You are building a ship’s frame or a support structure. Everything depends on precise angles. Then you unload your L-shaped steel and find it’s twisted or bowed. This mistake can ruin your project schedule and budget before you even start.

Ensuring the straightness of L-shaped steel profiles requires a complete approach. You need to check tolerances at the mill, use proper handling and storage methods, and apply correct bracing techniques during fabrication. The key is to control quality from production all the way to installation.

A bent steel angle is more than an annoyance. It is a source of major problems. It causes poor fit-up during welding. It leads to weak points in the final structure. I have talked with many project managers who face this issue. They often blame transportation. But the truth is, straightness issues can start much earlier. Let’s look at the specific standards and methods that guarantee your L-profiles are perfectly straight and true. This knowledge will save you time and money.

What is the verticality tolerance for steel structures?

Imagine a tall ship’s mast or a column on an offshore platform. If it is not vertical, the forces acting on it change. This can lead to a catastrophic failure. Knowing the allowed limits is the first rule of safe construction.

Verticality tolerance is the maximum allowed deviation from a perfect vertical line for a steel member. It is usually measured over a specific height. For example, a common tolerance might be height/1000 but not more than 25mm. This means a 10-meter column can be off by no more than 10mm.

Defining and Applying Verticality Limits

Verticality tolerance is not one universal number. It changes based on the structure’s type, its importance, and the standards you follow. You must know which rule applies to your project.

First, you must understand the source of the tolerance. Structural design codes provide these limits. For marine and general construction, two common codes are the American Institute of Steel Construction (AISC) Code of Standard Practice and various international standards like ISO or classification society rules (ABS, DNV). These codes give tables and formulas. They tell you how much a column or a vertical frame member can lean. The tolerance is often a ratio. A stricter project might use height/1500. A more general one might use height/500.

Second, the tolerance applies to the erected member, not just one piece of steel. When we talk about L-shaped steel profiles, they are often used as parts of a larger vertical element. The straightness of the individual L-angle contributes to the overall verticality of the built structure. If a single angle is bowed, it makes the whole assembly harder to align. This is why mill tolerance for straightness of a single piece is much tighter than the erection tolerance for a complete column.

Here is a table comparing different tolerances relevant to L-profiles:

| Tolerance Type | Typical Specification (Example) | Applies To | Why It Matters for L-Shaped Steel |

|---|---|---|---|

| Mill Straightness Tolerance | Deviation ≤ Length/1000, max 5mm per meter. (Per EN 10056-1) | A single, uncut length of L-angle steel from the mill. | Ensures the raw material is straight enough to fabricate with. A very bent angle cannot be used. |

| Fabrication Tolerance (for built-up members) | Camber and Sweep tolerance per AISC 303-16. | A built-up column or beam made from multiple plates and angles. | Dictates how straight the fabricated part must be before it leaves the shop. |

| Erection Verticality Tolerance | Plumb tolerance: Height/500, not to exceed 25mm. (Common spec) | The final, installed column or vertical frame in the field. | The ultimate requirement for the completed structure’s safety and appearance. |

Third, measurement is key. How do you check it? In the workshop, we use precision tools. A simple spirit level works for short pieces. For longer lengths, we use a taut wire or a laser level. For critical offshore components, surveyors use optical instruments like theodolites. The method must match the required precision. For our client in Qatar building oil tanker components, they specify laser alignment checks for all major vertical frames. We ensure the L-angles we supply have excellent inherent straightness to make their job easier.

Finally, remember causes and corrections. Why does a steel member go out of vertical? It can be from foundation settling, welding distortion, or inaccurate initial placement. For L-angles, welding heat is a major cause of distortion. The way you weld an L-angle to a plate can pull it out of alignment. You need to plan the welding sequence to balance the heat. Sometimes, you can use mechanical means to straighten a slightly bent angle. But it is always better to start with straight material. This is a core part of our quality check before shipment.

What is the angle of L section steel1?

This seems like a simple question. An L-shape has a 90-degree angle, right? In practice, it is not always that perfect. The precise angle is critical for fit-up and strength.

The nominal angle of standard L section steel1 (also called angle bar or angle iron) is 90 degrees. This is the angle between the two legs. However, manufacturing tolerances allow a small deviation from this perfect right angle.

The Reality of the 90-Degree Angle

The "90-degree" label is a design ideal. The actual product has a permissible variation. Understanding this tolerance is what separates professionals from amateurs.

First, let’s define the parts. An L-section has two legs. The longer side is often called the "long leg". The shorter side is the "short leg". The thickness is the material thickness. The place where the two legs meet is the "heel" or "root". The angle we care about is the inside angle at this root.

Second, every production standard includes an angular tolerance2. This tells you how much the actual angle can differ from 90 degrees. For example, the European standard EN 10056-13 specifies a tolerance for the "squareness of legs". For common L-profiles, the tolerance might be ±1 degree or even ±2 degrees for larger, thicker sections. The ASTM A6 standard4 in the USA also has similar provisions. This means an angle bar specified as 90 degrees could actually measure 89 degrees or 91 degrees and still be within the acceptable factory limit.

Why does this tolerance exist? The hot-rolling process5 is not perfect. The steel is shaped at extremely high temperatures. As it cools, minor distortions can happen. The mills control this very carefully, but a zero-tolerance policy would make production impossible and extremely expensive. The allowed tolerances ensure the product is fit for its structural purpose without unnecessary cost.

The impact of an out-of-tolerance angle is significant. Consider two L-angles that need to be welded back-to-back to form a T-shape or a box section. If one has an 89-degree angle and the other has a 91-degree angle, they will not sit flush. This creates a gap. The welder must fill this gap, which takes more time and weld material. More importantly, it can create stress concentrations. For marine applications where fatigue resistance is critical, such gaps are not acceptable. This is why serious buyers check the angular tolerance2 of samples.

Here is a look at key tolerances for L-section steel based on common standards:

| Feature | Typical Tolerance (Example from EN 10056-13) | Measurement Method | Consequence of Exceeding Tolerance |

|---|---|---|---|

| Leg Length (e.g., 150mm leg) | ±2mm to ±4mm, depending on size. | Measuring tape or caliper across the leg length. | Affects the overall dimensions of the fabricated part. |

| Thickness | Usually ±0.5mm to ±1.5mm. | Ultrasonic gauge or caliper. | Affects the weight and strength calculation. |

| Straightness | ≤ Length / 1000 (max often specified). | Placing on flat surface or using a taut string. | Causes misalignment during assembly; requires straightening. |

| Angular Deviation (from 90°) | Commonly ±1° to ±2°. | Using a precision steel protractor6 or angle finder tool. | Causes poor fit-up with other members; creates welding gaps7. |

| Twist (Torsion) | Very limited, often specified over a length. | Checking if both ends sit flat on a surface simultaneously. | Makes the profile unusable for straight applications. |

So, how do you ensure you get good angles? You specify the standard clearly in your order (e.g., EN 10056-13 for tolerance class). You can request a tighter tolerance, but this will increase the price. The most practical method for critical projects is to include angular checks in your pre-shipment inspection. When Gulf Metal Solutions ordered from us, their SGS inspector used a digital angle finder8 on random samples from the batch. This gave them data and peace of mind. We work with mills that have modern straightening and cooling beds to minimize these deviations from the start.

How to brace a steel structure?

Bracing is what keeps a skeleton standing. Without it, even the strongest beams can buckle sideways. For structures using L-shaped steel, bracing is often made from the same material.

Bracing a steel structure means adding diagonal members or other systems to provide stability against lateral forces like wind, waves, or seismic activity. These braces, often made from L-shaped steel angles, transfer horizontal forces down to the foundation, preventing the frame from collapsing or deforming.

The Principles and Practice of Bracing

Bracing is not just adding random crosses to a frame. It is a calculated system. The type, size, and connection of the brace all determine its effectiveness.

First, you need to know the types of bracing systems. There are two main categories: lateral bracing and torsional bracing. For frames made with L-profiles, we mostly deal with lateral bracing.

- Diagonal Bracing: This is the most common type. An L-angle is installed diagonally between two connection points in a rectangular bay, forming an "X" or a single diagonal. It works in tension or compression.

- K-Bracing and V-Bracing: These are variations where the brace does not go from corner to corner. They are used when there are openings in the bay.

- Portal Bracing: Used in buildings, it involves stiffening a frame with moment connections or additional members to act as a brace.

- Continuous Rod Bracing: Sometimes, a steel rod is used instead of an angle, but it only works in tension.

Second, the design determines the bracing requirements. The structural engineer calculates the expected lateral loads. Then they specify the brace member’s size, length, and connection details. An L-angle used as a brace must be strong enough to handle these calculated forces. The engineer will choose an angle size (like 100x100x10mm) with a specific steel grade (like A36 or S355) based on these calculations. The connection is crucial. A weak connection makes a strong brace useless. Braces are typically connected with bolts or welds to gusset plates.

Third, let’s talk about the specific role of L-shaped steel in bracing. L-angles are very popular for bracing. Why? They are readily available. They have good strength in both axes. They are easy to connect because they have two flat legs. You can bolt through one leg easily. For shipbuilding, L-angles are used extensively to brace decks, bulkheads, and hull frames against the dynamic loads of the sea.

Here is a breakdown of bracing considerations using L-angles:

| Aspect | Design Consideration | Practical Implication for Fabrication |

|---|---|---|

| Brace Member Selection | Size (leg length and thickness), Grade (yield strength), Length. | Must match the purchase order and material certificates. Check the MTR for grade compliance. |

| Slenderness Ratio | The brace’s length divided by its radius of gyration. Affects its buckling capacity. | Longer, thinner braces are more likely to buckle. The engineer’s design controls this. |

| Connection Design | Type (bolted or welded), Gusset plate thickness, Bolt grade and quantity, Weld size and length. | This is where most failures start. Follow the shop drawings exactly. Do not undersize welds. |

| Bracing Configuration | X-bracing, Single diagonal, K-brace, etc. | Determines how the braces are cut and fitted. Ends are often cut at an angle to fit the gusset plate. |

| Installation Sequence | When to install and tighten braces during erection. | Braces may be left slightly loose during initial frame alignment, then fully tightened. |

From a supplier’s perspective, we see common bracing issues. Sometimes, projects order generic L-angles for bracing without specifying the required grade. A36 may be fine for some parts, but a critical seismic brace might need a higher grade like A572 Gr. 50. Another issue is straightness. A severely bowed L-angle cannot be installed neatly in a diagonal brace. It will have to be forced into place, putting pre-stress on the connection. We always advise our clients, like the contractors in the Philippines, to be specific about the application. This allows us to ensure the mill selects coils with the right chemistry for better toughness, which is vital for braces that undergo cyclic loading.

What does l angle mean?

You hear "L-angle", "angle bar", "angle iron", and "L-section". They all point to the same fundamental shape. But knowing the exact terminology helps in clear communication and accurate ordering.

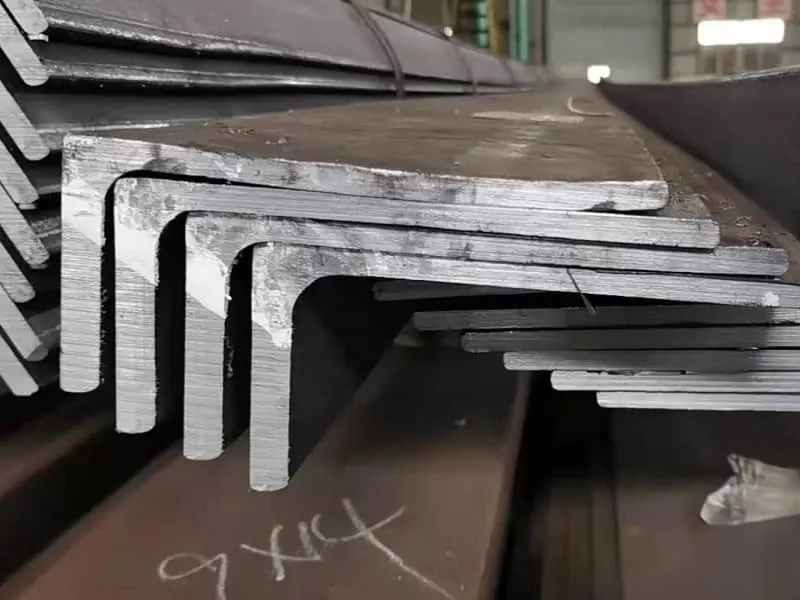

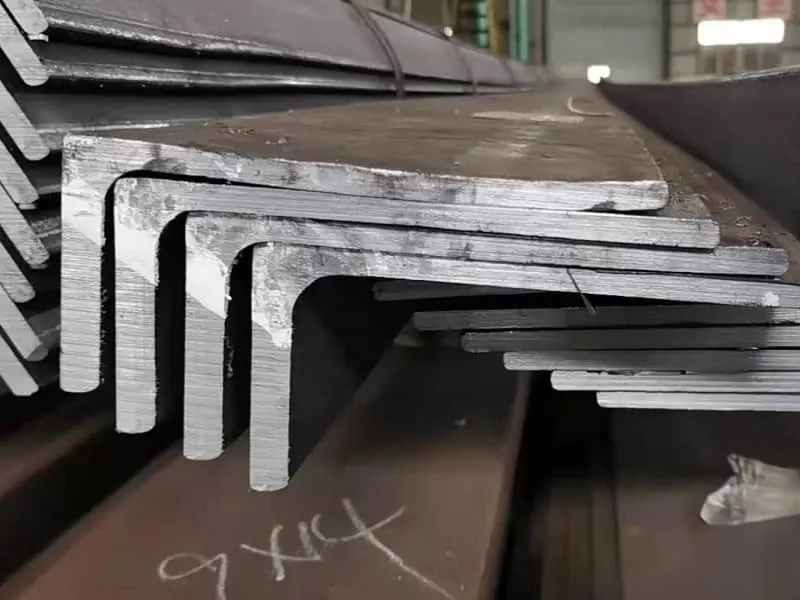

An L angle is a long steel profile with a cross-section shaped like the letter "L". It has two legs that meet at a 90-degree angle (with tolerance). It is a standard structural shape used for brackets, frames, bracing, and edges.

Decoding the L-Angle: Names, Sizes, and Uses

The term "L angle" is simple, but the world behind it is detailed. To use it correctly, you need to understand its naming conventions, how it’s made, and why it’s chosen for so many jobs.

First, let’s clear up the names. "Angle iron" is an older term from when these profiles were made of wrought iron. Today, they are made of steel, so "angle bar" or "steel angle" is more accurate. "L-section" or "L-profile" is the formal engineering term. In everyday site talk, all these terms are used interchangeably. When you talk to a supplier like us, using "L-angle" or "steel angle" is perfectly clear.

Second, you must know how to read the size. An L-angle is defined by three dimensions: the length of the first leg, the length of the second leg, and the thickness. They are usually written in this order: Leg x Leg x Thickness. For example, a 150x100x12mm L-angle has one leg 150mm long, the other leg 100mm long, and the material is 12mm thick. If both legs are equal, it’s an "equal leg angle" (e.g., 100x100x10mm). If the legs are different, it’s an "unequal leg angle". The thickness is always the same for both legs.

Third, the production process defines its characteristics. Most structural L-angles are hot-rolled. The steel is heated until it’s soft and then pushed through a series of rolls that shape it into the L-profile. This process creates a product with a slightly rounded inner heel. Some special L-angles can be cold-formed from sheet metal, but these are usually thinner and for lighter duty. For marine and heavy structural work, hot-rolled is the standard. The rolling process affects the internal grain structure, making the steel tougher.

Why is the L-angle so popular in marine steel? Its shape gives it good strength relative to its weight. It is very versatile. Look at any ship under construction, and you will see L-angles everywhere:

- Stiffeners: Attached to plates (decks, hull, bulkheads) to prevent them from buckling.

- Frames: The ribs of the ship’s hull are often made from large L-profiles.

- Brackets and Connections: Used to join beams, plates, and other members together.

- Edges and Trims: Provides a finished, strong edge on hatches and openings.

To summarize the key data about an L-angle, here is a typical information table:

| Characteristic | Description | Example (150x100x12mm) |

|---|---|---|

| Standard Designation | The shape code per standard. | L 150x100x12 (EN) or L6x4x1/2 (Imperial) |

| Leg Dimensions (A x B) | The outside lengths of the two legs. | A = 150 mm, B = 100 mm |

| Thickness (t) | The nominal thickness of the steel. | t = 12 mm |

| Cross-Sectional Area | The total area of the steel in the cross-section. | ~ 28.3 cm² (calculated) |

| Weight per Meter | The linear weight, critical for logistics and costing. | ~ 22.2 kg/m |

| Moment of Inertia (Ix, Iy) | Geometric properties that determine bending stiffness. | Different values for each axis. |

| Steel Grade | The material specification (e.g., A36, S355J2, AH36). | Defines yield strength, toughness, etc. |

| Surface Condition | As-rolled (black), blasted, primed, or galvanized. | Affects corrosion resistance and cost. |

When you order, you need to provide all these details: dimensions, grade, quantity, length, and any special requirements like testing or coating. A vague request like "we need some angle iron" leads to misunderstandings. Our clients, such as Gulf Metal Solutions, provide clear cut lists and grade specifications. This allows us to give an accurate price and confirm mill availability quickly. Understanding what "L angle" truly means is the first step in a successful procurement.

Conclusion

Ensuring straightness in L-shaped steel is a continuous process. It requires attention to mill standards, careful handling, and skilled fabrication and bracing techniques.

-

Explore this link to understand the various applications and benefits of L section steel in construction and manufacturing. ↩ ↩

-

Learn about angular tolerance to ensure precision in steel fabrication and its importance in structural integrity. ↩ ↩

-

Find out about the EN 10056-1 standard and its significance in ensuring quality in steel production. ↩ ↩ ↩

-

Explore the ASTM A6 standard to learn about its guidelines for steel manufacturing and quality assurance. ↩

-

Discover how the hot-rolling process impacts steel quality and the resulting tolerances in manufacturing. ↩

-

Learn how to effectively use a precision steel protractor for accurate angle measurements in steel fabrication. ↩

-

Understand the implications of welding gaps on structural integrity and how to avoid them. ↩

-

Discover the benefits of using a digital angle finder for precise angle measurements in construction projects. ↩