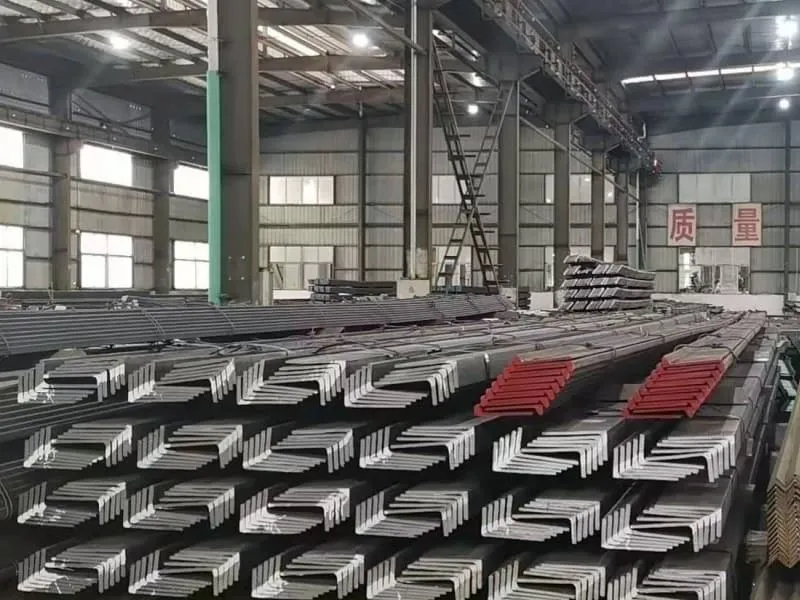

Ordering the wrong size or grade of L-shaped steel can stop a shipbuilding project. I see this confusion cause delays and extra costs for importers and contractors every year. Getting the specifications right the first time is critical.

Marine L-shaped steel, or angle bar, comes in standard sizes like 75x75x6mm up to 200x200x20mm, with unequal angles like 150x100x12mm also common. The key standards are set by ship classification societies (ABS, LR, DNV, BV, etc.) and general structural standards (EN 10025, ASTM A36). For ships, grades like AH36, DH36 with specific toughness and strength are mandatory.

To order confidently, you need to understand the size system, the strict marine rules, and how it differs from similar products. Let’s clarify each point step by step.

What size is L section steel?

L section steel sizes seem simple, but a small mistake in reading them leads to the wrong product. Saying "I need a 100 angle" is not enough and will cause problems.

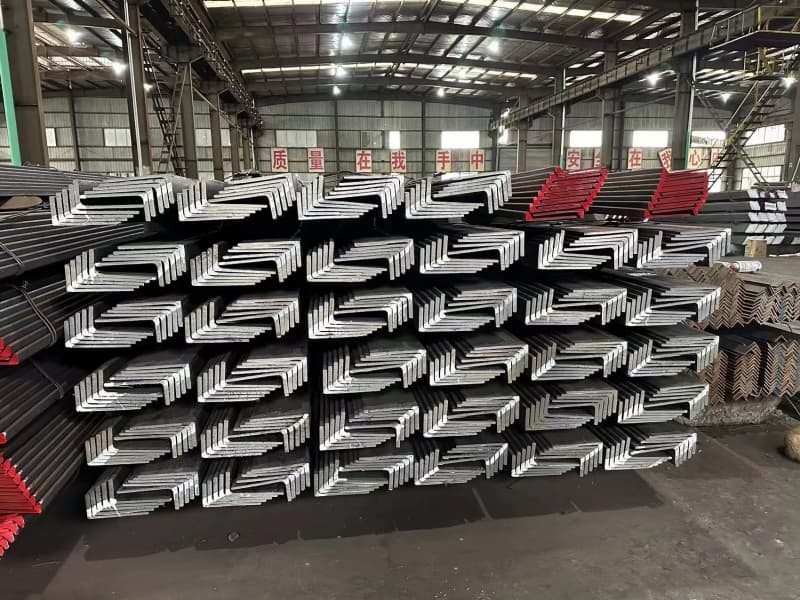

L section steel size is specified by the length of its two legs and the thickness of the web. It is written as "Leg x Leg x Thickness" in millimeters, for example, 100x100x10mm or 150x75x8mm. For equal angles, the legs are the same. For unequal angles, the legs are different lengths. The size does not include the radius of the inner curve.

Decoding the Size Specification for Precise Ordering

The three-number system tells you everything about the cross-section. But you must also consider length, tolerances, and weight to complete the order picture.

1. The Three-Number Nomenclature

- First Number: Length of the first leg (in mm).

- Second Number: Length of the second leg (in mm).

- Third Number: Thickness of the steel (in mm).

- Example:

L 150 x 100 x 12- This is an unequal angle.

- One leg is 150mm long.

- The other leg is 100mm long.

- The thickness of both legs is 12mm.

2. Equal vs. Unequal Angles

- Equal Angles: Both legs are the same length. Example:

L 80 x 80 x 8. These are common for symmetric bracing and frames. - Unequal Angles: Legs are different lengths. Example:

L 200 x 150 x 18. These are used where one side needs more material for connection or strength, like a shelf bracket or a specific ship frame detail.

3. Beyond the Basic Dimensions

The stated size gives you the nominal dimensions. Standards also define:

- Root Radius (r1): The inner curve where the two legs meet. A larger radius can mean slightly less material in the corner.

- Toe Radius (r2): The outer curve at the leg tips. This is usually small.

- Tolerances: Leg length and thickness will have allowed variations (e.g., ±2mm on leg length for larger angles). The mill certificate confirms actual dimensions.

- Theoretical Weight: This is calculated per meter based on the nominal size. It is expressed in kg/m. It is crucial for calculating total order weight and cost.

4. Common Size Ranges for Marine Work

For shipbuilding and heavy construction, common sizes are thicker and larger. Small angles (under 50x50x5) are rarely used for primary structure.

Here is a table of typical marine L-angle sizes:

| Type | Common Size (Leg x Leg x Thickness mm) | Theoretical Weight (kg/m) Approx. | Typical Marine Application |

|---|---|---|---|

| Equal Angle | 75 x 75 x 6 | 6.9 | Secondary bracing, small brackets, handrail supports. |

| Equal Angle | 100 x 100 x 10 | 15.1 | Primary frame bracing, hatch coamings, deck edge stiffeners. |

| Equal Angle | 150 x 150 x 15 | 34.0 | Stronger bracing, support for heavy equipment foundations. |

| Equal Angle | 200 x 200 x 20 | 60.1 | Major structural components in large vessels. |

| Unequal Angle | 150 x 100 x 12 | 22.8 | Efficient where connection points differ; common in ship design. |

| Unequal Angle | 200 x 150 x 18 | 48.6 | Heavy-duty framing and support structures. |

When you send an inquiry, providing the full three-number size is essential. Saying "L 100x100x10" is perfect. Saying "100mm angle" is vague—we won’t know if you mean leg length, or if you need equal legs, or what thickness. Clear size information is the first thing our sales team needs to give you an accurate price and check mill stock.

What is the standard specification for structural steel for ships?

The "standard" for ship steel is not one document. It is a system of rules set by classification societies. Ignoring these rules means your steel will be rejected at the shipyard. This is a non-negotiable area.

The standard specification for structural steel in ships is defined by international ship classification societies like ABS, Lloyd’s Register (LR), DNV, Bureau Veritas (BV), and others. These standards, such as ABS Rule for Hull Steel, specify grades (A, B, D, E, AH32, DH36, etc.), their mechanical properties (yield strength, impact toughness), chemical composition, and required testing. The steel must be supplied with a Mill Test Certificate (MTC) matching these rules.

Navigating the World of Marine Steel Specifications

Ship steel is different from construction steel. It must handle dynamic loads, resist brittle fracture in cold water, and be highly weldable. The classification societies act as independent regulators to ensure this.

1. The Role of Classification Societies

These are organizations like ABS (American), LR (British), DNV (Norwegian), BV (French), NK (Japanese), etc. They:

- Set technical rules for ship design and construction.

- Approve materials (like steel) that can be used.

- Survey ships during construction and in service.

- Issue a "class certificate" that is essential for insurance and operation.

2. Key Elements of the Specification

The rules cover several critical areas:

- Grades: This is the most common reference.

- Normal Strength: Grades A, B, D, E. Grade A is general purpose. Grades D and E have increasing levels of impact toughness (resistance to brittle fracture) for colder environments.

- High Strength: Grades AH32, DH32, EH32, AH36, DH36, EH36. The ‘H’ means high strength. The number (32, 36) indicates the minimum yield strength in kgf/mm² (315 MPa and 355 MPa respectively). The letter (A, D, E) again indicates toughness level.

- Delivery Condition: Ship steel is often supplied in the normalized (N) condition. This heat treatment ensures a fine, uniform grain structure for good toughness and weldability.

- Testing Requirements: The rules mandate specific tests:

- Tensile Test: For yield strength, tensile strength, elongation.

- Charpy V-Notch Impact Test: This is crucial. It measures the energy absorbed during fracture at low temperatures (e.g., 0°C, -20°C, -40°C). Grades D/E and DH/EH have strict impact energy requirements.

- Bend Test: To check ductility.

3. The Mill Test Certificate (MTC) – The Proof

The MTC is the legal document that proves the steel meets the ordered specification. It must list:

- Heat number/Cast number.

- Actual chemical composition (C, Mn, Si, P, S, etc.).

- Actual mechanical test results.

- Statement of compliance with the specified rule (e.g., "This material conforms to the requirements of LR for Grade AH36").

Here is a comparison of common marine steel grades:

| Grade | Minimum Yield Strength | Key Characteristic | Typical Use on Ship |

|---|---|---|---|

| Grade A | 235 MPa | General purpose, normal strength. | Internal secondary structures, non-critical areas. |

| Grade D | 235 MPa | Improved impact toughness at 0°C. | Hull plating in colder zones, important structural parts. |

| Grade E | 235 MPa | Superior impact toughness at -40°C. | Critical areas: bow, stern, ice-going vessels. |

| AH36 | 355 MPa | High strength, good toughness. | Main deck and bottom plating, primary L-angles and bulb flats. |

| DH36 | 355 MPa | High strength + improved low-temp toughness. | Plating and frames in colder waters for high-strength applications. |

| EH36 | 355 MPa | High strength + highest low-temp toughness. | Critical high-strength parts in Arctic conditions. |

For a buyer, the action is clear. Your purchase order must specify: Material, Size, Grade, and Standard. For example: "L Angle Steel, 150x100x12, Grade AH36, according to Lloyd’s Register Rules." This tells us exactly what certified material to source from our partner mills. Our client Gulf Metal Solutions values this precisely because their previous suppliers were inconsistent with certification. We provide the full MTC and support SGS inspection to verify it, ensuring zero issues at their project site.

What are the standard sizes of steel channels?

Channels are a different profile from L-angles. Confusing them can lead to a major design error. You must know the difference to order the correct structural section for your project.

Standard steel channels, like UPE or UNP series in Europe or C and MC shapes in the US, have a "U" shape with two parallel flanges. Common depth sizes range from 80mm to 400mm. In contrast, L-shaped steel (angle) has two legs forming a 90-degree angle. They are used for different purposes: channels for beams and posts, angles for bracing and frames.

Channels vs. Angles: Understanding the Distinction

While both are rolled sections, their structural behavior and applications are distinct. Using a channel where an angle is specified (or vice versa) will compromise the design.

1. The Anatomy of a Steel Channel

A channel has three main parts:

- Web: The vertical, central plate.

- Flanges: The two horizontal plates at the top and bottom of the web.

- Toe and Heel: The ends of the flanges.

Channels are designed to carry load as beams (in bending), with the web providing shear strength. They are good for spanning distances, like purlins on a roof or small beams.

2. Common Channel Size Systems

- European Standard (EN 10365): Uses designations like UPE (Parallel flanges, European series) and UNP (Parallel flanges, old series). Sizes are given by nominal height, e.g., UPE 200 (meaning ~200mm deep).

- American Standard (ASTM A6): Uses C-Shapes (standard channels) and MC-Shapes (miscellaneous channels). Sizes are given by depth in inches and weight per foot, e.g., C12x30 (12 inches deep, 30 lbs/ft).

3. How Channels Differ from L-Angles

This is the critical point for buyers:

- Shape: A channel has three sides (U-shape). An angle has two sides (L-shape).

- Structural Function:

- Channel: Best for bending in one direction (strong axis). It is weak to twisting (torsion). Good for beams, posts, and edges.

- Angle (L-Shape): Good for axial loads (tension/compression in bracing) and for connecting other members (as a gusset or bracket). Two angles can be bolted back-to-back to form a makeshift channel.

- Connection: An angle is easier to bolt or weld to a flat surface along one leg. A channel requires connection to its web or flanges, which can be trickier.

4. When to Use Which

- Use a Channel (C/UPE): For a horizontal beam supporting a floor. For a vertical column in a light structure. For the frame of a machine guard.

- Use an L-Angle: For diagonal bracing in a steel frame. For a shelf bracket. For framing around a ship’s hatch opening. For reinforcing the edge of a plate.

Here is a comparison table to eliminate confusion:

| Feature | L-Shaped Steel (Angle) | Steel Channel (e.g., UPE) | Implication for Ordering |

|---|---|---|---|

| Profile Shape | Two legs at 90°. | "U" shape with a web and two flanges. | They look completely different. Do not mix up the names. |

| Typical Size Designation | Leg x Leg x Thickness (e.g., 100x100x10). | Depth x Flange Width (e.g., UPE 180). | The naming format itself tells you what product it is. |

| Primary Structural Role | Bracing, connections, edge stiffening. | Beams, columns, longitudinal members. | Using an angle as a main beam is inefficient and may fail. |

| Common in Shipbuilding? | Yes, very common. Used for frames, brackets, stiffeners everywhere. | Less common than angles. Sometimes used for specific longitudinal or built-up sections. | If the ship drawing says "angle," you must supply an L-shape, not a channel. |

| Example Marine Use | Stiffening a bulkhead, making a ladder frame, hatch coaming. | Possibly as a deck edge or a built-up girder component. | Specs will clearly call for "Angle Bar" or "Channel." |

When you are sourcing marine steel, the design will almost always specify "angle bar" or "L-shaped steel" for framing and bracing. It will rarely specify a standard channel for primary hull structure. Knowing this difference prevents you from asking for a channel when you really need an L-angle. Always double-check the technical drawing or spec sheet.

What is L-shaped steel called?

L-shaped steel has several names used in different countries and industries. Using the wrong term in your search or inquiry can lead you to the wrong product or supplier. Clarity in terminology ensures you find exactly what you need.

L-shaped steel is most commonly called "angle iron1" or "steel angle2." In technical and trade contexts, it is called "angle bar3," "L-section4," or "equal/unequal angle." The formal term in standards is "rolled steel equal leg angles5" or "rolled steel unequal leg angles." In some regions, "L-bar" or simply "angle" is used.

A Glossary of Names for the Same Product

The variety of names reflects the product’s long history and global use. As a supplier to many countries, I hear all these terms. Knowing them helps you communicate with any partner.

1. Common Informal and Trade Names

- Angle Iron: This is a very old and still widely used term. It comes from the time when these sections were made from wrought iron. Today they are made from steel, but the name persists, especially in workshops and construction sites.

- Steel Angle: This is the most straightforward and common term in global trade. It is clear and unambiguous.

- Angle Bar: This is popular in Asia and the Middle East. Our clients in Saudi Arabia, Pakistan, and the Philippines often use this term. It is perfectly acceptable.

- L-Bar or L-Section: These names are descriptive of the shape. They are common in technical discussions and some European countries.

2. Formal Technical and Standard Names

When you look at a mill certificate or an international standard, the language is more precise.

- EN Standards (Europe): The standard is EN 10056-1. It calls them "Rolled steel equal leg angles" and "Rolled steel unequal leg angles."

- ASTM Standards (USA): ASTM A366 is a common specification for structural steel angle2s. The product is simply called "steel angle2."

- JIS Standards (Japan): They use the term "equal leg angle steel" and "unequal leg angle steel."

- Classification Society Rules: They typically refer to "angle bar3s" or specify by grade, like "AH36 Angle."

3. Regional Variations and Slang

- In some places, very small angles might be called "trim angle7."

- In shipbuilding, you might hear "stiffener angle" if it’s used for a specific purpose.

- The term "spherical flat steel" in our client’s feedback is likely a translation for "bulb flat steel8," which is a different, bulb-edged profile. This highlights why using standard English terms ("angle bar3," "bulb flat") avoids confusion.

4. The Importance of Using the Right Term with Suppliers

When you contact a supplier, using clear terms gets better results.

- Good Terms: "Steel Angle," "Angle Bar," "L-Shaped Steel."

- Vague Term: "L-iron" (less common, may cause a moment of hesitation).

- To Be Avoided: Just saying "angles" could be misinterpreted as another type of angle (like a wedge). Always include "steel" or "bar."

Here is a quick reference for global communication:

| Term You Can Use | Where It’s Commonly Understood | Best Used When… |

|---|---|---|

| Steel Angle | Global, most professional contexts. | Writing emails, purchase orders, talking to engineers. |

| Angle Bar | Asia, Middle East, global trade. | Communicating with traders and suppliers in these regions. |

| Angle Iron | USA, UK, Commonwealth, construction sites. | Informal talks, but clarify "steel" if precision is needed. |

| L-Section or L-Shaped Steel | Technical drawings, Europe, precise descriptions. | When you need to be very clear about the shape geometry. |

| Equal/Unequal Angle | Technical specs globally. | Specifying the exact type, e.g., "We need unequal angles, 150x100x12." |

In your email to us at sales@cnsteelsupplier.com, using "Marine Angle Steel," "Shipbuilding Angle Bar," or "L-shaped Steel" will instantly align our understanding. It tells us you are looking for the structural profile used in ships, not a decorative trim. This shared vocabulary is the first step in the efficient, error-free service that clients like Gulf Metal Solutions appreciate.

For a buyer like Gulf Metal Solutions, the "best" steel is the one that exactly matches the shipyard’s design specification and the vessel’s intended service route. Our job is to supply that precise grade—whether it’s an EH36 plate for an Arctic tanker or a batch of AH36 bulb flats for a container ship bound for Asia—with the full certification to prove it.

Conclusion

Knowing the standard sizes, the critical marine specifications, the difference from channels, and the correct names for L-shaped steel empowers you to order correctly. This knowledge prevents costly mistakes and ensures your shipbuilding or construction project gets the right material on time.

-

Explore this link to understand the applications and benefits of angle iron in construction and manufacturing. ↩

-

Discover the versatility of steel angle in various industries and how it can enhance structural integrity. ↩ ↩ ↩

-

Learn about angle bars, their specifications, and how they are utilized in construction projects. ↩ ↩ ↩

-

Find out the applications of L-section steel and its importance in engineering and architecture. ↩

-

This resource will clarify the standards and specifications for rolled steel equal leg angles. ↩

-

Explore the properties and applications of ASTM A36 steel in structural engineering. ↩

-

Learn about trim angles and their specific uses in construction and design. ↩

-

Understand the unique characteristics of bulb flat steel and its applications in shipbuilding. ↩