You want a ship that can withstand powerful ocean forces. The choice of the right structural steel determines if your ship will stay strong for decades or face failure. L-shaped steel is a key material in creating this robust framework.

L-shaped steel, often called angle bar, strengthens ship hulls by providing essential reinforcement and bracing. Its 90-degree angle design creates strong, stable connections between plates and frames, effectively resisting bending, twisting, and buckling under load. It is a critical component in shipbuilding for structural integrity.

But why exactly is this L-shaped profile so effective? To understand its true value, we need to start with the basics of shipbuilding steel itself.

What kind of steel is used for ship hulls?

Shipbuilders cannot use just any steel. Ordinary steel would crack under the ocean’s stress and rust away quickly. The hull needs a special kind of steel that combines immense strength with toughness and resistance to a corrosive environment.

Ship hulls primarily use specially graded marine steel plates1. These are often high-strength, low-alloy (HSLA) steels2 made through processes like Thermo-Mechanical Control Process (TMCP)3. Key grades include general strength A, B, D, E and high-strength AH32, DH36, EH40, which are certified by classification societies like ABS, LR, or DNV for weldability and impact resistance at low temperatures.

The Anatomy of Marine-Grade Steel

The steel for a ship is its skeleton and skin. It must perform multiple critical jobs at once. Let’s break down what makes marine steel unique.

1. The Core Requirement: Strength and Toughness

A ship is a giant beam floating on a dynamic, moving surface. It experiences constant bending forces as waves pass beneath it. The steel must have high yield strength4 to resist permanent deformation. More importantly, it needs toughness—the ability to absorb energy and deform without cracking, especially in cold waters. This is why grades like ‘EH36’ are common; the ‘E’ signifies good impact toughness at -40°C.

Modern manufacturing uses the Thermo-Mechanical Control Process (TMCP)3. This advanced rolling and cooling technique creates a finer internal grain structure in the steel. Finer grains make the steel simultaneously stronger and tougher. One study showed that advanced TMCP could improve a steel plate’s uniform elongation (a measure of ductility) by about 1.3 times compared to conventional methods.

2. Composition and Corrosion Resistance

Marine steels have carefully balanced chemical recipes. They contain elements like Manganese (Mn) for strength, Silicon (Si) for deoxidation, and controlled amounts of Copper (Cu) and Chromium (Cr) to enhance atmospheric corrosion resistance5. Harmful elements like Sulfur (S) and Phosphorus (P) are kept very low to ensure good weldability and prevent brittleness.

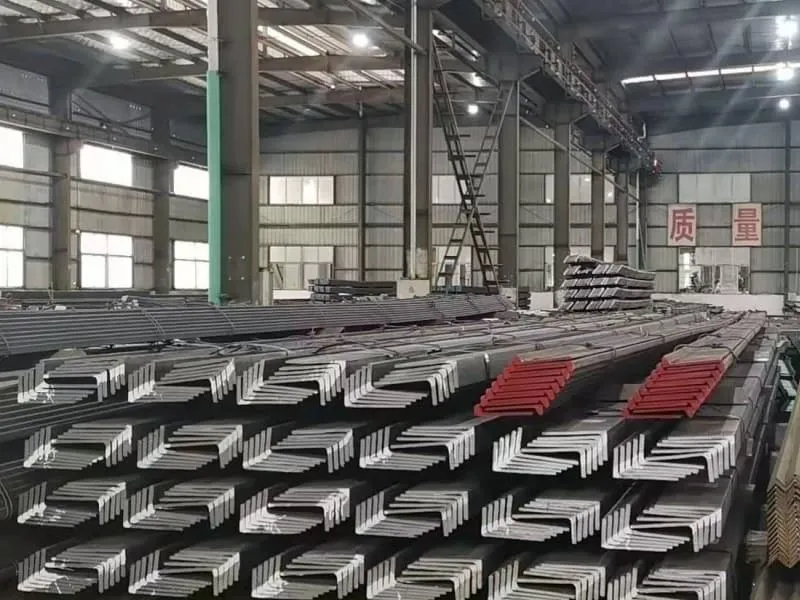

3. The Product Ecosystem: Plates and Sections

A hull is built from two main steel product forms:

- Steel Plates: These are the "skin" of the ship, forming the outer hull and decks. They are the largest and thickest components.

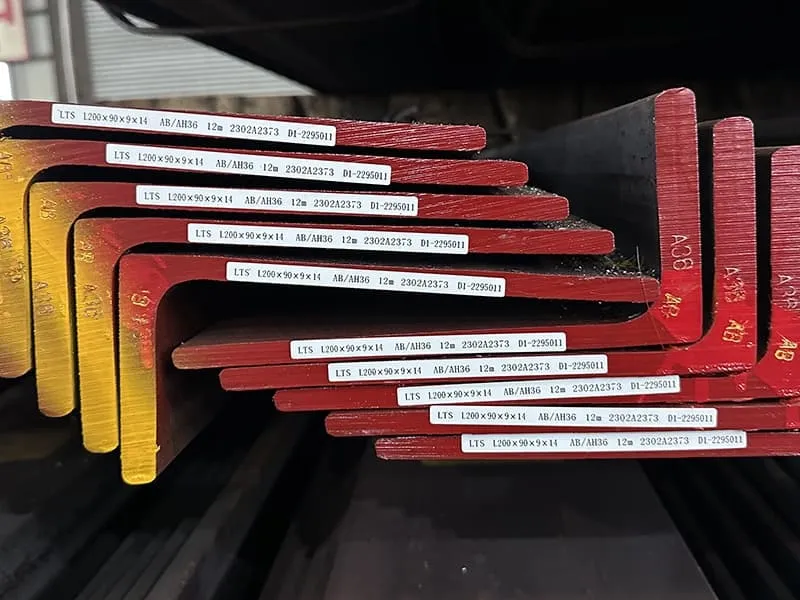

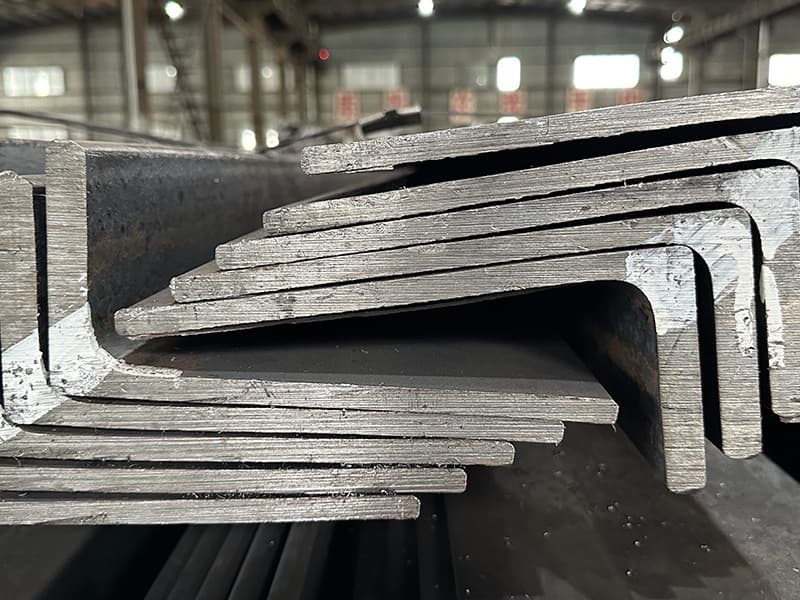

- Sections / Profiles: This is where L-shaped steel6 belongs. These are rolled into specific cross-sectional shapes (angles, bulbs, tees) and act as the internal "bones" or stiffeners. They are welded perpendicularly to the plates to prevent them from buckling under pressure.

The table below summarizes how these components work together:

| Component | Primary Form | Key Function in Hull | Common Grades |

|---|---|---|---|

| Hull Plating | Heavy, flat plate | Forms the watertight shell; resists water pressure and primary bending loads. | A, D, AH32, DH36, EH40 |

| Stiffeners & Frames | Sections (L-shaped, T-shaped, Bulb Flat) | Provides internal support to plates; prevents buckling; distributes local loads. | A, AH32, DH36 (Often matched to adjacent plate) |

| Primary Support | Built-up girders or heavy sections | Forms the main longitudinal and transverse framework (keel, stringers, web frames). | DH36, EH40, higher strengths |

As a supplier, we ensure that both the plates and the L-shaped sections we provide come from mills with proper classification society approvals. This guarantees that the entire structural system, from the skin to the skeleton, performs as a unified, certified whole.

What is the disadvantage of using steel in ship building?

Steel seems like the perfect choice for its strength. However, its great strength and density also create significant challenges. Two major issues constantly concern shipbuilders and owners: the relentless attack of corrosion1 and the heavy weight of the material itself.

The main disadvantages of steel in shipbuilding are its susceptibility to corrosion1 in seawater and its high density2, which adds significant weight to the vessel. Corrosion requires continuous maintenance, while weight impacts cargo capacity, fuel efficiency, and stability.

Confronting the Inevitable: Corrosion and Weight

Every material has trade-offs. For steel’s unmatched structural performance, we must actively manage its drawbacks throughout a ship’s life.

1. The Constant Battle: Corrosion

Seawater is an excellent electrolyte, making corrosion1 the steel hull’s eternal enemy. It happens in several ways:

- General Wastage: Uniform thinning of hull plates over time.

- Pitting Corrosion: Localized, intense attacks that can create holes.

- Galvanic Corrosion: Accelerated corrosion1 where different metals (like steel and a bronze propeller) are electrically connected in water.

The fight against corrosion1 is multi-layered:

- Coatings: This is the first and most critical line of defense. Ships undergo rigorous blasting and painting with epoxy and anti-fouling paints.

- Cathodic Protection: Sacrificial zinc anodes are attached to the hull. These anodes corrode instead of the steel. More advanced systems use an impressed current to achieve the same effect.

- Material Choice: Using marine-grade steels3 with corrosion1-resistant elements (Cu, Cr, Ni) is fundamental.

2. The Burden of Weight

Steel is dense. Every ton of steel used in the hull structure is a ton that cannot be used for payload. This affects the ship’s economics directly. Heavier ships need more power (fuel) to move at the same speed. This is why there is a constant drive to use higher-strength steels. By using a stronger grade, designers can reduce the thickness of plates and the size of stiffeners, saving weight without sacrificing safety. The development of advanced, high-ductility steels aims to make these thinner, stronger sections even more reliable in accidents.

3. Constructability Challenges

From a construction standpoint, steel has other downsides:

- Labor-Intensive Welding: Miles of welds are required, which is time-consuming and requires highly skilled labor.

- Repair Difficulties: As noted in a patent on hull reinforcement, traditional temporary reinforcement using welded-on steel angles often damages the hull during removal, requiring costly rework. This highlights a practical disadvantage in the building and repair process.

This last point is precisely why innovative solutions matter. One patent proposes a detachable reinforcement system4 using studs instead of continuous welding, minimizing hull damage and allowing reuse of the strengthening elements. It’s a direct response to steel’s practical drawbacks in the shipyard.

Why is high tensile steel used in ships?

Why would a shipbuilder choose a more expensive, higher-grade steel? The answer lies in a fundamental engineering goal: to build a stronger ship that can carry more cargo, not a heavier one. High tensile steel makes this efficiency possible.

High tensile steel is used in ships to achieve greater structural strength without increasing weight, or to reduce weight for the same strength. This improves the ship’s cargo capacity, fuel efficiency, and stability. It is especially critical in key stress areas like the midship hull and deck.

The Engineering Advantage of Higher Strength

Switching from ordinary steel to high tensile steel (HTS) is a strategic decision with cascading benefits. Let’s look at the "why" and "where."

1. The Principle of Weight Saving

This is the core driver. The strength-to-weight ratio is key. If a standard steel has a yield strength of 235 MPa and an HTS grade offers 355 MPa, the HTS is about 50% stronger. In theory, a structural member made from HTS could be made with less material to carry the same load. Thinner plates and smaller stiffeners translate directly into lightweight. For a large container ship, saving hundreds of tons of structural weight means it can carry hundreds of tons more containers.

2. Enhancing Performance and Safety

Beyond cargo, weight saving improves the ship’s performance. A lighter hull requires less power to propel, lowering fuel consumption and operating costs. It can also improve the ship’s stability. Furthermore, HTS allows for more robust design in high-stress zones. Areas prone to high stress, like the deck in the midship region (where bending moments are highest), can be built with HTS to provide an extra margin of safety without adding disproportionate weight.

3. Application in Critical Zones and Advanced Designs

HTS is not used uniformly throughout the ship due to cost. It is strategically applied:

- Strength Deck and Bottom Shell: In the midship area to resist hull girder bending.

- Sheer Strake: The topmost course of side plating, a critical area for longitudinal strength.

- Large Openings: Areas with large openings on the side (like for vehicle decks) weaken the hull. Patents show that using longitudinal walls built with strong frameworks (which would utilize sections like L-steel) is crucial here to restore global strength.

Advanced HTS grades are also being developed for crashworthiness. Research by companies like JFE Steel focuses on steel with high uniform elongation. This means the steel can deform and absorb massive amounts of energy during a collision or grounding before rupturing, significantly improving safety.

4. The Role of L-Shaped Steel in HTS Systems

L-shaped steel made from high tensile grades is vital. These angles form the stiffeners and brackets that tie the high-strength plates together. A bracket connecting a heavy deck beam to a side frame, made from AH36 L-steel, ensures the load is transferred effectively through the stronger structure. Our clients, such as project fabricators in the Middle East, often specify these higher grades for their critical offshore module supports, knowing the material’s performance is non-negotiable.

Why is steel used to build ships?

With all its disadvantages—corrosion, weight, welding1 complexity—why does steel remain the unchallenged king of shipbuilding materials? No other material offers the same complete package of strength, durability, manufacturability, and cost-effectiveness2 on such a massive scale.

Steel is used to build ships because it offers an unmatched combination of high strength3, toughness, ease of fabrication4 (through cutting and welding1), and cost-effectiveness2 for large-scale structures. Its durability, repairability5, and recyclability6 make it the most practical and reliable material for constructing large, seaworthy vessels that must last for decades.

The Unbeatable Value Proposition of Steel

When you compare steel to any alternative for a large ocean-going vessel, its advantages form a decisive list. Here’s a detailed breakdown.

1. Mechanical and Physical Properties: The Foundation

- High Strength and Stiffness: Steel can withstand the immense hydrostatic pressure of water and the dynamic loads from waves and cargo.

- Excellent Toughness: Modern marine steel remains ductile and crack-resistant even in the icy temperatures of Arctic waters. This is critical for safety.

- Predictable Behavior: Engineers have centuries of data on how steel behaves. Its properties are well-understood and predictable, which is essential for safe design.

2. Manufacturability and Economics: The Practical Choice

- Ease of Fabrication: Steel can be cut, rolled, and shaped with relative ease using established technology. This is crucial for building the complex curves of a ship’s hull.

- The Welding Revolution: The ability to join steel plates and sections seamlessly through welding1 is its single greatest advantage. Welding creates continuous, strong, and watertight connections that are efficient to execute. While welding1 has its challenges, as noted before, it is far more practical for giant structures than riveting (the old method) or adhesive bonding required for composites.

- Scale and Cost: Steel is produced in enormous volumes globally, making it readily available and cost-competitive. Building a 300-meter ship out of any other material would be astronomically expensive.

3. Durability and Lifecycle: The Long-Term View

- Repairability: This is a huge factor. A damaged steel hull can be repaired in almost any port in the world by cutting out the damaged section and welding1 in a new plate. Repairing advanced composite structures is far more specialized and difficult.

- Recyclability: At the end of its life, a steel ship is almost 100% recyclable. The steel is scrapped and melted down to make new products, a major environmental and economic benefit.

L-Shaped Steel: A Prime Example of Steel’s Advantages

The humble L-angle perfectly illustrates why steel wins. Its shape provides excellent stiffness in two directions with minimal material. It can be:

- Easily Rolled: Mass-produced in rolling mills.

- Simply Fabricated: Cut to length, drilled, or coped with standard tools.

- Conveniently Welded: Attached quickly to plates and other members along its two legs.

- Efficiently Used: It acts as a stiffener, a bracket, a frame, or a connection piece. A patent for a ship reinforcement structure explicitly lists angle steel as a standard material for making reinforcement components.

No other material offers this blend of functional geometry, manufacturing ease, and structural performance at a comparable cost for maritime applications. This is why steel, and components like L-shaped steel, remain fundamental to global shipping.

Conclusion

L-shaped steel is a vital component in shipbuilding, providing essential strength and stiffness. Its intelligent use, alongside advanced marine-grade plates, creates hulls that are durable, efficient, and safe for navigating the world’s oceans.

-

Discover the importance of welding in creating strong, watertight connections in ship construction. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Investigate the factors that make steel a budget-friendly option for constructing large vessels. ↩ ↩ ↩ ↩

-

Explore how high strength steel enhances ship safety and performance, making it a crucial choice for marine construction. ↩ ↩ ↩ ↩

-

Learn why ease of fabrication is vital for efficient shipbuilding, impacting timelines and costs significantly. ↩ ↩ ↩

-

Understand how the ability to repair steel ships easily contributes to their longevity and operational efficiency. ↩ ↩

-

Find out how the recyclability of steel benefits the environment and the economy at the end of a ship’s life. ↩ ↩