You’ve found a reliable Chinese supplier and placed your order for bulb flats. Then, the shipment arrives: the steel is rusted, bent, and half the bundles are loose. The damage costs more than your original savings. Safe shipping is the final, critical step.

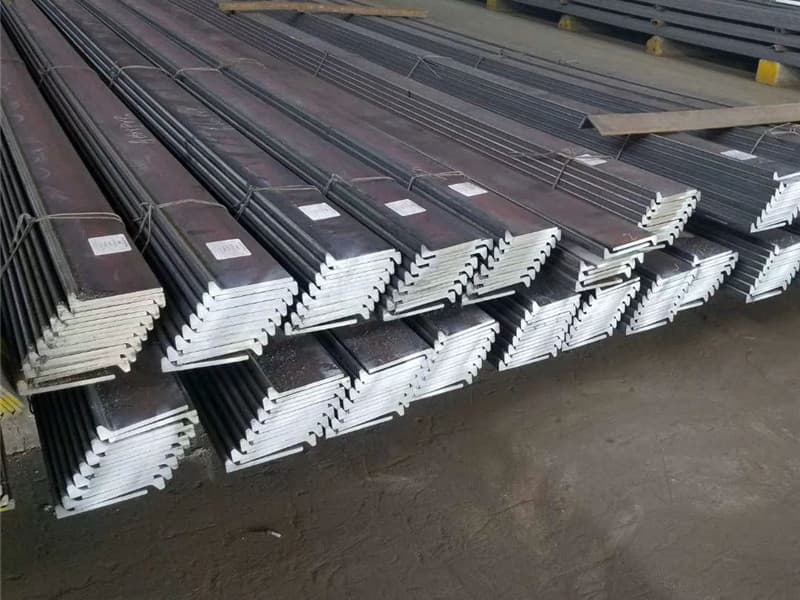

To ship bulb flat steel safely from China, use expert packaging with waterproof wrapping and rigid steel frames. Choose the right Incoterm (FOB or CFR), secure comprehensive marine cargo insurance, and work with a supplier who handles documentation and partners with reliable freight forwarders for secure stowage.

Shipping long, heavy steel profiles across oceans is a complex logistics operation. It’s not just about putting steel in a container. It’s about protecting your investment from moisture, physical impact, and bureaucratic delays. Here is the process that ensures your material arrives in workshop-ready condition.

Why is Chinese steel1 so cheap?

Many buyers see a low price from China and assume lower quality. But the price difference often comes from scale and efficiency, not cutting corners. However, the lowest price can sometimes signal hidden risks in quality or service.

Chinese steel1 appears cheaper due to massive production scale2, government support for industrial base3, and lower overall labor and operational costs. This creates competitive pricing. However, for marine-grade steel4, the price reflects the specific mill, the certification level, and the supplier’s value-added services5 like quality control6 and export logistics.

Unpacking the Price Advantage: Scale, Efficiency, and Market Reality

The perception of "cheap Chinese steel1" is a stereotype that needs careful examination. For bulk commodities like rebar, it often holds true. For technical products like certified marine bulb flats, the story is more nuanced. The price advantage exists, but it is rooted in specific factors, and smart buyers leverage it without falling into the trap of the absolute lowest bid.

Foundational Factors Driving Lower Costs:

- Unmatched Scale and Vertical Integration: China produces over half of the world’s steel. This scale allows for incredible efficiencies. Many large mills control the entire chain from iron ore mines and coking coal to the finished rolled product. This reduces transaction costs and provides supply security7.

- Government Policy and Industrial Strategy: The steel industry has been a pillar of China’s economic development. Historically, this has included support in the form of favorable loans, energy subsidies, and infrastructure investment. While these direct subsidies have decreased, the established industrial ecosystem and supply chain density remain a huge advantage.

- Lower Operational Costs: While rising, costs for labor, plant management, and certain environmental compliance can be lower than in Western Europe or North America. Modern Chinese mills are highly automated, but the overall cost structure remains competitive.

The Critical Distinction: Commodity vs. Specialized Marine Steel

This is where the "cheap" label becomes misleading. The market is segmented.

| Steel Type | Typical Chinese Price Driver | Quality & Certification | Risk for Marine Buyers |

|---|---|---|---|

| Commodity Steel (e.g., generic HRC, rebar) | Mass production, high volume, fierce competition. Price is the primary differentiator. | Basic national standard (GB). Often no third-party or international certification. | High Risk. Unsuitable for structural marine applications. Unknown properties, poor weldability. |

| Standard Marine Grade (e.g., AH36, DH36) | Scale of certified production. Many mills are class-approved. Competition between these mills drives price efficiency. | Produced to ASTM, EN, JIS standards with classification society approval (ABS, LR, DNV). | Managed Risk. Quality is verifiable via Mill Test Certificates8. The price is competitive but not "cheap" in a risky way. |

| High-Tech/Special Steel (e.g., FH40, offshore grades) | Technical capability and mill reputation. Only a few top-tier Chinese mills can produce these. | Highest level of certification, extensive testing. Price approaches or matches global competitors. | Low Risk (from quality), Higher Cost. You pay for advanced metallurgy and guaranteed performance. |

The "Cheap" Trap and How to Avoid It:

A quote that is significantly lower than the market average for certified material should be a red flag. The discount may come from:

- Non-Certified Mill: The steel is from a small, unapproved mill.

- Secondary/Rejected Material: It might be "factory surplus" or material that failed another client’s inspection.

- Hidden Costs: The low FOB price may exclude proper packaging, documentation, or professional export handling, adding cost and risk later.

Our Approach as a Professional Supplier:

We do not compete on being the "cheapest." We compete on value. Our prices from our partner mills in Shandong are competitive because of scale and location. But we ensure every cost is transparent. We invest in proper packaging, professional documentation, and English-speaking support. For a buyer like Gulf Metal Solutions, the total cost includes the assurance of quality, the savings from zero damage in transit, and the value of time saved from clear communication. That is the real economics of buying steel from China.

Who buys China’s steel?

China’s steel customers are vast and global. They range from neighboring countries building infrastructure to distant markets sourcing specific, cost-competitive materials. For marine products, the buyers are professional entities who understand how to navigate the market for quality.

A diverse global market buys China’s steel. Primary buyers include other Asian nations for construction, international trading houses, and direct industrial end-users worldwide. For marine steel plates and sections, buyers are specialized importers, shipyards, offshore fabricators, and project contractors who source certified materials for specific international projects.

The Global Client Profile: From Bulk Commodities to Niche Expertise

China doesn’t just sell steel; it sells different types of steel to different types of customers through different channels. Understanding this landscape helps you see where you fit as a buyer of specialized marine products and how to engage effectively.

Categorizing the Buyers:

- Government & State-Owned Enterprises (Domestic): The largest consumer is China’s own domestic market, driven by infrastructure, real estate, and heavy industry. This massive base allows mills to operate at full capacity.

- International Trading Houses & Stockists: These large companies buy bulk volumes of commodity steel (coils, rebar) and resell it globally. They provide liquidity and handle logistics but typically deal in standard grades, not project-specific marine certifications.

- Foreign Governments & Large Project Contractors: For massive infrastructure projects (railways, ports, dams) in Asia, Africa, and the Middle East, contractors often source structural steel directly from Chinese mills due to volume and cost requirements.

- Industrial End-Users & Fabricators (THE MARINE BUYER): This is your category. It includes:

- Shipyards and Offshore Yards: From Vietnam to Romania, yards building new vessels or platforms source hull plates, bulb flats, and angles.

- Engineering & Fabrication Companies: Companies that build modules, barges, or port structures.

- Specialist Steel Distributors/Wholesalers: Like our client in Saudi Arabia, they import in volume and supply local shipyards and projects. They are experts in their local market but rely on a reliable Chinese partner for the source material.

Why These Marine Buyers Choose China:

The decision is strategic, not just financial.

| Buyer Need | How Sourcing from China Addresses It | Potential Challenge | The Professional Supplier’s Role |

|---|---|---|---|

| Cost Competitiveness | Clear price advantage for equivalent certified quality. | Verifying that the quality is truly equivalent. | Providing full traceability via MTCs and supporting third-party inspection (SGS/BV). |

| Production Capacity & Scale | Ability to supply large, complex orders on a single schedule. | Managing long lead times and logistics. | Coordinating mill production with shipping and providing clear updates. |

| Range of Specifications | Mills produce a wide array of international standards (ASTM, EN, JIS, etc.). | Ensuring the correct standard is followed precisely. | Having technical expertise to confirm the spec and mill approval status before production. |

| Flexibility on MOQ | Some suppliers (like us) can aggregate orders or work with mills on flexible minimums. | Finding a partner for smaller project-based orders. | Offering flexible MOQ to service both large and mid-sized professional buyers. |

The Evolution of the Buyer-Supplier Relationship:

The old model was transactional: send an inquiry, get a price, place an order. The new model, especially for critical materials, is partnership-based. Sophisticated buyers look for:

- Technical Support: Ability to discuss grades, tolerances, and certifications.

- Communication Reliability: Fast, clear, English-speaking contact. This was the key pain point for Gulf Metal Solutions that we solved.

- Logistics Integration: A supplier who doesn’t just sell FOB but can help arrange cost-effective CFR/CIF shipment with insurance.

- Problem-Solving: A partner who proactively manages issues like production delays or document preparation.

In short, the people buying China’s marine steel are not bargain hunters. They are procurement professionals and engineers seeking a reliable link in their global supply chain. They buy based on total cost of ownership, which includes the price, the assurance of quality, and the cost of risk mitigation.

How can I import directly from China?

Importing directly cuts out middlemen and can increase your margin. But it also means you take on all the risks and tasks of international trade. Many first-time importers underestimate the complexity beyond just paying for goods.

To import directly from China, you need to: 1) Find and verify a reliable supplier, 2) Agree on clear Incoterms (FOB is common), 3) Arrange international freight and insurance, 4) Handle all import customs clearance and duties in your country. Using a supplier with export experience who provides clear documentation is crucial for a smooth process.

A Practical Roadmap for First-Time and Seasoned Importers

The idea of importing directly is attractive. The reality involves a series of detailed steps where mistakes are costly. Whether you’re new to this or looking to improve your existing process, here is a structured guide focused on steel products.

Phase 1: Supplier Sourcing and Verification (The Most Important Step)

This is where most failures begin. Finding a name on Alibaba is easy. Verifying a true partner is hard.

- Search & Shortlist: Use keywords like "ASTM A131 bulb flat steel manufacturer" or "ABS certified steel plate mill." Look for suppliers with detailed product pages and company information.

- Due Diligence: Ask for:

- Business License: A legitimate company will provide it.

- Mill Cooperation Proof: Evidence of long-term partnership with specific mills (photos, contracts). We openly share this with serious clients.

- Product Certificates Samples: Ask to see a blank sample of the Mill Test Certificate they provide.

- Customer References: Request contactable references in your region or similar industry.

- Communication Test: Send a detailed inquiry. Gauge their response time, technical knowledge, and English proficiency. Our client’s feedback about a "two-hour response" is a key indicator of operational discipline.

Phase 2: The Commercial Agreement

Once you have a trusted supplier, the deal must be crystal clear.

- Proforma Invoice (PI): This is your key document. It must include:

- Full product description (grade, size, standard, tolerance).

- Quantity in metric tons and number of pieces.

- Unit price and TOTAL price.

- Incoterms 2020: This defines responsibilities.

- EXW (Ex-Works): You handle everything from the factory gate. Only for experienced importers with agents in China.

- FOB (Free On Board): The most common and balanced. The supplier delivers goods to the port, clears Chinese export customs, and loads them onto the ship you nominate. You pay for main ocean freight and insurance.

- CFR (Cost and Freight): Supplier arranges and pays for ocean freight to your port. You pay insurance and import clearance. This simplifies things for you.

- Payment Terms: Typically T/T (Telegraphic Transfer): 30% deposit, 70% against copy of shipping documents.

- Packaging Details: Specify "export standard packing with waterproof wrapping and steel frames."

- Quality Assurance Clause: Specify that payment is subject to passing third-party inspection (like SGS) at the loading port. This protects you.

Phase 3: Logistics and Shipment Execution

This is the operational heart.

- Booking Freight: If terms are FOB, you (or your freight forwarder) book space on a vessel sailing from the load port (e.g., Qingdao, Tianjin) to your discharge port.

- Shipping Instructions: You give the supplier and your forwarder the Booking Note details.

- Pre-Shipment Inspection: Your appointed inspector (SGS) visits the supplier’s warehouse to check quantity, quality, markings, and packaging before the goods leave for the port.

- Documentation Collection: The supplier prepares the shipping documents:

- Commercial Invoice

- Packing List

- Bill of Lading (the title to the goods)

- Certificate of Origin

- Mill Test Certificates

- Insurance: You must purchase marine cargo insurance for the voyage. It is a small percentage of the cargo value and is non-negotiable.

Phase 4: Import Customs Clearance

When the ship arrives, your local customs broker (or your own team) uses the shipping documents to:

- Make Declaration to your country’s customs.

- Pay Import Duties and Taxes (VAT, etc.).

- Arrange Port Demurrage and Delivery: Pick up the container or loose cargo from the port.

Key Recommendation:

For your first few orders, consider using CFR terms with a supplier who has strong logistics experience. This lets them handle the complex China-side freight booking, while you focus on the import clearance in your country, which you know best. As trust builds, you can switch to FOB for more control over freight costs.

Is Chinese steel as good as US steel?

This is the wrong question. The right question is: "Can I source steel from a Chinese mill that meets my specific US (or other international) standard?" The answer is yes, absolutely. Quality is defined by the standard and the mill’s capability, not the country of origin.

Chinese steel can be exactly as good as US steel when it is produced to the same international standard (like ASTM A36 or A131) by a mill certified by the same classification societies (like ABS or LR). The quality is verified by the mill test certificate, not the mill’s location. Many top-tier Chinese mills have world-class technology and produce steel for the most demanding global projects.

A Data-Driven Comparison: Standards, Capability, and Verification

The "country of origin" debate is emotional and often outdated. In today’s globalized industry, quality is a function of process control, technology investment, and adherence to internationally recognized specifications. Let’s move beyond nationalism to a factual analysis.

The Equalizer: International Standards and Class Approval

A ship being built in a US shipyard to ABS rules does not mandate "US-made steel." It mandates "steel certified to ABS rules." A Chinese mill that has undergone the rigorous ABS type approval process has proven its capability to produce steel that meets those exact rules. The same applies for Lloyd’s Register (LR), DNV, and other societies.

Capability Spectrum in Any Country:

Neither "China" nor "the USA" produces monolithic quality steel. Both have a spectrum.

| Capability Tier | Chinese Mill Examples | US Mill Examples | Key Differentiator |

|---|---|---|---|

| Tier 1: World-Leading | Baosteel, Shagang, Ansteel (certain plants). Produce advanced AH/FH grades, stainless, for LNG carriers and offshore. | Nucor, SSAB, Cleveland-Cliffs (certain plants). Produce advanced grades for defense, energy, automotive. | Technology, R&D, and consistency. These mills compete globally on high-end products. Price differences narrow. |

| Tier 2: High-Quality Commodity | Many large, class-approved mills producing excellent AH36, DH36, A572 plate. This is where most marine steel is sourced. | Many integrated and mini-mills producing A36, A572, plate for construction and general industry. | Cost efficiency and scale. Chinese mills often have a scale advantage here. |

| Tier 3: Basic/Non-Certified | Small, local mills producing rebar and angle for domestic rural construction. | Smaller re-rollers or service centers selling non-prime or generic material. | Price-only competition. Material is unfit for certified marine use. |

Objective Factors for Comparison:

- Chemical and Mechanical Properties: An ASTM A36 plate from a certified Chinese mill will have the same specified ranges for carbon, manganese, yield, and tensile strength as one from a US mill. The MTCs are directly comparable.

- Dimensional Tolerances: Both will conform to ASTM A6 for dimensional tolerance. Modern mills everywhere use similar computer-controlled rolling technology.

- Surface Quality: This can be a point of difference. Some buyers have noted variability in surface finish (mill scale, pitting) from some Chinese sources in the past. This is where working with a quality-focused supplier is critical. We address this by:

- Sourcing from mills known for good surface control.

- Inspecting surface before shipment.

- Offering blasting/priming as an option.

The Real Differentiator: The Supplier, Not the Mill

For a buyer in Saudi Arabia or Mexico, the practical question isn’t "China vs. US." It’s "Which supplier gives me reliable access to certified quality, with clear communication and logistical support?"

- A US-based distributor might offer easier communication but at a significant price premium, as they are also importing the material.

- A direct Chinese supplier offers a better price but requires you to manage more of the process.

Our Value Proposition: We bridge this gap. We are the Chinese supplier with the process rigor and communication standards a Western buyer expects. We provide:

- Direct access to Tier 2 certified mills at competitive prices.

- English-speaking, responsive project management.

- Full documentation and inspection support (like SGS) to verify quality matches the standard, providing the same level of assurance you would expect from a local distributor.

The steel from our partnered mills is not "as good as" US steel. It is the same steel, defined by the same ASTM and ABS rulebook. Our role is to guarantee that equivalence and deliver it to your port reliably.

Conclusion

Safely shipping bulb flat steel from China hinges on expert packaging, clear Incoterms, full insurance, and, most importantly, a supplier who manages the entire process with professionalism and transparency, turning geographic distance into a competitive advantage.

-

Explore this link to understand the factors that contribute to the pricing of Chinese steel and its market dynamics. ↩ ↩ ↩

-

Learn how massive production scale influences pricing and efficiency in the steel industry. ↩

-

Discover the role of government policies in shaping the competitive landscape of China’s steel industry. ↩

-

Find out why marine-grade steel is crucial for specific applications and how it differs from commodity steel. ↩

-

Discover how value-added services enhance the purchasing experience and ensure quality in steel procurement. ↩

-

Understand the importance of quality control in steel production and how it impacts overall product reliability. ↩

-

Explore how supply security contributes to stable pricing and availability in the steel market. ↩

-

Learn about Mill Test Certificates and their significance in verifying the quality of steel products. ↩