Managing a shipbuilding project involves more than just buying steel plates. Sourcing angles, bulb flats, and plates from different suppliers creates logistical chaos and quality risks. I’ve seen projects delayed because critical steel components arrived late or with mismatched certifications.

A complete marine steel solution provides a single, reliable source for all primary steel components—plates, angles, bulb flats—with consistent classification society certification (ABS, DNV, etc.), coordinated logistics, and integrated quality control, streamlining procurement and ensuring material compatibility for the entire hull structure. This holistic approach reduces risk, saves time, and protects the project’s budget and timeline.

For shipyards, large fabricators, and project managers, this integrated approach transforms material supply from a constant headache into a reliable foundation. Let’s explore what makes this solution effective, starting with selecting the core material: the best marine steel.

What is the best marine steel?

Asking for the "best" marine steel is like asking for the best vehicle—it depends entirely on the specific task. A bulk carrier needs high-strength steel1 for maximum cargo, while an icebreaker needs ultra-tough steel2. There is no single "best," only the most suitable for the application.

The best marine steel is the grade that most precisely and cost-effectively meets the specific requirements of the vessel’s design, classification society rules3, and operating environment. For most ocean-going commercial vessels, high-strength grades like ABS AH36 or DNV NV A36 offer an excellent balance of strength (355 MPa yield), toughness, weldability, and weight-saving benefits. The selection is always a performance-to-cost optimization4, not a search for a universal winner.

A Framework for Selecting the Optimal Steel

The "best" choice results from a clear decision-making process that aligns material properties with project goals.

1. Defining "Best" by Primary Objective:

- Objective: Maximize Cargo Capacity (Deadweight).

- Solution: Use high-strength steel1s (AH36, AH40). Their higher yield strength allows for thinner plates and lighter sections, reducing hull weight. Every ton saved is an extra ton of payload.

- Objective: Operate in Arctic/Ice Conditions.

- Solution: Use high-toughness steels (DH36, EH36, FH40). The ‘D’, ‘E’, ‘F’ designations guarantee impact resistance at progressively lower temperatures (-20°C, -40°C, -60°C) to prevent brittle fracture.

- Objective: Build a Cost-Effective Standard Vessel.

- Solution: Use a mix of ordinary strength (Grade A, B)5 for less critical areas and high-strength (AH32) for key zones. This balances performance and budget.

2. The Role of Classification Society Rules:

The "best" steel must first be compliant. The chosen classification society (ABS, LR, DNV, BV) dictates the approved mills and specific grade specifications. The best steel is one with flawless, traceable certification from an approved mill.

3. Beyond the Plate: Consistency Across Product Forms:

A truly optimal solution requires the same grade to be available in all necessary forms: plates for the shell, angles for frames, bulb flats for longitudinals. Sourcing AH36 plates but only finding A36 angles weakens the structure’s integrity. A complete supplier ensures consistency.

Decision Matrix for Common Vessel Types:

| Vessel Type & Priority | "Best" Steel Strategy | Rationale |

|---|---|---|

| Large Container Ship / Bulk Carrier | Widespread use of AH36/DH36 for hull. | Weight reduction is directly convertible to increased revenue from cargo. |

| Oil Tanker (VLCC) | AH36 for hull strength, with Grade D/E in forward sections. | Combines weight savings for capacity with enhanced safety in impact-prone bow area. |

| Offshore Supply Vessel (North Sea) | DH36 or EH36 for hull. | Mandatory for operations in cold, rough waters; toughness is paramount. |

| General Cargo Ship (Standard Routes) | AH32 or combination of Grade B and AH32. | Provides good performance at a lower cost than AH36, suitable for less extreme optimization. |

| LNG Carrier (Cargo Tanks) | Special nickel-alloy steels6 or stainless steels for cryogenic service. | "Best" here is defined by extreme low-temperature properties, not strength. |

For a shipyard, the "best" steel is also the steel that arrives on time, with correct documentation, and from a supplier who provides technical support. This is where the concept of a solution becomes critical. This leads us to the next point: what type of solution does steel itself represent?

Which type of solution is steel?

In engineering, we talk about "solutions" to problems. Steel is not just a commodity; it is a material solution1 to the fundamental challenge of creating strong, durable, and versatile structures. A naval architect in Romania once told me his design was only as good as the material solution1 that could bring it to life.

Steel is a material solution1. It provides the physical means to solve engineering challenges related to strength, span, durability, and fabricability. In shipbuilding, it is the enabling solution that allows for the construction of large, complex, floating structures capable of carrying massive loads across oceans while resisting harsh environmental forces. It is the answer to the question: "What can we build it out of?"

How Steel Functions as an Integrated Solution

Thinking of steel as a solution shifts the perspective from buying a product to implementing a system.

1. Steel Solves the Strength-to-Weight Problem:

Before steel, ships were limited in size by wood’s strength. Steel’s high strength-to-weight ratio solved this. It allowed engineers to design larger hulls that were strong enough to handle ocean forces but not so heavy they couldn’t float efficiently. This solution enabled the megaships we see today.

2. Steel Solves the Fabrication and Construction Problem:

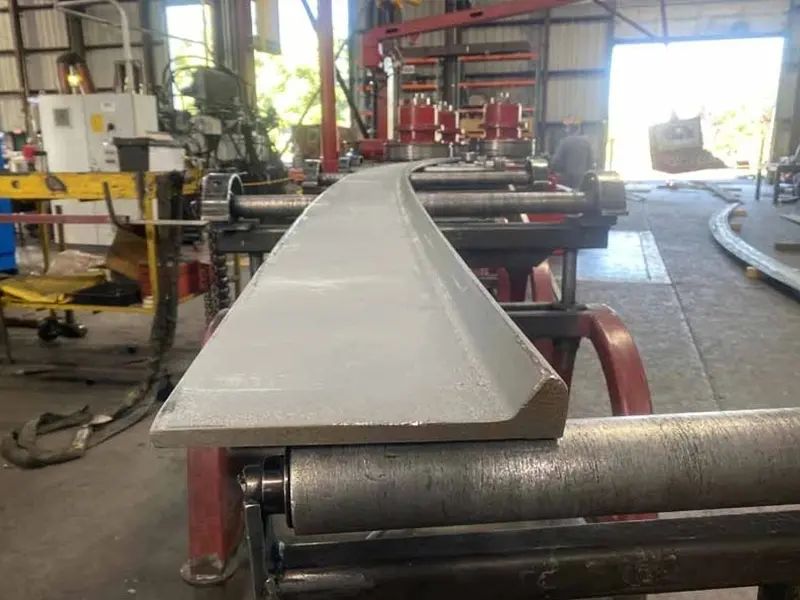

- Formability: Steel plates can be cut and curved into complex hull shapes.

- Joinability: The invention of reliable welding transformed steel into a monolithic solution2. A welded steel hull is essentially a single, continuous piece of material, far stronger than a riveted one. This solves the problem of creating large, watertight, and strong connections.

- Prefabrication: Steel components can be fabricated off-site in modules. This solves the problem of weather-dependent, slow on-site construction, dramatically accelerating project timelines.

3. Steel as a Systems Solution in a Complete Package:

A "complete marine steel solution3" takes this further. It addresses not just the material need, but the entire procurement and integration problem.

- Problem: Coordinating multiple suppliers for plates, angles, and bulb flats.

- Solution: Single-source supply with guaranteed chemical and mechanical compatibility.

- Problem: Managing certification and quality paperwork from various mills.

- Solution: Unified documentation package with consistent MTCs from partner mills.

- Problem: Dealing with logistical delays for different components.

- Solution: Coordinated production and shipping to ensure all materials arrive in sequence for construction.

The Solution Spectrum in Shipbuilding:

| Problem to be Solved | The "Steel" Solution | The "Complete Supplier" Solution |

|---|---|---|

| Need a strong hull material. | Use marine-grade carbon steel4. | Provide certified AH36/DH36 plates, angles, bulb flats. |

| Need to build it quickly. | Use welded steel construction. | Provide pre-cut, shaped components + logistics coordination for just-in-time delivery. |

| Need to ensure quality/safety. | Use class society-certified steel. | Provide third-party inspection (SGS) reports + full traceability MTCs. |

| Need to manage project budget. | Steel offers good lifecycle cost5. | Offer competitive bundled pricing and MOQ flexibility to match project phases. |

For a results-driven client, this integrated solution is invaluable. It turns the complex variable of material supply into a managed, predictable process. Part of this solution involves understanding what marine steel is not—it is not stainless steel, which serves a different purpose.

What is the difference between marine steel1 and stainless steel2?

This is a fundamental distinction that affects cost, application, and design. Confusing the two can lead to catastrophic design errors or massive budget overruns. A project engineer in Qatar once asked if they should build the entire hull from stainless steel2 for zero maintenance—the cost estimate ended that idea immediately.

The core difference is that marine steel1 (e.g., ABS AH36) is a high-strength, weldable carbon steel designed for primary hull structures, protected by coatings, while stainless steel2 (e.g., 316) is a corrosion-resistant alloy used for fittings, hardware, and specific systems where corrosion is the main concern, not structural strength. Marine steel is for the ship’s skeleton; stainless steel2 is for its non-structural skin and accessories.

A Detailed Comparison of Composition, Cost, and Application

These two materials belong to different families and solve different primary problems.

1. Composition and Core Property:

- Marine Steel (Carbon/Low-Alloy):

- Primary Alloy: Iron, with Carbon and Manganese as main additives.

- Core Property: High Strength and Toughness. Designed to carry the immense loads of the ship’s weight and cargo.

- Corrosion: Will rust if unprotected. Relies on paint systems, cathodic protection (zinc anodes), and sometimes coatings.

- Stainless Steel:

- Primary Alloy: Iron, with a minimum of 10.5% Chromium (forms a passive oxide layer). Grade 316 adds Molybdenum.

- Core Property: Corrosion Resistance. The chromium oxide layer is self-repairing and blocks rust.

- Strength: Generally lower yield strength than high-strength marine steel1s. Different thermal and electrical properties.

2. Cost Implications:

This is the most dramatic difference. Stainless steel (Grade 316) is typically 5 to 10 times more expensive per ton than marine carbon steel (like AH36). Using stainless for primary structures is economically unfeasible for almost all commercial vessels.

3. Application in Shipbuilding – A Clear Division of Labor:

- Marine Steel Applications (The Structure):

- Hull plating, decks, bulkheads.

- All frames, longitudinals, stiffeners (made from angles, bulb flats).

- Foundations for major machinery.

- Stainless Steel Applications (The Fittings & Special Systems):

- Deck railings, cleats, ladders, hatches.

- Piping for potable water or certain chemicals.

- Exhaust stacks, funnel cladding.

- Propeller shafts (special high-strength stainless alloys).

- Chemical tanker cargo tanks.

Selection Guide: When to Use Which

| Component | Recommended Material | Primary Reason |

|---|---|---|

| Ship’s Bottom Plate | Marine Steel (AH36/DH36) | Must provide global strength; protected by coatings and anodes. |

| Deck Handrail | Stainless Steel (316) | Constantly exposed to salt spray; requires minimal maintenance for safety. |

| Internal Cargo Hold Stiffener | Marine Steel Angle (Grade A/B) | Protected from direct weather; strength and cost are key. |

| Seawater Cooling Pipe | Cupronickel or Titanium, not standard stainless | 316 can still suffer from pitting in stagnant seawater; more exotic alloys are used. |

| LNG Cargo Tank Membrane | Special Stainless (304L, 316L) or Invar | Must withstand cryogenic temperatures and have specific thermal properties. |

A complete marine steel1 supplier understands this division. We supply the AH36 angles for the frame and can advise on or source the 316 stainless for the railings if needed, but we focus on providing the complete structural package. This package is defined by a range of grades for different needs.

What are the grades of marine steel plates1?

A ship is not built from one uniform grade of steel. Different areas face different stresses and environments. Using a single grade everywhere is either over-engineered and costly or under-engineered and dangerous. A complete solution offers the right grade for each part.

Marine steel plates are graded by classification societies into ordinary strength (A, B, D, E) and high-strength (AH32, AH36, DH36, EH36, FH40) categories. The letter indicates toughness level (A=basic, E=highest at -40°C), and the number indicates yield strength in kgf/mm² (e.g., 36=355 MPa). Plates are selected based on their location in the hull: high-strength for weight savings in the midship, high-toughness for impact zones in the bow.

Navigating the Grade System for Optimal Hull Design

Understanding this system allows for intelligent, efficient material selection across the vessel.

1. Ordinary Strength Steel Grades (A, B, D, E):

These grades are defined primarily by their notch toughness.

- Grade A: The basic grade. Used for non-critical secondary structures where high impact resistance is not needed.

- Grade B: The standard grade for general hull plating in non-extreme environments. Requires impact testing2 at 0°C.

- Grade D: Improved toughness for colder service. Impact testing at -20°C. Used in the forward part of the ship and for vessels in temperate/tropical zones where added safety is desired.

- Grade E: High toughness for Arctic service. Impact testing at -40°C.

2. High Strength Steel Grades (H-grades):

These combine increased strength with designated toughness levels.

- Naming: The letter (A, D, E) still denotes the toughness level. The number (32, 36, 40) denotes the minimum yield strength.

- Example: AH36: "A" toughness (0°C test), "H" high strength, "36" for 355 MPa yield.

- Example: DH36: "D" toughness (-20°C test), "H" high strength, "36" for 355 MPa yield.

3. Application-Based Grade Selection for Plates:

The hull is "zoned" based on stress and risk.

| Hull Zone / Plate Application | Typical Plate Grade | Why This Grade Fits |

|---|---|---|

| Midship Bottom & Side Shell | AH36 or DH36 | High global bending stresses; high strength saves weight. DH36 used if enhanced toughness is specified. |

| Bottom & Side Shell in Forward 1/4 Length | DH36 or EH36 | Subject to wave slamming (impact) and lower temperatures. High toughness is mandatory. |

| Deck Plating (Cargo Area) | AH36 | High strength to support cargo with minimal structural depth (weight saving). |

| Inner Bottom Plating | Grade B or AH32 | Lower stress application; cost-efficient strength. |

| Superstructure Plating | Grade A or lower strength grades | Non-primary structure; reducing weight high up improves stability. |

The Complete Solution in Practice:

When a shipyard orders a complete steel package, they provide a nesting list and a material specification3. The specification will call out different grades for different parts.

- A complete supplier reviews this list.

- They source AH36 plates for the midship shell, DH36 plates for the bow, and Grade A plates for non-critical bulkheads.

- They ensure the corresponding angles and bulb flats for each area match the plate grade in terms of strength and, where necessary, toughness.

- All materials are supplied with coordinated MTCs and logistics.

This is the essence of a true solution: providing not just metal, but the correct specification of metal, in the right form, at the right time, with the right proof. It turns a complex procurement puzzle into a single, manageable stream, allowing the shipbuilder to focus on what they do best: building ships.

Conclusion

A complete marine steel solution provides the optimal grades (like AH36, DH36) in all required forms (plates, angles, bulb flats) with unified certification and logistics. This integrated approach solves the core procurement, compatibility, and risk management challenges of shipbuilding, ensuring a stronger, more efficient, and timely project delivery.

-

Explore this link to understand the different grades of marine steel plates and their applications in shipbuilding. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Find out how impact testing ensures the safety and reliability of marine steel grades in various environments. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the concept of material specification and its role in ensuring the right materials are used in ship construction. ↩ ↩ ↩

-

Find out why marine-grade carbon steel is essential for building durable and strong marine structures. ↩ ↩

-

Understanding lifecycle costs helps in making informed decisions for long-term project budgeting. ↩ ↩

-

Find out why nickel-alloy steels are essential for cryogenic applications in LNG carriers. ↩