. Corrosion at Joints9

Joints are corrosion hotspots. Moisture gets trapped in crevices (like where an angle is welded to a plate). If the weld profile is poor or the coating is inadequate, corrosion starts here and can hide under the connection, weakening it unseen.

Here’s how these frame problems relate back to the quality of the supplied L-shaped steel:

| Steel Frame Problem | Link to L-Shaped Steel Quality | Prevention Strategy |

|---|---|---|

| Fit-Up Difficulties | Direct Link. Caused by dimensional defects (bow, twist, uneven legs) in the raw material. | Source steel with tight dimensional tolerances. Implement incoming inspection to check straightness before fabrication. |

| Weld Cracks at Connections | Indirect Link. Can be caused by poor steel chemistry (high Carbon Equivalent) making it difficult to weld, or by surface defects (seams) at the weld location. | Specify steel with a guaranteed, weldable chemistry (CEV). Inspect surface condition in the area to be welded. |

| Premature Corrosion10n at Joints](https://cnmarinesteel.com/the-role-of-marine-angle-steel-in-ship-hull-structures/)[^9] | Indirect Link. Heavy mill scale or pitted surface leads to poor coating adhesion around the welded joint. | Ensure steel is supplied with a surface condition suitable for painting (or specify pre-blasted). |

| Unexpected Buckling | Material Property Link. The frame design assumes certain mechanical properties (yield strength). If the steel does not meet the certified grade strength, it may buckle earlier. | Rely on certified material with valid Mill Test Certificates to ensure design assumptions are valid. |

For a fabricator like Gulf Metal Solutions, receiving dimensionally accurate, weldable L-shaped steel with a good surface is half the battle won. It allows their workshop to produce frames that fit together correctly and have durable connections, directly avoiding the most common and costly frame problems.

What are two problems with steel?

Steel is strong and reliable, but it has two fundamental, inherent behaviors that are not "defects" but must be actively managed: it corrodes, and it can become brittle. Ignoring these is the biggest mistake of all.

Two fundamental problems with steel are its susceptibility to corrosion (rust) when exposed to oxygen and moisture, and its ductile-to-brittle transition, where it loses toughness and can fracture suddenly at low temperatures. These are intrinsic material characteristics, not manufacturing defects.

The Inevitable Challenges: Corrosion and Brittleness

These are not problems you "fix" in the steel; they are realities you "manage" through design, specification, and maintenance. For marine L-shaped steel, managing these two problems is the entire point of using certified, marine-grade material.

Problem 1: Corrosion – The Constant Battle

Corrosion is a electrochemical process. Iron wants to return to its oxidized state (iron ore). We use energy to refine it into steel, and nature constantly tries to reverse that.

- The Mechanism in Marine Environments: Seawater is a perfect electrolyte. It accelerates corrosion through general rusting, pitting (localized deep holes), and galvanic corrosion (when steel is connected to a more noble metal like bronze).

- Implication for L-Shaped Steel: The inside corner (root) of an L-angle is a classic crevice. It traps water, salt, and debris, creating an oxygen-depleted zone that accelerates corrosive attack. This is a major hotspot.

- How Marine-Grade Steel and Certification Help:

- Controlled Chemistry: Some marine grades include small amounts of copper (Cu) and chromium (Cr) for slightly better atmospheric corrosion resistance.

- Surface Quality: A defect-free surface (no deep pits, seams) is essential for coating adhesion. The coating system (paint) is the primary barrier.

- Predictability: Certified steel ensures consistent properties, allowing for accurate corrosion allowance calculations in design (e.g., adding extra thickness to account for wastage over the vessel’s life).

Problem 2: The Ductile-to-Brittle Transition

This is a safety-critical, temperature-dependent behavior.

- The Mechanism: At room temperature, good steel is ductile. It yields and deforms a lot before breaking, giving visible warning. As temperature drops, a transition occurs. Below a certain temperature (the Ductile-to-Brittle Transition Temperature, or DBTT), the same steel can fail in a brittle manner with little deformation, like glass.

- Implication for Marine L-Shaped Steel: A ship in cold seas is at risk. A crack starting at a defect (like a seam or weld toe) can propagate rapidly through brittle steel, causing catastrophic hull failure. The infamous WWII Liberty ship failures demonstrated this.

- How Marine-Grade Steel and Certification Solve This:

This is the core purpose of grading (A, B, D, E, F). The grade letter guarantees a minimum impact toughness at a specified low temperature.- Grade D steel is tested at -20°C.

- Grade E at -40°C.

- Grade F at -60°C.

A DNV or ABS certificate for NV D36 L-shaped steel is a legal guarantee that the material has passed these impact tests. It pushes the DBTT to a temperature well below the vessel’s operating environment.

This table contrasts how these inherent problems are managed with different material choices:

| Inherent Problem | Consequence with Substandard/Uncertified Steel | How Certified Marine L-Shaped Steel Mitigates It |

|---|---|---|

| Corrosion | Accelerated, unpredictable wastage. Coating fails early due to poor surface. | Provides a consistent, defect-free surface for optimal coating. Certified chemistry may offer slight enhancement. Enables accurate corrosion management planning. |

| Brittle Fracture | Risk of sudden, catastrophic failure in cold conditions with no warning. | Guaranteed low-temperature toughness via impact testing and grading (D, E, F). The certificate is the proof of safety. |

| Additional: Fatigue | Cracks initiate easily from surface defects under wave cyclic loads. | A defect-free surface (no seams, cracks) and good toughness improve fatigue resistance. |

Therefore, when you procure L-shaped steel, you are not just buying a shape. You are buying a managed solution to steel’s two biggest problems. The certification and grade are your assurance that the material has been produced and tested to perform reliably despite these inherent challenges. This is why buying on price alone for critical structures is a profound risk.

Conclusion

Avoid L-shaped steel defects by sourcing from certified mills, inspecting for rolling and dimensional flaws, and understanding that managing steel’s inherent corrosion and brittleness is the goal of marine-grade certification.

-

Understanding connection problems is crucial for ensuring structural integrity and preventing failures in steel frames. ↩

-

Exploring welding defects can help you identify potential issues and improve the quality of your steel structures. ↩

-

Identifying bolting problems is key to ensuring the strength and safety of steel connections. ↩

-

Learning about lateral-torsional buckling can enhance your design strategies and prevent structural failures. ↩

-

Learning about local buckling can inform your design choices and enhance the stability of steel frames. ↩

-

Understanding excessive deflection helps in designing frames that maintain their integrity and functionality. ↩

-

Addressing fit-up issues is essential for achieving accurate and durable steel frame assemblies. ↩

-

Understanding cumulative error can help you avoid significant misalignment in large steel structures. ↩

-

Exploring corrosion causes can help you implement effective prevention strategies for steel structures. ↩

-

Understanding premature corrosion can help you select better materials and coatings for long-lasting steel frames. ↩