Your ship’s structural strength depends on bulb flats. You order a batch, but something feels wrong. The price is too good, the certificate looks odd. Fake or substandard bulb flats can cause hidden structural failure, risking the entire vessel.

Identifying fake marine bulb flat steel requires checking three key areas: verifying the authenticity of the classification certificate, inspecting the physical product for correct dimensions and markings, and performing material tests. A genuine product will have a traceable heat number, precise bulb profile, and a valid Mill Test Certificate from an approved mill.

I supply genuine certified bulb flats to shipbuilders worldwide. I’ve seen the damage that counterfeit products can cause. They often come from unauthorized workshops that copy the shape but not the metallurgy. Let me show you the clear, practical steps to protect your project from this costly and dangerous fraud.

How to spot fake stainless steel?

First, let’s clarify: marine bulb flats are typically made from high-strength low-alloy (HSLA) steel like AH36 or DH36, not stainless steel. But the methods for spotting fakes in stainless steel teach us important lessons about material verification that apply to all specialty steels.

Spotting fake stainless steel involves simple tests: a magnet will weakly stick to real austenitic stainless (like 304), checking for a lack of rust, and verifying the grade marking. For bulb flats, the principles are similar: check for correct material markings, verify certificates, and be wary of prices far below market average.

Applying Anti-Counterfeit Logic to Marine Structural Steel

The tricks used to fake stainless steel—wrong material, fake markings, forged paperwork—are the same for fake marine bulb flats. Understanding these tactics is your first defense.

Common Counterfeit Strategies and Detection Methods

Fraudsters target areas where buyers might cut corners or lack expertise.

| Fraud Tactic (for Stainless/Marine Steel) | How to Detect It | Application to Bulb Flat Verification |

|---|---|---|

| Material Substitution | Selling coated mild steel as stainless, or selling ordinary structural steel (like Q235) as marine-grade steel. | Spark Test or Spectrometer: A genuine AH36 bulb flat will have a specific chemical signature (low Carbon, specific alloys). A portable XRF gun can reveal if the chemistry matches the grade. |

| Fake or Copied Markings | Laser etching or painting fake grade marks (e.g., "304", "AH36") onto cheaper material. | Check Marking Method: Genuine mill marks are usually stamped (indented) or hot-rolled into the steel during production. Painted or etched marks that sit on the surface are suspicious. Verify the heat number is stamped, not just on a tag. |

| Forged or Altered Certificates | Providing photocopied, digitally altered, or completely fabricated Mill Test Certificates. | Certificate Forensics: Check for blurry logos, inconsistent fonts, and missing official stamps or surveyor signatures. Contact the mill or classification society directly to verify the certificate number and heat number. |

| "Too Good to Be True" Pricing | Luring buyers with a price 20-30% below reputable suppliers. | Market Awareness: Know the current market price for certified AH36/DH36 bulb flats. If a quote is drastically lower, it is a major red flag. The cost saving comes from skipping proper metallurgy and certification. |

The Professional Verification Protocol for Bulb Flats

For critical components, you need a systematic approach.

- Pre-Shipment Inspection (PSI): This is the most effective barrier. Hire a third-party inspection company like SGS, BV, or TÜV to inspect the material at the supplier’s warehouse or port. They will:

- Verify the certificate authenticity with the issuing mill/class.

- Check dimensions and tolerances against the order.

- Witness material testing (chemistry, mechanical) if required.

- Confirm proper marking and packaging.

- Material Testing Upon Receipt: Even with PSI, do a basic check when the goods arrive. Use a caliper to check the bulb’s key dimensions: flange width, web height, and bulb radius. Significant deviations indicate poor manufacturing control or a non-standard product.

- Chain of Custody: Buy from established suppliers with long-term relationships to certified mills. A supplier like us, who openly discusses mill partnerships and offers SGS support, has a transparent supply chain. A trader who is vague about their source is a risk.

The client feedback from Gulf Metal Solutions highlights this: "The product quality is stable." This stability comes from a non-negotiable commitment to genuine, certified material from known sources. For a results-driven buyer, stability is the antithesis of the risk posed by counterfeit products.

What are bulb flats used for?

Understanding the critical role of bulb flats helps explain why faking them is so dangerous. They are not just any steel bar; they are engineered components with a specific job in a ship’s skeleton.

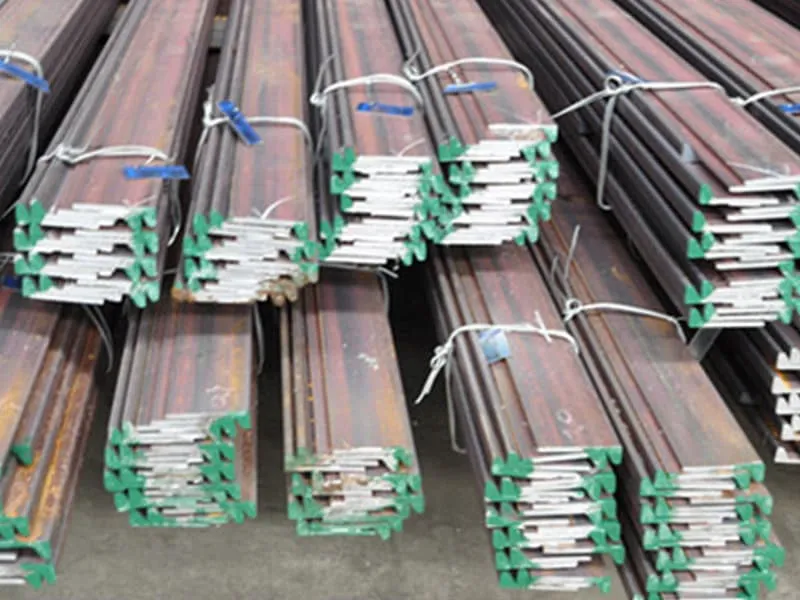

Bulb flats, also called bulb plates or shipbuilding flats, are specialized steel bars with a thickened, rounded edge (the bulb) along one side. They are primarily used as stiffeners in ship hull construction. The bulb adds significant strength and stiffness with minimal additional weight, making them ideal for supporting large steel plates.

The Engineering Behind the Bulb: Why Form Follows Function

The unique shape of a bulb flat is a result of naval architectural optimization. It solves a specific structural problem very efficiently.

Primary and Secondary Uses in Marine Structures

Their main use is well-defined, but they appear in various locations.

| Application Location | Function | Why Bulb Flats Are Chosen |

|---|---|---|

| Hull Longitudinal Stiffeners | Attached vertically to the inner side of the hull plating (bottom and sides) to resist bending and buckling from water pressure. | The bulb provides a high Section Modulus, meaning it resists bending very effectively. This allows for wider spacing of stiffeners, saving weight and labor. |

| Deck Longitudinal Stiffeners | Attached to the underside of deck plates to support cargo and equipment loads. | Same principle as hull stiffeners. Provides strength where the deck spans between major transverse frames. |

| Bulkhead Stiffeners | Used on watertight and non-tight bulkheads to prevent buckling under pressure (from water or cargo). | Provides necessary rigidity to large flat plate areas. |

| Other Marine Construction | Sometimes used in offshore platform jackets, large sea gates, and dock construction. | Wherever a strong, lightweight stiffener is needed for large steel panels. |

The Consequences of Using Fake Bulb Flats

If a fake bulb flat—made of weaker steel or with the wrong dimensions—is installed, the engineering calculations fail.

- Reduced Structural Strength: The fake component may not have the yield strength (355 MPa for AH36) or the toughness required. Under load, it could yield (bend permanently) or crack, especially in cold water.

- Buckling Failure: The primary job is to prevent the thin hull plate from buckling. A weak stiffener will allow the plate to deform, compromising watertight integrity and the hull’s hydrodynamic efficiency.

- Weld Failure: Fake steel often has improper chemistry, leading to poor weldability. Welds joining it to the hull plate could crack, creating points of structural failure and accelerated corrosion.

- Class Rejection: During construction or survey, if a surveyor discovers uncertified or non-conforming material, they will demand its replacement. This leads to catastrophic project delays and cost overruns as workers must cut out and replace the installed fakes.

When you specify "bulb flat," you are not just ordering a shape; you are ordering a performance guarantee. That guarantee is encoded in the grade (AH36/DH36) and validated by the classification certificate. A supplier who cannot provide that chain of assurance is not supplying a marine bulb flat; they are supplying a dangerous imitation.

What are the different types of flat steel?

"Flat steel" is a broad category. Bulb flats are one very specific type within it. Confusion arises when suppliers try to pass off a cheaper, more common type of flat steel (like a plain flat bar) as a bulb flat. Knowing the differences helps you identify misrepresentation.

The main types of flat steel relevant to construction are: Flat Bars1 (plain rectangular sections), Plates (wide and thick, cut to shape), Sheets/Coils (thin, for cladding or forming), and Special Sections2 like Bulb Flats3. Bulb flats are distinguished by their integral bulb, which plain flat bars do not have.

A Guide to Common Flat Steel Products

To avoid being tricked, you must recognize what you are not buying.

Comparison of Common "Flat" Products4

Each has distinct characteristics and uses.

| Type | Cross-Section Description | Typical Dimensions | Common Uses | How It Differs from a Bulb Flat |

|---|---|---|---|---|

| Flat Bar (or Bar Stock) | A simple solid rectangle. | Thickness: 3mm to 50mm. Width: 10mm to 300mm. | Brackets, framing, supports in general fabrication. Low-stress applications. | No bulb. It is symmetrical and has a much lower strength-to-weight ratio. Cheaper. |

| Steel Plate5 | A wide, flat sheet. It has no predefined "section" shape until cut. | Thickness: 3mm to 300mm+. Width: 1500mm+. | Hull plating, deck plates, pressure vessels. The primary plating of structures. | It is the surface that bulb flats stiffen. It is not a stiffener itself. |

| Bulb Flat | An asymmetric section with a flat flange and a rounded bulb along one edge. | Flange width: 80-400mm. Thickness: 6-30mm. Bulb size is proportional. | Primary and secondary stiffeners in ship and offshore structures. | Defined by the bulb. The bulb increases the section modulus dramatically compared to a flat bar of the same weight. |

The Substitution Scam: Flat Bar vs. Bulb Flat6

This is a common fraud. A dishonest supplier might offer "bulb flat" but deliver a simple flat bar.

- Why They Do It: A mild steel flat bar (like Q235) costs significantly less than a certified marine bulb flat (AH36). The profit margin for the fraudster is huge.

- How to Catch It: It’s visually obvious. A bulb flat has a distinct, rounded protrusion. A flat bar has sharp, 90-degree corners on all sides. Measure the section. If there’s no bulb, it’s not a bulb flat.

- Performance Gap: Even if the flat bar is made of AH36 steel (which is unlikely), its structural efficiency as a stiffener is far inferior. Using it would require many more pieces or much larger sizes to achieve the same strength, negating any weight savings and likely violating the ship’s design.

We supply both flat bars and bulb flats, for different purposes. We are precise in our naming because we know the consequences of mix-ups. A professional buyer should always request a cross-sectional drawing or profile sketch from the supplier to confirm the exact shape being quoted. This simple step eliminates one of the most basic forms of product fraud.

Which is better, CR or HR?

This question about Cold-Rolled (CR) vs. Hot-Rolled (HR) steel often comes up in fabrication. For marine bulb flats, the answer is definitive and helps rule out inappropriate products. Bulb flats are always hot-rolled. Any supplier offering "cold-rolled bulb flats" is either mistaken or misleading you.

For structural shapes like bulb flats, angles, and beams, Hot-Rolled (HR) is the only correct process. HR steel has better structural properties (toughness, ductility) for load-bearing applications. Cold-Rolled (CR) steel is for thin sheets and strips where precise dimensions and a smooth surface are prioritized, not for primary structural sections.

Understanding the Manufacturing Process and Its Impact

The rolling process fundamentally changes the steel’s properties. Using the wrong process creates a product unfit for marine service.

Hot-Rolled vs. Cold-Rolled: A Structural Perspective

Here’s why the process matters for a load-bearing component.

| Characteristic | Hot-Rolled (HR) Steel | Cold-Rolled (CR) Steel | Implication for Bulb Flats |

|---|---|---|---|

| Process | Steel is shaped at temperatures above its recrystallization point (over 1000°C). | Steel is shaped at room temperature, after initial hot-rolling. | Bulb flats require the high-temperature process to form the complex bulb shape and achieve the required grain structure. |

| Surface Finish | Has a rough, scaled surface (mill scale). | Has a smooth, shiny surface. | Marine bulb flats will have mill scale. They are blast-cleaned and painted before use. A shiny surface would be highly suspect. |

| Mechanical Properties | Softer, more ductile, with better toughness. It normalizes the steel’s structure. | Harder, stronger in yield (due to work hardening), but less ductile and with lower toughness. | Marine structures need toughness and ductility to absorb energy and deform without breaking. HR provides this; CR does not. |

| Internal Stresses | Generally low residual stress. | High internal residual stresses from the cold-working process. | High residual stresses can lead to distortion during welding and increase susceptibility to stress corrosion cracking. |

| Typical Products | Structural beams, angles, channels, plates, bulb flats. | Sheet metal, strips, automotive panels, appliances. | Bulb flats are structural sections, categorically HR products. |

Why "CR Bulb Flat" is a Red Flag

If a supplier uses this term, it reveals a lack of basic technical knowledge or an intent to deceive.

- Technical Impossibility: It is virtually impossible to cold-roll the thick, asymmetric bulb profile. The forces required would be enormous, and the material would crack. The bulb is formed in the hot state.

- Material Misrepresentation: They might be trying to sell you a cold-rolled flat bar (which exists) and calling it a "bulb flat." This goes back to the flat bar substitution scam.

- Wrong Material for the Job: Even if they somehow cold-formed a bulb-like shape, the material would have poor toughness and be completely unsuitable for a marine environment. It would be brittle and could fail catastrophically.

All certified marine bulb flats from legitimate mills are hot-rolled. The Mill Test Certificate will often state the delivery condition as "Hot Rolled" or "As Rolled." When you evaluate a supplier, their use of correct terminology is a quick litmus test for professionalism. We use precise language because our clients, like the engineers at Gulf Metal Solutions, expect and require it. There is no room for ambiguity when safety is at stake.

Conclusion

Protecting your project from fake bulb flats requires knowledge, vigilance, and reliable partners. Always verify certificates, inspect the physical product, and understand the correct specifications for marine-grade materials.

-

Explore this link to understand the various applications of Flat Bars in construction and their importance in structural integrity. ↩

-

Discover the different types of Special Sections in flat steel and their unique applications in various industries. ↩

-

Learn about the benefits of Bulb Flats in shipbuilding, including their structural efficiency and design advantages. ↩

-

This guide will help you understand how to effectively compare various flat steel products for your specific needs. ↩

-

This resource will clarify the distinctions between Steel Plates and Bulb Flats, helping you make informed decisions in your projects. ↩

-

Explore this link to learn about the Substitution Scam and how to avoid being misled by suppliers. ↩