Are you tired of receiving substandard marine angle steel that compromises your project’s integrity? The market is flooded with counterfeit products that look genuine but fail under real marine conditions. This guide will help you avoid costly mistakes.

Genuine marine angle steel must meet specific certification standards and exhibit precise physical characteristics. You can identify it through material certificates, surface quality checks, and specialized testing methods. Proper verification ensures the steel can withstand harsh marine environments without premature corrosion or structural failure.

As someone who has worked in marine steel distribution for years, I’ve seen how counterfeit materials can derail entire projects. The following sections break down the identification process into practical, actionable steps that even newcomers can follow. These methods have helped our clients from Saudi Arabia to Vietnam avoid costly procurement errors.

How to tell if it’s real stainless steel?

Many suppliers claim their steel is "marine-grade" when it’s actually regular stainless steel with inferior corrosion resistance. This deception leads to accelerated rusting and structural weaknesses in saltwater environments. Don’t fall for surface-level appearances alone.

Real marine-grade stainless steel1 contains specific alloy compositions that provide enhanced corrosion resistance. You can verify authenticity through spark testing2, magnet tests, and chemical analysis. Genuine marine steel maintains its integrity in saltwater conditions while imitations show rust within months.

Understanding Marine-Grade Stainless Steel Composition

Marine environments demand steel that can resist saltwater corrosion, which requires specific chemical compositions. Regular stainless steel might look similar but lacks the necessary alloying elements for long-term marine use.

The most reliable identification method involves understanding material grades. Marine angle steel typically comes in grades like 316/L or 2205 duplex stainless steel. These contain higher molybdenum content (2-3%) for improved pitting resistance compared to regular 304 stainless steel.

Key Identification Methods:

| Test Method | Genuine Marine Steel Results | Counterfeit Steel Results |

|---|---|---|

| Magnet Test | Slightly magnetic or non-magnetic | Strongly magnetic |

| Spark Test | Short, red sparks with few branches | Long, white sparks with many branches |

| Acid Test | Minimal reaction to nitric acid | Strong reaction with bubbling |

| Salt Spray Test | No rust after 24 hours | Visible rust within hours |

Surface inspection provides immediate clues. Genuine marine angle steel3 has uniform surface finishing without discoloration or mill scale. The edges should be clean-cut without burrs or unevenness. Look for consistent coloring – any rainbow-like patterns might indicate improper heat treatment.

Chemical verification remains the most accurate method. Reputable suppliers provide material test certificates that specify chemical composition. For marine applications, chromium content should be 16-18% and nickel 10-14% for austenitic grades. The presence of molybdenum (2-3%) is crucial for saltwater resistance.

Physical testing in actual conditions offers final confirmation. We recommend purchasing small samples first for testing in marine environments. Genuine marine steel will show no significant corrosion after 30 days of saltwater exposure, while inferior materials will exhibit pitting and surface rust.

How do I tell what type of steel I have?

Receiving the wrong steel type can compromise your entire marine project’s structural integrity. Many buyers discover the problem only after installation, when replacement costs become astronomical. Proper identification prevents these expensive mistakes.

You can identify steel type through visual inspection, spark testing1, and chemical analysis2. Each steel grade produces distinct spark patterns and reacts differently to various tests. Material certification from recognized authorities provides the most reliable verification of steel type and grade.

Comprehensive Steel Identification Techniques

Identifying steel type requires systematic approach combining multiple verification methods. Relying on just one method can lead to misidentification, especially with sophisticated counterfeits.

Start with visual examination. Marine angle steel has specific dimensional tolerances and surface characteristics. Genuine products have clean, sharp edges with consistent leg dimensions. The surface should be free from excessive scaling, pits, or cracks. Look for permanent branding or stenciling that indicates manufacturer and grade.

Steel Grade Identification Matrix:

| Steel Grade | Spark Color | Spark Pattern | Magnetic Response | Common Marine Applications |

|---|---|---|---|---|

| 316/L Stainless | Red | Short, few branches | Weakly magnetic | Hull structures, deck fittings |

| 2205 Duplex | Dark red | Medium length, bushy | Magnetic | Offshore platforms, shipbuilding |

| AH36 Shipbuilding | White | Long streams, many forks | Strongly magnetic | Ship hulls, marine structures |

| Corten Steel | Yellow | Long, spreading | Magnetic | Coastal architecture, containers |

Spark testing provides immediate field identification. When grinding the steel, observe the spark color, length, and pattern. High-carbon steels produce bright white sparks with many branches, while stainless steels create darker red sparks with fewer branches. Marine-grade steels typically show specific patterns that experienced technicians can recognize.

Chemical spot testing offers another verification layer. Simple test kits can detect approximate chromium, nickel, and molybdenum content. For example, marine-grade stainless steel will show high chromium and molybdenum levels, while ordinary steel won’t. These tests are particularly useful for distinguishing between similar-looking grades.

Certification documentation remains crucial. Genuine marine steel comes with complete paperwork including mill test certificates, chemical composition reports, and mechanical property documentation. Verify these documents against the actual material batch numbers. Reputable suppliers like us provide full traceability from mill to customer.

Hardness and strength testing completes the identification process. Marine steels have specific hardness ranges and yield strengths. Simple field tests can approximate these properties, though laboratory testing provides definitive results. For critical applications, we always recommend third-party verification through organizations like SGS.

What does angle steel look like?

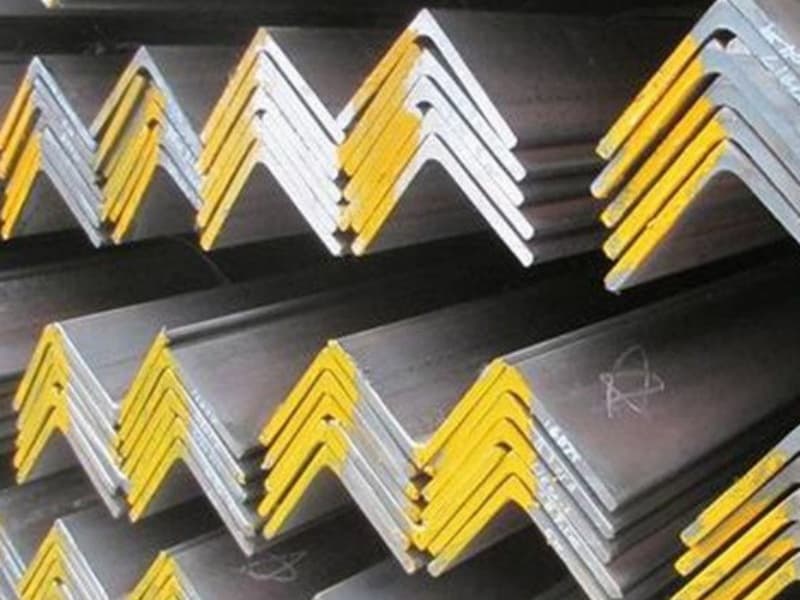

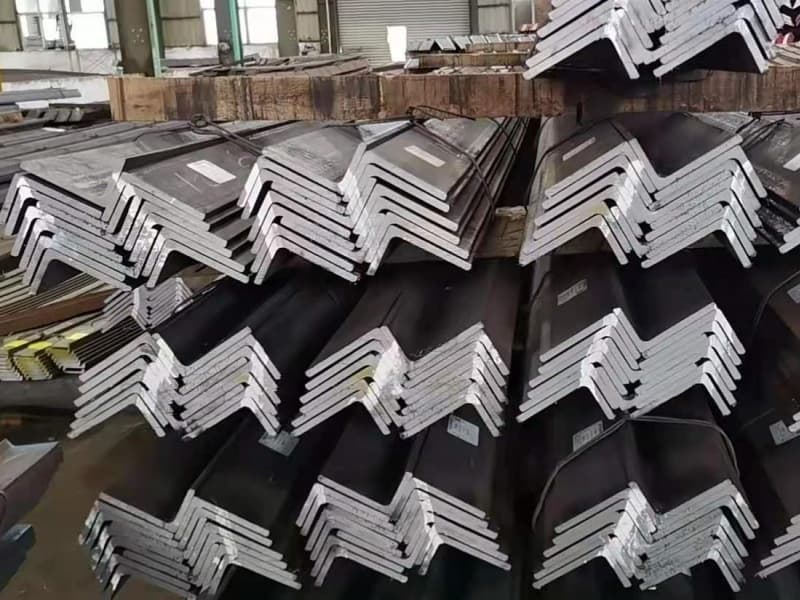

Many first-time buyers struggle to distinguish marine angle steel1 from regular construction angle steel. The visual differences might seem subtle, but they significantly impact performance in marine environments. Learning these visual cues prevents purchasing mistakes.

Marine angle steel features clean, sharp edges with uniform dimensions and specialized surface treatments. It typically has protective coatings2 or specific finishes that distinguish it from ordinary angle steel. The steel shows consistent coloration without rust spots or discoloration, even after exposure to marine conditions.

Visual Characteristics of Authentic Marine Angle Steel

Understanding the visual markers of genuine marine angle steel1 helps buyers make informed decisions quickly. These characteristics develop during proper manufacturing and processing specifically for marine applications.

Examine the edge quality first. Marine angle steel has precisely cut edges without rolling burrs or unevenness. The corner radius should be consistent throughout the length, indicating proper rolling mill calibration. Imperfect edges suggest inferior manufacturing processes unsuitable for marine use.

Surface finish provides crucial visual clues. Authentic marine angle steel1 exhibits uniform surface texture without scale, pits, or irregularities. The surface might have specific treatments like pickling, passivation, or specialized coatings that protect against saltwater corrosion. These treatments create distinctive visual appearances that differ from regular steel.

Visual Identification Checklist:

| Feature | Genuine Marine Angle Steel | Regular Angle Steel |

|---|---|---|

| Surface Quality | Uniform, clean, no scale | Variable, often with mill scale |

| Edge Condition | Sharp, clean, consistent radius | Often burred, inconsistent |

| Coating | Specialized marine coatings | Basic or no coating |

| Markings | Clear grade identification | Often unmarked or generic |

| Color | Uniform, no discoloration | Often discolored or rusty |

Dimensional consistency indicates manufacturing quality. Marine angle steel maintains tight dimensional tolerances with consistent leg lengths and thicknesses. Measure multiple points along the length – variations beyond standard tolerances suggest inferior production standards. Genuine products also show straightness without twisting or camber.

Protective elements offer visual verification. Marine angle steel often features specialized coatings or treatments visible under close inspection. Galvanized marine steel shows uniform zinc coating without runs or bare spots. Stainless marine steel displays specific surface finish3es (2B, No. 4, or BA) that provide both corrosion resistance and identifiable appearance.

Markings and branding provide authentication evidence. Reputable manufacturers permanently mark their marine steel with grade identification, manufacturer logo, and production batch. These markings should be clear, consistent, and match accompanying documentation. Absence of proper marking often indicates non-marine quality steel.

How to know original steel?

The original steel market suffers from sophisticated counterfeiting that even experienced buyers can miss. Fake documentation, surface treatments that mimic genuine products, and relabeled inferior steel create significant risks for marine projects. Proper verification protects your investment.

Original marine steel comes with complete traceability and certification from recognized mills. You can verify authenticity through documentation checks, physical testing, and supplier verification. Original steel maintains consistent properties and performance that counterfeit products cannot match.

Verification Methods for Original Marine Steel

Ensuring steel originality requires multiple verification approaches1 that address both documentation and physical properties. Single-method verification often fails to detect sophisticated counterfeits.

Begin with documentation verification. Original marine steel comes with complete certification packages including mill test certificates, chemical analysis reports, and mechanical property documentation. Verify these documents against the actual material using batch numbers and heat codes. Contact the original mill if possible to confirm authenticity.

Originality Verification Protocol:

| Verification Method | Original Steel Indicators | Counterfeit Indicators |

|---|---|---|

| Documentation | Complete MTC with mill stamps | Incomplete or generic certificates |

| Physical Marking | Clear, permanent mill markings | Faint, inconsistent, or missing markings |

| Third-Party Verification | Passes SGS/BV inspection | Fails independent testing |

| Supplier Reputation | Established track record | New or unknown supplier |

| Price | Market-appropriate | Significantly below market |

Physical marking inspection provides immediate evidence. Original steel bears permanent markings from the production mill, including heat numbers, grade identification, and manufacturer logos. These markings should be consistent, clear, and match the documentation. Counterfeit products often have poorly applied or inconsistent markings.

Third-party verification offers independent confirmation. Organizations like SGS, Bureau Veritas, or DNV provide material verification services that confirm composition, properties, and origin. For critical applications, we always recommend independent inspection before shipment. This protects both buyer and supplier against authenticity disputes.

Supplier evaluation completes the verification process. Original steel comes through established supply chains with transparent sourcing. Evaluate the supplier’s relationship with steel mills, their inspection capabilities, and their industry reputation. Genuine suppliers provide full transparency about material origin and processing history.

Performance testing under marine conditions provides final confirmation. Original marine steel maintains its properties in saltwater exposure tests, showing minimal corrosion and no significant property degradation. Conduct accelerated testing or request historical performance data from the supplier to verify long-term durability.

Conclusion

Identifying genuine marine angle steel requires multiple verification methods and careful supplier selection. Proper identification protects your projects and ensures long-term performance in demanding marine environments.

-

This resource will provide insights into various methods to verify the authenticity of steel, crucial for your investment. ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the various protective coatings that enhance the durability of marine angle steel against corrosion and wear. ↩ ↩ ↩

-

Learn about the importance of surface finish in marine angle steel and how it affects performance in harsh environments. ↩ ↩