Selecting the wrong L-shaped steel for marine applications can lead to premature failure and costly repairs. Many project managers struggle with this critical decision without proper guidance.

Choose marine L-shaped steel by evaluating four key factors: corrosion resistance for seawater exposure, classification certification for vessel compliance, appropriate dimensions for structural requirements, and impact toughness for operating temperatures. Always verify material certification matches your project specifications.

Making the right choice requires understanding several technical considerations. Let me guide you through the essential factors for successful material selection.

What is the best steel for seawater?

Seawater presents one of the most aggressive environments for steel materials. The combination of salt, oxygen, and biological activity creates perfect conditions for rapid corrosion if you choose the wrong material.

For seawater applications, marine-grade steels1 like AH36, DH36, or EH36 offer the best balance of corrosion resistance2 and mechanical properties. These high-strength, low-alloy steels incorporate corrosion-resistant elements and undergo strict quality control to withstand marine environments when properly protected.

Comprehensive Analysis of Steel Performance in Seawater

The selection of steel for seawater exposure involves understanding multiple corrosion mechanisms and how different steel compositions resist them. Seawater corrosion occurs through several simultaneous processes that attack steel in different ways, requiring materials with specific characteristics to ensure long-term performance.

General corrosion represents the uniform material loss across exposed surfaces. While this appears straightforward, the rate varies significantly depending on water temperature, oxygen content, and flow conditions. Marine-grade steels combat general corrosion through carefully controlled chemical compositions that form stable protective layers on the surface, slowing the corrosion process.

Pitting corrosion poses a more serious threat as it creates localized attacks that penetrate deeply into the material. Chloride ions in seawater aggressively initiate pitting, especially in stagnant conditions or under deposits. The alloying elements in marine steels, particularly copper and phosphorus, help create more uniform protective layers that resist pit initiation and propagation.

Galvanic corrosion occurs when dissimilar metals contact each other in seawater, creating battery-like effects that accelerate corrosion of the less noble metal. Marine projects often involve multiple materials, making compatibility crucial. Proper isolation between different metals and careful material selection minimize galvanic corrosion3 risks.

The manufacturing process significantly influences corrosion resistance2:

- Hot Rolling: Standard process that creates scale requiring removal

- Controlled Rolling: Enhanced properties through precise temperature control

- Normalizing: Heat treatment for improved microstructure and consistency

- Surface Preparation: Critical for subsequent coating performance

Protection systems work with the base material:

- Coatings: Barrier protection through paints and specialized coatings

- Cathodic Protection: Electrical systems that sacrifice anodes to protect steel

- Design Considerations: Avoiding crevices and stagnant areas

Here’s a comparison of steel options for seawater:

| Steel Type | Corrosion Resistance | Typical Applications | Protection Required |

|---|---|---|---|

| Carbon Steel | Poor, rapid corrosion | Non-marine, temporary structures | Heavy coating, frequent maintenance |

| Marine Grade AH36/DH36 | Good with protection | Ship hulls, offshore structures | Coating systems, cathodic protection4 |

| Stainless Steel 316 | Excellent | Fittings, specialized components | Minimal, but risk of pitting in stagnant areas |

| Copper-Nickel Alloys | Superior | Heat exchangers, piping systems | Minimal maintenance required |

We recently advised a client in Saudi Arabia on steel selection for a desalination plant structure. They initially considered standard structural steel, but our recommendation of AH36 marine grade with appropriate coating systems ensured long-term performance in the aggressive Red Sea environment.

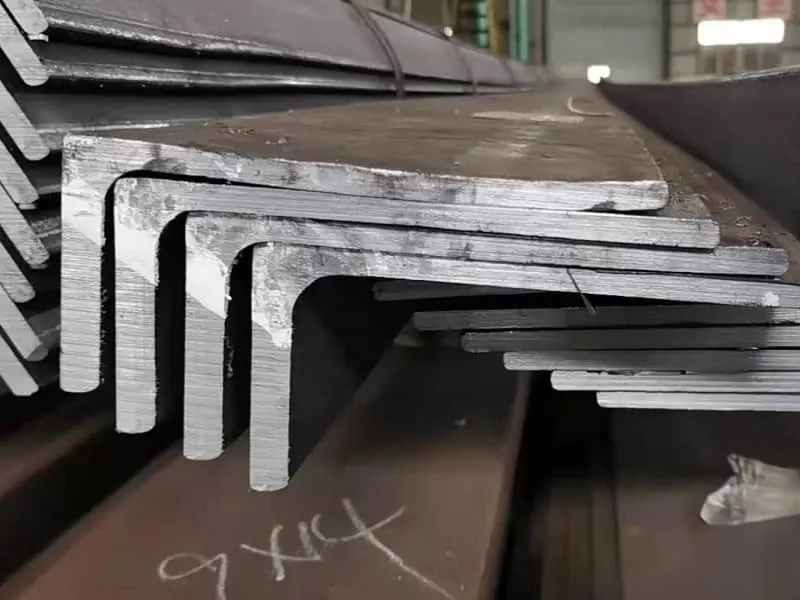

What is L-shaped steel called?

If you’ve encountered different names for L-shaped steel products, you’re experiencing the varied terminology used across industries and regions. Understanding these names helps ensure clear communication in your projects.

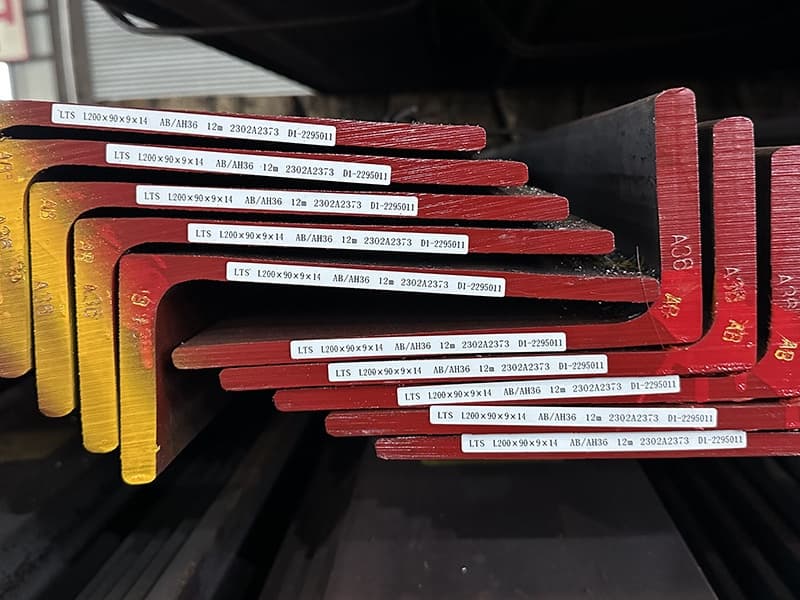

L-shaped steel is commonly called angle iron1, angle bar2, or steel angle. Technical specifications use "L" followed by dimensions (e.g., L100×75×10). Marine versions are specifically termed marine angle steel3 or shipbuilding angles4, indicating classification society certification for marine use.

Understanding L-Shaped Steel Terminology and Applications

The varied names for L-shaped steel reflect its long history and widespread use across different industries and geographical regions. Each term carries specific connotations and usage patterns that professionals should understand to avoid confusion in specifications and procurement.

The term "angle iron1" dates back to the early industrial era when these sections were primarily manufactured from wrought iron. Despite the transition to steel production, the name persists in many regions, particularly in North America and in general construction contexts. Many experienced tradespeople and older specifications still use this traditional terminology.

"Angle bar" represents a more modern term that acknowledges the material transition to steel while maintaining the descriptive "angle" reference. This terminology is common in Asian markets and international trade, where clear, descriptive names facilitate communication between parties with different language backgrounds. The term appears frequently in shipping documents and commercial invoices.

In technical and engineering contexts, the formal designation system provides precise, unambiguous information. The "L" prefix immediately identifies the shape, followed by numerical dimensions that specify the exact size and thickness. This standardized approach ensures that designers, engineers, and fabricators worldwide can interpret specifications correctly regardless of language differences.

The marine industry employs specific terminology to distinguish quality-controlled products. "Marine angle steel" or "shipbuilding angles4" indicates that the material meets classification society requirements for chemical composition, mechanical properties, and certification documentation. These designations signal that the steel has undergone rigorous testing for impact toughness, corrosion resistance, and weldability.

Regional terminology variations include:

- North America: Angle iron, structural angle5, L-shape

- United Kingdom: Angle section, steel angle, equal/unequal angle6

- Europe: L-profile7, equal/unequal leg angle, steel L-section

- Asia: Angle bar, L-bar, steel angle section

Industry-specific applications influence naming conventions:

- Shipbuilding: Marine angle, hull angle, stiffener angle

- Construction: Structural angle, framing angle, bracing angle8

- Manufacturing: Support angle, bracket angle, frame angle

- Infrastructure: Bridge angle, construction angle

The table below correlates names with applications:

| Industry Term | Primary Applications | Quality Requirements |

|---|---|---|

| Marine Angle Steel | Ship frames, hull stiffeners, offshore structures | Classification certification, impact testing |

| Structural Angle | Building frames, bridge components, support systems | Standard specifications, load capacity verification |

| General Purpose Angle | Equipment frames, brackets, non-critical structures | Basic mechanical properties, commercial quality |

Our international clients use various terms for the same products. A contractor from Qatar might request "angle iron1," while a shipyard from the Philippines specifies "marine angle bar2." We train our team to recognize all terminology variations to ensure accurate communication and correct product delivery.

What is the thickness of 50×50 L angle1?

When specifying 50×50 L angle1, the thickness becomes a critical parameter that determines the section’s strength, weight, and suitability for specific applications. Understanding available thickness options2 helps in proper material selection.

The thickness of a 50×50 L angle1 typically ranges from 3mm to 6mm for standard applications, with 5mm being most common. Marine applications often use thicker sections from 4mm to 8mm, selected based on structural requirements, corrosion allowance3, and classification society rules for specific vessel types.

Detailed Guide to 50×50 L Angle Thickness Selection

The thickness of a 50×50 L angle1 significantly influences its mechanical properties and application suitability. Thinner sections offer weight savings and cost advantages but provide less load-bearing capacity and corrosion allowance3. Thicker sections deliver higher strength and longer service life but increase material costs and structural weight.

The section modulus4, which determines bending resistance, increases disproportionately with thickness. A 50x50x6 angle has approximately 44% higher section modulus4 than a 50x50x5 angle, despite only a 20% increase in thickness. This non-linear relationship means small thickness increases can provide significant strength improvements when designing for bending loads.

Corrosion allowance represents another critical consideration in thickness selection. Marine environments gradually consume material through corrosion, even with protective systems. Classification societies often mandate minimum thicknesses that include a corrosion allowance3, typically 1-2mm over the design life. Thinner sections may not provide adequate corrosion reserve.

Manufacturing constraints affect available thickness options2. Very thin sections below 3mm may lack straightness and flatness consistency, while very thick sections above 8mm become difficult to form and may require specialized rolling equipment. The most cost-effective thicknesses typically fall within the 4-6mm range where production volumes are highest.

Standard thickness availability follows preferred number series:

- Light Duty: 3mm, 4mm for secondary structures

- Standard Duty: 5mm, 6mm for primary applications

- Heavy Duty: 8mm, 10mm for high-stress areas

Application-specific thickness considerations:

- Marine Structures: Account for corrosion loss over design life

- Dynamic Loading: Consider fatigue life and stress concentrations

- Fabrication Requirements: Ensure weldability and formability

- Weight Constraints: Balance strength against weight penalties

Here’s how thickness affects 50×50 angle performance:

| Thickness | Section Weight (kg/m) | Section Modulus (cm³) | Typical Applications |

|---|---|---|---|

| 3mm | 2.32 | 1.47 | Light framing, non-structural uses |

| 4mm | 3.05 | 1.89 | Secondary structures, interior framing |

| 5mm | 3.77 | 2.29 | Primary marine applications, standard framing |

| 6mm | 4.47 | 2.66 | High-stress areas, corrosion-critical applications |

We recently supplied 50x50x5 L angles to a shipyard in Thailand for interior bulkhead stiffeners. The 5mm thickness provided optimal balance between strength requirements and weight considerations while allowing adequate corrosion allowance3 for the vessel’s 25-year design life.

What is the L shaped piece of metal used in construction?

The L-shaped metal piece1 serves as one of the most versatile and fundamental components in construction projects. Its simple geometry provides remarkable strength and connection flexibility across various applications.

The L-shaped metal piece1 is angle steel2, used primarily for structural framing3, bracing, and support systems. In marine construction4, it reinforces hull plates, supports decks, and creates stiffening frames. In building construction, it forms structural frames, provides edge reinforcement5, and serves as connection elements6.

Comprehensive Analysis of L-Shaped Steel Construction Applications

L-shaped steel sections serve as fundamental building blocks across construction industries, providing solutions for structural support, connection detailing, and reinforcement requirements. The 90-degree cross-section offers an optimal balance of strength, stiffness, and connection versatility that makes it suitable for countless applications.

In marine construction4, L-shaped steel performs critical structural functions that ensure vessel integrity and safety. The sections attach to hull plating to create T-shaped stiffeners that prevent buckling under water pressure. This application demands precise dimensional control and high-quality welds to maintain watertight integrity and structural performance under dynamic loading conditions.

Shipbuilding applications require specific considerations:

- Hull Stiffening: Primary and secondary stiffeners against water pressure

- Deck Support: Longitudinal and transverse support systems

- Bulkhead Reinforcement: Stiffening of watertight compartments

- Foundation Structures: Support for machinery and equipment

- Connection Elements: Joining different structural components

Building construction utilizes L-shaped steel for different but equally important purposes. The sections form part of structural frameworks, provide lateral bracing, and serve as connection elements6 between different structural members. The simplicity of angle connections allows for efficient fabrication and erection processes in building construction.

Construction applications include:

- Structural Framing: Primary and secondary structural members

- Bracing Systems: Diagonal bracing for stability systems

- Connection Plates: Joining beams, columns, and other members

- Edge Reinforcement: Strengthening concrete and masonry elements

- Support Brackets: Mounting platforms for equipment and fixtures

The material selection differs between marine and construction applications:

- Marine Grades: AH36, DH36, EH36 with impact testing

- Construction Grades: S235, S275, S355 with standard testing

- Surface Preparation: Varies based on corrosion protection requirements

The table below compares marine and construction applications:

| Application Area | Primary Functions | Special Requirements |

|---|---|---|

| Marine Construction | Hull stiffening, deck support, bulkhead framing | Corrosion resistance, impact toughness, classification certification |

| Building Construction | Structural framing, connections, bracing systems | Load capacity, fire resistance, architectural compatibility |

| Bridge Construction | Bracing members, connection elements6, support frames | Fatigue resistance, weld quality, environmental durability |

| Industrial Construction | Equipment supports, platform framing, access structures | Load capacity, vibration resistance, maintenance access |

We supply L-shaped steel to both marine and construction clients worldwide. A recent project in Saudi Arabia required large quantities of L-shaped steel for a port terminal construction. The material needed to withstand the corrosive marine atmosphere while providing the structural strength for heavy crane operations and container handling equipment.

Conclusion

Selecting the right L-shaped steel for marine projects requires careful consideration of material properties, environmental conditions, and regulatory requirements. Proper selection ensures structural performance and project success.

-

Explore the versatility of L-shaped metal pieces in construction and their various applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about angle steel’s role in structural framing and its importance in construction projects. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Understand the significance of structural framing and how it supports buildings and structures. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover how L-shaped steel enhances safety and integrity in marine construction projects. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn how edge reinforcement strengthens concrete and masonry elements in construction. ↩ ↩

-

Explore the role of connection elements in joining structural components effectively. ↩ ↩ ↩ ↩

-

Understand the significance of L-profiles in steel construction and their various applications. ↩

-

Discover how bracing angles contribute to structural stability in construction projects. ↩