As a marine steel supplier, I get this question all the time. My clients are busy project managers and importers. They need to trust their materials are certified and correct. A Mill Test Certificate is their first line of defense, but only if it’s real.

A genuine Mill Test Certificate (MTC) is a verified quality passport issued by the steel mill. To verify it for marine angle steel, you must cross-check its unique certificate number and chemical-mechanical properties against the original mill’s database and perform a visual-material inspection of the steel itself.

You understand the importance of the MTC. But simply having a piece of paper isn’t enough. In the global marine steel trade, verifying that document is as critical as the steel it describes. The next sections will show you exactly what to look for, how to check it, and why the specific MTC 3.1 is so trusted in our industry. This knowledge protects your project from costly delays and failures.

How to verify a mill test certificate1?

Imagine receiving a shipment of marine angle steel. The MTC looks perfect. But a week later, your fabricator reports welding issues. The root cause? A falsified certificate. This nightmare is preventable with a systematic verification process.

To verify a mill test certificate1, you must perform a three-step check: contact the issuing mill to confirm the certificate number, match the listed chemical and mechanical properties2 with your material’s test results, and inspect the steel for consistent markings and surface quality.

Let’s dive deeper into each verification step. This process turns you from a passive document receiver into an active quality controller.

A Step-by-Step Guide to MTC Verification

Verification is not just reading the certificate. It is an active investigation. I advise my clients, like Gulf Metal Solutions in Saudi Arabia, to follow this exact protocol for every batch.

Step 1: Database Verification with the Mill

Every legitimate MTC from a major mill has a unique certificate or heat number. This is your most powerful tool.

- Action: Go to the steel mill’s official website. Look for a "Certificate Verification" or "Quality Query" section. In China, mills like Baowu, Shagang, and Ansteel have these portals.

- What to Input: Enter the full certificate number, heat number, and grade (e.g., AH36, D36).

- Expected Result: The online database should return a digital copy of the exact same MTC. Every detail—chemical composition3, mechanical properties2, dimensions—must match your paper copy perfectly. If the number is not found, or the details differ, it is a major red flag.

Step 2: Property Cross-Checking

The data on the MTC must align with both the order specifications and reality.

- Chemical Composition: Check key elements like Carbon (C), Manganese (Mn), Silicon (Si), Phosphorus (P), and Sulfur (S). For marine grades, low P and S are critical for toughness. Compare these values against the standard (e.g., ABS, LR, DNV GL rules).

- Mechanical Properties: Verify Yield Strength (ReH), Tensile Strength (Rm), and Elongation (A%). For example, AH36 angle steel must have a minimum yield strength of 355 MPa. If the MTC shows 360 MPa but your on-site test shows 340 MPa, the material or certificate is faulty.

- Third-Party Inspection: This is our standard service. Before shipment, we support SGS, BV, or CCIC inspections. The inspector will take samples from your specific batch and test them in a lab. The lab report must confirm the MTC data. This objective check gives importers immense peace of mind.

Step 3: Physical and Marking Inspection

The steel itself tells a story. The MTC is its biography, and they must agree.

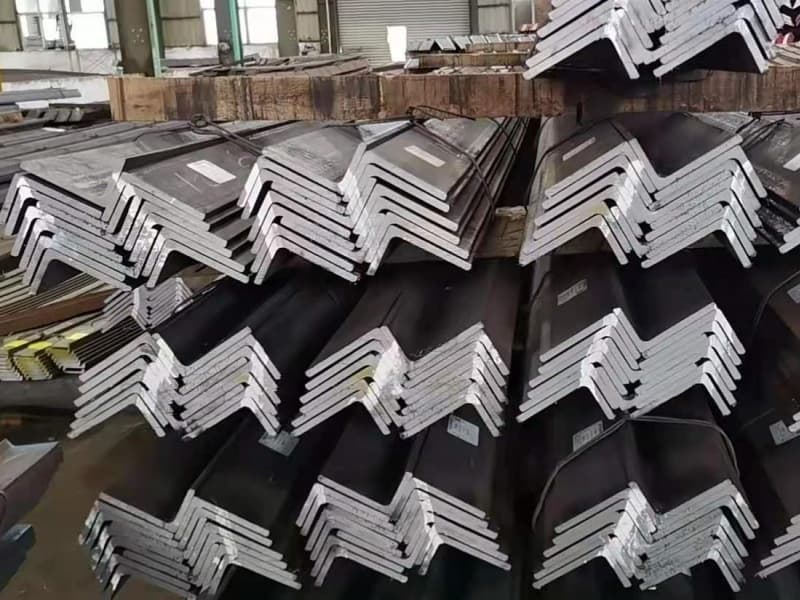

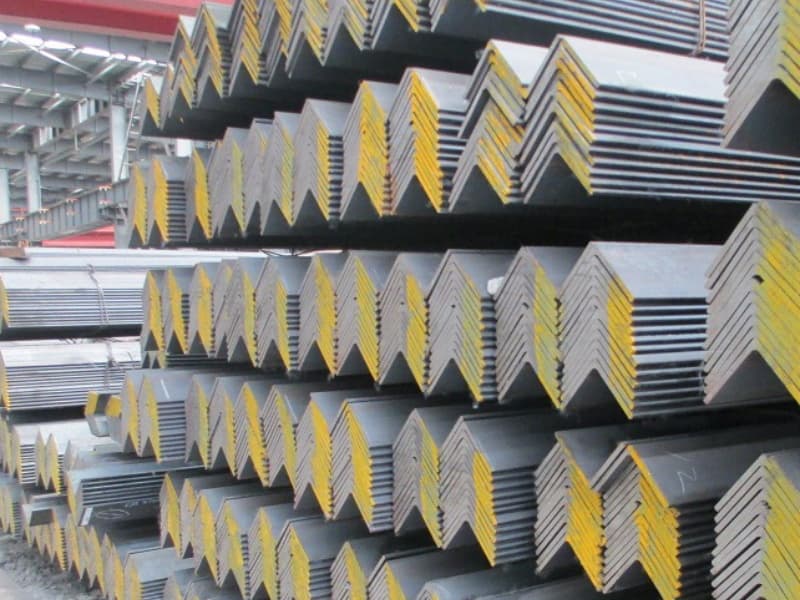

- Mill Markings: Look for the mill’s logo, grade (e.g., AH36), heat number, and size stamped or rolled onto the steel angle4‘s surface. The heat number on the steel must match the heat number on the MTC.

- Visual Quality: Check the surface condition. Marine angle steel should be free of deep cracks, heavy rust, or uneven dimensions that contradict the "sound condition" stated on the MTC.

- Bundle Tags: Each bundle should have a tag repeating the certificate number, heat number, grade, and size. Check this tag against your MTC.

Here is a quick checklist for your team:

| Verification Step | What to Check | Tool/Method | Acceptable Outcome |

|---|---|---|---|

| 1. Authenticity | Certificate/Heat Number | Mill’s Online Portal | Exact match found in official database. |

| 2. Data Accuracy | Chemical & Mechanical Properties | Compare MTC to Order Specs & 3rd-Party Report | All values meet or exceed required standards. |

| 3. Material Match | Steel Markings & Bundle Tags | Visual Inspection On-Site | Stamped heat number on steel matches MTC heat number. |

Following these steps takes effort. But it is the only way to ensure the marine angle steel you buy is the high-quality, certified product you paid for. It turns the MTC from a formality into a powerful tool for risk management.

What does a mill test certificate look like?

You open an email from a new supplier. An MTC is attached. Your eyes scan the document. Is it complete? Is it professional? Knowing the standard layout helps you spot problems in seconds.

A standard mill test certificate is a formal, multi-section document. It features the mill’s official letterhead and logo, a unique certificate number, detailed chemical and mechanical test results for a specific heat/batch, and authorized signatures or stamps from the mill’s quality department.

Let’s break down a typical MTC for marine angle steel. This will help you read it like a pro.

Anatomy of a Standard MTC

While designs vary by mill, all legitimate MTCs contain the same core information blocks. Think of it as a medical report for a batch of steel.

Header Section: The Source of Truth

This is the document’s identity card. It must be clear and professional.

- Mill Information: The full name, logo, and address of the producing steel mill (e.g., Shandong Iron and Steel Group Co., Ltd.). Be wary of certificates with no logo or a generic "Trading Company" header.

- Certificate Title: Clearly states "Mill Test Certificate1," "Inspection Certificate," or "Chemical and Physical Test Report."

- Unique Identifiers: The Certificate Number and Heat Number/Cast Number are the most important codes. They are the keys to online verification.

Product & Order Details: The "What and For Whom"

This links the document to your specific purchase.

- Product Description: Specifies the product form (e.g., "Equal Angle Steel," "Bulb Flat").

- Grade/Standard: The material grade (e.g., AH36, DH36) and the governing standard (e.g., ABS Grade AH36, EN 10025-6).

- Dimensions & Quantity: Lists the size (e.g., 100x100x10mm) and the total weight or quantity of material from this heat.

- Purchase Order/Consignee: May include your company name or order reference.

The Core Test Data: The "Proof of Quality"

This is the technical heart of the MTC. It has two main tables.

- Table 1: Chemical Composition2 (Ladle Analysis):

This shows the percentage of each element in the molten steel. For marine steels, you are looking for very low levels of Phosphorus (P) and Sulfur (S) to ensure good weldability and impact toughness at low temperatures. A certificate missing this table is worthless. - Table 2: Mechanical Properties3:

This presents the results of tests performed on samples from the finished product. Key entries include:- Yield Strength4 (ReH): The stress at which the steel begins to deform permanently.

- Tensile Strength (Rm): The maximum stress the steel can handle before breaking.

- Elongation (A%): How much the steel can stretch before breaking, indicating ductility.

- Impact Test (Charpy V-Notch)5: For marine grades, this is critical. It shows the energy absorbed at low temperatures (e.g., -20°C or -40°C), proving toughness in cold environments.

Footer & Authorization: The Legal Stamp

This gives the document its official authority.

- Statement of Conformity6: A sentence declaring the material conforms to the specified standard.

- Authorized Signatures & Stamp: Must include the signature of the mill’s quality control manager or an authorized inspector, accompanied by the mill’s official quality department stamp. A signature without a stamp, or a digital stamp that looks copied, is suspicious.

A clean, well-organized MTC with all these sections shows a mill’s professionalism. When my team prepares documents for clients, we ensure every MTC is complete, clear, and ready for your verification process. A messy or incomplete certificate is often the first sign of a problem.

What is a mill test certificate?

You place a large order for marine angle steel. You trust the supplier. But trust is not a quality control1 method. The Mill Test Certificate2 is the tangible proof that turns trust into verified fact.

A Mill Test Certificate2 is an official quality document issued by a steel mill. It acts as a "birth certificate" for a specific batch of steel, providing verified data on its chemical composition3 and mechanical properties4 to prove it meets ordered standards.

Understanding the MTC’s role is fundamental to sourcing marine steel. It is not just paperwork.

The MTC: More Than a Piece of Paper

The MTC serves multiple critical functions in the B2B steel supply chain. It is a communication tool, a legal record, and a safety guarantee.

Primary Function: Proof of Conformity

The core job of an MTC is to provide objective evidence. When you order ABS AH36 angle steel, you are not just buying a shape. You are buying a set of performance promises: a specific strength, a specific chemistry for welding, and certified toughness. The MTC is the mill’s sworn statement that this particular batch of steel meets those exact promises. It bridges the gap between the abstract standard (the rulebook) and the physical product (the steel on your dock).

Its Role in the Supply Chain

The MTC creates a chain of accountability.

- For the Mill: It is a declaration of their quality control1. Issuing it makes them liable for the data.

- For the Supplier/Exporter (like us): It is the key document we provide to you. It validates our claim of selling certified mill material, not uncertified or "market" steel. Our ability to provide genuine, traceable MTCs from partnered mills like those in Shandong is a core part of our service.

- For You, The Importer/Fabricator: It is your primary tool for incoming quality assurance. You use it to verify the material before fabrication. It is also essential for your own documentation. When you build a ship section for a shipyard, you must submit the MTCs of all steel used to the Classification Society5 surveyor (like Lloyd’s Register, DNV GL). No valid MTC often means the steel cannot be used in class-approved construction.

Legal and Commercial Importance

Think of the MTC as part of your contract.

- It is a Condition of Sale: Your purchase order likely states "Material must be supplied with original Mill Test Certificate2s." Failure to provide them can be grounds for rejection or a claim.

- It Supports Claims: If steel fails during fabrication, the first evidence you and the surveyor will examine is the MTC. If the MTC data is wrong, your claim against the supplier or mill is strong. If there is no MTC, your position is very weak.

- It Ensures Traceability: In the unlikely event of a major failure in service, the heat number on the MTC allows authorities to trace the problem back to the exact production batch. This is crucial for safety investigations.

In short, the MTC is the foundational document of quality and traceability6 in the steel industry. It protects everyone in the chain. That’s why we never treat it as an afterthought. For every shipment of marine angle steel or plate, the MTC is prepared with the same care as the steel’s packaging.

What is a MTC 3.1 certificate?

You see "MTC 3.1" on a certificate. It sounds technical. But in marine and pressure vessel projects, this is not just a type of MTC—it is the gold standard of certification with the highest level of independent verification.

An MTC 3.1 Certificate is an inspection certificate issued by the material manufacturer (the mill) but witnessed and validated by an independent inspector (e.g., from a Classification Society like BV or LR). It provides the highest level of assurance that the material meets the specified requirements.

The "3.1" designation comes from EN 10204, the European standard defining types of inspection documents. Understanding its requirements is key for high-stakes projects.

Understanding EN 10204 and MTC 3.1

EN 10204 classifies inspection documents based on who declares conformity and what level of independent verification is involved. MTC 3.1 sits at a high level.

The EN 10204 Hierarchy

- Type 2.1: A simple "Statement of Compliance" issued by the mill, without specific test results. It’s a declaration, not detailed proof.

- Type 2.2: A standard Mill Test Certificate with specific test results (chemical, mechanical), issued by the mill itself. This is the most common type we supply for general marine applications.

- Type 3.1: An Inspection Certificate with specific test results. The key difference? The mill’s test report is verified and endorsed by the mill’s own in-house, independent inspection department that is separate from the production team. This internal auditor confirms the data.

- Type 3.2: An Inspection Certificate with specific test results, verified and signed off by an external, independent third-party inspector (e.g., a surveyor from DNV GL, ABS, or SGS) appointed by the purchaser. This is the highest level.

Why MTC 3.1 is Crucial for Marine Steel

In practice, for critical marine applications like offshore structures, main hull components, or pressure vessels, project specs and Classification Society rules often demand a certificate equivalent to 3.1 or 3.2.

- It Adds a Layer of Scrutiny: The "independent" inspector (internal for 3.1, external for 3.2) witnesses or reviews the testing. They ensure the samples are taken correctly from the batch and that the test methods and results are accurate.

- It Carries More Weight: For a shipyard building an oil tanker, submitting MTC 3.1 certificates to the class surveyor smooths the approval process. The surveyor has greater confidence in data validated by an independent party.

- Our Role as Your Supplier: When a client like a project contractor in Qatar needs MTC 3.1 or 3.2 for their marine plate, we coordinate this from the start. We work with our partner mills to ensure their independent quality department (for 3.1) or a nominated third-party inspector (for 3.2) is involved in the testing and certification process. We manage this complexity so you receive the correct, validated documents without hassle.

Here is a comparison to clarify:

| Certificate Type (EN 10204) | Who Issues It? | Key Feature | Common Use Case |

|---|---|---|---|

| 2.2 – Mill Test Certificate | The Production Mill | Reports test data. No independent verification. | General marine components, non-critical structures. |

| 3.1 – Inspection Certificate | The Mill’s Independent Inspection Dept. | Mill’s own internal inspector verifies & signs off. | Critical hull parts, offshore applications, high-spec projects. |

| 3.2 – Inspection Certificate | Independent Third-Party (e.g., DNV, SGS) | External inspector appointed by buyer verifies & signs. | Most critical applications, pressure vessels, specified by class rules. |

Knowing to ask for an MTC 3.1 when your project demands it is a mark of a professional buyer. It moves beyond basic quality to assured, audited quality.

Conclusion

Verifying Mill Test Certificates is a non-negotiable skill for sourcing marine steel. It protects your investment, ensures safety, and keeps your projects on track.

-

Find out about effective quality control practices in steel manufacturing to ensure product reliability and safety. ↩ ↩ ↩ ↩ ↩

-

Explore this link to understand the significance of Mill Test Certificates in ensuring quality and compliance in steel supply. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the impact of chemical composition on steel properties and performance, crucial for making informed purchasing decisions. ↩ ↩ ↩

-

Discover the essential mechanical properties of steel that determine its suitability for various applications in construction and manufacturing. ↩ ↩ ↩

-

Understand the role of Classification Societies in maintaining safety and standards in shipbuilding and marine construction. ↩ ↩

-

Explore the importance of traceability in the steel industry for safety, accountability, and quality assurance. ↩ ↩