Your steel arrives late. The Mill Test Certificate is missing. The surface finish is poor. These procurement problems cause project delays, budget overruns, and quality failures. Many of these issues are predictable and preventable with the right strategy.

Common problems include material specification errors, delayed shipments, inconsistent quality, certification issues, and corrosion management failures. You avoid them by working with certified suppliers, insisting on pre-shipment inspection, using precise contracts, understanding logistics, and implementing a robust corrosion protection plan from the start.

Procurement mistakes are expensive, but they follow patterns. Recognizing these patterns allows you to build defenses into your purchasing process. Let’s identify the most frequent issues and provide practical solutions you can apply immediately.

Does marine grade steel1 rust?

You bought expensive "marine grade" steel, expecting it to be rust-proof. A few months after installation, you see brown spots. You feel cheated. This misunderstanding about the material’s fundamental nature is a major source of problems and disappointment.

Yes, marine grade steel1 rusts. It is not stainless steel. The term "marine grade" refers to its enhanced mechanical properties (strength, toughness) and weldability for structural use in ships. Its corrosion resistance2 is only marginally better than ordinary steel. It requires protective coatings and cathodic protection to prevent rust in seawater environments.

The confusion between "marine grade" and "corrosion-proof" is a root cause of many procurement and maintenance failures. Buyers underestimate the need for a complete protection system. Let’s clarify the reality and set correct expectations.

The Reality of Rust: Expectations vs. Engineering

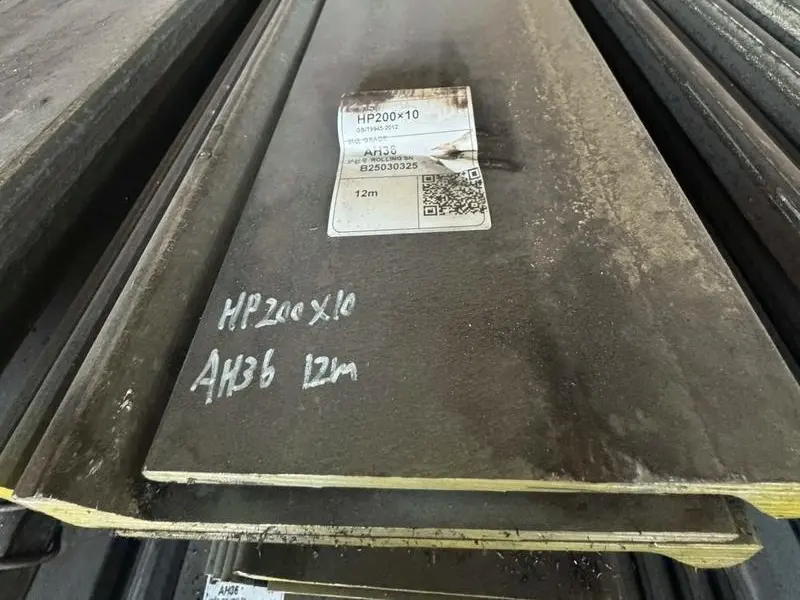

Marine grade steel (like ABS AH36) is a carbon steel. Its primary job is to provide structural strength. Its corrosion resistance2 is a secondary concern managed by other means.

Why It Rusts: The Chemistry

Marine grade steel contains iron. Iron oxidizes in the presence of water and oxygen to form iron oxide (rust). Seawater contains salt (chlorides), which acts as an electrolyte. This electrolyte makes the rusting process, an electrochemical reaction, occur much faster.

How "Marine Grade" is Different:

It has a cleaner chemical composition with lower levels of sulfur and phosphorus. This gives it better toughness and weldability, which are critical for surviving dynamic ocean loads. However, this cleaner chemistry does not stop the basic rusting reaction.

The Core Problem in Procurement:

Buyers often think they are buying a finished, protected product. They are not. They are buying a raw material that is part of a system. The procurement failure3 occurs when the steel is purchased without a simultaneous plan for its protection.

How to Avoid This Problem:

| Mistake | Consequence | Solution |

|---|---|---|

| Believing "marine grade" means rust-proof. | Early, unexpected corrosion. Costly repairs and loss of faith in the material. | Educate your team. Understand that marine grade steel1 is the substrate for a protection system. |

| Procuring steel without planning for coatings. | The steel begins to rust in the yard before fabrication or coating can be applied. | Integrate procurement. Plan the coating specification and application schedule alongside the steel purchase. |

| Accepting steel with poor surface condition (heavy mill scale, rust). | Coatings will not adhere properly, leading to premature failure. | Specify surface preparation4. Require the steel to be blast-cleaned and primed at the supplier or immediately upon arrival. |

| Not budgeting for cathodic protection5 (for submerged parts). | Accelerated, localized corrosion below the waterline. | Design the complete system. Include CP anodes in your material list for any submerged structure. |

A professional supplier helps you avoid this. We don’t just sell you AH36 plate. We discuss your project’s corrosion protection plan. We can supply steel with a shop primer applied, which protects it during storage and fabrication. We understand that you are buying a component of a system, and we provide material suitable for that system. This proactive approach prevents the rust surprise.

What are the problems with the steel industry?

You face delayed deliveries and inconsistent quality. You blame your supplier. But sometimes, the root cause is deeper. It lies in broader industry problems that affect every link in the supply chain, from the mill to your yard.

Major problems in the steel industry include volatile raw material prices, overcapacity leading to price wars and quality compromises, fragmented and opaque supply chains, lengthy production lead times for specialty grades, and stringent environmental regulations that increase costs and complexity.

These macro-level issues trickle down to your project. You cannot solve global overcapacity, but you can structure your procurement to be resilient against these industry-wide shocks. Let’s connect the big problems to your daily challenges.

From Global Issues to Your Dock: Navigating Industry Challenges

Understanding the industry’s pressure points helps you ask better questions and choose more resilient suppliers.

1. Price Volatility and Overcapacity1:

- The Problem: China produces over half the world’s steel. Periods of overcapacity lead to aggressive price competition. Mills and traders may cut corners on quality or use sub-standard raw materials to offer lower prices.

- Your Risk: The supplier who gives you the rock-bottom price may be sourcing from a low-quality mill during a price war. The steel may not meet the claimed specification.

- How to Avoid: Do not make price the sole deciding factor. Partner with suppliers who have long-term, stable relationships with specific certified mills. Their price may not be the absolute lowest, but it will be stable and tied to a known quality level.

2. Opaque and Fragmented Supply Chains2:

- The Problem: Many companies are just traders. They buy and sell steel without controlling the source or quality. They often lack technical knowledge.

- Your Risk: Delays happen because the trader is waiting for their own supplier. Quality is inconsistent because the source changes with each order.

- How to Avoid: Vet your supplier thoroughly. Ask: "Which mill do you source this grade from? Is it a fixed partnership?" Choose suppliers who are transparent about their sources. Our business model is based on long-term cooperation with certified mills, not spot-market buying.

3. Long Lead Times for Specialized Products3:

- The Problem: Marine grades (AH/DH/EH) are not produced continuously like common rebar. Mills schedule production heats for these grades. This can mean lead times of 8-12 weeks from order to readiness for shipment.

- Your Risk: Project delays if you do not plan for this lead time.

- How to Avoid: Plan early and communicate. Place orders as soon as designs are finalized. Work with a supplier who gives you realistic production timelines, not just optimistic guesses.

4. Logistics and Geopolitical Disruptions4:

- The Problem: Port congestion, shipping container shortages, and trade policy changes can delay shipments for months.

- Your Risk: Your steel is stuck on a ship or at a port, incurring demurrage charges and stalling your project.

- How to Avoid: Factor in buffer time. Use experienced suppliers with strong logistics partners. Consider FOB terms and use your own freight forwarder for more control, or rely on a supplier with a proven track record in shipping to your region.

A Comparative View of Supplier Types:

| Supplier Type | Common Industry Problem They Exhibit | Risk to You | Mitigation Strategy |

|---|---|---|---|

| Commodity Trader | Opaque supply chain, source changes with price. | Unpredictable quality, shipment delays. | Avoid for critical marine steel. Use only for non-critical items. |

| Small Mill (Uncertified) | May compromise on chemistry to cut costs during price wars. | Steel may not meet mechanical or toughness specs. | Insist on classification society certification (ABS, LR, DNV). |

| Specialized Supplier with Mill Partnerships | Buffers you from raw material volatility through fixed agreements. | Higher initial price perception. | Preferred choice. Provides stability, traceability, and technical support. |

Our client feedback highlights solutions to these industry problems: "fast response," "stable quality," and "good packaging" (logistics). These are not accidents. They are the result of a business model designed to counteract the industry’s inherent instability.

Which type of corrosion is most common in marine environments?

You see rust on a ship’s hull. It looks like general surface rust, but hidden beneath could be a more dangerous form of corrosion. Treating all rust the same way is a mistake. You must identify the specific enemy to fight it effectively.

The most common and aggressive type of corrosion in marine environments is pitting corrosion1. It is a localized form of attack that creates small, deep holes (pits) in the metal surface. It is particularly dangerous because it causes significant material loss in a small area, leading to perforation or acting as a stress concentrator for cracks, while the overall structure may still look mostly intact.

General surface rust is visible and manageable. Pitting corrosion is a hidden threat. It often starts at imperfections, under deposits, or in crevices. Understanding why it happens is key to preventing it through smart procurement and design.

The Silent Threat: Understanding and Preventing Pitting Corrosion

Pitting is an electrochemical process that is self-accelerating. Once a pit starts, it creates conditions that make it grow deeper faster.

Why Pitting is So Common in Seawater:

- Chloride Ions: Seawater is rich in chlorides. Chloride ions break down the protective passive layer on metals like steel and even stainless steel.

- Oxygen Concentration Cells2: A small defect, scratch, or deposit on the steel surface creates a tiny area with less oxygen. This area becomes anodic (corrodes) relative to the surrounding, oxygen-rich area (cathodic). The small anode area means the corrosion current is concentrated, digging a deep pit.

- Stagnant Conditions: Pitting thrives under barnacles, in crevices, or under silt where water flow is low and chlorides can concentrate.

How Procurement and Material Choice Influence Pitting:

The steel you buy and how you prepare it sets the stage for pitting resistance.

For Carbon Steel3 (e.g., AH36):

- Risk: Very high. Carbon steel has no natural passive layer.

- Defense: A continuous, high-quality coating system4 is the primary defense. Any pinhole, scratch, or damage in the coating becomes a potential pit initiation site.

- Procurement Action: Specify steel with a surface suitable for coating (blast-cleaned). Inspect delivered steel for deep scratches or pits in the mill scale that could become problem areas later.

For Stainless Steel5 (e.g., 316L):

- Risk: Moderate to high, depending on grade and condition. Stainless steel relies on its passive layer.

- Defense: Use the correct grade (316/L over 304). Ensure surfaces are clean and free of contaminants (like iron particles from cutting tools). Avoid crevice designs6.

- Procurement Action: Source 316/L with a known, clean surface finish (e.g., 2B, polished). Ensure it is handled and packed to prevent surface damage.

Common Procurement Mistakes That Lead to Pitting:

| Mistake | How it Encourages Pitting | How to Avoid |

|---|---|---|

| Accepting steel with deep mill scale or surface defects. | Pits can initiate under or within the scale. | Specify and inspect for surface quality. Require blast cleaning if needed. |

| Using 304 stainless in splash or immersion zones. | 304 is highly susceptible to chloride pitting. | Specify 316/L for all marine stainless applications. |

| Poor packaging leading to transit damage (scratches, dents). | Each scratch is a potential pit initiation site. | Work with suppliers known for good packaging (like our client feedback mentions). |

| Not planning for coating maintenance. | Coating damage over time is inevitable. Unrepaired damage leads to pitting. | Factor in inspection and maintenance costs from the start. |

A good supplier helps you mitigate pitting risk. We provide steel with a surface condition conducive to coating. We recommend the right grade for the environment. We use packaging that protects the steel edges and surfaces during the long sea voyage. This proactive approach addresses corrosion at the procurement stage.

What are the major causes of the collapse of steel structures?

You see news of a pier collapse or a ship accident. The immediate cause might be an overload or an impact. But the root cause is often a slow, progressive failure that started with a procurement or material choice made years before.

The major causes of steel structure collapse are not typically sudden overloads. They are usually progressive failures: corrosion-induced section loss1, fatigue cracking2 from cyclic loads, brittle fracture3 due to poor material toughness, and connection failures4 (often at welds or bolts). These causes are frequently linked to material quality, design, or maintenance issues that originate in the procurement phase.

Catastrophic failure is often the final act of a long process. The seeds are sown when the wrong material is specified, when quality is not verified, or when corrosion is not managed. Procurement is the first line of defense against these causes.

Tracing Collapse Back to Procurement: A Failure Chain Analysis

Let’s connect each major cause of collapse to decisions and problems in the material supply chain.

1. Corrosion-Induced Section Loss:

- Failure Mechanism: Over decades, corrosion eats away the steel’s cross-section. The remaining steel can no longer carry the design load.

- Procurement Link: Buying steel without a verifiable, long-term corrosion protection5 plan. Accepting poor surface finish that compromises coating adhesion. Using the wrong material (e.g., plain carbon steel in a highly aggressive zone without adequate protection).

- How to Avoid: Procure steel as part of a complete corrosion protection system. Specify surface preparation. Choose suppliers who understand this system.

2. Fatigue Cracking:

- Failure Mechanism: Repeated wave loads, vibrations, or stress cycles cause microscopic cracks to initiate and grow. These cracks grow over time until the remaining section fails suddenly.

- Procurement Link: Using steel with poor inherent toughness or with internal defects (inclusions, laminations). Using steel with a high Carbon Equivalent6 that leads to a brittle, crack-prone Heat-Affected Zone (HAZ) after welding.

- How to Avoid: Insist on steel with certified Charpy impact toughness values7 at the service temperature. Source from mills with good internal quality control (low inclusion content). Use steel with a low CE for better weldability and a tougher HAZ.

3. Brittle Fracture:

- Failure Mechanism: In cold conditions, a small crack or defect can cause sudden, catastrophic crack propagation through the steel with little warning. The steel breaks like glass.

- Procurement Link: This is almost entirely a material quality issue. Using steel that does not meet low-temperature toughness requirements for the operating environment.

- How to Avoid: For ships or structures in cold waters, specify "D" or "E" grades (e.g., DH36, EH36) which guarantee toughness at -20°C or -40°C. Never substitute an "A" grade where a "D" or "E" grade is required.

4. Connection Failures (Welds/Bolts):

- Failure Mechanism: Welds crack or bolts shear. This is often the weakest link.

- Procurement Link: Using steel with poor weldability (high CE) leading to cold cracks in welds. Using mismatched or substandard filler material. Using bolts of incorrect grade or with inadequate corrosion protection.

- How to Avoid: Verify the weldability (CE) of the base metal. Source welding consumables and fasteners with the same level of certification (e.g., matching AH36 with E7018-H4R electrodes). Treat fasteners as critical components.

Procurement Checklist to Prevent Failure:

| Potential Cause of Collapse | Critical Procurement Question | Action to Take |

|---|---|---|

| Corrosion | "What is the complete, long-term protection system for this steel?" | Specify coatings, CP, and material grade together. Buy pre-primed steel. |

| Fatigue/Brittle Fracture | "Does the Mill Test Certificate show adequate Charpy impact energy at my operating temperature?" | Demand MTCs and verify impact test results. Specify DH/EH grades for cold service. |

| Weld Failure | "What is the Carbon Equivalent6 of this batch of steel?" | Calculate CE from the MTC. Ensure it is suitable for your welding procedure. |

| General Quality | "Can I trace this steel back to its production heat?" | Only accept steel with full traceability and original MTCs. |

Procurement is not just buying a commodity. It is the process of acquiring structural integrity8. By focusing on the causes of failure during procurement, you build resilience into the structure from its very first component. Our role is to supply the certified, traceable, and fit-for-purpose materials that form that foundation of safety.

Conclusion

Avoiding marine steel procurement problems requires clear specifications, supplier vetting, quality verification, integrated corrosion planning, and an understanding that material choice directly impacts long-term structural safety.

-

Understanding corrosion-induced section loss is crucial for preventing structural failures and ensuring long-term safety. ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the impact of fatigue cracking to learn how to enhance the durability and lifespan of steel structures. ↩ ↩ ↩ ↩ ↩

-

Discover the causes of brittle fracture to improve material selection and prevent catastrophic failures. ↩ ↩ ↩ ↩

-

Learn about connection failures to ensure the integrity of welds and bolts in your projects. ↩ ↩ ↩ ↩

-

Learn about effective corrosion protection systems to extend the life of steel structures. ↩ ↩ ↩

-

Explore the significance of Carbon Equivalent in welding to ensure strong and durable connections. ↩ ↩ ↩

-

Understanding Charpy impact toughness values helps in selecting the right materials for varying temperatures. ↩

-

Understanding procurement’s role in structural integrity is vital for building safe and reliable structures. ↩