Your project ends, and your relationship with the steel supplier ends too. Next project, you start from zero—new negotiations, new quality risks, new communication hurdles. This transactional approach costs you time, money, and sleep. The real competitive advantage lies in a strategic partnership.

Build long-term partnerships with marine steel exporters by moving beyond price-focused transactions. Focus on shared values: mutual commitment to quality and specifications, transparent and proactive communication, fair risk and benefit sharing, and a joint investment in process improvement and supply chain efficiency over multiple projects.

A partnership is a two-way street. It requires effort and a shift in mindset from both the buyer and the supplier. It’s not about finding a vendor; it’s about co-creating a reliable, efficient, and valuable supply channel. Let’s explore the foundation and practical steps to build such a relationship.

What is the best marine steel?

You ask a potential partner, "What’s the best steel you have?" If they immediately quote the highest grade at the highest price, they see you as a transaction. A partner’s answer would be different: they would ask about your application first.

There is no single "best" marine steel. The optimal choice depends on the specific application, structural requirements, and environmental conditions. For primary hull structures, certified grades like ABS AH36/DH36/EH361 offer the best balance of strength, toughness, and weldability. A true partner helps you select the most cost-effective and fit-for-purpose grade, not just the most expensive one.

The question "what is best?" reveals a buyer’s desire for security and quality. A partner understands this and provides security not through overspecification, but through correct specification and guaranteed consistency. Let’s turn this into a partnership-building dialogue.

From Product Pitch to Collaborative Specification

A transactional supplier sells a product from a catalog. A partner engages in a technical discussion to define the right solution. This process builds trust and shared understanding.

How a Transactional Interaction Goes:

- Buyer: "I need the best marine steel for a ship."

- Supplier: "We have EH40, the highest grade. It’s $X per ton." (Focus on product/price).

- Outcome: The buyer may overpay, or the supplier may push a product that’s in stock, not what’s ideal.

How a Partnership-Oriented Interaction Goes:

- Buyer: "We’re building a bulk carrier for the North Atlantic route."

- Partner Supplier: "I see. For the hull in cold waters, we typically recommend DH36 for its guaranteed low-temperature toughness2. For the internal decks, AH36 is sufficient and saves cost. Let’s review the scantling drawing to be sure." (Focus on application, cost-effectiveness, collaboration).

- Outcome: The buyer gets a tailored, optimized material list. Trust is built.

The Foundation of Partnership: Shared Language and Standards

A long-term relationship thrives on clarity. Both parties must agree on what "quality" means.

- Specifications: Agreeing on the exact standard (e.g., ABS Rule 2, EN 10225).

- Certification: Requiring and consistently providing MTC 3.1 certificates3.

- Testing: Agreeing on standard test parameters (e.g., Charpy impact at -20°C4 for D grades).

A Partner’s Value Beyond the Product:

The "best" steel a partner provides includes intangibles:

- Predictability: Consistent lead times from known mill sources.

- Technical Support: Help with welding procedure specifications based on the steel’s chemistry.

- Proactive Alerts: Notifying you of potential market delays or material substitutions well in advance.

Building the Partnership Through Specification:

Use the material selection process as a collaborative exercise. Share your project drawings and challenges. A supplier who invests time to understand your needs is demonstrating partnership potential. Our business is based on this approach. We don’t just sell "ship plate"; we discuss the vessel type, route, and fabrication plans to recommend the right grades from our portfolio, building a foundation for a repeat business relationship.

Who makes steel for ships?

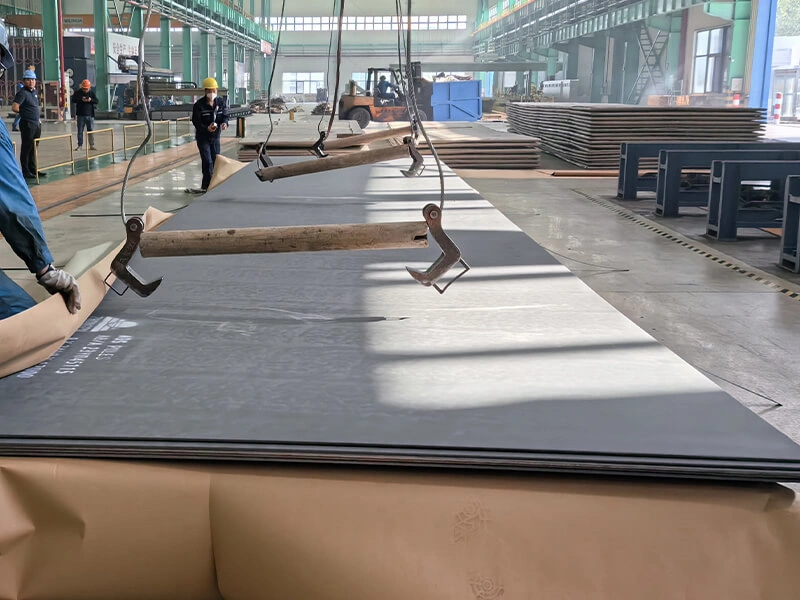

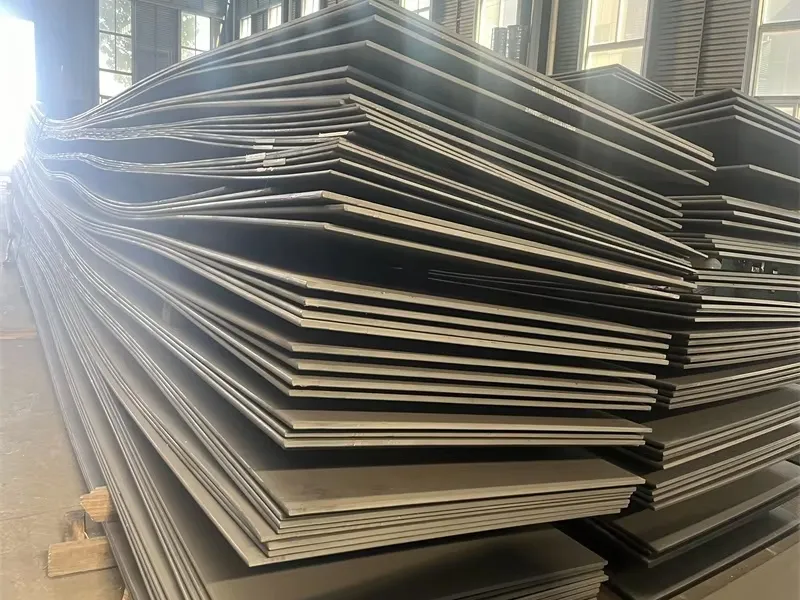

You need a reliable source. Knowing who makes the steel is more important than knowing who sells it. A partner is transparent about their supply chain and has strong, stable relationships with the producers.

Steel for ships is made by large, certified steel mills approved by international classification societies like ABS, DNV, LR, BV, or KR1. These mills specialize in producing plates and sections to strict maritime standards. Major producers include integrated mills in China (e.g., Baowu, Shagang2), South Korea (POSCO3), Japan (Nippon Steel4), and Europe (e.g., Dillinger, ArcelorMittal5).

A partner doesn’t hide behind the label "factory." They are proud of their mill partnerships and are transparent about them. This transparency is a cornerstone of trust and long-term supply stability. Let’s explore why this matters.

The Importance of Upstream Stability: Mill Partnerships

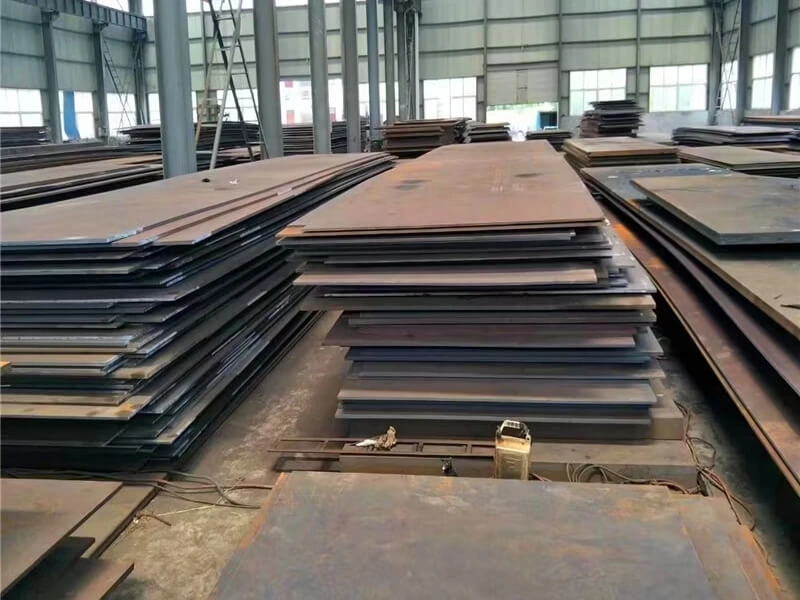

Your relationship with an exporter is only as strong as their relationship with the mills. A long-term partnership requires stability at this source level.

Signs of a Transactional Supplier (High Risk):

- Vague about sources: "We have many mill partners." Source changes with each order based on the lowest price.

- No long-term agreements: Buys from the spot market.

- Consequence for you: Inconsistent quality, unpredictable lead times, no leverage in case of issues.

Signs of a Partner Supplier (Lower Risk):

- Transparent about sources: Names specific mills and may provide their approval certificates.

- Has long-term cooperation6: Uses phrases like "our cooperative mill" or "long-term agreement." This is a core part of our business status.

- Consequence for you: Consistent quality, reliable supply, priority during shortages, and a shared channel for resolving mill-side issues.

How Mill Partnerships Benefit You, the Buyer:

- Priority Allocation: When mill capacity is tight, a partner supplier with a long-term contract gets allocated production slots. A spot buyer gets turned away.

- Consistent Chemistry: Sourcing from the same mill(s) means the steel’s chemical composition (and thus its weldability) remains consistent order after order.

- Technical Collaboration: The supplier can work directly with the mill’s metallurgists to address specific project requirements or troubleshoot rare issues.

- Traceability and Accountability: The supply chain is shorter and clearer. If a problem occurs, the path back to the origin is direct.

Evaluating a Supplier’s Mill Relationships:

Ask direct questions to assess partnership potential:

- "Which mill do you source ABS AH36 plate from? Is this a fixed relationship?"

- "Can you provide a copy of the mill’s classification society approval certificate?"

- "What is your process if we need a non-standard size or a special test?"

Our model is built on this principle. Our "long-term cooperation6 with certified mills" isn’t just a marketing line; it’s the engine of our reliability. It allows us to offer "stable quality" and "fast delivery" because we have secured, predictable access to production. When a buyer like Gulf Metal Solutions commits to us, they are not just buying from a trader; they are gaining indirect access to a stable mill partnership.

Why is steel important in marine technology?

A partner understands why you need steel, not just that you need it. They appreciate the critical role steel plays in your projects. This shared context aligns your goals—your success depends on the steel’s performance, and their success depends on enabling yours.

Steel is fundamental to marine technology because it provides the unique combination of high strength1, good toughness, excellent weldability2, and relative cost-effectiveness3 required to construct large, safe, and seaworthy structures4. Its properties allow for the building of massive ships and offshore platforms that can withstand extreme ocean forces, making modern global trade and offshore energy possible.

Understanding this importance transforms the supplier’s role from a material provider to a critical enabler. A partner internalizes this and acts accordingly. Their service levels reflect the fact that a steel delay is not just a late delivery; it’s a halted multi-million dollar project.

Aligning Values: From Commodity to Critical Enabler

When both parties see steel as a strategic, project-critical material5, the nature of the relationship changes.

The Transactional View (Commodity):

- Supplier’s Mindset: "We sell tons of steel. This order is one of many."

- Focus: Moving volume, hitting sales targets, minimizing cost per ton.

- Behavior: Standard processes, slow response to "non-standard" requests, limited flexibility.

The Partnership View (Critical Enabler):

- Supplier’s Mindset: "Our steel is the skeleton of their project. Our reliability directly impacts their success."

- Focus: Ensuring the right steel arrives at the right time in the right condition to keep the project moving.

- Behavior: Proactive communication, flexibility to handle urgent needs, investment in quality control, and problem-solving orientation.

How Partnership Behavior Manifests in Practice:

Based on the pain points and solutions from our case study:

| Project Need (Why Steel is Important) | Transactional Supplier Response | Partner Supplier Response (Our Solution) |

|---|---|---|

| Urgent technical clarification during design. | Slow or no response from a general sales email. | Assign a dedicated, fluent English sales rep for direct, rapid communication. |

| Absolute certainty of quality for class approval. | Provides basic MTC, may resist third-party checks. | Proactively offers SGS/third-party inspection support to jointly verify quality. |

| Managing cash flow on a large project. | Inflexible terms: "100% advance payment only." | Provides flexible MOQ and payment terms6 to align with the project’s financial flow. |

| Navigating complex import logistics to avoid port delays. | Ships FOB, leaving logistics to the buyer. | Offers shipping to port with customs clearance support, managing the risk. |

Building the Partnership on Shared Understanding:

As a buyer, you can foster this by educating your supplier about your projects. Share the big picture. Explain the consequences of delay or quality failure. A supplier who "gets it" will rise to the challenge. Our typical client is a "project-based distributor and fabricator." We understand that their reputation and profitability hinge on receiving perfect material on schedule. This alignment of understanding is why they provide positive feedback on stability and planning for future orders.

What grade is marine carbon steel1?

You send an order for "marine steel." A transactional supplier might send a generic grade. A partner will confirm the exact specification, because they know that "marine carbon steel1" is a family of grades, and the wrong one can fail.

Marine carbon steel refers to a range of grades defined by classification society rules. Common grades include Normal Strength (Grade A, B, D, E)2 and Higher Strength (AH32, DH32, EH32, AH36, DH36, EH36, AH40, etc.). The letter indicates notch toughness (A=basic, D=improved, E=excellent), and the number indicates the minimum yield strength in kgf/mm² (e.g., 36 = 355 N/mm²).

Precision in grade specification is the bedrock of a technical partnership. Getting it wrong has legal, safety, and financial consequences. A partner insists on clarity here because their long-term reputation depends on your project’s success.

Precision as a Partnership Pillar: The Language of Grades

Miscommunication on grade is a fatal error. A long-term partnership is built on a shared, precise technical language.

Decoding the Grade Designation:

A grade like ABS DH363 tells a complete story:

- ABS: The certifying society (American Bureau of Shipping). Could be LR, DNV, etc.

- D: The quality grade. It means the steel is normalized or controlled-rolled for improved toughness, suitable for colder service temperatures.

- H36: The strength grade. ‘H’ for High tensile, ’36’ for 36 kgf/mm² yield strength (approx. 355 N/mm²).

Why Partners Are Meticulous About Grades:

- Safety and Compliance: Using Grade A where Grade D is specified for a cold-environment vessel could lead to brittle fracture.

- Cost Optimization: Using EH36 (highest toughness) everywhere is wasteful if AH36 suffices for most parts. A partner helps optimize the grade selection to control cost without compromising safety.

- Weldability: Different grades have different Carbon Equivalent (CE) values4. The welding team needs to know the exact grade to set their procedures correctly.

The Partnership Dialogue Around Grades:

- Buyer’s RFQ: "We need plate for the bottom shell of a container ship operating in Asian waters."

- Partner’s Response: "For that application, ABS AH36 is the standard grade. We will need the thicknesses and dimensions from your nesting plan. Please confirm." (Seeks clarity, confirms standard practice).

- Later, for a different project: "We need brackets for an Arctic supply vessel."

- Partner’s Response: "For Arctic service, we must specify at least a D grade, likely DH36 or EH36, depending on the design temperature. Let’s review the specification together." (Adds value through technical guidance).

How Partners Ensure Grade Integrity:

- Clear Contracts: The purchase order and sales contract explicitly state the full grade designation (e.g., "ABS AH36").

- Document Verification: The Mill Test Certificate5 is checked upon receipt to ensure the heat chemistry and mechanical tests match the ordered grade.

- Material Marking: They ensure the steel is physically marked with the grade and heat number for traceability at your yard.

For us, this precision is part of our service. We don’t accept vague orders. We ask questions to confirm the grade. We provide the MTCs that prove the grade. This meticulousness prevents errors that could damage a fledgling partnership and instead reinforces trust with every correctly delivered order. It’s how we build the confidence that leads to planning "the next order" together.

Conclusion

Long-term partnerships with marine steel exporters are built on technical collaboration, transparency in the supply chain, a shared understanding of steel’s critical role, and meticulous attention to specifications, moving beyond price to shared value creation.

-

Understanding marine carbon steel is crucial for selecting the right grade for your project, ensuring safety and compliance. ↩ ↩ ↩ ↩ ↩

-

Explore the properties of Normal Strength grades to make informed decisions for your marine applications. ↩ ↩ ↩ ↩

-

Discover the significance of ABS DH36 to ensure you choose the right steel for your vessel’s safety and performance. ↩ ↩ ↩ ↩

-

Understanding CE values is essential for proper welding procedures, ensuring structural integrity in marine applications. ↩ ↩ ↩ ↩

-

Learn about Mill Test Certificates to ensure the steel you receive meets the required specifications and standards. ↩ ↩ ↩

-

Explore how flexible terms can improve cash flow and project efficiency in large-scale projects. ↩ ↩ ↩