Your L-shaped steel arrives bent, rusted, and tangled. The bundles are broken, and sorting the usable pieces takes days. Transit damage turns your high-quality order into scrap, causing project delays and financial loss.

Safe export transport for L-shaped steel requires specialized packaging (tight bundling with steel straps on protective dunnage), correct loading and securing inside the container or on the ship, and choosing the right shipping method (container or breakbulk) based on length and volume. Weather protection and clear marking are also essential.

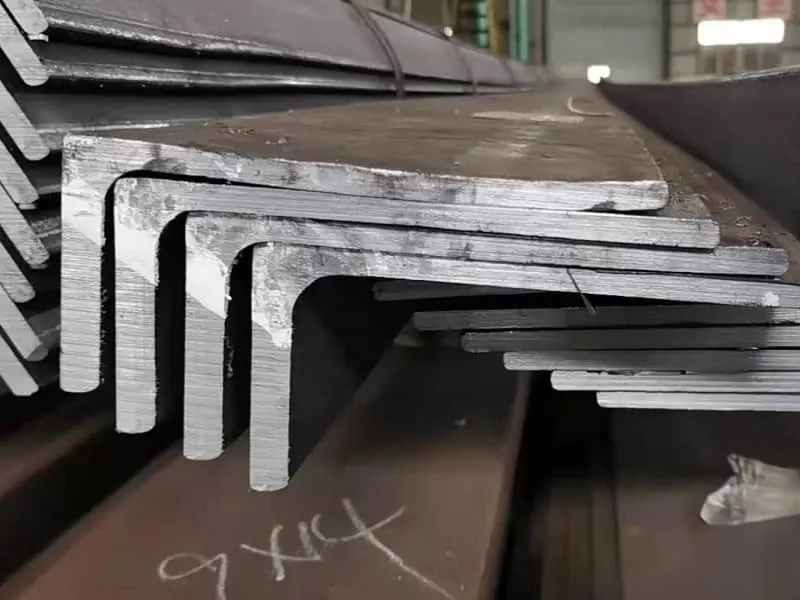

L-shaped steel is not a simple cargo. Its long, slender shape and sharp edges make it prone to bending, scratching, and causing damage. Safe transport is a deliberate process that starts at the factory. Let’s walk through each critical step to ensure your material arrives in perfect condition.

How do you transport steel?

You need to move steel from the mill to the port, then across the ocean, and finally to your yard. Each leg of the journey uses different equipment and poses different risks. A one-size-fits-all approach will fail.

You transport steel using a combination of land and sea logistics: Heavy trucks and flatbed trailers1 move it from mill to port. At the port, it is loaded onto shipping containers2 (for smaller sizes) or directly into a breakbulk cargo ship’s hold3 (for oversized pieces). The method depends on the steel’s dimensions, weight, and the required delivery speed.

Transport is a chain. A weak link at any point—loading, inland haulage, port handling, or sea voyage—can break the entire effort. Let’s examine each link and the specific risks for L-shaped profiles.

The Transport Chain: From Mill Gate to Customer’s Yard

The journey involves multiple handoffs. Success depends on precise coordination and the right equipment at each stage.

Stage 1: Inland Transport (Mill to Port)

- Equipment: Heavy-duty flatbed trucks or trailers. For very long sections (over 12m), specialized long-load trucks are used.

- Key Risks for L-Shaped Steel:

- Overhang: Long angles hanging off the back of a trailer can swing or hit obstacles.

- Bending: Improper support along the length can cause permanent deformation.

- Securing: L-shaped steel can twist if not strapped down correctly.

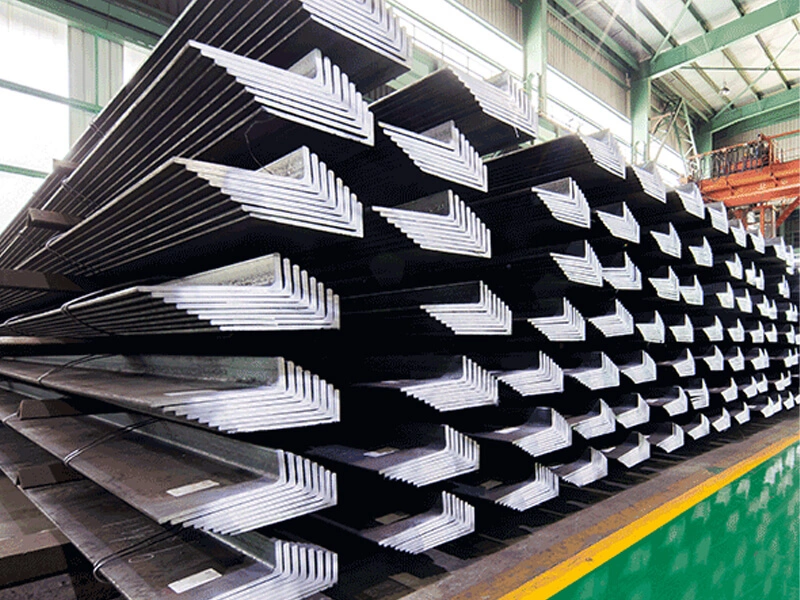

- Mitigation: Use enough steel straps4 (not ropes) over the bundles. Place timber dunnage5 (wooden blocks) under the bundles at strategic points to distribute weight and allow for forklift lifting later. The bundles must be tight to prevent individual pieces from shifting.

Stage 2: Port Handling and Storage

- Equipment: Forklifts with long forks, side-loaders, or quay cranes with lifting beams6 and slings.

- Key Risks:

- Crushing: Using slings incorrectly can crush the bundle, bending the outer angles.

- Dropping: Slippage from wet or oily surfaces.

- Corrosion: Exposure to salt air and rain if stored in the open for too long.

- Mitigation: Require the use of lifting beams6 that pick up the bundle from underneath (using the dunnage). Good packaging includes waterproof wrapping7. Storage should be brief and on level ground.

Stage 3: Ocean Transport (Container vs. Breakbulk)

This is the most critical decision.

- Container Shipping: Steel is packed inside a standard 20ft or 40ft container.

- Pros: Secure, less handling, door-to-door service.

- Cons: Size limits. Standard container width is ~2.3m. L-shaped steel longer than about 11.8m for a 40ft container will not fit. Also, sharp edges can damage the container interior.

- Breakbulk Shipping: Bundles are lifted individually into the ship’s hold.

- Pros: No length limitation. Can handle very long pieces (e.g., 18m).

- Cons: More handling, exposure to weather and seawater spray, higher risk of physical damage.

Comparative Risk Table:

| Transport Stage | Primary Risk for L-Steel | Professional Mitigation |

|---|---|---|

| Inland Trucking | Bending from improper support. | Use multiple timber supports. Strap bundles tightly every 1.5-2 meters. |

| Port Handling | Bundle collapse or crushing by slings. | Design bundles with sturdy dunnage for lifting. Specify "Lift from dunnage only." |

| Container Shipping | Damage to container or cargo from shifting/edges. | Use air bags or wooden braces inside container to block movement. Protect edges with corner guards. |

| Breakbulk Shipping | Seawater exposure, hook damage, loss overboard. | Heavy-duty waterproof wrapping7 (e.g., plastic + tarpaulin). Secure bundles to ship’s structure with lashings. |

Our client feedback specifically mentions "the packaging is the best… we have received." This is not an accident. It’s the result of a standardized packing procedure we enforce for all exports, designed to protect the steel through every stage of this complex chain.

How is steel shipped overseas?

Your steel is at the Chinese port. Now, how does it actually cross the ocean? The choice of vessel and stowage method determines the cost, speed, and safety of the sea voyage.

Steel is shipped overseas primarily in shipping containers1 (for standard-sized material) or as breakbulk/general cargo2 (for oversized or heavy pieces). Container shipping is faster and more secure. Breakbulk is used for items too large for containers. The steel is loaded, secured, and documented according to international shipping regulations (IMDG Code for safety).

The sea voyage is the longest and least controllable leg. Once the ship sails, you can’t fix poor loading. Understanding the two main methods helps you make the right choice and set proper expectations.

Choosing the Right Vessel: Container vs. Breakbulk

The decision is driven by dimensions, volume, and project requirements. For L-shaped steel3, length is often the deciding factor.

Method 1: Containerized Shipping (The Box)

- Process: Bundles of L-steel are loaded into a container at the warehouse or port terminal. The container is then sealed and transported as a single unit.

- Container Types4:

- Standard Dry Container: 20′ (5.9m internal length) or 40′ (12.03m internal length). L-steel must fit diagonally or be cut to length.

- Open Top Container: Has a removable soft top. Allows loading via crane for items slightly over height.

- Flat Rack Container: Has no sides, just ends. Ideal for very wide or over-height cargo. L-steel bundles are secured directly to the rack.

- Loading & Securing Inside a Container:

- Floor Protection: Lay timber dunnage on the container floor to raise bundles and allow airflow.

- Positioning: Place bundles tightly against the container wall and each other.

- Blocking and Bracing5: Use air bags, wooden wedges, or steel braces to fill empty spaces and prevent any movement during the ship’s rolling. This is critical. Unsecured steel can shift and tear through the container walls.

- Lashing: Secure bundles to the container’s lashing points with steel straps or chains.

Method 2: Breakbulk Shipping (The Hold)

- Process: Individual bundles are lifted by the ship’s crane and stowed in the vessel’s cargo hold6 or on deck.

- Stowage: The ship’s chief officer plans the stowage to balance the vessel and protect the cargo. Bundles are placed on timber dunnage and then lashed (tied down) to the ship’s structure using wire ropes, chains, and turnbuckles.

- Key Considerations for L-Steel:

- Weather: Breakbulk cargo is exposed. Waterproof wrapping is mandatory. Even with wrapping, some surface moisture exposure is possible.

- Multiple Ports: Your cargo may be stowed under other cargo destined for an earlier port. This requires careful planning.

Decision Guide for L-Shaped Steel:

| Cargo Characteristic | Recommended Method | Reason |

|---|---|---|

| Length ≤ 11 meters, standard quantity. | Container (40ft Dry or Flat Rack). | Cost-effective, secure, faster transit. |

| Length > 12 meters, or very large volume. | Breakbulk. | Only practical method for very long pieces. |

| High-value, corrosion-sensitive finish (e.g., pre-primed). | Container. | Maximum protection from elements. |

| Urgent delivery required. | Container. | More frequent sailings and faster port turnaround. |

| Part of a large project with other oversized items. | Breakbulk. | Allows consolidation of all oversized project cargo on one vessel. |

We manage this decision for our clients. Based on the order list, we recommend the optimal shipping method. For a recent shipment to Saudi Arabia, the L-steel was under 12m, so we shipped it in containers with expert blocking and bracing, ensuring it arrived at Dammam port in the same condition it left our warehouse.

How is steel used in transportation?

You are shipping steel, but steel is also the material that builds the ships, trucks, and infrastructure doing the shipping. It is both the cargo and the enabler. This dual role highlights its fundamental importance.

Steel is used in transportation as both the cargo being shipped1 and the primary material for building the transportation infrastructure. It constructs ships, trucks, railcars, port cranes, bridges, and shipping containers. Its strength, durability, and formability make it ideal for creating the vehicles and structures that move global trade.

This creates a self-reinforcing loop. The steel industry relies on transportation to reach markets, and the transportation industry relies on steel to exist. Let’s focus on the marine logistics segment to see this interdependence in action.

The Backbone of Logistics: Steel in Marine Transport Infrastructure

From the smallest fastener to the largest gantry crane, steel is everywhere in the port-to-port journey of your L-shaped steel.

1. Steel in Marine Vessels:

- Cargo Ships: The hull, decks, frames, and bulkheads of container ships, bulk carriers, and general cargo vessels are made from marine-grade steel2 (AH/DH/EH grades).

- Tugs and Service Vessels: Also steel-built.

- Shipping Containers: The standard ISO container is made from Corten steel3 (weathering steel) for its strength and corrosion resistance. Your L-steel likely travels inside one.

2. Steel in Port Infrastructure:

- Quays and Wharves: Steel sheet piles and tubular piles form the retaining walls.

- Cranes: Gantry cranes, ship-to-shore cranes, and mobile harbor cranes have massive steel structures to handle heavy loads.

- Warehouses and Sheds: Steel-framed buildings store cargo.

- Accessories: Bollards, fenders, and ladders are often steel fabrications.

3. Steel in Land-Side Transport:

- Truck Chassis and Trailers: Made from high-strength steel4 to carry heavy loads like your steel bundles.

- Railway Lines and Cars: Rails are steel. Freight cars have steel frames.

- Bridges: Steel bridges allow trucks and trains to access ports.

Implication for Your L-Steel Shipment:

The quality and specifications of the steel in this infrastructure directly impact the safety and efficiency of your shipment.

- A crane made from certified structural steel5 can safely lift your 20-ton bundle.

- A truck trailer with a robust steel frame can carry the load without buckling.

- A steel shipping container protects your cargo from the elements.

The Role of a Supplier Who Understands Both Sides:

We supply steel for this infrastructure (e.g., plates for shipyards, sections for crane manufacturers) and we ship steel through this infrastructure. This gives us a unique perspective. We understand the stresses cargo faces during transport because we know how the transport equipment is built. This informs our packaging and handling standards. We know that a poorly secured bundle can damage a truck’s bed or a container’s interior, and we act to prevent it.

A Practical Connection:

When you order L-shaped steel for building port infrastructure (like a crane or a storage rack), you are using steel to build the system that will later handle more steel. Ensuring the quality of your purchased steel is therefore an investment in the long-term reliability of the logistics chain itself.

What are the 4 methods of transportation?

You need to get your steel from point A to point B. You have four basic choices, each with different costs, speeds, and capacities. Picking the wrong method for your L-shaped steel1 order leads to excessive cost or logistical impossibility.

The four fundamental methods of transportation are Road, Rail2, Sea3, and Air4. For international export of heavy goods like L-shaped steel1, the journey typically combines Road (to port), Sea3 (ocean crossing), and then Road5 again (to final destination). Rail2 is sometimes used for long inland hauls. Air freight is cost-prohibitive for steel except for tiny, urgent samples.

Each method has a "sweet spot" in terms of cost, speed, and cargo type. For bulk marine steel, sea freight is the only viable intercontinental method. But the other three play critical supporting roles. Let’s analyze each one’s role in an export shipment.

A Modal Analysis: Selecting the Right Tool for Each Leg

An export shipment is a multi-modal journey. You use different modes for different parts of the trip based on geography and economics.

- Role: First and Last Mile. From mill/warehouse to port of loading, and from port of discharge to final customer’s yard.

- Advantages: Flexible, door-to-door service, no transloading needed for short distances.

- Disadvantages: High cost per ton-mile, subject to traffic and road regulations (weight, length, height limits).

- For L-Steel: Critical. Requires specialized flatbed trucks. Length restrictions vary by country (e.g., max 13.6m in EU, longer permits possible elsewhere).

- Role: Long Inland Haul. Used in large countries (like China, USA) to move heavy goods from inland mills to coastal ports.

- Advantages: Very low cost per ton-mile for long distances, high capacity, energy-efficient.

- Disadvantages: Inflexible schedules, requires transloading at both ends (truck to rail, rail to truck).

- For L-Steel: Common in China. Mills in Liaocheng may use rail to move steel to the port of Qingdao6. Bundles are loaded onto railcars designed for long steel products.

- Role: Intercontinental Bulk Movement. The backbone of global trade for heavy commodities like steel.

- Advantages: Lowest cost per ton-mile for long distances, massive capacity.

- Disadvantages: Slowest method (weeks), subject to weather and port congestion.

- For L-Steel: The non-negotiable core of export. As discussed, via container or breakbulk vessels.

- Role: Urgent, High-Value, Low-Weight Shipments.

- Advantages: Fastest method (days).

- Disadvantages: Extremely high cost, severe weight and size limitations.

- For L-Steel: Only for critical small samples (e.g., a 1-meter cut piece for lab testing or approval). Never for production quantities.

Building a Multi-Modal7 Export Plan for L-Steel:

A typical shipment from our location in Shandong, China to a client in the Middle East looks like this:

- Leg 1 (Road5/Rail2): Bundled L-steel moves from our warehouse in Liaocheng to the Port of Qingdao6. This is ~400km, done by truck or a combination of truck and rail.

- Leg 2 (Sea3): Bundles are loaded into containers or as breakbulk onto a cargo vessel in Qingdao6. The vessel sails to, for example, Jebel Ali, UAE or Dammam, Saudi Arabia. This takes 2-3 weeks.

- Leg 3 (Road5): Containers are de-vanned or breakbulk bundles are picked up from the port by local trucks and delivered to the client’s fabrication yard, perhaps in Dubai8 or Riyadh.

Key Considerations for Multi-Modal7 Success:

| Mode | Critical Checkpoint for L-Steel | Supplier’s Responsibility |

|---|---|---|

| Road5/Rail2 (Inland) | Bundle integrity for repeated handling. Weight/ length compliance. | Ensure packaging can withstand multiple lifts. Provide accurate weight and dimensions for transport planning. |

| Sea3 (Main Voyage) | Correct securing method (container blocking or ship lashing). Weather protection. | Choose appropriate sea freight method. Apply waterproof wrapping. Provide lifting plans for breakbulk. |

| All Modes | Documentation. Every handoff requires correct paperwork (packing list, bill of lading, customs docs). | Prepare and provide a complete, accurate document set that travels with the cargo. |

Our service includes managing this multi-modal chain. We handle the inland leg to the port, book the ocean freight, and prepare all documents. This turnkey approach, mentioned in our client solutions, removes a massive burden from the buyer and ensures a smoother journey for the L-shaped steel1.

Conclusion

Safe transport of L-shaped steel for export requires robust packaging, the correct choice between container and breakbulk shipping, and careful management of the multi-modal journey from factory to final destination.

-

Find expert insights on the logistics and considerations for successfully exporting L-shaped steel. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the cost-effectiveness and capacity advantages of rail transport for heavy goods. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover why sea transport is essential for intercontinental shipping, especially for bulk goods like steel. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Understand the high costs and restrictions of air transport, making it suitable only for urgent, small shipments. ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the benefits of road transport, including flexibility and door-to-door service, crucial for efficient logistics. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about Qingdao’s role in global trade and its importance for shipping heavy goods. ↩ ↩ ↩ ↩ ↩ ↩

-

Explore how multi-modal transportation optimizes shipping efficiency and cost-effectiveness. ↩ ↩ ↩ ↩

-

Discover key logistics factors for successful shipping operations to Dubai, a major trade hub. ↩