Your shipyard just won a major contract to build two new container ships. Your current steel supplier handled small repairs well. But now you need hundreds of tons of certified angle steel delivered in synchronized batches. Your growth will stall if your supply chain cannot scale with you. The wrong supplier choice now can create bottlenecks that delay your entire production line.

Scaling marine angle steel supply requires moving from transactional buying to strategic partnership. You need a supplier with deep mill alliances for large-volume allocation, flexible logistics for JIT delivery, and robust quality systems that remain consistent at scale. This ensures your growing project pipeline is supported by a reliable, high-capacity material flow.

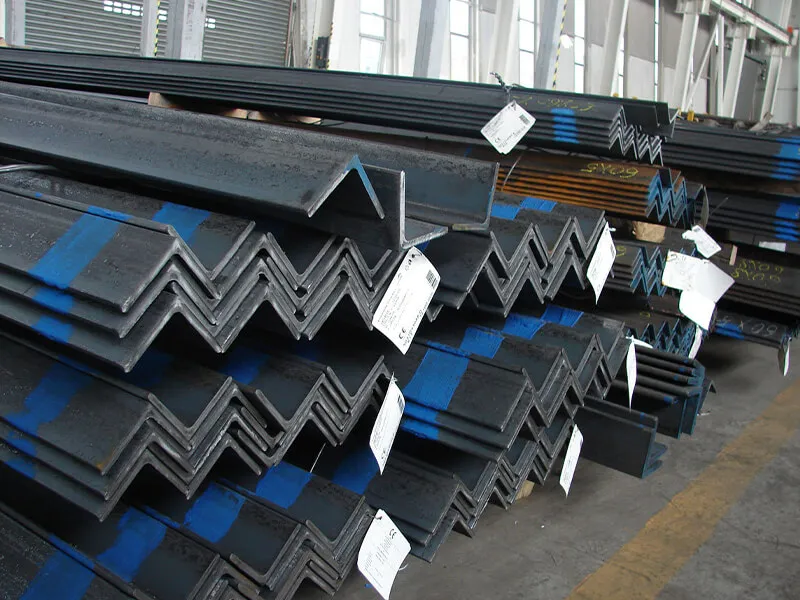

Scaling up is not just about ordering more tons. It is about transforming your supply chain from a simple vendor into a seamless extension of your production planning. To build this partnership, you must understand the core materials you are scaling. Let’s start with the basic but often misunderstood question of price, which becomes even more critical at high volumes.

What is the price of 40x40x5 angle per kg?

You are estimating the budget for a 500-ton angle steel order. You look at the price per kilogram. This number seems straightforward. But at this scale, a small misunderstanding in the price basis can lead to a massive budget error. The quoted price per kg must reflect the total cost of getting project-ready material to your yard.

The price per kg for a 40x40x5mm angle1 is a variable starting point. It depends heavily on grade, volume, and terms. For high-volume marine projects, you should negotiate a blended price based on the total landed cost2 per ton. This cost includes the base material, processing, certification, and door-to-port logistics, not just the EXW mill price.

From Unit Price to Total Landed Cost: The Scaling Perspective

When you scale, your focus must shift from the simple per-kg rate to a comprehensive cost model. This model accounts for all variables that impact your final project cost and cash flow.

1. Volume-Based Pricing Tiers and Mill Allocations.

A supplier’s ability to offer a stable, competitive price at scale depends on their relationship with major mills.

- Tiered Pricing: Reputable suppliers have price breaks at different volume thresholds (e.g., 50 tons, 200 tons, 500 tons). For a growing shipyard, locking in a price for your forecasted annual volume is smarter than buying per project.

- Mill Allocation: Large mills plan their production months in advance. A supplier with a long-term cooperation agreement, like we have, can secure allocation from the mill’s production schedule. This guarantees your material will be rolled when you need it, especially during global steel shortages. Without this, you may face long lead times or premium spot-market prices.

2. The Total Landed Cost Breakdown for Scalable Supply.

Managing cost at scale means understanding every component. Here is what a scalable cost structure should include:

| Cost Component | Impact at Small Scale | Impact at Large Scale (Key for Scaling) |

|---|---|---|

| Base Material Price | Primary focus. | Still important, but stability and allocation matter more than minor price fluctuations. |

| Processing Fees | Often avoided to save cost. | Critical to include. Pre-cutting, blasting, and priming at source save huge time/labor costs in your yard, speeding up production. |

| Certification | One-time cost per batch. | Standardized. Ensure every batch has the same class certificate without extra negotiation. |

| Packaging | Basic protection. | Must be industrial-grade. High-volume shipments need uniform, stackable, waterproof packaging to prevent damage in transit and storage. |

| Inland & Ocean Freight | A significant line item. | Opportunity for consolidation. A good supplier can combine your angle steel with plates and other sections into full-container loads (FCL) for major cost savings. |

| Insurance | Standard cost. | Volume discount may apply. |

| Import Clearance | Your responsibility. | A scalable supplier offers logistics support3 (DDP/DAP options) to handle this, simplifying your process as order frequency increases. |

3. The Risk of the "Lowest Price" at Scale.

Choosing a supplier based only on the lowest per-kg quote for a large order is extremely risky. That supplier may lack the financial strength to secure mill allocation4. They may not have the logistics capability to handle multiple shipments. Their quality control might become inconsistent under pressure. A disruption in a 50-ton order is a problem. A disruption in a 500-ton order is a project crisis.

My Insight from the Field

We worked with a shipyard in Vietnam that was expanding. Their old supplier gave a good price for 20-ton orders. When they placed a 300-ton order, that supplier failed. The supplier could not secure the mill allocation4 and asked for a 60-day delay. The shipyard came to us in a panic. Because of our long-term mill agreements, we re-allocated existing scheduled production to them. We delivered the first 100 tons in three weeks. We then established a quarterly rolling schedule. The yard’s purchasing manager told us the lesson was clear: “For growth, we need a supplier’s system, not just their price list.” Now, they plan their steel procurement with us a year in advance, just like they plan their shipbuilding slots.

What is ASTM a 36 steel angle?

Your design team is working under pressure. They specify "steel angle" on a drawing for a non-critical interior platform. A junior purchaser sources ASTM A361 because it is available and cheap. This works for a small job. But as your yard grows, this kind of informal specification creates a dangerous mix of materials on site. Scaling efficiently requires disciplined material standardization2.

ASTM A361 is a common carbon steel specification for general construction angles. It is not a marine-grade steel3. For shipyards, using A36 is typically limited to non-structural4, interior, or temporary work platforms. Scaling your supply chain means clearly segregating A36 for non-hull applications from certified marine grades for primary structure, to ensure safety, simplify procurement, and avoid costly mix-ups.

Strategic Material Segregation: A36 in a Growing Marine Ecosystem

A growing shipyard uses many types of steel. A clear policy on where and how to use A36 is a mark of professional maturity and scalable operations5.

1. Defining the Limited Role of A36 in a Shipyard.

A36 has properties that make it unsuitable for the harsh marine environment, but it has uses where those properties are not required.

- Permissible Applications:

- Temporary Works: Scaffolding, construction platforms, temporary bracing in the building dock.

- Non-Critical Interior Structures: Office partitions inside vessels, non-load-bearing locker frames, workshop furniture.

- Shipyard Facility Maintenance: Repair sheds, warehouse racks, non-critical yard infrastructure.

- Absolute Prohibitions:

- Any part of the ship’s hull, framing, or primary structure.

- Any component exposed to seawater or weather.

- Any item subject to classification society rules.

2. The Scalability Problem with Mixed Specifications.

As order volumes grow, mixing A36 and marine-grade angles in your supply chain causes operational inefficiencies.

- Procurement Complexity: Your team must manage two completely different supply streams with different quality checks, certificates, and storage requirements.

- Risk of Mix-Ups: The visual difference between an A36 angle and an AH36 angle is zero. A mix-up in the storage yard or during fabrication could lead to the wrong material being welded into the hull. This is a catastrophic quality failure that would require expensive cutting and rework.

- Inventory Management: It complicates your stock management. You need separate, clearly labeled storage areas.

3. A Strategy for Scalable, Clear Sourcing.

To scale cleanly, implement a clear policy and work with a supplier who can support it.

- Internal Policy Document: Create a simple guide. "All steel for Hull Structure No. 1 must be [ABS AH36/ DH36]. All steel for Yard Infrastructure can be [ASTM A361]."

- Supplier Collaboration: Partner with a supplier who can provide both streams efficiently but keeps them completely separate. They should:

- Provide A36 from standard mills for your yard needs.

- Provide class-certified marine angles from approved mills for your hull needs.

- Use distinct packaging and documentation for each type to prevent confusion upon delivery.

My Insight from the Field

A container ship manufacturer in Thailand had recurring issues. Their warehouse would receive both A36 and marine-grade angles. The materials were sometimes stored together. On one project, a work crew used A36 angles for some secondary hull stiffeners. The mistake was only caught during the class surveyor’s visit. The rework cost over $20,000 and caused a two-week delay. After this, we helped them implement a color-coding system. We now paint a small, non-corrosive green stripe on the end of all marine-grade angles we supply. A36 angles have no stripe. This simple, visual control eliminated the mix-up risk entirely. This is the kind of scalable solution a growth-focused partnership provides—solving not just supply, but your internal process challenges.

What is marine-grade structural steel1?

Your shipyard is taking on larger, more complex vessels. The procurement list simply says "marine steel." This is no longer sufficient. You need to understand the specific categories within marine-grade steel. Structural steel is the backbone. Confusing it with other types can lead to using over-specified or under-specified material, wasting money or compromising safety as you scale.

Marine-grade structural steel refers to the high-strength, high-toughness rolled sections and plates used for the primary load-bearing parts of a vessel or offshore structure. This includes angles, bulbs, beams, and plates that form the hull, frames, and decks. It is characterized by classification society certification2 (like ABS, LR), mandatory impact toughness testing3, and precise chemical composition for weldability in severe environments.

Building a Scalable Foundation with the Right Structural Steel

Scaling your production means standardizing on the optimal structural grades for your typical projects. This reduces engineering time, simplifies procurement, and improves inventory predictability.

1. The Hierarchy of Marine Structural Steels.

Not all marine structural steel is the same. The grades form a hierarchy based on strength and toughness.

- Normal Strength (Grade A, B, D, E): These are the base grades. The letter indicates toughness level (A=basic, E=exceptional low-temperature toughness). They have a yield strength4 of around 235 MPa. Used for standard ship hulls in non-extreme climates.

- High Strength (AH32/36, DH32/36, EH32/36): The "H" means high strength. The number indicates the yield strength4 in kgf/mm² (32 = 315 MPa, 36 = 355 MPa). These grades allow for thinner, lighter structures while maintaining strength. They are the workhorses for modern container ships, bulk carriers, and tankers. Scaling supply often means securing large volumes of these specific grades.

2. Key Considerations for Scaling Structural Steel Supply.

When you plan to build multiple ships of a similar type, your structural steel supply must become a predictable, high-quality pipeline.

- Grade Standardization: If your yard specializes in coastal container ships, you might standardize on AH36 for most structures. This allows you to negotiate long-term volume prices and guarantee mill allocation for that specific grade.

- Consistent Certification: Every single batch must come with the correct, valid class certificate. The certificate is part of the product. A supplier’s quality management system must ensure zero defects in documentation, as missing or wrong certificates can halt production.

- Dimensional Consistency: For angles, consistent leg length and straightness are crucial for automated cutting and welding lines. As you scale, manual correction of bent angles becomes a major bottleneck. A premium supplier ensures material arrives with excellent dimensional tolerances, ready for production.

3. Table: Common Marine Structural Steel Grades for Scalable Shipbuilding.

This table helps in planning your standardized material list.

| Grade (Example: ABS) | Minimum Yield Strength | Key Characteristic | Typical Application in Scaling |

|---|---|---|---|

| ABS Grade A | 235 MPa | Normal strength, basic toughness. | Smaller vessels, inland waterway ships. A baseline grade. |

| ABS Grade D | 235 MPa | Normal strength, improved low-temperature toughness. | Standard ocean-going ships (bulk carriers, tankers) where higher toughness is required. |

| ABS Grade AH36 | 355 MPa | High strength, good toughness. | The most common target for scaling. Used for hull plating and frames of large container ships and tankers to reduce weight. |

| ABS Grade DH36 | 355 MPa | High strength, higher toughness than AH36. | Critical parts of vessels operating in colder waters, or for offshore structures. |

| ABS Grade EH36 | 355 MPa | High strength, exceptional toughness. | Ice-class vessels, Arctic operations, or the most critical stress areas. |

My Insight from the Field

A shipyard in the Philippines was building a series of 10 identical landing craft. For the first three, they sourced structural steel from different mills based on price and availability. This caused variation in weldability. Their welding parameters5 had to be adjusted for each batch, slowing down production. For the next series, they partnered with us. We supplied the entire structural package (plates and AH36 angles) from a single certified mill partner. The consistent chemistry meant the welding team could use one optimized procedure for the entire production run. Their welding speed increased by an estimated 15%, and defect rates fell. This shows that scaling supply is not just about volume, but about consistency. Consistent material enables you to scale your production efficiency.

What is a marine-grade aluminum angle1?

Your shipyard wins a contract to build a high-speed ferry or a superyacht. The design calls for aluminum to reduce weight. You are used to steel. Suddenly, you need to scale a supply chain for a completely different material. Aluminum procurement has different rules, costs, and supplier networks. Failing to understand this can derail your growth into new, lucrative market segments.

A marine-grade aluminum angle1 is an extruded L-shaped profile2 made from aluminum alloys3 like 5083, 5086, or 6061. These alloys are selected for excellent corrosion resistance4 in seawater, good weldability, and high strength-to-weight ratio. They are used in aluminum ship superstructures, high-speed craft hulls, masts, and fittings where weight saving is critical, but they require completely different sourcing and fabrication expertise than steel.

Scaling into Aluminum: A Different Supply Chain Game

Adding aluminum capability is a strategic growth decision. It requires building a parallel, specialized supply chain.

1. Why Aluminum? The Driver for Growth into New Vessels.

- Weight Reduction: Aluminum is about one-third the density of steel. This allows for higher speeds, greater fuel efficiency, or increased payload.

- Corrosion Resistance: Marine aluminum alloys3 form a stable, self-protecting oxide layer, offering excellent resistance to seawater without painting (though painting is still often used).

- Applications: Superstructures on cruise ships and naval vessels to lower the center of gravity. Entire hulls for patrol boats, ferries, and luxury yachts. Deckhouses and railings.

2. Key Differences from Steel Supply Chain Management.

Scaling aluminum supply is not like scaling steel. You must account for these differences:

- Production Process: Steel angles are rolled. Aluminum angles are extruded. This means different mills, different minimum order quantities (often based on extrusion die cost5), and different lead times6.

- Alloy Specificity: You must specify the exact alloy (e.g., 5083-H116). The alloy and temper (like H116) define its strength and workability. Using the wrong one can lead to failure.

- Cost Structure: Aluminum is more expensive per kilogram than steel. However, you use fewer kilograms. The cost driver is often the extrusion die cost5 for custom profiles, which is amortized over the order volume.

- Welding and Fabrication: Requires specialized MIG or TIG welding with inert gas, different skilled workers, and a separate workshop area to prevent carbon steel contamination (which causes galvanic corrosion).

3. Building a Scalable Aluminum Supply Partnership.

To scale reliably, you need a supplier who understands both worlds or a dedicated aluminum specialist.

- Technical Support: The supplier must provide exact alloy certificates and often, welding procedure specifications7 (WPS).

- Logistics Handling: Aluminum must be packed and handled to prevent surface scratches and gouges, which are more critical than for steel.

- Inventory Strategy: Aluminum is often made-to-order due to extrusion die cost5s. Your scaling plan must include longer lead times6 for aluminum components in your project schedule.

| 4. Comparison: Steel vs. Aluminum Angle Supply for Scaling. | Aspect | Marine Steel Angle (e.g., AH36) | Marine Aluminum Angle (e.g., 5083) | Implication for Scaling Your Shipyard |

|---|---|---|---|---|

| Primary Process | Hot rolling. | Extrusion. | Requires building relationships with different types of mills. | |

| Key Cost Driver | Raw material (iron ore) price, alloy content. | Alloy price, extrusion die cost5, energy for extrusion. | For aluminum, large, repeat orders of the same profile are essential for cost-effectiveness. | |

| Lead Time | Relatively short (weeks), based on mill rolling schedule. | Longer. Includes die fabrication time for first order (several weeks). | Plan aluminum procurement much earlier in the design phase. | |

| MOQ | Flexible, can be lower for standard sizes. | Higher, especially for custom profiles, to justify die cost. | Standardize on a few aluminum angle sizes across multiple projects to achieve volume. | |

| Your Yard Changes | Standard steel workshops, handling, and welding. | Requires dedicated area for storage and fabrication to prevent steel-aluminum contact and contamination. | A capital and operational investment in new facility space and training. |

My Insight from the Field

We had a client in the Middle East, a shipyard that traditionally built steel workboats. They secured a contract to build an aluminum crew transfer vessel. They tried to use their steel supplier for aluminum angles. That supplier sourced a cheap, non-marine aluminum alloy. The material cracked during welding trials. The project was in jeopardy. They contacted us. We don’t extrude aluminum ourselves, but through our network, we connected them with a certified aluminum extruder. We acted as the coordinator, ensuring the 5083-H116 alloy was supplied with proper certificates. More importantly, we helped them set up a separate storage and marking system to avoid mixing with steel. This experience taught us that scaling a shipyard’s capabilities often means becoming a solutions hub for our clients, even if it involves products outside our core range, by leveraging trusted partnerships.

Conclusion

Scaling your marine angle steel supply is a strategic project. It demands a partner with mill access for volume, expertise in material segregation, and the flexibility to support your expansion into new materials and vessel types.

-

Explore this link to understand the applications and benefits of marine-grade aluminum angles in shipbuilding. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Find out how extruded L-shaped profiles are made and their significance in construction. ↩ ↩ ↩ ↩

-

Discover the top aluminum alloys suitable for marine environments and their unique properties. ↩ ↩ ↩ ↩ ↩

-

Learn about the corrosion resistance of aluminum and why it’s crucial for marine applications. ↩ ↩ ↩ ↩ ↩ ↩

-

Explore how extrusion die costs impact the overall pricing of aluminum products. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the lead times involved in sourcing aluminum and how to plan accordingly. ↩ ↩

-

Get insights into the importance of welding procedure specifications in aluminum fabrication. ↩