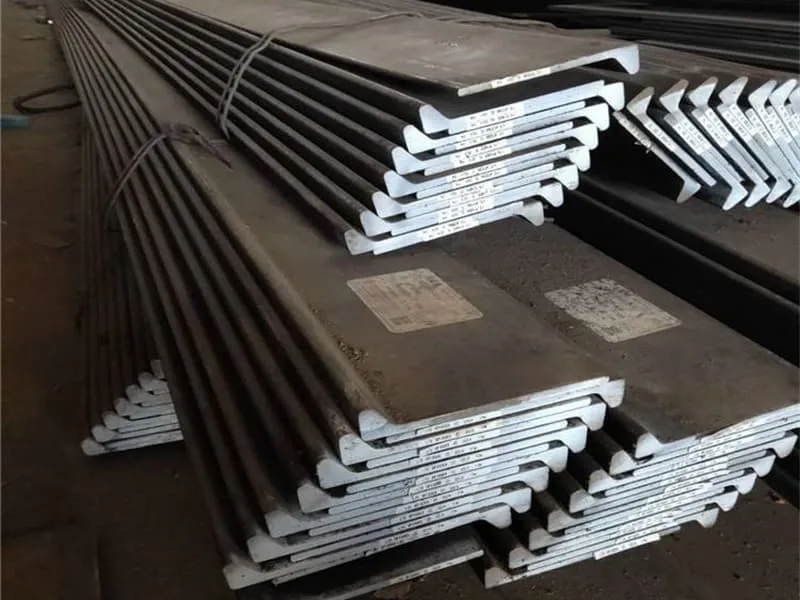

A shipyard in Saudi Arabia struggled with their first bulb flat steel import from China. Their experience revealed common pitfalls in the import process.

Importing bulb flat steel from China involves supplier verification, price negotiation, quality inspection arrangement, shipping coordination, and customs clearance. The process typically takes 30-45 days from order to delivery, requiring proper documentation and understanding of international trade procedures for successful procurement.

Navigating the import process can be challenging. Let me guide you through each step to ensure successful procurement of quality bulb flat steel.

How to import from China step by step?

A first-time importer from Mexico found the process overwhelming. Breaking it into clear steps made their procurement successful.

Importing from China involves finding verified suppliers, requesting quotations, negotiating terms, arranging quality inspection, organizing shipping logistics, handling customs clearance, and final delivery. Each step requires specific documentation and coordination between multiple parties to ensure smooth transaction completion.

Comprehensive Import Process Breakdown

The import process follows a logical sequence that ensures both quality assurance and legal compliance. Understanding each step prevents costly mistakes.

Supplier Identification and Verification1

Start by researching potential suppliers through reliable channels. Check supplier credentials and manufacturing capabilities. Verify business licenses and export experience. Contact multiple suppliers to compare offerings. Request references from previous international clients. This due diligence ensures you work with reputable partners.

Product Specification and Quotation

Provide detailed technical specifications to suppliers. Include grade requirements, dimensions, tolerances, and certifications. Request formal quotations with breakdown of all costs. Compare offers based on price, quality, and service terms. Clarify any unclear points before proceeding. Detailed specifications prevent misunderstandings later.

Quality Assurance Planning2

Arrange third-party inspection before shipment. Specify inspection standards and acceptance criteria. Agree on testing methods and sampling plans. Confirm certification requirements for marine applications. Plan for potential quality disputes resolution. Quality assurance protects your investment.

Shipping and Logistics Coordination3

Choose between sea freight and air freight options. Sea freight is cost-effective for large steel shipments. Select reliable freight forwarders with steel experience. Arrange cargo insurance for full protection. Coordinate loading and documentation procedures. Proper logistics ensure timely delivery.

Payment and Documentation4

Agree on secure payment terms with suppliers. Letters of credit provide payment security. Prepare all required import documents in advance. Ensure compliance with both Chinese export and your country’s import regulations. Keep copies of all transaction records. Proper documentation prevents customs delays.

Customs Clearance and Delivery5

Work with customs brokers in your country. Provide complete documentation for clearance. Pay applicable duties and taxes. Arrange final transportation from port to site. Conduct final inspection upon receipt. Smooth clearance ensures project timelines.

| Step | Duration | Key Activities | Critical Documents |

|---|---|---|---|

| Supplier Selection | 5-7 days | Research, verification | Business licenses |

| Quotation | 3-5 days | Specification, negotiation | Proforma invoice |

| Production | 15-20 days | Manufacturing, testing | Mill certificates |

| Shipping | 10-15 days | Booking, loading | Bill of lading |

| Customs | 3-7 days | Clearance, payment | Import declaration |

We guide clients through this process regularly. Our experience helps importers in Philippines and Vietnam avoid common mistakes.

Do I need a permit to import from China?

A contractor from Qatar was surprised by import permit requirements. Understanding regulations prevented shipment delays.

Import permit requirements vary by country and product type. Most countries require general import licenses, while specific products like steel may need additional certifications. Always check with your local customs authority about steel import regulations, quality standards, and any restricted materials before placing orders.

Import Permit and Regulation Analysis

Import regulations protect national interests and ensure product safety. Understanding these requirements is crucial for successful steel imports.

General Import License Requirements

Most countries require basic import registration. Businesses need importer identification numbers. Some countries mandate specific import licenses for steel products. The requirements vary based on import value and frequency. Individual importers may have different rules than companies. Check with your national trade authority.

Product-Specific Certifications

Steel imports often need additional certifications. Quality certificates must meet national standards. Some countries require proof of origin documentation. Environmental compliance certificates may be necessary. Safety standards certification ensures material suitability. These certifications demonstrate product quality.

Customs Documentation Requirements

Proper documentation is essential for clearance. Commercial invoices must detail the transaction. Packing lists describe the shipment contents. Certificates of origin confirm manufacturing location. Bill of lading serves as title document. Missing documents cause customs delays.

Quality and Standards Compliance

Imported steel must meet national standards. Chemical composition requirements may differ by country. Mechanical properties must match local specifications. Testing methods should follow accepted standards. Certification from recognized bodies facilitates approval. Compliance ensures material acceptance.

Restricted and Prohibited Materials

Some steel products face import restrictions. Countries may impose anti-dumping duties on certain steel types. Environmental regulations restrict some coating materials. Security concerns may affect specific steel grades. Always verify if your product falls under restrictions. Compliance avoids legal issues.

Country-Specific Considerations

Import rules vary significantly by destination. Middle Eastern countries often have strict quality requirements. Southeast Asian nations may have different certification needs. European countries follow EU-wide regulations. American countries have their own standards. Research your specific market requirements.

Common Import Documentation

| Document | Purpose | Issued By | Importance |

|---|---|---|---|

| Commercial Invoice | Value declaration | Supplier | Customs valuation |

| Packing List | Content description | Supplier | Cargo verification |

| Certificate of Origin | Manufacturing location | Chamber of Commerce | Duty determination |

| Bill of Lading | Title document | Shipping company | Cargo release |

| Insurance Certificate | Risk coverage | Insurance company | Claim processing |

We help clients understand their specific import requirements. Our experience with different markets ensures smooth customs clearance.

How to import LED light from China?

While this question focuses on LED lights, the import principles apply to steel products too. The fundamental processes share many similarities.

LED light import process involves supplier qualification, sample testing, quality control planning, shipping arrangement, and customs clearance. Although different from steel products, the core import steps remain similar – verification, quality assurance, logistics, and compliance form the foundation of successful importing from China.

Cross-Industry Import Principles

While product specifics differ, successful importing follows universal principles that apply across different commodities from China.

Supplier Verification Fundamentals

All imports require supplier due diligence. Verify manufacturer credentials and production capabilities. Check business history and export experience. Assess quality management systems. Confirm compliance with international standards. These checks apply whether importing steel or consumer goods.

Quality Control Essentials

Quality assurance follows similar patterns. Define clear specifications and standards. Arrange pre-shipment inspection. Use third-party verification services. Establish acceptance criteria and testing methods. Quality control principles transfer across product categories.

Shipping and Logistics Commonality

Logistics management shares basic elements. Choose appropriate transportation methods. Arrange cargo insurance coverage. Handle documentation requirements. Coordinate with freight forwarders. Manage delivery timelines. These logistics fundamentals apply universally.

Payment Security Considerations

Secure payment methods work across products. Letters of credit provide protection. Escrow services offer alternatives. Payment terms negotiation follows similar principles. Currency exchange considerations apply. Payment security is crucial for all imports.

Customs Compliance Basics

Customs procedures share common requirements. Accurate product classification is essential. Proper valuation declaration matters. Documentation completeness ensures smooth clearance. Duty and tax calculations follow similar principles. Compliance knowledge transfers between products.

Key Import Process Similarities

| Process Element | Steel Import Application | LED Import Application | Common Principles |

|---|---|---|---|

| Supplier Check | Mill verification | Factory audit | Due diligence |

| Quality Control | Material testing | Product testing | Standards compliance |

| Shipping | Bulk sea freight | Container shipment | Logistics management |

| Payment | Letter of credit | Same payment methods | Financial security |

| Customs | HS code classification | Different HS codes | Documentation accuracy |

Understanding these common principles helps importers navigate different product categories. Our clients appreciate this cross-industry knowledge.

Why is Chinese steel so cheap?

A shipowner from Saudi Arabia questioned Chinese steel pricing. Understanding the cost structure helped them make informed decisions.

Chinese steel offers competitive pricing due to large-scale production, government support, lower labor costs, efficient supply chains, and modern manufacturing technology. However, quality variations exist, making supplier selection crucial for obtaining the right balance between cost and performance for marine applications.

Chinese Steel Competitive Analysis

Chinese steel’s price advantage comes from multiple factors that create cost efficiencies throughout the production and supply chain.

Production Scale Advantages

Chinese steel mills operate at massive scales. Large production volumes reduce per-unit costs. Continuous operation maximizes equipment utilization. Bulk raw material purchasing lowers input costs. The scale advantage is difficult for smaller producers to match. This efficiency translates to competitive pricing.

Government Policy Support

The steel industry receives various forms of support. Energy subsidies reduce production costs. Tax incentives encourage export activities. Infrastructure support lowers transportation expenses. Research funding promotes technological advancement. These policies contribute to price competitiveness.

Labor Cost Structure

Labor costs in China remain competitive. Skilled workers are available at reasonable rates. Technical education produces qualified workforce. Manufacturing expertise has developed over decades. The labor cost advantage persists despite recent increases. This affects final product pricing.

Supply Chain Efficiency

Integrated supply chains reduce costs. Raw material access is well-established. Transportation networks are highly developed. Port facilities handle large volumes efficiently. The entire supply chain is optimized for export. These efficiencies benefit international buyers.

Manufacturing Technology

Modern mills use advanced technology. Automated processes increase productivity. Energy-efficient equipment reduces operating costs. Quality control systems minimize waste. Continuous improvement maintains competitiveness. Technology investment pays off in lower costs.

Quality and Price Relationship

Price variations reflect quality differences. Standard grades offer the lowest prices. Marine grades command moderate premiums. Specialized products have higher costs. Understanding this relationship helps buyers select appropriately. The right quality level matches application requirements.

Chinese Steel Cost Components

| Cost Factor | Chinese Advantage | Impact on Price | Quality Consideration |

|---|---|---|---|

| Raw Materials | Domestic availability | Lower input costs | Consistency important |

| Labor | Competitive wages | Reduced manufacturing cost | Skill level varies |

| Energy | Subsidized rates | Lower production cost | Environmental compliance |

| Scale | Massive production | Economies of scale | Quality control challenge |

| Technology | Modern equipment | Higher efficiency | Requires maintenance |

We help clients understand these cost dynamics. Buyers in Thailand and Malaysia make informed decisions based on this knowledge.

Conclusion

Successful bulb flat steel import from China requires understanding both the process and market dynamics. Proper planning ensures quality materials at competitive prices with reliable delivery.

-

Understanding supplier verification is crucial to avoid scams and ensure quality products. ↩

-

Quality assurance is vital for protecting your investment and ensuring product standards. ↩

-

Effective logistics coordination is essential for timely delivery and cost management. ↩

-

Proper payment and documentation practices prevent customs delays and financial losses. ↩

-

Understanding customs processes ensures smooth clearance and adherence to regulations. ↩

-

Knowing the timeline helps in planning and managing expectations for your import project. ↩