A shipyard in Saudi Arabia once received fake MTC documents. This experience taught me the critical importance of proper certificate verification.

Mill Test Certificate verification involves checking document authenticity, verifying chemical composition and mechanical properties against standards, confirming heat number traceability, and validating classification society stamps. Proper MTC verification ensures marine steel meets required specifications and maintains full traceability for shipbuilding applications.

MTC verification is your first defense against substandard materials. Let me guide you through the essential verification steps that protect your projects.

How to verify mtc?

A contractor from Qatar almost accepted invalid MTC documents. Systematic verification prevented a potential quality disaster.

MTC verification1 requires checking mill accreditation2, verifying signature authority, confirming heat number consistency3, validating testing dates4, and cross-referencing with material markings. Third-party verification services like SGS provide additional assurance for critical marine applications where certificate authenticity is paramount.

Comprehensive MTC Authentication Process

MTC verification1 involves multiple layers of checks that ensure document authenticity and data reliability. Each check serves a specific purpose in the verification chain.

Document Origin Verification

Start by verifying the issuing mill’s authenticity. Check if the mill holds valid accreditation for the specified grade. Confirm the mill’s quality system certifications are current. Verify the mill’s contact information matches official records. Some mills provide online verification portals for certificate authentication. This first step ensures the document comes from a legitimate source.

Signature and Authorization Validation

Examine the signatures and stamps on the MTC. Verify that signing personnel have proper authority levels. Check if signatures match the mill’s authorized signatory list. Confirm classification society stamps are genuine and current. Look for any signs of photocopying or digital manipulation. Proper authorization ensures the certificate carries legal weight.

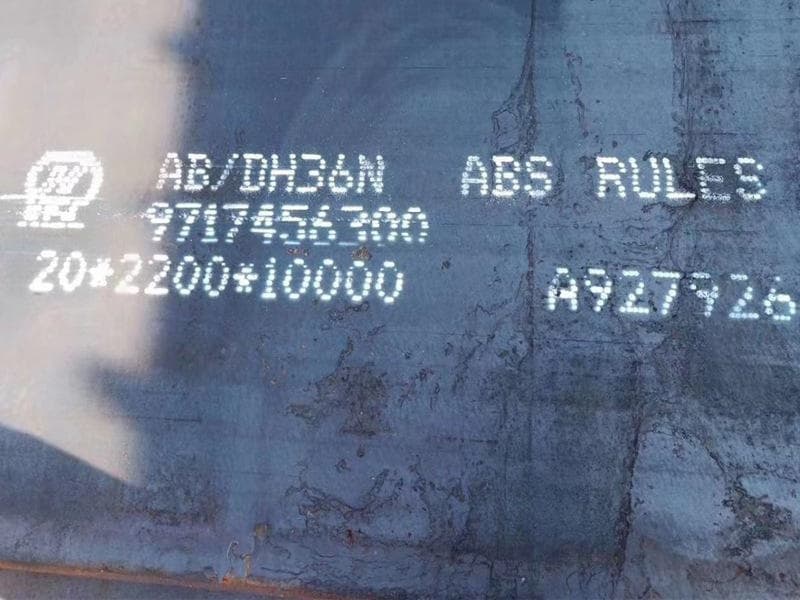

Heat Number Traceability

The heat number provides crucial traceability. Verify the heat number format matches the mill’s standard system. Check that the same heat number appears on all related documents. Confirm the heat number corresponds to the production date. Ensure material markings on plates match the MTC heat number. This traceability links the certificate to specific material batches.

Testing Date and Sequence Analysis

Review the testing timeline for logical consistency. Check that chemical analysis dates precede mechanical testing. Verify heat treatment dates align with production schedules. Confirm the certificate issuance date follows all testing completion. Look for any date inconsistencies that might indicate document tampering. Proper sequencing indicates genuine testing procedures.

Third-Party Verification Options

For critical applications, consider independent verification. Third-party inspectors can contact mills directly for confirmation. Testing laboratories can verify MTC data through sample analysis. Classification societies maintain records of certified materials. These independent checks provide additional security against document fraud.

Digital Security Features

Modern MTCs often include security elements. Look for holograms, watermarks, or security threads. Check digital certificates for electronic signatures. Verify QR codes link to authentic verification portals. These features help prevent document forgery and unauthorized alterations.

MTC Verification Checklist

| Verification Element | Check Method | Acceptance Criteria |

|---|---|---|

| Mill Accreditation | Database check | Valid and current |

| Signatures | Authority list match | Authorized personnel |

| Heat Number | Format and consistency | Matches material marking |

| Testing Dates | Logical sequence | Chronological order |

| Classification Stamp | Society verification | Genuine and valid |

| Security Features | Physical/digital check | Present and authentic |

We implement these verification steps for all shipments to clients in Vietnam and Philippines. Their projects benefit from guaranteed material quality and traceability.

How to check mill test certificate?

A shipowner from Mexico developed a systematic MTC checking procedure after receiving non-compliant steel.

Mill test certificate checking1 involves verifying chemical composition meets grade requirements, confirming mechanical properties match specifications, checking impact test results for required temperatures, validating heat treatment records, and ensuring all data falls within acceptable tolerance ranges per applicable standards and classification society rules.

Technical Data Verification Methodology

MTC checking requires careful examination of technical data against specification requirements. Each data category must meet specific criteria for marine applications.

Chemical Composition Analysis2

Review each element against the grade specification. Check carbon content stays within the specified range. Verify manganese levels meet minimum and maximum requirements. Confirm silicon content falls within allowed limits. Ensure phosphorus and sulfur levels remain below maximum thresholds. Check micro-alloying elements like niobium and vanadium if specified. The composition must guarantee adequate weldability and toughness.

Mechanical Property Verification3

Examine yield strength values for compliance. Check that tensile strength meets specification requirements. Verify elongation percentages achieve minimum values. Confirm reduction of area measurements if provided. Ensure mechanical properties correspond to the tested thickness. The properties must provide adequate safety margins for marine service.

Impact Test Results Assessment4

Review Charpy V-notch test temperatures. Verify impact energy values meet minimum requirements. Check the number of tests conducted meets standards. Confirm test specimen orientation is correct. Ensure test temperatures match the grade designation. The impact toughness must suit the intended service environment.

Heat Treatment Records5

Examine heat treatment type and parameters. Check normalizing temperatures and times if applicable. Verify quenching and tempering records for Q&T steels. Confirm cooling rates for TMCP plates. Ensure heat treatment certificates accompany the MTC when required. Proper heat treatment ensures consistent microstructure and properties.

Non-Destructive Testing Results6

Review ultrasonic testing reports if specified. Check testing standards and acceptance criteria. Verify testing coverage meets requirements. Confirm personnel certification for testing operators. Ensure retest results for any initially rejected materials. NDT provides additional quality assurance beyond destructive testing.

Dimensional and Surface Data

Check plate dimensions against ordered sizes. Verify thickness measurements at multiple locations. Confirm surface quality descriptions match requirements. Examine straightness and flatness measurements. Ensure edge condition meets specification. Dimensional accuracy affects fabrication efficiency.

MTC Technical Data Verification

| Data Category | Verification Method | Compliance Criteria |

|---|---|---|

| Chemical Composition | Compare with grade spec | All elements within range |

| Yield Strength | Check minimum values | Meets grade requirement |

| Tensile Strength | Verify range | Within specification |

| Elongation | Confirm minimum values | Adequate ductility |

| Impact Energy | Temperature correlation | Suitable for service |

| Dimensions | Measurement check | Within tolerance |

Our quality team checks every MTC against purchase order requirements. Clients in Thailand and Malaysia receive complete verification reports with their shipments.

What is the material test certificate verification?

A naval architect from Romania needed to understand MTC verification for their quality system. The process became part of their standard procedure.

Material test certificate verification1 is the systematic process of authenticating MTC documents and validating their technical content against project specifications, ensuring the certified material properties match the supplied steel plates and comply with classification society requirements for traceability and quality assurance in marine structures.

MTC Verification System Overview

MTC verification serves as the cornerstone of material quality assurance. It combines document authentication with technical validation to ensure material reliability.

Document Authentication Process2

Authentication begins with verifying the certificate’s origin. Check the mill’s accreditation for the specific steel grade. Verify the document format matches the mill’s standard template. Confirm the issuance date aligns with production schedules. Check for consecutive certificate numbering when applicable. Authentication ensures the document is genuine and unaltered.

Technical Data Validation3

Technical validation involves detailed data analysis. Compare chemical analysis with specification limits. Verify mechanical properties meet minimum requirements. Check testing methods against standard procedures. Confirm sampling locations represent the entire heat. Validate heat treatment parameters when specified. This ensures the material possesses the required properties.

Traceability Verification4

Traceability checks confirm material identification. Verify heat numbers match between MTC and material markings. Check plate identification against certificate descriptions. Confirm heat size and product quantity relationships. Ensure testing samples correlate to the actual material. Traceability provides the chain of custody from production to application.

Classification Society Compliance5

For marine applications, verify classification society requirements. Check for valid society approval stamps. Verify the society’s specific testing requirements are met. Confirm surveyor signatures when required. Check that special testing like Z-quality is documented. Society compliance ensures acceptance by regulatory authorities.

Cross-Reference Verification6

Cross-referencing provides additional verification layers. Compare MTC data with mill’s production records. Check consistency between different testing laboratories. Verify material markings against certificate information. Confirm packaging lists match MTC quantities. Cross-referencing detects discrepancies that might indicate issues.

Verification Documentation

Proper documentation supports the verification process. Maintain verification checklists and records. Document any discrepancies and their resolution. Keep verification reports for quality audits. Update verification procedures based on experience. Documentation provides evidence of due diligence.

MTC Verification System Components

| System Component | Purpose | Implementation |

|---|---|---|

| Document Authentication | Verify genuineness | Signature validation, security features |

| Technical Validation | Confirm properties | Data comparison with specs |

| Traceability Check | Ensure identification | Heat number matching |

| Compliance Verification | Meet standards | Classification society rules |

| Cross-Reference | Detect discrepancies | Multiple source comparison |

| Documentation | Provide evidence | Records and reports |

We maintain comprehensive verification records for all shipments. Clients in Pakistan and Myanmar receive detailed verification reports with their material documentation.

How to review mtc?

A quality manager from Saudi Arabia developed a standardized MTC review procedure that caught several material discrepancies.

MTC review involves systematic examination of header information, technical data, testing methods, compliance statements, and approval signatures. The review process checks data consistency, verifies standard compliance, confirms specification alignment, and validates proper completion of all required sections according to established quality procedures.

Structured MTC Review Methodology

A systematic MTC review follows a structured approach that examines all certificate elements in logical sequence. Each review step serves specific quality assurance purposes.

Header Information Review

Start with the certificate header information. Check the issuing mill’s complete name and address. Verify the certificate number and issuance date. Confirm the purchase order and item references. Check product description matches ordered material. Review heat number and heat size information. The header provides the certificate’s basic identification.

Material Specification Check

Review the specified material grade and standard. Verify the grade designation matches purchase requirements. Check the applicable standard edition and date. Confirm any supplementary requirements are addressed. Review special designations like Z-quality or through-thickness properties. The specification defines the quality expectations.

Chemical Composition Analysis

Examine the chemical analysis section in detail. Check each element against specification limits. Verify the analysis method and laboratory identification. Confirm the sampling location and method. Review any additional elements beyond basic composition. Check carbon equivalent calculations for weldability assessment.

Mechanical Properties Verification

Review all mechanical test results systematically. Check yield strength values meet minimum requirements. Verify tensile strength falls within specified range. Confirm elongation percentages achieve minimum values. Review impact test temperatures and energy values. Check additional tests like bend tests or hardness if required.

Testing Methodology Validation

Examine the testing methods and standards used. Verify tensile testing followed recognized standards. Check impact test specimen orientation and preparation. Confirm heat treatment parameters if applicable. Review non-destructive testing methods and results. Validate testing equipment calibration records.

Approval and Compliance Statements

Review all approval stamps and signatures. Check classification society stamps are present and valid. Verify mill quality department approval signatures. Confirm any third-party inspection stamps. Review compliance statements against specification requirements. Check for any non-conformance reports or deviations.

Data Consistency Check

Perform cross-checks within the certificate data. Verify chemical composition aligns with mechanical properties. Check heat treatment records match the tested properties. Confirm dimensions correspond to tested specimens. Review any additional test results for consistency. Look for any data discrepancies that require explanation.

MTC Review Checklist

| Review Section | Key Elements | Verification Method |

|---|---|---|

| Header | Mill, date, numbers | Cross-reference with order |

| Specification | Grade, standard | Match with requirements |

| Chemical | Elements, limits | Compare with specification |

| Mechanical | Strength, toughness | Check minimum values |

| Testing | Methods, standards | Validate procedure compliance |

| Approval | Stamps, signatures | Verify authority and validity |

We provide MTC review services for clients in Philippines and Qatar. Their projects benefit from expert review that ensures material compliance and quality.

Conclusion

Proper MTC verification ensures marine steel quality and traceability. Systematic checking protects against substandard materials and supports regulatory compliance in shipbuilding projects.

-

Explore this link to understand the importance and process of MTC verification in ensuring material quality. ↩ ↩ ↩ ↩

-

Learn about the steps involved in authenticating documents to ensure their genuineness and reliability. ↩ ↩ ↩

-

Discover how technical data validation ensures that materials meet required specifications and standards. ↩ ↩ ↩

-

Understand the significance of traceability in maintaining the integrity of material identification and quality. ↩ ↩ ↩

-

Find out how compliance with classification society standards is crucial for marine applications and regulatory acceptance. ↩ ↩

-

Explore the role of cross-referencing in detecting discrepancies and ensuring material reliability. ↩ ↩