Misreading a steel drawing can cost you thousands in wrong material. As a supplier, I see clients struggle with confusing symbols and terms. This confusion leads to wrong orders and project delays.

To read L-shaped steel drawings, first identify the "L" symbol or callout for an angle section. Then, read the specification, which is usually in the format "L Leg1 x Leg2 x Thickness" (e.g., L 100x100x10). Understand if it’s an equal or unequal angle. Finally, check the material grade and standard (e.g., AH36 per LR) in the notes or bill of materials to ensure it’s suitable for marine use.

Understanding drawings is about decoding a universal language. Let’s start with the most basic symbol: the letter "L" itself.

What is L in steel?

On a drawing, "L" is not just a letter. It is a specific symbol with a precise meaning. Ignoring its context is the first step to a major ordering mistake.

In steel drawings and specifications, "L" is the standard abbreviation or symbol for an angle section, specifically an L-shaped steel bar. It is used as a prefix in callouts like "L 150x100x12" to immediately tell the reader that the part is made from angle iron, not a flat bar, channel, or beam.

The "L" as a Technical Designator

The use of "L" is a convention in engineering and architectural drafting. It acts as a quick visual and textual cue. We need to understand where it appears and what information follows it.

1. Where You Will Find the "L" Symbol

- On Drawings (Plans & Elevations): The cross-section of an angle might be drawn with a small "L" next to it, or a leader line might point to the member with the callout "L 80x80x8".

- In Section Views: When a part is cut through, the "L" shape will be visible, and dimensions will be placed on it.

- In Schedules or Bills of Materials (BOM): This is the most common and important place. The BOM is a table that lists every piece of steel needed. The "Member" or "Section" column will have entries like "L 100x100x10", "L 150x75x9", etc.

- In Written Specifications: The technical document accompanying drawings will state something like: "All structural angles shall be L 75x75x6 unless otherwise noted."

2. What Follows the "L" – The Critical Numbers

The "L" is always followed by numbers. These numbers define the physical size.

- Format: L [Leg Length 1] x [Leg Length 2] x [Thickness]

- Example: L 120 x 80 x 10

- The "L" means it is an angle.

- "120" is the length of the first leg (120 mm).

- "80" is the length of the second leg (80 mm).

- "10" is the thickness of the steel (10 mm).

- Equal Angles: If the legs are the same, it may be written as L 90 x 90 x 8 or sometimes abbreviated as L 90 x 8.

3. Distinguishing "L" from Other Section Symbols

A drawing uses different letters for different profiles. Confusing them is a serious error.

- L: Angle (L-Shaped).

- PL or ⬜: Plate (Flat, rectangular).

- FB: Flat Bar (Thinner, narrower than a plate).

- C or UPE: Channel (U-shaped).

- I or W: I-beam or Wide Flange Beam.

- HP or BF: Bulb Flat (has a bulb on one edge).

Here is a table of common drawing callouts:

| Drawing Callout | What It Means | Key Identifying Feature |

|---|---|---|

| L 150x100x12 | Unequal angle, legs 150mm & 100mm, 12mm thick. | The "L" prefix and three dimensions. |

| PL 15 x 200 | Plate, 15mm thick, 200mm wide. | "PL" prefix, usually only two dimensions (thickness & width). |

| C 200×75 | Channel, 200mm deep, 75mm flange width. | "C" prefix, two main dimensions. |

| FB 50×10 | Flat Bar, 50mm wide, 10mm thick. | "FB" prefix, two dimensions. |

| I 300 | I-beam, 300mm depth (standard series). | "I" prefix, one main dimension (depth). |

When our sales team receives a drawing from a client, the first thing we do is locate the BOM or the callouts. Finding the "L" entries tells us immediately what angle sizes are needed. This is how we quickly provide a preliminary quote. For a busy project manager, being able to point to the "L 120x80x10" on the drawing and say "this is what I need" makes the entire procurement process fast and accurate.

What is L-shaped steel called?

You have found the "L" on the drawing. Now you need to communicate with suppliers and fabricators using the correct industry names. Using vague or local slang can slow down the process.

L-shaped steel is most accurately and professionally called "steel angle" or "angle bar." Other common names include "angle iron," "L-section," and "L-bar." In technical specifications and purchase orders, the terms "equal angle" or "unequal angle" are used to specify the exact type based on leg dimensions.

The Vocabulary of Angles: From the Workshop to the Mill Certificate

Different names are used in different contexts. Knowing which term to use with whom prevents misunderstandings in global trade.

1. Formal and Technical Names

These names appear on official documents. They are precise and unambiguous.

- Steel Angle: This is the universal technical term. It is understood by engineers, draftsmen, and mills worldwide. It is the best term to use in written communication.

- Angle Bar: This is a very common term in international trade, especially in Asia and the Middle East. It is perfectly acceptable and clear.

- Rolled Steel Equal/Unequal Leg Angle: This is the full, formal description found in material standards like EN 10056-1 or ASTM A6. It describes the manufacturing process (rolled) and the geometry.

2. Common Informal and Workshop Names

These terms are used on site and in everyday conversation. They are useful to know but can be less precise.

- Angle Iron: A historical term from when sections were made of wrought iron. It is still widely used, especially in construction and fabrication shops. When used, it implicitly means "steel angle iron."

- L-Bar or L-Section: Descriptive terms focusing on the shape. They are common in Europe and in technical discussions.

3. The Importance in Specifications and Ordering

When you translate a drawing callout into a purchase order, you must use clear terminology.

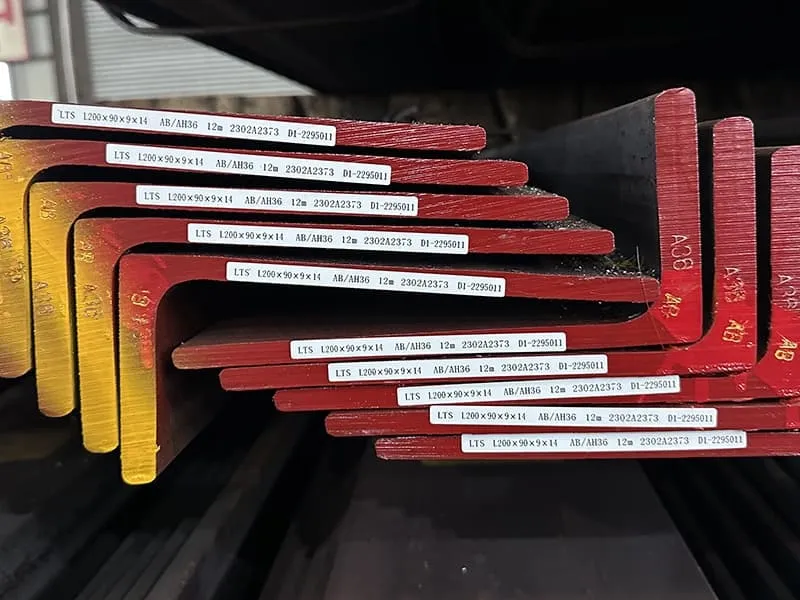

- From Drawing to PO: The drawing says

L 150x100x12. - Good PO Description:

Steel Angle, Unequal, 150mm x 100mm x 12mm, Grade S355JR. - Also Good:

Angle Bar, L 150x100x12, Material Grade AH36 per LR. - Vague (Avoid):

L-iron, size 150/100/12.

4. Regional Variations and Clarifications

- Our client in Saudi Arabia used the term "ship L-shaped steel." This is excellent because it adds context (marine use).

- The term "spherical flat steel" in their feedback is likely a translation for bulb flat steel, a different profile. This highlights why sticking to "angle bar" or "L-angle" is safer.

Here is a guide on what to call it and when:

| Context (Who you are talking to) | Best Term to Use | Why It Works |

|---|---|---|

| Engineer or Designer | Steel Angle, L-Section. | Technically precise language they use daily. |

| International Supplier (Us) | Angle Bar, Steel Angle, L-shaped Steel. | Clear, standard trade terms we see in 90% of inquiries. |

| Workshop Foreman | Angle Iron, Angle. | The language of the workshop; they will understand immediately. |

| Purchase Order / Formal Email | Steel Angle Bar (Unequal/Equal). | Formal, clear, and leaves no room for interpretation. |

| Online Search | "marine angle bar", "shipbuilding steel angle". | Adds context to find specialized suppliers like us, not general hardware stores. |

When you email sales@cnsteelsupplier.com, using "Angle Bar" or "Marine L-Angle" in your subject line helps us route your inquiry to the right specialist. It tells us you are not looking for decorative trim but for structural marine components. This shared vocabulary is the foundation of the clear communication that our clients, like the results-driven manager at Gulf Metal Solutions, value so highly.

What is L-angle steel?

"L-angle steel" is the full, descriptive name. It combines the shape ("L") with the product type ("angle steel"). Understanding this term confirms you are looking at the right item on a material list or in a catalog.

L-angle steel is simply another name for steel angle or angle bar. The term explicitly describes its shape: an "L" formed by two legs at a 90-degree angle. "L-angle" is often used in catalogues, supplier websites, and informal specifications to distinguish it from other angle types (like bulb angles, which are different) and to emphasize its geometric form.

L-Angle Steel in the Family of Rolled Sections

Calling it "L-angle steel" places it within a broader category. It helps differentiate it from similar but distinct products.

1. Defining Characteristics of L-Angle Steel

The name tells you three things:

- Material: It is made of steel.

- Shape: It has an L cross-section.

- Product Type: It is an angle (a standard structural shape).

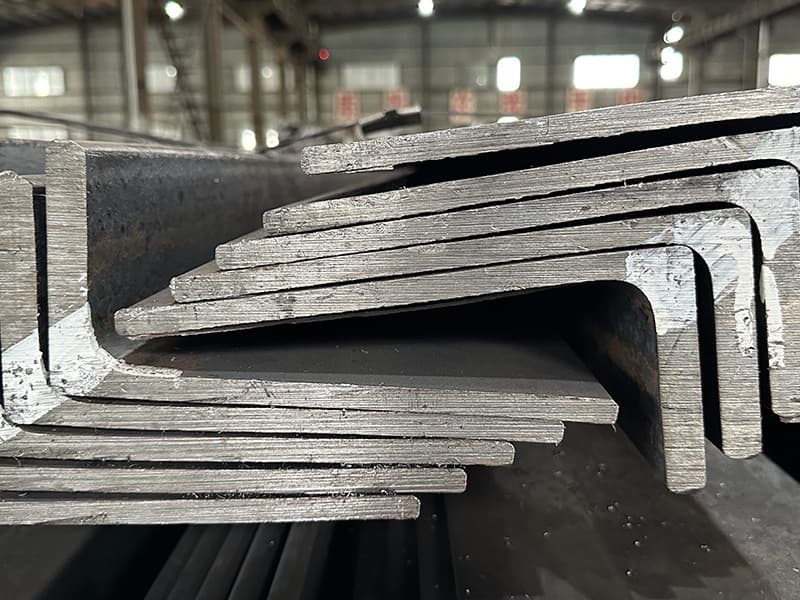

It is produced by hot-rolling a steel billet through a series of shaped rollers. The final product has a consistent cross-section along its length.

2. L-Angle vs. Other "Angle" Products

Not all angles are simple L-angles. This is a key point of confusion.

- L-Angle (Standard Angle): This is the classic, 90-degree angle with two straight legs. It is the subject of this article.

- Bulb Angle: This is a special profile. It looks like an L-angle, but one leg has a rounded, thickened edge (a bulb) at the tip. It is less common and used for specific, high-stiffness applications. It is not what is typically meant by "L-angle."

- Unequal Angle: This is still an L-angle. The term "L-angle" covers both equal and unequal leg versions. "Unequal" just describes the proportions.

3. How It Appears in Technical Documentation

You might see it written in several ways, all meaning the same thing:

- "L-angle steel, 100x100x8"

- "L 100x100x8 angle"

- "Steel angle (L) 100x100x8"

The parenthesis around the L is common. It means "in the shape of an L".

4. The Practical Implication for Buyers

When a fabricator asks for "L-angle," they expect the standard, hot-rolled section. They do not expect a bulb angle or a cold-formed piece of sheet metal bent into an L-shape. The term implies a standard, structural-grade product.

To visualize the specifics, here is a breakdown of what defines an L-angle steel section:

| Characteristic | Description for L-Angle Steel | Note/Exception |

|---|---|---|

| Leg Length (A, B) | The long sides of the "L". Can be equal (A=B) or unequal (A≠B). | Always measured in mm. |

| Thickness (t) | The thickness of the steel for both legs. | Uniform across the section (except at the root radius). |

| Root Radius (r1) | The inner curve where the two legs meet. | Defined by the rolling standard; not a sharp corner. |

| Toe Radius (r2) | The small curve on the outer tips of the legs. | Usually very small. |

| Standard Length | Typically 6m, 9m, 12m, or as per mill practice. | Can be ordered "cut to length." |

| Surface | Hot-rolled, with mill scale. | Can be shot-blasted or primed if specified. |

For a project contractor, knowing that "L-angle steel" refers to this specific hot-rolled product is crucial. It affects cost, lead time, and mechanical properties. If you request a quote for "L-angle steel," we will assume you need standard structural angles from our mill partners. We will not quote for light-gauge bent sheet metal. This clarity in terminology ensures the material delivered to your port is exactly what your structural design requires.

What does l angle mean?

Finally, "L angle1" is the most condensed term. It is essentially shorthand. But in engineering and procurement, shorthand must be perfectly understood, or it leads to errors.

"L angle1" is a common abbreviation for "L-shaped angle2." It means exactly the same as "steel angle3" or "angle bar4." The "L" describes the shape, and "angle" confirms it is a rolled structural section. On quick notes, sketches, or in conversation, "L angle1" is a perfectly acceptable way to refer to this product.

The Utility and Limits of the "L Angle" Abbreviation

This term is useful in fast-paced environments but requires a shared baseline of understanding. Let’s explore its proper use and potential pitfalls.

1. Where "L Angle" is Used Effectively

- Verbal Communication: On a noisy job site or during a phone call, saying "We need more 100 by 100 L angle1" is quick and clear.

- Internal Notes: In a foreman’s notebook or on a material take-off list, writing "L angle1, 150x75x10" is efficient.

- Informal Emails: When communicating with a known contact who understands the context, the subject line "Quote for L angle1" might be sufficient.

2. Where "L Angle" Can Be Ambiguous or Insufficient

The term is too vague for formal procurement. It lacks critical specifics.

- Missing Material Grade: "L angle1" does not tell you if it’s mild steel (S235), high-strength (S355), or marine-grade5 (AH36).

- Missing Standard: It doesn’t specify if it needs to meet ASTM6, EN, JIS, or a ship classification society rule.

- Potential for Confusion: In some contexts, "angle" alone could be misinterpreted as an angular measurement (e.g., a 45-degree angle) rather than a steel product.

3. From Informal Term to Formal Order

The journey from a sketch to a delivered product must clarify the abbreviation.

- The drawing has a symbol and the callout

L 80x80x8. - The site foreman writes on a list: "L angle1, 80x80x8, for handrails."

- The procurement manager writes the inquiry: "Please quote for Steel Angle Bar, equal, size 80x80x8mm, Quantity 500m, Grade S275JR."

- Our formal quote reads: "Item: Rolled Steel Equal Angle. Size: 80mm x 80mm x 8mm. Standard: EN 10056-1. Grade: S275JR. …"

4. The Role of Context

The term "L angle1" is safe when both parties have established context. For example, after we have been supplying AH36 ship plates to a client, and they email "next we need L angle1 for frames," we understand they likely need marine-grade5 angles. But for a first inquiry with a new supplier, more detail is essential.

Here is how "L angle1" fits into the communication spectrum:

| Communication Level | Typical Phrase | Is It Enough? | What’s Missing for an Order |

|---|---|---|---|

| Site Sketch / Verbal | "Get L angle1, 100×100." | No. | Thickness, grade, length, quantity, standard. |

| Internal Material List | "L angle1, 150x100x12, Qty: 1T" | Better, but not for supplier. | Material standard/grade, delivery details. |

| Initial Supplier Inquiry | "Please quote L 150x100x12 angle bar4." | Yes, for a first quote. We will ask for grade and usage. | We will ask clarifying questions. |

| Formal Purchase Order | "Steel Angle, UNEQUAL, 150x100x12, Grade AH36 per LR." | Yes, this is complete. | Nothing. This is the perfect specification. |

For a rational, results-driven buyer like the one at Gulf Metal Solutions, efficiency is key. They might start with a concise email: "Need quote for L angle1 120x80x10." Our responsive sales team will then ask the two critical questions: "What material grade7?" and "What is the end use (to confirm the standard)?" This quick exchange, based on a understood shorthand, gets to the complete specification faster than a long, unspecific email. It turns the simple term "L angle1" into the start of an efficient transaction.

Conclusion

Reading L-shaped steel drawings is a skill that prevents costly errors. It starts by recognizing the "L" symbol, understanding the names like "angle bar," and knowing that terms like "L-angle" refer to the standard hot-rolled section. Always cross-reference the drawing callout with the material notes to get the full grade and standard specification for accurate ordering.

-

Understanding the meaning of ‘L angle’ is crucial for accurate communication in engineering and procurement. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the applications of L-shaped angles in construction and manufacturing for better project planning. ↩

-

Learn about various steel angles to choose the right one for your structural needs. ↩

-

Discover the versatility of angle bars in construction and how they can enhance your projects. ↩ ↩

-

Explore the advantages of marine-grade steel for durability in marine applications. ↩ ↩

-

Learn about ASTM standards to ensure compliance and quality in your engineering projects. ↩

-

Understanding material grades ensures you select the right quality for your projects, avoiding costly mistakes. ↩