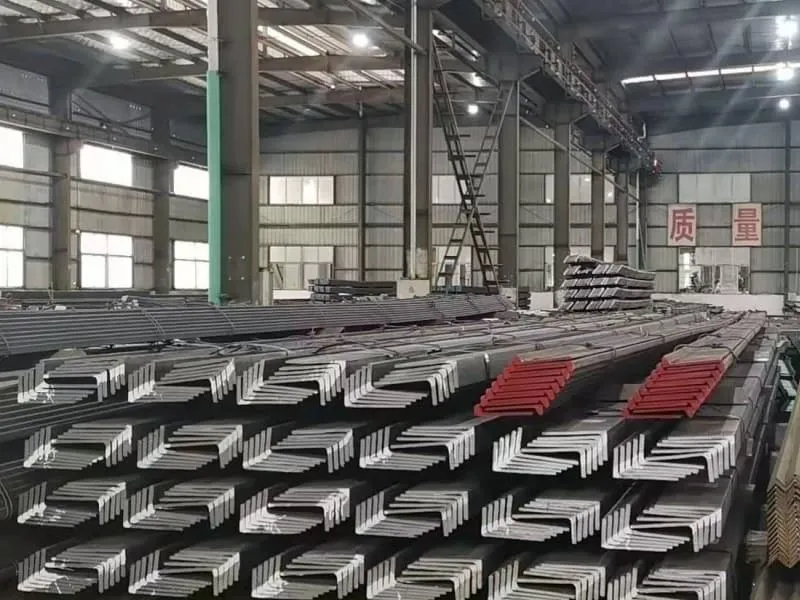

Imagine you receive a shipment of L-shaped steel. The certificates look perfect. You start building your ship’s frame. Then, cracks appear. The steel is substandard. Your project faces costly delays, safety risks, and legal trouble. This is the harsh reality of fake steel certificates in the marine industry.

To avoid fake certificates, you must verify the issuing mill, check the certificate’s unique number on the mill’s official website, and insist on supporting test reports from recognized bodies like SGS. Buying directly from certified mill partners like us eliminates this risk, as we provide traceable, mill-issued documentation.

This initial check is just the first step. The world of marine steel certification is complex, and a fake document is only one of many pitfalls. Many buyers focus only on the price per ton, not realizing that the paperwork holding up that steel is what truly guarantees its performance in harsh ocean environments. I’ve seen too many projects get into trouble because of overlooked details in certification. In the following sections, I will break down everything you need to know—from understanding what a certificate truly is to performing a thorough quality check—so you can buy your marine L-shaped steel with complete confidence.

How to see a fake certificate?

You are busy. A supplier emails a certificate. It looks official with stamps and logos. Your instinct might be to trust it. But this trust can be very expensive. Fake certificates are designed to look real at a quick glance.

You can spot a fake certificate by checking for inconsistencies: mismatched mill logos, low-quality printing, vague chemical composition1 data, missing heat or batch numbers, and the absence of a verifiable online record. Always cross-reference the certificate number2 directly with the steel mill’s official database.

Let’s dive deeper into the specific red flags. A certificate is not just a piece of paper; it’s a legal document that follows the steel from the melt to your yard.

Key Indicators of a Fraudulent Certificate

Do not just look at the certificate. You must examine it. Here are the critical points to check in a structured way:

| Check Point | What to Look For in a Genuine Certificate | Common Signs of a Fake Certificate |

|---|---|---|

| Issuing Mill Details | Clear, full name of the producing steel mill (e.g., "Shandong Iron and Steel Group Co., Ltd."). Address and contact details match the mill’s official information. | Generic names like "China Steel Manufacturer," blurred logos, or incorrect addresses. |

| Certificate Number | A unique, often alphanumeric serial number. This number is the key to online verification3. | Missing number, sequential or overly simple numbers (e.g., 00001), or a number that yields no results online. |

| Heat Number / Batch ID | A specific code tied to the exact melt of steel. This is crucial for traceability. Every piece from that batch can be traced back. | Missing entirely, appears fabricated, or does not match the marking on the steel material itself. |

| Chemical Composition & Mechanical Properties | Precise, numerical values for elements (C, Mn, Si, S, P, etc.) and properties (Yield Strength, Tensile Strength, Impact Test). Values must meet the stated grade standard (e.g., AH36). | Rounded numbers, values that are suspiciously "perfect," or properties that don’t align with the claimed grade. |

| Testing & Inspection Stamps | Official stamps or seals from the mill’s quality department and/or third-party inspector. Stamps are clear and applied directly. | Blurry, photocopied stamps, or stamps from unknown or uncertified inspection agencies. |

| Paper & Print Quality | High-quality paper, sharp laser printing, and clear embossed seals you can feel. | Poor-quality paper, smudged ink from a regular printer, or flat, printed-on "seals." |

The most reliable step is online verification3. Reputable mills have systems where you enter the certificate number2 or heat number on their website to see the original test records. If the supplier hesitates to provide the number or says the system is "down," consider it a major warning. In my experience, the fastest way to get caught with a fake is to have a mill’s name on a document you can’t verify with that same mill. For our clients, like Gulf Metal Solutions from Saudi Arabia, we immediately provide the mill certificate details for their own verification. This transparency builds the trust needed for long-term business, especially when they are sourcing critical materials for projects in Dammam or other Gulf ports.

What is a steel certificate?

Think of a steel certificate as a passport for your material. A passport proves your identity and origin. A steel certificate does the same for every beam, plate, or angle. Without it, the steel has no proven history or guaranteed properties. It is just a piece of metal of unknown quality.

A steel certificate, or Mill Test Certificate (MTC)1, is an official document from the steel producer. It guarantees the material’s chemical composition2, mechanical properties3, and that it meets the specified international standards, such as ABS, DNV, or LR rules for marine grade steel4.

This document is the cornerstone of quality assurance5 in our industry. It is not created by the trader or the exporter; it originates from the steel mill’s quality control department. The certificate follows a specific production batch, known as a "heat." When you buy marine L-shaped steel, you are not just buying the physical shape; you are buying the performance promises recorded on that certificate.

The Anatomy and Legal Weight of a Certificate

Understanding the certificate’s parts helps you understand its importance. It is a technical and legal document.

1. The Header and Identification Section: This includes the mill’s name, logo, and the certificate number. It states the product (e.g., "L-shaped Steel"), grade (e.g., "AH36"), and standard (e.g., "ABS Grade AH36"). This section answers who, what, and to which rule.

2. The Chemical Analysis Table: This is like the steel’s DNA profile. It lists the percentage of carbon, manganese, silicon, sulfur, phosphorus, and other elements. For marine steel, low sulfur and phosphorus are critical for toughness and weldability. If these numbers are wrong, the steel can crack during fabrication or fail in cold temperatures.

3. The Mechanical Properties Table: This shows how the steel behaves under force. Key values include:

- Yield Strength: The stress at which the steel begins to deform permanently. For AH36, this is a minimum of 355 MPa.

- Tensile Strength: The maximum stress the steel can withstand while being stretched.

- Elongation: A measure of ductility, showing how much the steel can stretch before breaking.

- Impact Test Results (Charpy V-notch): Perhaps the most critical for marine applications. This test measures the steel’s toughness at low temperatures (often -20°C or -40°C), simulating icy ocean conditions. The certificate will show the energy absorbed in Joules.

4. The Heat/Batch and Delivery Note Details: This links the document to a specific production run and your specific order. The heat number is the unique code for the molten steel batch. The delivery note number ties the certificate to your commercial invoice and packing list.

In legal and practical terms, this certificate is your primary evidence if a dispute arises. If steel fails during construction or classification society survey, the first thing the surveyor will ask for is the MTC. If it is fake or inaccurate, you, the buyer, bear all liability—not the supplier who provided the bogus paper. This is why our business model is built on direct partnerships with certified mills. We provide our clients with the authentic, traceable MTC as a standard part of the shipment, along with the option for an additional SGS inspection report6 for double verification. This approach solved the "quality inconsistency" pain point for Gulf Metal Solutions, giving them the confidence to use our steel in their fabrication projects.

What are the three types of certificates?

When sourcing steel, you will hear about different certificates. They are not all the same. Using the wrong type of certificate for your project can lead to rejection by a classification society or a port authority. It is like using a driver’s license to board an international flight—it proves identity but not the right level of authorization for the task.

The three main types are the Mill Test Certificate (MTC)1, the Third-Party Inspection Certificate2, and the Classification Society Certificate3. The MTC is the basic factory report. The third-party certificate (like from SGS) adds an independent layer of verification. The Classification certificate (from ABS, DNV, etc.) is mandatory for approved marine structures.

Each certificate serves a distinct purpose and carries different levels of authority and cost. Choosing the right one depends on your project requirements, client specifications, and risk tolerance.

A Detailed Comparison and When to Use Each

Here is a breakdown to help you decide which certificate you need for your marine L-shaped steel order.

| Certificate Type | Issued By | Key Purpose & Content | Best For / When Required |

|---|---|---|---|

| Mill Test Certificate (MTC)1 | The steel production mill4 itself. | It is the factory’s self-declaration of quality. It confirms the steel meets the ordered grade standard (like ASTM A1315) and provides the heat-specific chemical and mechanical test data. | Standard commercial orders where the mill is reputable and the buyer has an established trust. It is the minimum document for any professional steel purchase. |

| Third-Party Inspection Certificate2 | An independent inspection company (e.g., SGS, Bureau Veritas, Intertek). | An inspector witnesses the testing (often at the mill or warehouse), verifies the MTC data, checks dimensions, weight, and surface quality, and issues a report confirming compliance. | High-value orders, new suppliers, or strict buyers. It adds a crucial layer of objectivity. We offer this to all clients to mitigate their quality risk, as requested by our client in Saudi Arabia. |

| Classification Society Certificate3 | A marine classification society6 (e.g., American Bureau of Shipping (ABS), DNV, Lloyd’s Register (LR)). | The most stringent level. The society surveys the mill’s production process, approves specific grades, and may witness testing. Their certificate states the material is approved for building classed vessels or offshore structures. | Building ships, offshore platforms, or other marine structures that require class approval. This is not optional; it is a mandatory regulatory requirement for the vessel’s insurance and operation. |

Important Note: The relationship between these documents is hierarchical. A Classification Certificate is usually based on an MTC from an approved mill, sometimes with additional supervised tests. A Third-Party Report verifies the information on an MTC or checks the material against the purchase order.

A common mistake is to think a Third-Party Report replaces an MTC. It does not. The Third-Party Report references the MTC. You need both. Another mistake is assuming a standard MTC for "AH36 steel" is enough for a classed ship. It is not. You must specifically order "ABS Grade AH36" and receive the corresponding Classification Society Certificate3.

For most of our B2B clients7—importers, wholesalers, and project contractors in countries from Vietnam to Mexico—they start with the MTC and often add the Third-Party Inspection for peace of mind. For clients directly involved in shipbuilding, we coordinate with our mill partners to supply materials with the necessary Classification Certificates. Understanding this hierarchy protects you from buying material that is technically correct but legally unusable for your specific project.

How to identify steel quality1?

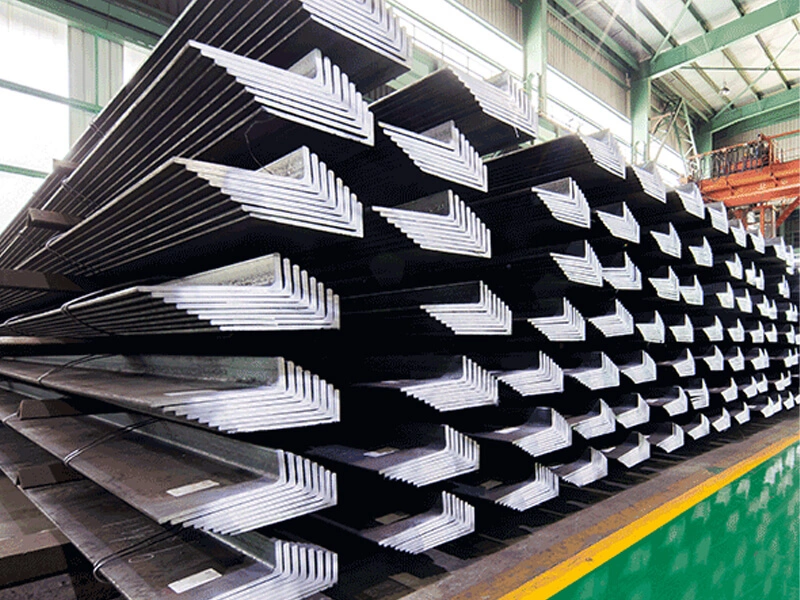

The certificate is the promise. The physical steel is the product. You must know how to check if the product lives up to the promise. Relying only on paperwork is risky. A visual and basic physical inspection can reveal problems that a fake certificate tries to hide.

You identify steel quality1 by combining document verification2 with physical checks3: examine the surface for deep pits, cracks, or unevenness; check the dimensions and straightness; look for proper mill marking4 (heat number, grade); and, if possible, conduct simple on-site tests for hardness or spark. The material must match its certificate in every aspect.

Quality assessment happens in stages: before shipment, upon arrival, and during fabrication. Let’s explore what you can do at each point.

A Step-by-Step Guide to Practical Quality Checks

You do not need a full laboratory on site. A systematic approach using your eyes, basic tools, and some knowledge is very effective.

Stage 1: Pre-Shipment Inspection (The Most Important)

This is your best chance to catch issues before the steel leaves the country. If you use a supplier like us, you can request an SGS or similar inspection before loading.

- Verify Markings: Every reputable mill permanently marks their products. For L-shaped steel, look for stenciled or rolled-on markings on the web or leg. This should include the heat number, grade (e.g., AH36), mill logo, and size. Cross-check this heat number with the one on the MTC. If they don’t match, it’s a major red flag.

- Dimensional Accuracy: Use calipers and tape measures to check the flange width, web height, thickness, and length. Compare against the ordered tolerances (usually per ASTM or EN standards). Incorrect dimensions cause fit-up problems during construction.

- Surface Condition: Marine steel must have a good surface. Look for:

- Laminations/Seams: These are long, shallow defects rolled into the surface. They can become initiation points for cracks.

- Pitting & Scaling: Excessive rust pitting reduces thickness. Heavy, flaky mill scale can hide defects and affect welding.

- Straightness: Place the L-angle on a flat surface. It should not have a significant twist or camber (bow). A small amount is permissible, but excessive bending makes fabrication difficult.

Stage 2: Receival Inspection at Your Warehouse

When the container arrives, do a quick check before unloading everything.

- Check Packaging: Good packaging prevents damage in transit. Our client from Saudi Arabia specifically noted our packaging was "the best." Look for proper bundling, waterproof wrapping, and protective edges to prevent dents and scratches during shipping.

- Spot Check: Randomly select a few pieces from different bundles and repeat the visual and marking checks. Ensure the material hasn’t been damaged in transit.

Stage 3: Basic On-Site Tests During Fabrication

As cutting and welding begin, more clues about quality emerge.

- Spark Test (for rough grade identification): Using a grinder, observe the spark stream. Different steel grades produce different spark patterns (length, color, branching). While not exact, it can quickly reveal if a piece is mild steel masquerading as high-strength steel.

- Weldability Observation: Quality marine steel should weld smoothly. Poor steel may show excessive spatter, porosity in the weld, or even cracking in the Heat-Affected Zone (HAZ) next to the weld.

- Hardness Test (using a portable durometer): This gives a quick indication of strength. You can take readings on a sample and compare them to expected ranges for the grade.

Ultimately, identifying quality is about consistency. The steel should be consistent piece-to-piece, bundle-to-bundle, and order-to-order. This consistency is what builds long-term partnerships. Our production model—long-term cooperation with specific, certified mills—is designed to deliver this exact consistency. It ensures that the L-shaped steel you receive for a ship in Thailand has the same reliable quality as the plate we sent for an oil tanker project in Romania. The certificate starts the story, but the physical steel must deliver the happy ending.

Conclusion

Buying marine L-shaped steel safely requires diligence. Always verify certificates directly with the mill, understand the three certificate types, and never skip the physical quality checks. Partnering with transparent, mill-connected suppliers is the most effective long-term strategy to avoid fakes and ensure project success.

-

Understanding steel quality is crucial for safety and performance in construction. Explore this link for comprehensive assessment techniques. ↩ ↩ ↩ ↩ ↩ ↩

-

Document verification is key to ensuring material integrity. Discover best practices for verifying steel quality documents. ↩ ↩ ↩ ↩ ↩ ↩

-

Physical checks can reveal hidden defects. Learn about essential checks to ensure steel quality before use. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Mill markings provide essential information about steel. Explore why they are critical for quality assurance. ↩ ↩ ↩

-

Understand the ASTM A131 standard and its role in ensuring the quality of marine steel. ↩ ↩

-

Explore the functions of marine classification societies in maintaining safety and standards in maritime construction. ↩ ↩

-

Find out how B2B clients can navigate steel certification to ensure compliance and quality in their projects. ↩