You need to procure bulb flat steel for your shipbuilding project, but you’re unsure how to approach Chinese suppliers. An incomplete inquiry can lead to delayed responses, inaccurate quotes, and confusion over technical specifications. How do you craft a professional request that gets you a clear, competitive, and comparable offer quickly?

To request an accurate bulb flat steel quotation from Chinese suppliers, provide a clear and complete inquiry that includes the product’s standard name (e.g., Hot-rolled bulb flats per GB/T 9945), precise dimensions, material grade, certification needs, quantity, delivery terms, and destination port. A detailed inquiry minimizes back-and-forth communication and helps suppliers provide a firm, all-inclusive price.

A well-structured inquiry does more than just ask for a price; it establishes you as a knowledgeable buyer and filters out non-specialized traders. Based on my daily experience of handling requests from global clients, I will guide you through the essential information to include and clarify key terminology to ensure you and your supplier are on the same page.

What is a bulb flat1?

If your inquiry uses vague terms like "steel bar" or "L-shaped steel," you will waste time clarifying. Using the correct, standardized name is the critical first step to ensure you are quoted for the exact marine structural component you need.

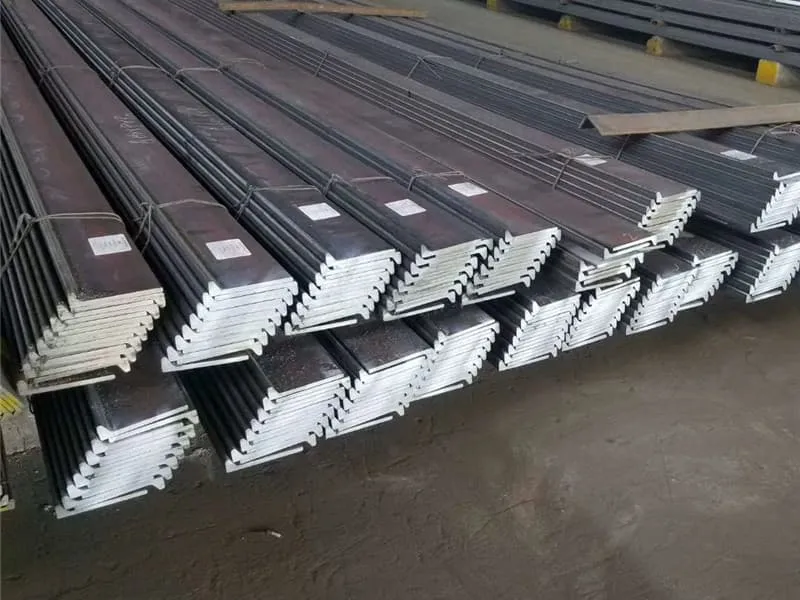

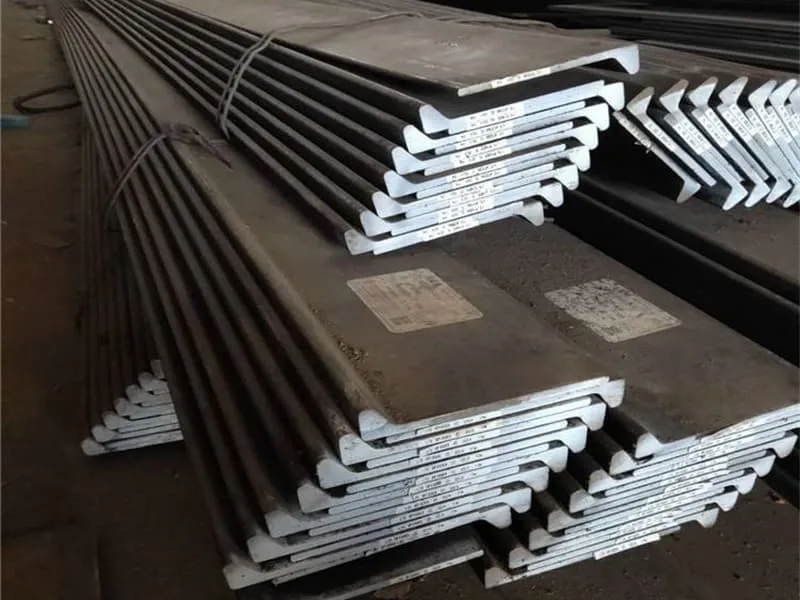

A bulb flat1, also known as bulb bar or ball flat steel, is a specialized hot-rolled steel profile2 with an asymmetrical cross-section consisting of a flat web and a bulb (rounded thickening) at one edge. This unique shape provides a high strength-to-weight ratio, making it the preferred stiffener in ship hulls and offshore structures.

Key Specifications to Define in Your Quotation Request

When you request a quote, you must define the bulb flat1 with precision. The table below outlines the essential technical parameters that transform a generic request into a clear, actionable specification for suppliers.

| Specification Point | What It Means | Why It’s Crucial for Quoting | How to Specify in Your Inquiry |

|---|---|---|---|

| Standard Profile Name | Bulb Flat or Hot-rolled bulb flat1. This is the official term in standards like GB/T 9945-2025. | Using the correct name immediately aligns you with professional marine suppliers and avoids quotes for angles, tees, or simple flat bars. | Start with: “Product: Hot-rolled bulb flat1 (Ball flat steel).” |

| Dimensions (Height x Thickness) | Total Height (H) and Web Thickness (t) in millimeters. The bulb dimensions are standardized for each series. | This is the primary cost driver. It determines the weight per meter and the specific rolling mill setup required. | “Size: 300 mm x 12 mm.” Always state Height x Thickness. |

| Material Grade & Standard | The steel grade defines strength, toughness, and weldability (e.g., AH36, DH32). The standard (e.g., ASTM A131, GB/T 9945) governs the technical requirements. | The grade directly impacts material cost. Specifying the standard ensures the product meets the necessary technical benchmarks for shipbuilding. | “Material Grade: DH36, conforming to ASTM A131 / GB/T 9945.” |

| Certification Requirements | Approval from classification societies like ABS, LR, DNV, BV, CCS. This is mandatory for marine applications. | Certified steel undergoes extra testing and quality control, affecting price. Never assume it’s included; always state it explicitly. | “Certification: Must supply with valid ABS and LR certificates, including full Mill Test Certificate (MTC) 3.1.” |

| Length & Tolerances | Required piece length (e.g., 12,000 mm) and acceptable dimensional deviations. | Affects production yield and packaging. Specifying tolerances (or referring to national standards) prevents disputes over dimensional accuracy. | “Length: 12,000 mm (+50 mm, -0 mm). Dimensional tolerances must comply with GB/T 9945.” |

| Quantity | Total weight in metric tons or the number of pieces. | Quantity significantly affects the unit price. Larger volumes typically secure better pricing from mills. | “Quantity: 150 Metric Tons (approx. 1,250 pcs of 12m length).” |

I recall an inquiry from a project manager in Mexico that simply stated: “Price for 300x12mm steel bars.” This ambiguity led to a week of back-and-forth emails. When we finally clarified, they needed ABS-certified AH36 bulb flat1s for hull longitudinals. If we had quoted for common A36 flat bars based on the initial request, the material would have been rejected at the shipyard, causing major delays and costs. The lesson is to always begin your request with the precise product name and key specs. This demonstrates your expertise and enables the supplier to provide an accurate and valid quote immediately.

What is the use of bulb bar1?

Including the application in your inquiry is not just extra detail—it provides critical context. It tells the supplier why you need the material, allowing them to advise on the most suitable grade, certification, and even potential optimizations, adding value beyond a simple price quote.

The primary use of a bulb bar1 (bulb flat) is as a longitudinal or transverse stiffener2 in shipbuilding and offshore engineering. It is welded to hull plates3, decks, and bulkheads to provide exceptional resistance to buckling4 and bending under loads from water pressure, cargo, and dynamic sea forces.

How Stating the Application Leads to a More Accurate and Valuable Quotation

Different structural applications have distinct requirements. Sharing the context helps a knowledgeable supplier ensure the quotation meets all your project’s technical and regulatory needs.

| Your Stated Application | What a Knowledgeable Supplier Understands | Key Advice/Clarification They Should Provide | Impact on Your Quotation & Project Safety |

|---|---|---|---|

| Hull Longitudinal Stiffeners | The material is for primary structural members, subject to fatigue loading and often located in corrosive ballast tanks. | Recommend higher-toughness grades5 (e.g., DH36/EH36) over standard AH36 for critical zones. Emphasize the need for pristine surface quality to ensure coating adhesion and corrosion protection. | The quote will rightly include the cost premium for enhanced grade and superior surface finish, excluding unsuitable, cheaper alternatives. |

| Deck Stiffeners | The member contributes to the global hull girder strength, resisting bending stresses. Corrosion exposure is different from wet areas. | Confirm if high-strength steel is needed for weight saving. Discuss the choice between normal and prime surface quality based on the coating specification. | The supplier may offer sensible options between grades, helping optimize cost without compromising the design intent. |

| Bulkhead Stiffeners in Cargo Holds | The environment may involve abrasion from bulk cargo (e.g., ore, coal). | Inquire about cargo type. For abrasive environments, suggest considering a slight thickness corrosion allowance or discussing material hardness properties. | The price may justifiably vary based on these additional durability requirements, preventing premature failure. |

| Offshore Platform Leg Stiffeners | The material will face harsh marine conditions and high cyclic loads. | Stress the importance of strict low-temperature impact testing6 (e.g., at -20°C or -40°C) and possibly Z-direction (through-thickness) properties to resist lamellar tearing. | The quotation will detail these specific test requirements and associated costs, which are essential for project integrity. |

| Repair & Retrofit Project | You need material that must exactly match an existing vessel’s original specifications. | Request the original ship drawings7 or class records. They can help identify the equivalent modern grade and standard (e.g., matching an old "HT" grade to a current AH/DH grade). | The quote might be for a non-standard size or a smaller batch, accurately reflecting the lower volume and potential special-order production. |

A shipyard in Vietnam once asked us for a “bulb bar1 for hull stiffeners.” We provided a standard quote for AH36. Later, they shared the structural drawing which had a note: “For Ice Class 1A.” We immediately revised our quote to specify DH36 grade with enhanced low-temperature impact values, as this was a class rule for that ice-class notation. While the price per ton was higher, this proactive guidance based on the application saved them from the catastrophic risk and cost of using non-compliant steel. By clearly stating the use—"bulb bar1 for ice-class hull stiffeners8"—you enable a competent supplier to act as a technical partner, leading to a correct and reliable quotation.

What is another name for a flat bar?

Terminology confusion is a major source of error and wasted time in procurement. If you accidentally refer to a bulb flat1 as a “flat bar,” you will receive quotes for a fundamentally different, non-structural product. Knowing the alternative names helps you avoid this costly mistake and communicate with precision.

Another common name for a flat bar is “mild steel flat2” or “MS flat.” These terms refer to a basic, rectangular cross-section steel bar with no bulb. It is a commodity product used for brackets, frames, and general fabrication, not for primary structural stiffening in shipbuilding.

Terminology Clarification to Prevent Miscommunication and Misquotes

Using imprecise language can derail your procurement process. The following table clarifies the naming conventions to ensure you and your supplier have a shared understanding.

| Term Commonly Used | What It Typically Refers To | Common Misunderstanding & Risk | How to Ensure Absolute Clarity in Your Inquiry |

|---|---|---|---|

| Flat Bar | A long steel product with a simple rectangular cross-section (defined by width and thickness). No bulb. | Buyers sometimes use “flat bar” as a generic term for any bar-shaped steel, inadvertently including bulb flat1s. | Never use the standalone term “flat bar” when you need a bulb flat1. Always use the full, technical term. |

| MS Flat (Mild Steel Flat) | A flat bar made from low-carbon mild steel (e.g., ASTM A36). It has lower strength and is not typically certified for marine applications. | In some regions, “MS” is used loosely for all steel. An inquiry for “MS flat” will not yield a quote for marine-grade bulb flat1s. | Specify the required material grade3 (e.g., AH32, DH36). Avoid the generic “MS” designation for shipbuilding materials. |

| Bar Stock | A very general term for long steel products sold in bars, which can be round, square, flat, or hexagonal. | Extremely vague. A supplier will need to ask for clarification, delaying the process. | Always specify the profile shape in the first sentence of your inquiry. |

| Plain Bar | Emphasizes a simple shape without deformations, ribs, or bulbs—the opposite of a bulb flat1. | Correctly describes a flat bar but completely misses the defining feature of a bulb flat1. | Use the term that describes the unique feature: “bulb flat1.” |

| Technical Drawing Notes | Older drawings may use codes like “FB” for flat bar or “HP” (High Perpendicular) for bulb flat1. | If you quote only a drawing code like “HP200,” ensure the supplier knows it corresponds to a bulb flat1 of 200mm height. | In your inquiry, translate drawing codes: “Item per drawing code HP200: Bulb Flat, 200 mm height.” |

We received an RFQ from a procurement officer in Saudi Arabia with the subject: “Quotation for MS Flat.” However, the attached PDF drawing clearly depicted a bulb flat1 profile. If we had automatically quoted for common mild steel flat2 bar, our product would have been completely wrong for their project. We picked up the phone to clarify. The buyer appreciated this proactive step, noting that previous suppliers had just sent incorrect flat bar quotes without checking. This wasted his team’s time in re-quoting. To avoid this, use a clear and precise subject line like: “Quotation Request: Marine Grade Bulb Flat Steel.” This immediately signals your requirements to specialized exporters and filters out general traders.

What is a steel flat bar1?

Understanding what a standard steel flat bar1 is helps you appreciate why bulb flats2 are engineered differently and command a higher price. This knowledge prevents “sticker shock” when comparing quotes and solidifies why the correct material is a necessary investment for your vessel’s structural integrity.

A steel flat bar1 is a basic, hot-rolled or cold-finished product with a simple rectangular cross-section, defined by its width and thickness. It is a commodity used for manufacturing brackets, frames, supports, and in general fabrication where high bending stiffness is not the primary concern.

Why Bulb Flats and Flat Bars Are Fundamentally Different and Priced Differently

A quote for a standard flat bar will be significantly lower than for a bulb flat. The table below details the reasons for this cost difference, ensuring you compare quotes for equivalent value and do not make a selection based on price alone.

| Factor | Standard Steel Flat Bar | Marine Bulb Flat Steel | Impact on Quotation & Procurement Decision |

|---|---|---|---|

| Production Process & Complexity | Simple rolling process from standard billets. Many mills worldwide can produce it. | Requires specialized rolling stands and precise pass design to form the asymmetrical bulb. Fewer mills have this capability, especially for certified marine grades. The process is designed to control twisting and ensure precise dimensions. | Bulb flats have inherently higher production costs, which is reflected in the price per ton. This cost is for engineered performance. |

| Material Grade & Specifications | Often common grades like ASTM A36, SS400 (mild steel) with minimal mandatory testing. | Requires controlled-chemistry, high-strength low-alloy steel3 (e.g., AH/DH/EH grades) with mandatory Charpy V-notch impact testing4 at low temperatures. | The alloying elements and rigorous testing add substantial material and quality assurance costs. |

| Certification & Traceability | Usually comes with a generic material certificate. No classification society approval is involved. | Must have full traceability back to the melt (heat number) and be produced in a mill approved by ABS, LR, DNV, etc. A Mill Test Certificate 3.1/3.25 is mandatory. | The certification process6 is integral and adds cost. Its inclusion in the quote is non-negotiable for marine use. |

| Dimensional Tolerances | Tolerances (for thickness, width) are relatively wide, suitable for general purpose use. | Tolerances for height, thickness, straightness, and bulb geometry are very tight as per national standards (e.g., GB/T 9945) to ensure proper fit-up in automated shipyard construction. | Tighter tolerances require more precise process control, increasing cost and the rate of mill rejection for off-spec material. |

| Market Nature | A widely available commodity with high competition. Prices closely track raw material (iron ore) costs. | A niche, engineered product. Price is influenced by mill order books, technical service, and the specific certification package. | Your bulb flat quote is for a specialized structural component, not a commodity. The price reflects this specialization and guaranteed performance. |

A fabricator in the Philippines constructing small barges once requested quotes for both “flat bar 200×12” and “bulb flat 200×12.” The flat bar quote was over 30% cheaper. They were tempted to substitute to save costs. We explained the structural mechanics: a flat bar of the same height has a much lower section modulus7 (bending resistance) than a bulb flat. For a non-critical, internal partition, a flat bar might suffice. However, using it as a main hull stiffener would compromise the structure’s integrity. We helped them make an informed decision: use cost-effective flat bars for non-structural applications and invest in bulb flats2 for the primary hull. Your quotation request should reflect this understanding. When you request a bulb flat quote, expect and justify a higher price based on superior engineering, material, and certification. A flat bar quote is not a benchmark; they are different products for fundamentally different purposes.

Conclusion

A precise, detailed, and professionally structured quotation request is your most effective tool for efficient procurement. It ensures you receive accurate, comparable offers for the right material, builds a foundation of trust with suppliers, and ultimately safeguards your project’s timeline, budget, and structural integrity.

-

Explore this link to understand the various applications and benefits of steel flat bars in construction and manufacturing. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about bulb flats and their unique engineering features that make them suitable for specialized applications. ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the properties of high-strength low-alloy steel and why it’s essential for structural integrity in marine applications. ↩ ↩ ↩

-

Understand the significance of Charpy V-notch testing in ensuring material quality and performance in critical applications. ↩ ↩

-

Find out why Mill Test Certificates are crucial for traceability and quality assurance in steel production. ↩ ↩

-

Understand the certification process for marine steel and why it ensures safety and compliance in construction. ↩ ↩

-

Learn about section modulus and its role in determining the bending resistance of structural components. ↩ ↩

-

Learn about the unique requirements for ice-class hull stiffeners and their role in vessel safety. ↩