A shipyard in Saudi Arabia recently rejected a shipment due to surface defects. The experience highlighted the importance of quality control in marine steel.

Common marine steel plate defects include laminations, surface cracks, pitting corrosion, inclusion clusters, and dimensional inaccuracies. These can be avoided through strict mill quality control, proper handling, adequate protection during storage and transport, and thorough inspection before acceptance for shipbuilding applications.

Understanding and preventing defects ensures vessel safety and longevity. Let me explain the common issues and their prevention methods.

What are the failure modes of steel plates?

A naval architect from Qatar needed to understand potential failure modes for their risk assessment. This knowledge informed their inspection protocols1.

Steel plate failure modes include brittle fracture2 from low-temperature exposure, fatigue cracking3 from cyclic loading, corrosion wastage4 from marine environment, buckling under compressive loads5, and ductile tearing6 from overloading. Each failure mode requires specific prevention strategies through material selection7, design considerations, and maintenance practices.

Comprehensive Steel Plate Failure Analysis

Steel plates can fail through various mechanisms depending on loading conditions, environmental exposure, and material properties. Understanding these failure modes helps in prevention and risk management.

Brittle Fracture Mechanisms

Brittle fracture occurs without significant plastic deformation. This failure typically happens at low temperatures where steel loses ductility. The fracture propagates rapidly through the material. Stress concentrators like notches or cracks initiate failure. Improper material selection7 for service temperature causes this problem. Prevention requires using toughness-appropriate grades like EH36 for cold environments.

Fatigue Failure Process

Fatigue failure results from repeated cyclic loading. Microscopic cracks initiate at stress concentration points. The cracks gradually propagate with each load cycle. Final fracture occurs when the remaining cross-section cannot support the load. This failure affects areas with vibration or wave-induced stresses. Prevention involves proper detail design and stress calculation.

Corrosion-Induced Failures

Marine environments accelerate corrosion significantly. Uniform corrosion reduces plate thickness over time. Pitting corrosion creates localized penetration points. Galvanic corrosion occurs between dissimilar metals. Stress corrosion cracking combines tensile stress and corrosive environment. Prevention requires comprehensive corrosion protection systems.

Buckling and Stability Failures

Buckling occurs when compressive loads exceed critical values. Thin plates buckle at stresses below yield strength. The failure is sudden and catastrophic. Imperfections and residual stresses reduce buckling strength. Improper stiffener spacing contributes to this problem. Prevention involves proper structural design and plate thickness selection.

Ductile Fracture Characteristics

Ductile fracture involves significant plastic deformation. The failure occurs after yielding and necking. Microvoids coalesce to form the fracture surface. Overloading beyond design capacity causes this failure. Material with adequate ductility shows warning before failure. Prevention requires proper load calculation and safety factors.

Creep and High-Temperature Effects

Creep failure occurs under sustained loading at high temperatures. The material deforms progressively over time. This affects exhaust systems and certain machinery spaces. The failure develops slowly but predictably. Prevention requires material selection7 for temperature conditions and proper design.

Failure Mode Prevention Strategies

| Failure Mode | Primary Causes | Prevention Methods | Detection Techniques |

|---|---|---|---|

| Brittle Fracture | Low temperature, notches | Proper grade selection, detail design | Impact testing, UT |

| Fatigue | Cyclic loading, stress concentrations | Smooth transitions, adequate thickness | Dye penetrant, visual |

| Corrosion | Saltwater exposure, inadequate protection | Coatings, cathodic protection | Thickness measurement, visual |

| Buckling | Compression, thin sections | Proper stiffening, thickness | Dimensional check, calculation |

| Ductile Fracture | Overload, inadequate strength | Proper design factors, material certification | Load monitoring, inspection |

We help clients understand failure risks and implement appropriate prevention measures. Proper material selection7 and design are the first defense against failures.

What are the defects of steel materials?

A quality inspector from Mexico developed a comprehensive defect checklist after encountering various steel quality issues. Their system improved material acceptance standards.

Steel material defects include surface defects1 (scale, rust, pits), internal defects2 (inclusions, segregation, laminations), dimensional defects3 (warpage, thickness variation), and mechanical property defects (inadequate strength, poor toughness). These originate from manufacturing issues, handling damage, or improper storage and can be detected through visual inspection and testing.

Comprehensive Steel Defect Classification

Steel defects can be categorized systematically based on their origin, location, and impact on material performance. Understanding this classification helps in defect prevention and quality control4.

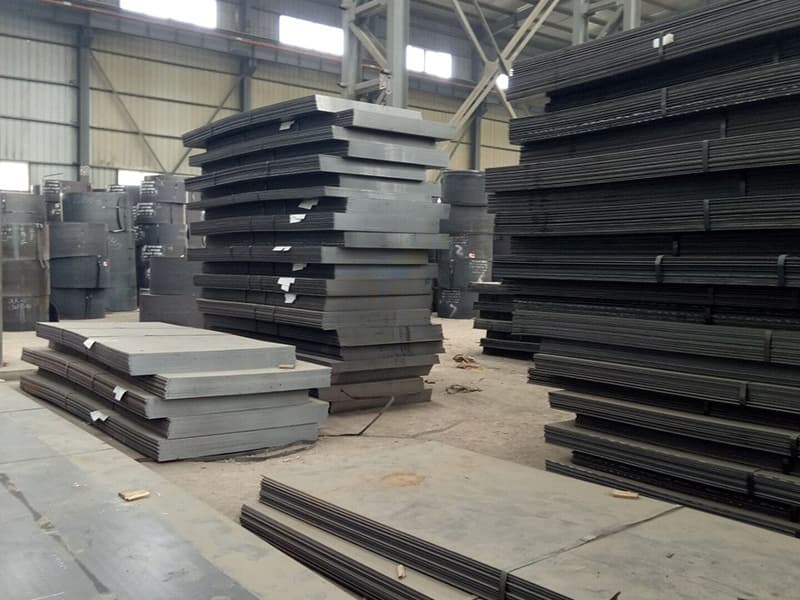

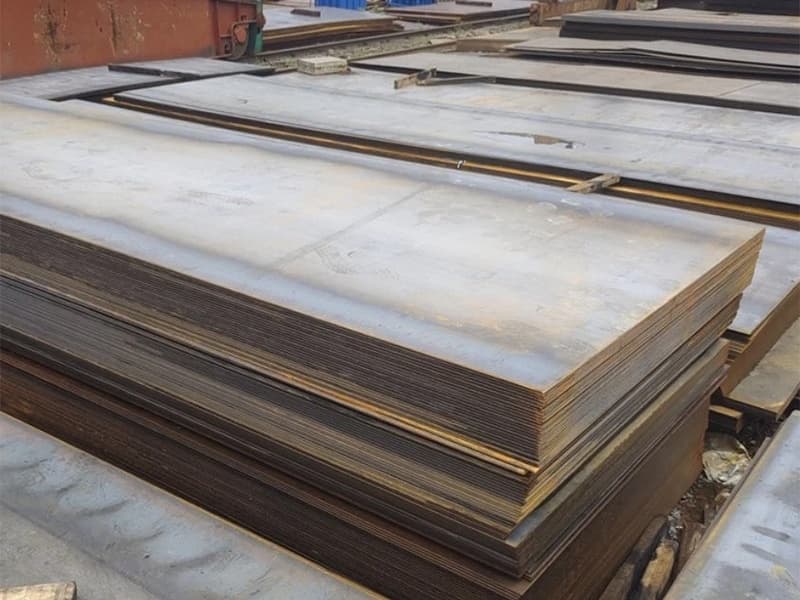

Surface Defects and Imperfections

Surface defects affect the external appearance and integrity. Roll marks appear as repetitive patterns from rolling mill issues. Scale is the oxide layer that forms during hot rolling. Rust results from improper storage or inadequate protection. Pitting occurs from localized corrosion attack. Scratches and gouges come from handling damage. These defects can initiate corrosion or cracks.

Internal Metallurgical Defects

Internal defects originate during steelmaking and processing. Inclusions are non-metallic particles trapped in the steel. Segregation refers to uneven distribution of alloying elements. Laminations are separations within the steel plate. Pipe defects form during solidification with centerline shrinkage. These defects reduce strength and may cause unexpected failures.

Dimensional and Geometrical Defects

Dimensional inaccuracies affect fabrication and fit-up. Warpage or camber describes curvature in flat plates. Thickness variation exceeds specified tolerances. Flatness deviations prevent proper contact surfaces. Length inaccuracies cause fitting problems. These defects increase fabrication time and cost significantly.

Mechanical Property Deficiencies

Property defects involve failure to meet specification requirements. Inadequate yield or tensile strength compromises load capacity. Poor toughness increases brittle fracture risk. Insufficient elongation indicates ductility problems. Hardness outside specified range affects machinability. These defects may not be visible but affect performance critically.

Chemical Composition Variations

Composition defects involve deviation from specified chemistry. Carbon content outside limits affects strength and weldability. Manganese deficiency reduces toughness. High sulfur or phosphorus causes embrittlement. Alloying elements outside ranges alter properties. These defects are detected through chemical analysis.

Defect Prevention and Control

Most defects can be prevented through proper controls. Manufacturing process control minimizes origin defects. Proper handling prevents surface damage. Adequate storage conditions avoid corrosion. Thorough inspection detects defects early. Supplier qualification ensures consistent quality. These measures reduce defect occurrence significantly.

Steel Defect Classification and Impact

| Defect Category | Specific Examples | Origin | Impact on Performance |

|---|---|---|---|

| Surface | Scale, rust, pits, scratches | Manufacturing, handling | Corrosion initiation, appearance |

| Internal | Inclusions, laminations, segregation | Steelmaking, rolling | Strength reduction, failure risk |

| Dimensional | Warpage, thickness variation | Rolling, cooling | Fabrication problems, fit-up issues |

| Mechanical | Low strength, poor toughness | Processing, composition | Structural integrity compromise |

| Chemical | Off-spec composition | Steelmaking, alloying | Property variation, weld issues |

We implement rigorous quality control4 to prevent defects in all supplied materials. Our clients receive steel that meets their exact specifications.

What are three methods of corrosion prevention?

A shipowner from Saudi Arabia needed effective corrosion protection for their new vessel. Multiple methods provided comprehensive protection.

Three primary corrosion prevention methods are protective coatings (paints, epoxies), cathodic protection (sacrificial anodes, impressed current), and material selection (corrosion-resistant alloys, proper grade selection). Combining these methods provides comprehensive protection for marine steel plates in harsh seawater environments.

Comprehensive Corrosion Prevention Strategies

Corrosion prevention requires a multi-layered approach that addresses different corrosion mechanisms. Understanding each method’s principles and applications ensures effective protection.

Protective Coating Systems

Coatings provide a physical barrier between steel and corrosive environment. Primer coats ensure good adhesion and provide initial protection. Intermediate coats build film thickness for better barrier properties. Topcoats offer weather resistance and aesthetics. Specialized coatings like epoxies and polyurethanes serve marine applications. Proper surface preparation is crucial for coating performance and longevity.

Cathodic Protection Principles

Cathodic protection makes the steel structure cathodic to prevent corrosion. Sacrificial anode systems use metals like zinc or aluminum that corrode preferentially. The anodes require periodic replacement as they deplete. Impressed current systems use external power sources with inert anodes. These systems provide protection to larger structures economically. Proper design ensures adequate current distribution and protection level.

Material Selection and Design

Choosing appropriate materials significantly affects corrosion resistance. Marine grades have better inherent corrosion resistance than structural steels. Corrosion allowance adds extra thickness to accommodate metal loss. Design considerations include avoiding crevices and ensuring good drainage. Material compatibility prevents galvanic corrosion. Proper selection reduces maintenance requirements and extends service life.

Environmental Control Methods

Controlling the environment can reduce corrosion rates. Dehumidification systems maintain low humidity in enclosed spaces. Chemical treatment of water systems inhibits corrosion. Temperature control minimizes condensation risks. These methods are particularly effective for internal spaces and specific systems. Environmental control complements other protection methods.

Maintenance and Monitoring

Regular maintenance ensures ongoing protection effectiveness. Coating inspection identifies damage needing repair. Anode consumption monitoring determines replacement timing. Thickness measurements track corrosion rates. Planned maintenance prevents unexpected protection failures. Monitoring provides data for protection system optimization.

Combined Protection Approach

The most effective strategy combines multiple methods. Coatings provide the primary barrier protection. Cathodic protection covers coating defects and damaged areas. Proper material selection forms the foundation. This multi-layer approach ensures redundancy in protection. The combination addresses various corrosion mechanisms simultaneously.

Corrosion Prevention Method Comparison

| Method | Protection Mechanism | Applications | Limitations | Maintenance Needs |

|---|---|---|---|---|

| Coatings | Physical barrier | All exposed surfaces | Damage susceptibility, aging | Regular inspection, repair |

| Cathodic Protection | Electrochemical | Submerged areas, hull | Limited range, anode consumption | Anode replacement, system check |

| Material Selection | Inherent resistance | Critical areas, special applications | Higher cost, availability | Minimal if properly selected |

| Environmental Control | Atmosphere modification | Enclosed spaces, tanks | System reliability, cost | System maintenance, monitoring |

We help clients implement comprehensive corrosion protection strategies. Proper protection ensures long service life and reduced maintenance costs.

How do you prevent steel corrosion?

A shipyard in Philippines implemented a comprehensive corrosion prevention program. The systematic approach significantly extended vessel service life.

Steel corrosion prevention involves surface preparation and coating application, cathodic protection system installation, proper material selection for marine environments, regular inspection and maintenance, and controlled storage conditions. This multi-layered approach addresses different corrosion mechanisms throughout the steel’s service life.

Comprehensive Steel Corrosion Prevention

Preventing steel corrosion requires a systematic approach that considers all stages from manufacturing to service. Each prevention method targets specific corrosion mechanisms and service conditions.

Surface Preparation Fundamentals

Proper surface preparation is the foundation of corrosion protection. Abrasive blasting removes mill scale and rust completely. surface profile creation ensures coating adhesion. Cleaning removes contaminants like salts and oils. The preparation standard must match coating requirements. Inadequate preparation causes premature coating failure. The investment in proper preparation pays through extended protection life.

Coating System Selection and Application

Coating systems must match service environment requirements. Epoxy coatings provide excellent water resistance. Polyurethane topcoats offer UV protection and aesthetics. Zinc-rich primers provide cathodic protection at breaks. The coating thickness must meet specification requirements. Proper application techniques ensure uniform coverage without defects. The system should be compatible with other protection methods.

Cathodic Protection Implementation

Cathodic protection complements coating systems. Sacrificial anodes protect localized areas effectively. Impressed current systems suit large structures. The protection potential must be controlled within optimal range. Stray current effects must be considered in design. Regular monitoring ensures continuous protection effectiveness. The system design considers current density requirements.

Material Selection Strategy

Material choice significantly influences corrosion resistance. Marine grades offer better performance than structural steels. Corrosion-resistant alloys serve in critical areas. Proper material matching prevents galvanic corrosion. Corrosion allowance compensates for expected metal loss. The selection balances performance requirements with economic factors. Lifecycle cost analysis guides optimal material choice.

Design Considerations for Corrosion Prevention

Design details significantly affect corrosion susceptibility. Avoidance of crevices prevents crevice corrosion. Proper drainage eliminates water accumulation. Adequate access facilitates inspection and maintenance. Smooth transitions reduce stress concentrations. The design should minimize areas difficult to protect. These considerations are incorporated early in design stages.

Maintenance and Inspection Regime

Regular maintenance ensures ongoing protection effectiveness. Scheduled inspections identify early corrosion signs. Coating repairs address damage promptly. Anode replacement maintains cathodic protection. Thickness monitoring tracks corrosion rates. Records support maintenance planning and decision making. The regime should be proactive rather than reactive.

Operational Considerations

Operational practices affect corrosion rates. Controlled operating conditions minimize corrosion acceleration. Proper cleaning prevents contaminant accumulation. Temperature and humidity control reduces corrosion risk. Crew training ensures proper maintenance execution. Operational procedures should support corrosion prevention goals.

Corrosion Prevention Implementation Stages

| Stage | Key Activities | Objectives | Quality Controls |

|---|---|---|---|

| Design | Material selection, detail design | Minimize corrosion risk, ensure maintainability | Design review, specification |

| Fabrication | Surface preparation, coating application | Establish protection foundation | Inspection, thickness measurement |

| Installation | System integration, protection activation | Complete protection system | Testing, commissioning |

| Operation | Regular inspection, maintenance | Sustain protection effectiveness | Monitoring, record keeping |

| Maintenance | Repair, replacement | Restore protection integrity | Quality assurance, documentation |

We supply steel with proper initial protection and guide clients on maintaining corrosion resistance. Comprehensive protection ensures long-term performance.

Conclusion

Understanding common steel defects and implementing comprehensive prevention strategies ensures marine steel plates perform reliably throughout their service life. Proactive quality control and corrosion prevention significantly extend vessel longevity and safety.

-

Learn about surface defects and how they affect steel integrity and performance. ↩ ↩

-

Discover the internal defects that can compromise steel strength and reliability. ↩ ↩

-

Find out how dimensional defects can impact fabrication and fitting processes. ↩ ↩

-

Discover the role of quality control in ensuring high standards in steel production. ↩ ↩ ↩

-

Understanding buckling is essential for structural design, ensuring stability and safety under load. ↩

-

Ductile tearing can indicate overload; knowing how to mitigate it is key for maintaining structural integrity. ↩

-

Proper material selection is the first line of defense against failures; exploring this can enhance safety. ↩ ↩ ↩ ↩