Your new ship design is complete. Now you need to choose the steel for the hull and deck. Selecting the wrong grade or type can lead to safety risks, higher costs, and failed inspections. How do you make the right choice for each part of the ship?

Selecting marine steel plate requires matching grade, toughness, and strength to specific structural zones. Use normal strength Grades A-D for general areas and high-strength AH/DH/EH grades for critical zones like the keel and sheer strake. Stainless steels like 316 are for corrosion-resistant fittings, not primary hull structure, and must be specified separately.

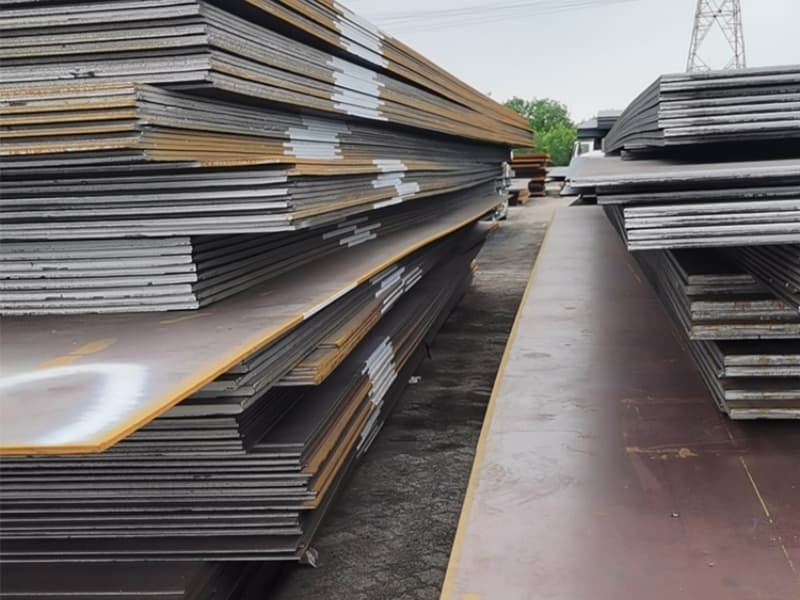

The hull and deck are not a single piece; they are a complex system under different stresses. The steel selection must be just as precise. Let’s start by understanding the toolbox of available marine steel grades.

What are the grades of marine steel plates?

Marine steel is not one material. It is a family of grades, each with a specific combination of strength and toughness. The grade is a code that tells you exactly what the steel is capable of.

Marine steel plates are graded in two main families: Normal Strength (Grades A, B, D, E)1 with a yield strength of about 235 MPa, and High Strength (Grades AH, DH, EH, FH)2 with yield strengths of 315, 355, 390 MPa and higher. The letter indicates toughness level (A is basic, E is for -40°C), and ‘H’ indicates higher strength.

This grading system, standardized by classification societies like ABS, LR, and DNV, is a global language. It allows a shipyard in Vietnam, a designer in Norway, and a mill in China to all agree on the material’s performance.

Decoding the Grade Name

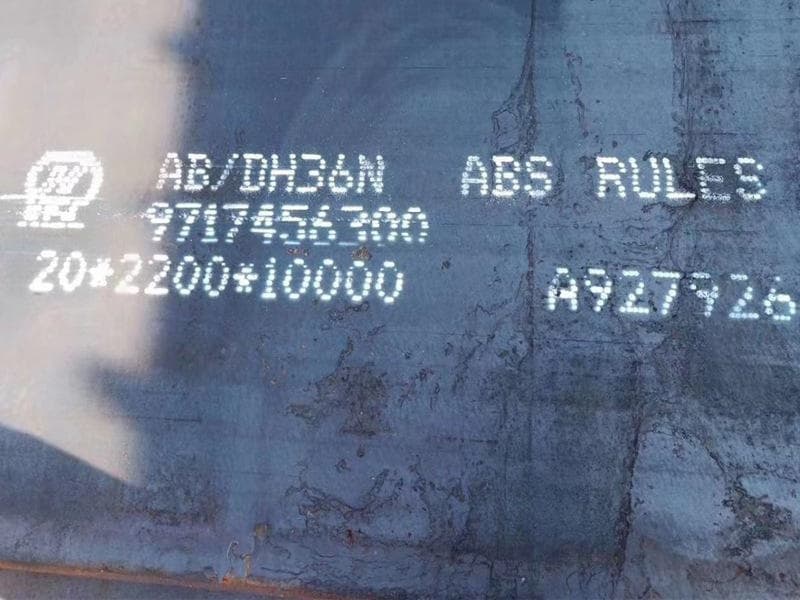

The grade name is a clear formula. Take DH36 as an example:

- D: This letter indicates the notch toughness3 level. Grade D steel is tested for impact resistance at -20°C.

- H: This letter stands for High Tensile Strength. Normal strength grades (A, B, D, E) do not have an ‘H’.

- 36: This number indicates the minimum yield strength in ksi4 (kilopounds per square inch). 36 ksi equals approximately 355 MPa.

So, DH36 means a high-strength steel (355 MPa yield) with good toughness at -20°C. An EH36 grade would have the same strength but even higher toughness, tested at -40°C.

How to Select the Right Grade for Hull and Deck

You select the grade based on two things: the structural importance of the area and the lowest service temperature the ship will face.

| Ship Area / Function | Recommended Grade(s) | Reasoning for Selection |

|---|---|---|

| Inner Bottom, Non-critical Decks | Grade A or B | These are lower-stress areas. Grade A or B provides adequate strength and good weldability at a lower cost. |

| Midship Hull Plating, Main Deck | Grade D or AH32/DH36 | These zones experience high global bending stresses. Grade D offers good toughness; AH/DH grades offer higher strength, allowing for thinner, lighter plates. |

| Keel, Sheer Strake, Bilge Strake | Grade D, E or DH36, EH36 | These are the most critically stressed parts. They require the highest toughness (Grade E/H) to prevent catastrophic crack propagation. |

| Ballast Tanks, Waterline Zone | Grade D or DH with enhanced corrosion protection | These areas suffer from wet/dry cycles and corrosion. Good toughness is required, paired with high-performance coatings. |

| Superstructure | Higher Grade Steels (e.g., DH36) | Reducing weight high up on the ship is crucial for stability. High-strength steels allow for lighter construction here. |

The selection is strategic. You don’t use the highest grade everywhere. You use the most cost-effective grade that meets the specific safety requirement for each zone. This approach, called "selective strength5," is standard in modern shipbuilding. When you issue a purchase order, specifying "ABS DH36 Plate for Main Deck6" gives the supplier and the shipyard complete clarity.

Is 304 stainless steel1 ok for marine use?

This is a very common question with a nuanced answer. 304 stainless steel1 is often called "marine-grade" in consumer products, but in professional shipbuilding and offshore engineering, its use is limited and specific.

304 stainless steel1 is generally NOT recommended for prolonged, direct seawater immersion. It is susceptible to pitting and crevice corrosion in chloride-rich environments. It may be acceptable for short-term exposure, interior trim, or non-critical above-deck fittings where it stays dry and is regularly cleaned, but 316 stainless is the preferred choice for harsh marine service.

Stainless steel works by forming a passive chromium oxide layer. Chlorides in seawater can break down this layer, leading to localized, aggressive pitting. The key is the molybdenum2 content.

Why 304 Stainless Falls Short for Structural Marine Use

For hull and deck primary structure, 304 stainless is not an option. The reasons are fundamental:

- It’s Not a Structural Hull Steel: It is not covered by the classification society rules (ABS, DNV, etc.) for hull structural steel. It lacks the defined yield strength, toughness, and weldability specifications required for the ship’s main frame.

- Corrosion Risk in Real Conditions: Even above deck, salt spray, rain, and humidity create a corrosive film. Without molybdenum2, 304 is vulnerable over time, especially in welds and crevices.

- Cost vs. Performance: While cheaper than 316, using 304 in a marine environment risks early failure and costly replacement, negating any initial savings.

Limited, Non-Structural Applications

There might be very controlled interior applications:

- Galley equipment and sinks (if frequently cleaned with fresh water).

- Decorative interior trim far from weather decks.

- Temporary construction fixtures.

However, for any exterior fitting, piece of equipment, tank, or pipe that will see saltwater, splash, or constant salt-laden air, 316 stainless steel3 is the minimum standard. The rule is simple: for marine environments, if there’s a choice between 304 and 316, always choose 316 for reliability. For the hull and deck structure itself, you use the certified carbon/manganese steels like AH36 or DH36, not stainless steel.

Is 304 or 316 stainless steel1 marine grade?

Between the two, 316 stainless steel1 is the true, reliable "marine-grade" stainless for engineering applications. The difference of 2-3% Molybdenum makes a dramatic improvement in performance.

316 stainless steel1 is the true ‘marine-grade’ stainless steel for engineering applications. The addition of 2-3% Molybdenum (Mo)2 significantly enhances its resistance to pitting and crevice corrosion in chloride environments like seawater, making it suitable for pumps, valves, railings, and tanks. 304 stainless lacks Molybdenum and is not recommended for harsh, permanent marine exposure.

The term "marine-grade" for stainless steel is about corrosion resistance3, not structural strength. 316 provides that resistance where 304 often fails.

The Science Behind the Choice: Molybdenum’s Role

The key difference is the alloying element Molybdenum (Mo)2.

- AISI 304: Contains 18% Chromium (Cr), 8% Nickel (Ni), and 0% Mo.

- AISI 316: Contains 16% Cr, 10% Ni, and 2-3% Mo.

Molybdenum strengthens the passive oxide layer, making it much more difficult for chloride ions to penetrate and initiate pits. This is quantified by the Pitting Resistance Equivalent Number (PREN)4.

- PREN = %Cr + 3.3x(%Mo) + 16x(%N)

- 304 stainless PREN: ~18

- 316 stainless PREN: ~24-26

A higher PREN indicates better pitting corrosion resistance3. The jump from 304 to 316 is significant.

Application Guide: Where to Use 316 Stainless on a Ship

For hull and deck applications, 316 stainless is used for components and fittings, not the plating itself.

| Application on Hull/Deck | Recommended Material | Reason |

|---|---|---|

| Primary Hull & Deck Plating | ABS AH36/DH36 Carbon Steel5 (with coatings) | Provides structural strength and toughness. Coatings protect against corrosion. |

| Deck Drainage Scuppers, Piping | 316 Stainless Steel | Resists corrosion from constant or intermittent seawater contact. |

| Handrails, Ladders, Deck Cleats | 316 Stainless Steel | Withstands salt spray and physical abrasion, maintaining appearance and strength. |

| Ballast Tank & Cargo Tank Heating Coils | 316L or more resistant grades6 | Resists corrosion from heated, stagnant seawater. |

| Exterior Door Frames, Window Frames | 316 Stainless Steel | Provides long-term durability in the splash zone and marine atmosphere. |

It is critical to understand that 316 is not a substitute for hull structural steel. They work together in a ship: the AH36 plate provides the strength to handle waves and cargo, protected by paint systems. The 316 stainless fittings handle the localized corrosion where paint might get damaged or where components are replaced. Specifying "316 stainless" for a railing is as important as specifying "DH36" for the deck plate it’s welded to; both need to be correct for the system to last.

How to specify a steel plate?

Specifying a steel plate is more than just giving a grade. A complete, unambiguous specification prevents errors, ensures you get exactly what you need, and forms the basis of your contract with the supplier.

To specify a steel plate, you must provide: 1) Quantity, 2) Dimensions (thickness, width, length), 3) Material Grade & Standard1 (e.g., ABS AH36), 4) Delivery Condition2 (e.g., As-rolled, Normalized, TMCP), 5) Certification Requirement (e.g., with ABS MTC), and 6) Any additional processing (cutting, edge prep, priming).

A vague specification leads to quotes for different products, delays for clarification, and the risk of receiving non-compliant material. A precise specification is the first step in quality control.

The Elements of a Complete Plate Specification

Let’s break down each element for a marine plate order:

- Quantity: State the total weight in metric tons (e.g., 150 MT) or the number of plates (e.g., 50 plates).

- Dimensions:

- Thickness (t): In millimeters (e.g., 15 mm). Specify if it’s minimum or nominal.

- Width (W) and Length (L): In millimeters or meters (e.g., 3000 mm W x 12000 mm L).

- Tolerances: You can reference a standard (e.g., "Thickness tolerance per EN 10029 Class A3").

- Material Grade & Governing Standard: This is the core. You must state both the grade and the ruling body.

- Incorrect: "AH36 plate."

- Correct: "ABS AH36 steel plate." or "BV DH36 steel plate per BV Rules."

- This tells the supplier the exact set of chemical and mechanical rules to follow.

- Delivery Condition2: This affects the steel’s microstructure and properties.

- AR: As-Rolled (basic condition).

- N: Normalized (heated and cooled for better toughness, common for thicker plates).

- TMCP: Thermo-Mechanically Controlled Process (advanced rolling for excellent strength/toughness combination).

- Certification & Testing: This is non-negotiable.

- "Supply with full ABS Mill Test Certificate (MTC)4."

- "Third-party inspection (SGS/BV) at mill prior to shipment is required."

- Additional Requirements:

- Processing: "Sheared edges," "Shot blasted and primed with shop primer."

- Marking: "Each plate to be stamped with Grade, Heat No., and thickness."

- Packaging: "Seaworthy packing with VCI paper5 and wooden cradles."

Example Specification for a Deck Plate

A clear purchase order line item would read:

"Qty: 80 MT. Dimensions: 20mm t x 2500mm W x 10000mm L (cut-to-length). Material: ABS AH36, Normalized (N) condition. Certification: Full ABS MTC required. Processing: Shot blasted & primed one side. Packing: Standard seaworthy export packing."

This leaves no room for misinterpretation. When a professional supplier like us receives this, we can provide an accurate price, confirm production slot with the mill, and plan logistics immediately. For our clients, such as project contractors in the Middle East, this clarity is essential for keeping their complex projects on schedule and within budget. It ensures the steel that arrives at the dock is exactly the steel that was designed into the ship.

Conclusion

Selecting marine steel plate requires a strategic approach: choose hull grades like AH/DH/EH for strength and toughness based on structural zone, use 316 stainless for corrosive fittings, and always provide a complete, unambiguous material specification to ensure you receive exactly what your project requires.

-

Understanding the significance of material grades ensures compliance with industry standards and quality assurance. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring delivery conditions helps in selecting the right steel for specific applications, enhancing performance. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Understanding tolerances is crucial for ensuring the steel fits perfectly in its intended application. ↩ ↩ ↩ ↩ ↩

-

Learn about MTCs to ensure the steel meets required specifications and quality standards. ↩ ↩ ↩

-

Learn about proper packing methods to protect steel during transport and ensure it arrives in perfect condition. ↩ ↩ ↩

-

Find out why 316L and other resistant grades are preferred for specific marine applications due to their enhanced properties. ↩ ↩