Imagine this: you’ve just installed a massive steel structure offshore, and within months, a brown, flaky disease starts to eat it away. The repair costs are staggering, and the project timeline is in shambles. This isn’t just a bad dream; it’s the brutal reality of corrosion in marine environments.

The key to ensuring corrosion resistance in marine steel lies in a multi-layered defense system. This system combines selecting the right corrosion-resistant steel grades with applying robust protective coatings and implementing targeted cathodic protection. It’s about building a shield against the sea’s relentless attack.

Every year, marine corrosion costs the global industry billions. But for professionals like you, the cost is more than financial—it’s about project integrity and reputation. You don’t just need steel; you need a guaranteed solution. In this article, we’ll move beyond theory and into practical, actionable strategies. We’ll break down exactly how to protect your marine steel investments, drawing from real-world engineering practices and the specific demands of international projects in places like the Middle East and Southeast Asia.

How is corrosion protection1 of steel in marine environment2?

You’ve seen the pictures: rusted hulls, crumbling piers. The marine environment2 is a perfect storm for steel destruction. Saltwater, oxygen, and constant wet-dry cycles create an electrochemical nightmare. If you’re relying on standard steel here, you are essentially throwing money into the ocean.

Protecting steel in marine environment2s requires a barrier system. This system physically and chemically separates the steel from seawater. The most common method is using high-performance paint coatings3 or metal sprays like aluminum or zinc. This barrier is often combined with cathodic protection to stop any corrosion that starts at coating flaws.

The challenge is that the marine environment isn’t uniform. We must protect steel differently depending on where it is. The strategy for a submerged piling is not the same as for a deck structure in the splash zone. Let’s dive deeper into the specific zones and their protection methods.

Understanding the Attack: Corrosion Zones in Marine Environments

We can’t fight an enemy we don’t understand. Marine corrosion isn’t a single, simple process. It changes dramatically based on the steel’s exact location. Treating the entire structure the same way is a costly mistake. Smart protection starts with zoning.

The marine environment2 is typically divided into five distinct corrosion zones4:

| Zone | Environment Description | Primary Corrosion Mechanism | Key Protection Challenges |

|---|---|---|---|

| Atmospheric Zone | Above the splash zone, exposed to sea air and salt spray. | Thin electrolyte layer from salt deposits enables fast oxidation. | UV degradation of coatings, salt accumulation, frequent wet/dry cycles. |

| Splash & Spray Zone | Area intermittently wetted by waves and spray, but not permanently submerged. | Almost continuous wetness with high oxygen supply. This is often the most corrosive zone. | Constant mechanical impact from waves, severe wet/dry cycles, highest corrosion rate. |

| Tidal Zone | Area between high and low tide. Periodically submerged and exposed. | Changing water levels create an oxygen concentration cell, accelerating corrosion at the waterline. | Differential aeration, biological fouling, abrasive action from debris. |

| Continuous Immersion (Submerged) | Permanently below the water line. | General corrosion fueled by dissolved oxygen in seawater. | Low temperature, biofouling5 (barnacles, mussels), reduced oxygen with depth. |

| Mud/Seabed Zone | Steel embedded in the seabed or buried. | Often anaerobic (low oxygen) conditions, which can enable microbial corrosion. | Soil chemistry variations, difficult inspection and maintenance, sulfate-reducing bacteria. |

For each of these zones, the protection strategy must be tailored. In the atmospheric and splash zones, the first line of defense is always a high-grade, multi-layer coating system. Epoxy primers, intermediate coats, and polyurethane topcoats are standard. For extreme splash zone areas, engineers often specify thick-film coatings6 or even monolithic claddings like rubber or glass flake reinforced epoxy. These can be several millimeters thick.

For the submerged and tidal zones, coatings are still critical, but they are almost always supported by cathodic protection7 (CP). This is because it’s nearly impossible to maintain a perfect, flaw-free coating underwater for decades. CP acts as a backup system. It works by making the steel structure the cathode of an electrochemical cell, stopping the corrosion reaction. This can be done with sacrificial anodes8 (blocks of zinc or aluminum alloy attached to the steel) or impressed current systems (using a power source and inert anodes).

The seabed zone presents unique challenges. Here, coatings can be damaged during installation. A combination of a robust coating for handling and a CP system designed for the seabed’s soil resistivity is essential. Understanding this zoning is the first, non-negotiable step in creating an effective and cost-efficient corrosion protection1 plan for any marine project.

How do you make steel corrosion-resistant?

You wouldn’t use a bicycle to cross an ocean. So why use basic steel in seawater? The first step in the fight isn’t adding protection onto the steel; it’s building protection into the steel itself. This means starting with the right material from the mill.

You make steel corrosion-resistant by altering its chemical composition during production. The primary method is adding specific alloying elements like chromium, nickel, copper, and phosphorus. These elements help form a stable, self-protecting oxide layer on the steel’s surface that resists further attack, dramatically slowing down the corrosion process.

This isn’t alchemy; it’s metallurgy. But simply adding alloys isn’t a magic bullet. Different environments and budgets call for different steel grades. Let’s look at the main types of corrosion-resistant steel1 and when to use them.

Choosing the Right Steel: A Guide to Corrosion-Resistant Grades

Not all "corrosion-resistant" steels are the same. Selecting the wrong grade can lead to premature failure or unnecessary expense. The choice depends on the environment’s severity, the structure’s design life, and the overall maintenance strategy. We can group them into three main categories.

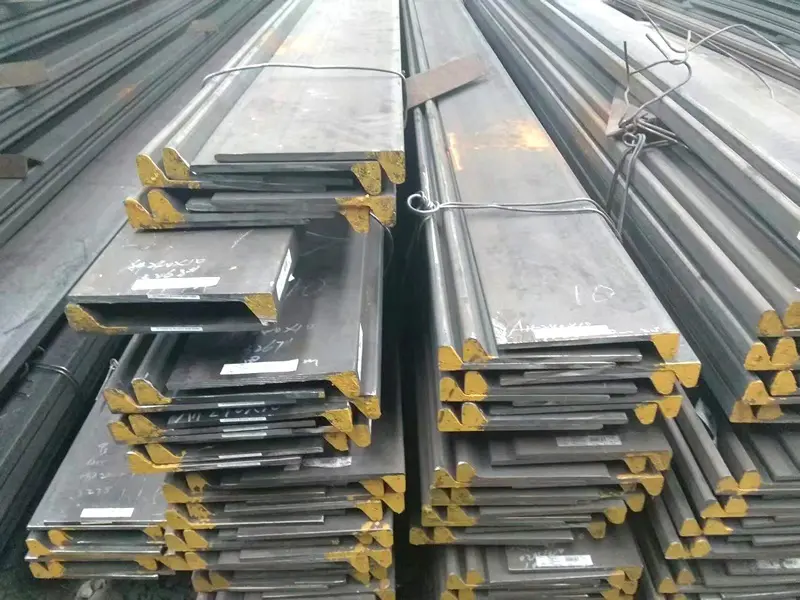

First, we have Weathering Steels2 (like ASTM A588/A709 Grade 50W3). These are low-alloy steels containing small amounts of copper, chromium, nickel, and phosphorus. When exposed to the atmosphere, they form a dense, adherent rust patina that blocks further moisture and oxygen penetration. This patina is stable and protective. Key point: These are excellent for atmospheric zones in marine environments (e.g., bridge towers above the splash line) but are not suitable for immersion or the splash zone. The constant wetness prevents the stable patina from forming.

Second, and most crucial for marine applications, are Marine-Grade Steels4. These are often produced to standards like ABS (American Bureau of Shipping), DNV (Det Norske Veritas), or LR (Lloyd’s Register). Their corrosion resistance comes from tighter control over chemistry (lower sulfur and phosphorus to reduce harmful inclusions) and often from being supplied with a mill scale that is suitable for immediate coating. Grades like AH36, DH36, EH36 are common. Their primary advantage is guaranteed toughness and weldability for structural integrity in ships and offshore platforms. Their base corrosion resistance is better than ordinary steel, but they still require coatings and cathodic protection5 for long-term service.

The third category is Stainless Steels and Nickel Alloys6. These are the high-performance options. By adding significant chromium (over 10.5%) and often nickel, they form a passive chromium oxide layer that is incredibly resilient. Grades like 316/L (with molybdenum) offer excellent resistance to chloride pitting and are used for critical fittings, fasteners, and equipment in harsh splash zones. For the most severe environments, like seawater piping, duplex stainless steels7 (e.g., 2205) or high-nickel alloys like C276 may be specified. The downside is cost. Using these for primary structural members is often prohibitively expensive.

Here’s a simple decision framework from my experience supplying to projects:

- For primary hull structures, offshore jacket legs, and submerged components: Use certified Marine-Grade Steel (e.g., AH36/DH36) + Coating System + Cathodic Protection.

- For atmospheric structures like walkways, handrails, and housing on platforms: Consider Weathering Steel for low-maintenance or use marine-grade steel with a coating for a uniform appearance.

- For critical small components, pumps, and valves in constant contact with seawater: Specify 316 Stainless Steel or better.

Making the steel itself more resistant is the foundation. It reduces the burden on the external protection systems and provides a crucial safety net if those systems are damaged.

How to protect structural steel from corrosion?

You have the right steel. Now, the real work begins. A perfect steel plate is defenseless against the sea without a strong, continuous shield. Applying this shield is a precise science, not a simple painting job. A single missed spot or a poorly mixed batch of paint can be the weak link that costs you everything.

The most common way to protect structural steel is by applying a multi-layer coating system1. This involves surface preparation (usually abrasive blasting to a specified cleanliness and roughness), followed by applying a primer, an intermediate coat, and a finish coat. Each layer has a specific function, creating a combined barrier that is thicker and more resilient than any single layer could be.

Think of it like putting on a winter coat. You wouldn’t just wear a thin shirt in a snowstorm. You layer up. But in marine engineering, the "storm" never stops. The quality of application is just as important as the coating material itself. Let’s break down the process.

The Coating System: A Layer-by-Layer Defense Strategy

A successful coating project is 50% preparation and 50% execution. Skipping steps or compromising on standards is the fastest route to failure. I’ve seen projects where beautiful, expensive coatings failed in two years because the surface prep was done in high humidity. The process is sequential and unforgiving.

Step 1: Surface Preparation – The Most Critical Step. All coatings must adhere to a clean, properly profiled surface. The international standard is abrasive blasting to Sa 2½2 (Near-White Metal) according to ISO 8501-1. This removes all mill scale, rust, and contaminants, leaving a uniformly gray-white surface. At the same time, the blasting creates an anchor profile (roughness), typically between 50-100 microns. This profile massively increases the surface area and gives the primer something to mechanically "bite" into. Testing this with comparator discs is essential.

Step 2: Primer Application – The Reactive Foundation. The primer is not just paint; it’s often a chemically active layer. The most common types for marine use are Zinc-Rich Primers (Inorganic or Epoxy)3. These primers contain a high load of zinc dust. The zinc acts as a sacrificial material, offering galvanic protection at tiny scratches or pinholes (like a built-in mini cathode). Epoxy primers are also widely used for their excellent adhesion and barrier properties. This layer must be applied soon after blasting, before any flash rust appears.

Step 3: Intermediate/Build Coat – The Barrier Workhorse. This layer, often a high-build epoxy4, provides the main film thickness and barrier resistance. Its job is to be impermeable to water, oxygen, and chloride ions. It builds up the total dry film thickness (DFT)5, which is carefully specified (e.g., 300 microns total system). DFT is measured wet and dry with gauges to ensure compliance.

Step 4: Finish/Topcoat – The First Line of Defense. The topcoat, usually a polyurethane or polysiloxane, provides resistance to UV degradation, abrasion, and chemicals. It also gives the structure its final color and gloss. Modern topcoats are engineered to be more flexible to withstand thermal expansion and contraction of the steel.

The entire process requires strict control of environmental conditions6: temperature, dew point, and relative humidity. Applying coatings when the steel temperature is below the dew point will cause moisture to condense under the paint, guaranteeing blistering and failure. For a project in the Gulf, we had to schedule all blasting and priming work for the early morning hours to avoid the high afternoon humidity. This level of detail is what separates a lasting structure from a maintenance nightmare.

How to prevent corrosion in marine engineering?

So you’ve chosen resistant steel and applied a perfect coating. Is the job done? Not even close. In marine engineering, corrosion prevention is an active, ongoing process. It’s a philosophy that spans from the drawing board to decommissioning. The most elegant technical solution can fail if it’s not inspectable, maintainable, or designed with corrosion in mind.

True corrosion prevention in marine engineering is a holistic management system. It integrates material selection, protective system design, smart structural detailing to avoid traps, and a planned regime of inspection and maintenance. It combines the "passive" protection (coatings, materials) with "active" systems like cathodic protection and uses design to eliminate corrosion-prone features.

This is where theory meets the gritty reality of salt, waves, and budgets. It’s about making smart choices upfront that save millions later. Let’s explore the critical, often-overlooked aspects of this holistic approach.

Beyond Coatings: The Holistic Corrosion Management Framework

Focusing only on coatings is like building a castle with strong walls but leaving the gate open. A complete strategy closes all entry points. This framework has three pillars: Design, Active Systems, and Lifecycle Management1.

Pillar 1: Corrosion-Aware Design2. This is the cheapest and most effective prevention method. It involves designing structures to avoid features that trap water, debris, and salt.

- Avoid Crevices: Welded butt joints are better than overlapping plates that create crevices. Where bolts are used, sealants should be specified.

- Ensure Drainage: All horizontal surfaces should be sloped. Box sections should have drain holes. Standing water is a corrosion accelerator.

- Facilitate Access: Design must allow space for workers to properly prepare surfaces, apply coatings, and conduct future inspections. A beautiful but inaccessible detail will be the first to corrode.

Pillar 2: Active Protection Systems – Cathodic Protection (CP)3. For all submerged and buried steel, CP is non-negotiable. It’s the ultimate backup.

- Sacrificial Anode (Galvanic) CP4: Simple, reliable, and maintenance-free. Blocks of aluminum-zinc-indium or magnesium alloys are welded or bolted to the structure. They corrode instead of the steel. They are ideal for smaller structures or where power is unavailable. The downside is they are consumed and must be replaced every 5-25 years.

- Impressed Current CP (ICCP)5: Used for large structures like ships, jetties, and offshore platforms. It uses an external DC power source and durable anodes (like mixed metal oxide) to force a protective current onto the steel. ICCP systems are powerful, long-lasting, and can be adjusted, but they are more complex, require power, and need monitoring.

Pillar 3: Inspection, Monitoring, and Maintenance (IM&M)6. A protection system without a plan to check it is a gamble. An IM&M plan is a scheduled roadmap.

- Regular Visual Inspections: Check for coating breakdown, rust stains, and mechanical damage, especially in the splash zone.

- Coating Assessment7: Use simple tools like a holiday detector (to find pinholes) and adhesion testers.

- CP System Monitoring: For ICCP, read output voltage and current regularly. For sacrificial systems, measure "potential" readings with a reference electrode to ensure the steel is adequately protected.

- Maintenance: The plan must budget for and schedule timely repairs—touching up damaged coatings, replacing depleted anodes, and cleaning fouling.

For example, a client of ours in Saudi Arabia, Gulf Metal Solutions, was supplying steel for a desalination plant outfall pipeline. We didn’t just ship AH36 plates. Our technical discussion focused on the CP design for the submerged sections and recommended a specific high-build epoxy coating system for the sections in the tidal zone, considering the high temperature and UV exposure. This holistic advice, aligning material supply with protection engineering, is what builds long-term partnerships and ensures project success.

Conclusion

Ensuring corrosion resistance in marine steel is not a single action but a complete strategy. It starts with the right steel, is built with meticulous coating, and is sustained through smart design and active monitoring. This layered defense is the only way to guarantee longevity at sea.

-

Understand how Lifecycle Management can enhance the durability and performance of marine structures. ↩ ↩ ↩ ↩ ↩

-

Understanding Corrosion-Aware Design can help you implement effective strategies to prevent corrosion in marine structures. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore how Cathodic Protection systems can safeguard your marine structures from corrosion effectively. ↩ ↩ ↩ ↩

-

Discover how Sacrificial Anodes work to protect submerged structures from corrosion. ↩ ↩ ↩ ↩

-

Find out how ICCP systems provide powerful protection for large marine structures. ↩ ↩ ↩ ↩

-

Learn why a robust IM&M plan is crucial for the longevity of marine engineering projects. ↩ ↩ ↩ ↩

-

Explore effective techniques for assessing coatings to ensure optimal corrosion protection. ↩ ↩ ↩

-

Learn how sacrificial anodes work to protect steel structures from corrosion in seawater. ↩