Choosing the wrong type of angle steel can compromise your structural design and increase project costs. Many engineers face this critical decision without understanding the practical implications.

Equal angle steel has legs of identical length (L50×50×5), while unequal angle steel has legs of different lengths (L100×75×8). Equal angles provide symmetrical strength, while unequal angles offer design flexibility for asymmetric loading conditions and space-constrained applications in shipbuilding and construction.

The choice between these two types affects everything from structural performance to fabrication costs. Let me explain the key differences to help you make informed decisions.

What is the difference between equal and unequal angles?

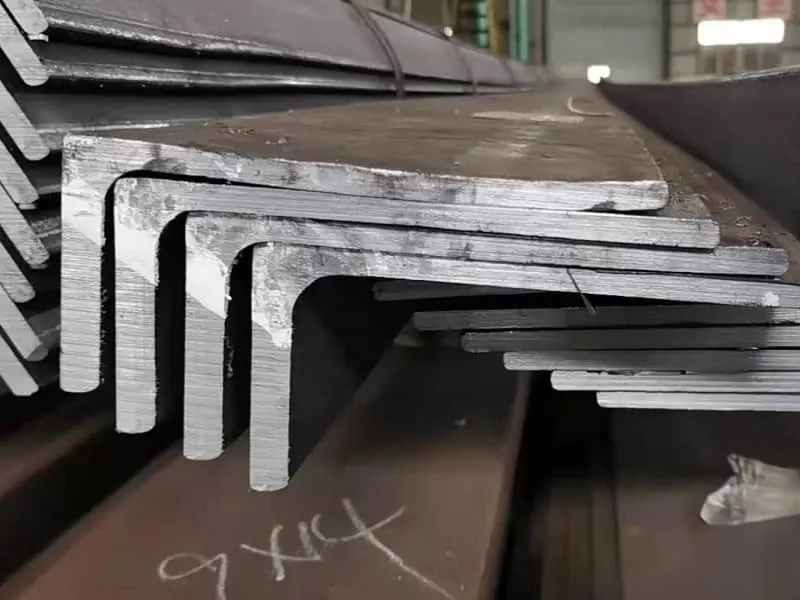

When you examine steel angle sections on a construction site, the distinction seems simple. But the engineering implications of choosing equal versus unequal angles are significant and affect your entire project.

Equal angles1 have identical leg lengths and thickness, providing balanced properties in all directions. Unequal angles2 have different leg lengths, creating distinct strong and weak axes that allow optimized performance for specific loading conditions and connection requirements.

Detailed Analysis of Equal vs Unequal Angle Properties

The fundamental difference between equal and unequal angles lies in their geometric symmetry and resulting mechanical behavior. Equal angles1, with their identical leg dimensions, exhibit consistent section properties about both principal axes. This symmetry simplifies design calculations and provides predictable performance regardless of loading direction.

Unequal angles2 introduce intentional asymmetry to address specific engineering challenges. The longer leg provides greater resistance to bending in one direction, while the shorter leg offers different properties in the perpendicular direction. This characteristic makes unequal angles particularly valuable in applications where space constraints or connection geometry dictate specific dimensional requirements.

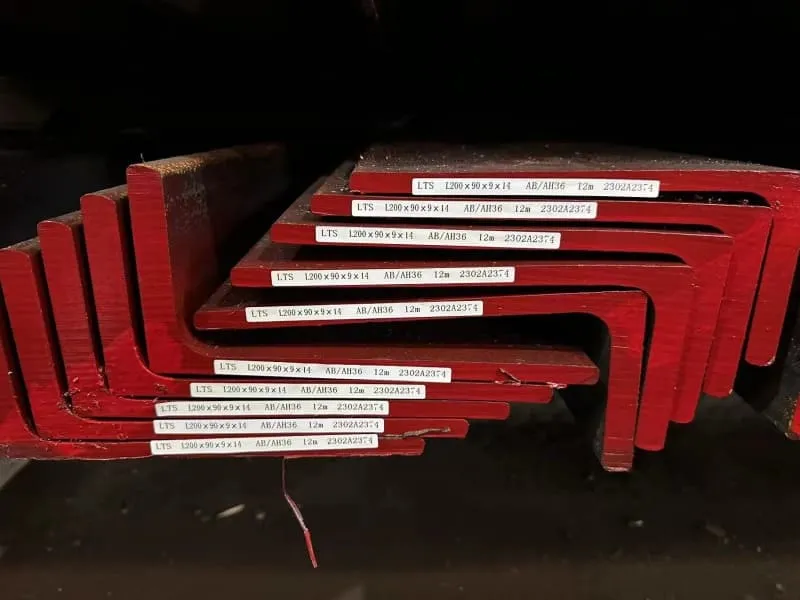

The manufacturing process for both types involves hot rolling, but unequal angles require more precise control to maintain consistent dimensions between the different leg lengths. Both types are available in various steel grades, including marine grades like AH36 and DH36 for shipbuilding applications. The material properties remain consistent within each grade, but the section geometry determines how those properties are utilized in structural design.

From a structural performance perspective, equal angles distribute stress more evenly when subjected to multidirectional loading. Unequal angles2 concentrate strength along their longer axis, making them ideal for applications where primary loading occurs in one predominant direction. This directional strength optimization can lead to material savings and weight reduction in properly designed structures.

Here’s a comprehensive comparison of their characteristics:

| Characteristic | Equal Angles | Unequal Angles |

|---|---|---|

| Geometric Symmetry | Perfect symmetry about both axes | Asymmetric with distinct strong/weak axes |

| Section Modulus3 | Equal in both directions | Different values for each axis |

| Connection Flexibility | Standard connections work from either side | Requires specific orientation planning |

| Design Complexity | Simplified calculations | Requires careful axis consideration |

| Cost Factors | Generally more economical | Slightly higher due to manufacturing complexity |

We recently advised a shipyard in Vietnam on selecting angles for their new container ship design. They initially specified equal angles throughout, but our analysis showed that using unequal angles in specific areas could reduce weight by 8% while maintaining structural integrity. The longer leg provided better support to hull plating, while the shorter leg optimized connection to transverse frames.

What is L-shaped steel1 called?

If you’ve heard multiple terms for the same L-shaped steel1 products, you’re not alone. The naming conventions vary by region, industry, and application, but they all refer to the same fundamental structural shape.

L-shaped steel1 is commonly called angle iron2, angle bar, or steel angle3. In technical specifications, it’s designated as "L" followed by dimensions (e.g., L100×75×10). Marine-grade versions are specifically called marine angle steel4 or shipbuilding angles5, meeting classification society standards.

Comprehensive Guide to L-Shaped Steel Terminology

The various names for L-shaped steel1 reflect its long history and widespread use across different industries. The term "angle iron2" dates back to when these sections were primarily made from wrought iron. Although modern versions use steel, the traditional name persists in many regions, particularly in North America and general construction contexts.

In technical and engineering documents, the formal designation system provides precise information. The "L" prefix is followed by the leg dimensions and thickness. For equal angles, a single dimension suffices (e.g., L80×80×8), while unequal angles require both leg lengths (e.g., L150×100×12). This standardized naming ensures clear communication between designers, suppliers, and fabricators across international projects.

The marine industry uses specific terminology to distinguish quality-controlled products. "Marine angle steel" or "shipbuilding angles5" indicates that the material meets classification society requirements for chemical composition, mechanical properties, and certification. These products undergo rigorous testing for impact toughness, corrosion resistance, and weldability to ensure performance in harsh marine environments.

Regional variations in terminology include:

- United States: Angle iron, structural angle6, L-shape

- United Kingdom: Angle section, steel angle3

- Europe: L-profile, equal/unequal leg angle

- Asia: Angle bar, L-bar, steel L-section

Industry-specific applications also influence naming:

- Shipbuilding: Marine angle, hull angle, stiffener angle

- Construction: Structural angle, framing angle, bracing angle

- Manufacturing: Support angle, bracket angle, frame angle

The table below shows how naming correlates with application:

| Industry Term | Typical Applications | Key Requirements |

|---|---|---|

| Marine Angle Steel | Ship frames, hull stiffeners, deck supports | Classification certification, corrosion resistance |

| Structural Angle | Building frames, bridge components, support systems | Load capacity, weldability, dimensional accuracy |

| General Purpose Angle | Equipment frames, brackets, non-critical structures | Basic strength, cost efficiency, availability |

Our clients from different regions use various terms for the same products. A contractor from Saudi Arabia might request "angle iron2," while a shipyard from the Philippines asks for "marine angle bar." We ensure our team understands all terminology variations to provide accurate quotations and deliver the correct products for each application.

What is UB and UC in steel?

When you move beyond angle sections to larger structural members, you encounter UB and UC designations that serve different purposes in structural frameworks. Understanding these designations helps in selecting the right members for your project.

UB stands for Universal Beam1 (I-beam with parallel flanges), while UC means Universal Column2 (I-section with nearly equal flange width and depth). UB sections optimize bending resistance3, while UC sections provide efficient compression loading4 for columns and struts in shipbuilding and construction.

Understanding Universal Beam1 and Universal Column2 Applications

Universal Beam1s (UB) and Universal Column2s (UC) represent two categories of I-shaped structural steel sections that serve distinct purposes in structural engineering. The fundamental difference lies in their geometric proportions and resulting mechanical properties, which make each type suitable for specific loading conditions.

Universal Beam1s feature relatively narrow flanges compared to their depth, creating a section that is highly efficient in resisting bending moments. The significant depth provides a large section modulus, allowing UB sections to carry heavy loads over long spans with minimal deflection. This makes them ideal for applications like main beams, girders, and primary support members where bending strength is the primary design consideration.

Universal Column2s have more balanced proportions, with flange widths that approach the section depth. This geometry provides similar strength characteristics in both major axes, making UC sections particularly effective for compression loading4. The balanced properties prevent buckling in multiple directions, which is crucial for column applications where loads may come from various directions or where bracing is limited.

In marine applications5, both UB and UC sections find specific uses:

- UB Sections: Main deck girders, transverse frames, foundation beams

- UC Sections: Pillar supports, vertical framing, compression members

- Both Types: Available in marine grades with classification certification

The manufacturing standards6 for these sections ensure consistent quality and properties. Designations typically include the serial size (e.g., UB 203×133×30 or UC 152×152×30), where the numbers represent nominal depth, flange width, and mass per meter. These standardized sizes allow engineers to select appropriate sections from published tables with known properties.

Here’s a detailed comparison of their characteristics:

| Parameter | Universal Beam1 (UB) | Universal Column2 (UC) |

|---|---|---|

| Section Proportions | Deep web, relatively narrow flanges | Balanced depth and flange width |

| Primary Function | Resisting bending moments | Carrying compression loads |

| Typical Applications | Beams, girders, horizontal members | Columns, pillars, vertical supports |

| Buckling Resistance | Strong in major axis, weaker in minor axis | More balanced resistance in both axes |

| Marine Usage | Deck girders, primary framing | Pillar supports, vertical structures |

We supplied UC sections to a shipyard in Romania for pillar supports in a new bulk carrier. The balanced strength characteristics of the UC sections provided optimal performance for the vertical loading conditions while accommodating space constraints in the cargo hold area.

What is an unequal angle section1 of steel?

Unequal angle sections solve specific engineering challenges that equal angles cannot address efficiently. Their asymmetric design2 provides unique advantages in space-constrained applications and specialized loading conditions.

An unequal angle section1 is an L-shaped steel member with legs of different lengths (e.g., L150×100×12). This asymmetry creates distinct strong and weak axes, allowing engineers to optimize material usage for specific directional loading and connection requirements in shipbuilding and structural applications.

Comprehensive Guide to Unequal Angle Section Applications

Unequal angle sections represent a specialized category of structural steel that addresses the limitations of symmetric sections in certain applications. The different leg lengths create a section with unique properties that can be leveraged to achieve specific engineering objectives, particularly where space constraints or connection geometry dictate dimensional requirements.

The geometric asymmetry of unequal angles results in different section properties about the two principal axes. The axis parallel to the longer leg (x-x axis) typically has a significantly higher section modulus3 and moment of inertia compared to the axis parallel to the shorter leg (y-y axis). This directional strength characteristic allows designers to align the stronger axis with the primary loading direction, optimizing material efficiency.

In shipbuilding applications4, unequal angles provide several advantages:

- Hull Stiffening: Longer leg attaches to hull plating, shorter leg connects to frames

- Space Optimization: Fits into tight spaces where equal angles would be too large

- Weight Reduction: Allows use of thinner sections while maintaining strength

- Connection Flexibility: Accommodates specific connection geometries and bolt patterns

The manufacturing process for unequal angles requires precise control to maintain consistent dimensions between the different leg lengths. Hot rolling remains the primary production method, with careful attention to temperature control and roll alignment to ensure uniform material properties throughout the section. Quality control includes verification of leg dimensions, thickness consistency, and straightness tolerances.

Design considerations for unequal angles include:

- Principal Axis Orientation: Must align strong axis with primary load direction

- Connection Design: Requires specific detailing for asymmetric geometry

- Buckling Analysis: Different buckling characteristics about each axis

- Fabrication Planning: May require special handling and positioning during assembly

Here are typical marine applications for unequal angles:

| Application | Typical Size | Design Rationale |

|---|---|---|

| Hull Frame Stiffeners | L200×150×16 | Longer leg supports hull plating efficiently |

| Deck Edge Support | L180×90×14 | Fits limited space at deck edges |

| Bulkhead Reinforcement | L120×80×10 | Provides strength where equal angle would be oversized |

| Equipment Foundations | L150×100×12 | Accommodates specific bolt patterns and clearances |

We recently supplied L180×120×15 unequal angles to a shipyard in Malaysia for hull framing in a new tanker design. The unequal configuration allowed them to maximize the attachment area to the hull plating while minimizing the projection into the cargo space, optimizing both structural performance and valuable internal volume.

Conclusion

Understanding the differences between equal and unequal L-shaped steel enables better material selection and structural optimization. Each type serves specific purposes in shipbuilding and construction projects.

-

Explore this link to understand the unique properties and applications of unequal angle sections in engineering. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn how asymmetric design enhances structural efficiency and performance in various applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the significance of section modulus in optimizing material usage and structural integrity. ↩ ↩ ↩ ↩ ↩

-

Find out how unequal angles improve shipbuilding efficiency and structural performance. ↩ ↩ ↩ ↩

-

Find out how steel sections are utilized in marine engineering for optimal performance. ↩ ↩ ↩

-

Explore the manufacturing standards that ensure quality and consistency in structural steel. ↩ ↩