You are designing a ship’s frame. You need a strong, lightweight section. You see both L-shaped steel and bulb flat steel on the material list. They look similar but have different strengths. Choosing wrong can add weight or weaken your structure.

The key difference is in their shape and strength. L-shaped steel (angle bar) is a simple 90-degree angle, good for general framing and bracing. Bulb flat steel has a flat bar with a rounded "bulb" at one edge, providing much higher strength and stability against buckling for ship hull stiffeners.

Understanding these two profiles is essential for efficient marine design. One is a common workhorse. The other is a specialized performer. Let’s explore their differences from the ground up.

What is the difference between flat and long steel?

A shipyard orders "steel." This simple word covers many forms. Flat steel and long steel are two basic categories that define the starting point for products like plates, coils, bars, and structural sections.

Flat steel products are wide and thin, like plates and sheets, used for surfaces such as hull plating. Long steel products (or long products) are extended lengths with a specific cross-section, like beams, angles, and bars, used for frames, stiffeners, and structural support.

This primary division dictates how steel is produced, sold, and used in a ship.

The Production and Application Divide

The difference starts at the steel mill and goes all the way to the shipyard.

How They Are Made: A Rolling Process Story

Both start as a slab of steel from a continuous caster. Then their paths diverge.

- Flat Steel Production: The hot slab goes through a series of rolling mills that squeeze it horizontally. The goal is to reduce thickness while increasing width. The final products are wide and relatively thin. This process makes:

- Steel Plate: Thick (often 3mm and above), used for ship hulls, decks, and bulkheads.

- Sheet/Coil: Thinner material, used for interiors, ducting, or light panels.

- Long Steel Production: The hot slab or billet is shaped by rolling it through a series of specially designed grooved rolls. These rolls form the desired cross-sectional shape (like an L, I, or T) along the entire length. The product is defined by its profile, not its width. This process makes:

- Structural Sections: Beams (I-beams, H-beams), angles (L-shaped), channels, and bulb flats.

- Bars: Round bars, square bars, rebar.

How They Are Used in Shipbuilding: Form Follows Function

Their applications are distinct because of their shapes.

- Flat Steel (Plates) is for Surfaces and Primary Strength:

- Hull Shell: The outer "skin" of the ship, taking water pressure.

- Decks and Bulkheads: Creating floors and walls inside the ship.

- Function: It provides the continuous, watertight surface and carries global stresses (like bending of the entire hull).

- Long Steel (Sections) is for Support and Stiffening:

- Frames and Stiffeners: These are the "bones" of the ship. They are welded to the back of the plates to prevent them from buckling or deflecting.

- Beams and Girders: Support decks and carry heavy loads.

- Function: They provide local strength and stability, transferring loads to the main hull structure.

The Direct Comparison Table:

| Characteristic | Flat Steel (e.g., Plate) | Long Steel (e.g., Angle, Bulb Flat) |

|---|---|---|

| Primary Form | Wide, thin sheet or plate. | Long length with specific cross-sectional profile. |

| Key Measurement | Thickness x Width x Length. | Profile Dimensions (e.g., 100x100x10mm) x Length. |

| Main Production Process | Flat rolling to reduce thickness. | Shape rolling through grooved rolls. |

| Primary Shipbuilding Use | Hull plating, decks, bulkheads (the "skin"). | Frames, stiffeners, beams (the "skeleton"). |

| Ordering Focus | Grade, thickness, width. | Grade, section type, dimensions (leg size, bulb size). |

| Example Products | AH36 Plate, DH40 Plate. | L-shaped Angle Steel, Bulb Flat, HP Bulb. |

Understanding this fundamental split helps you speak the language of shipbuilding. When you need a surface, you think "plate" (flat steel). When you need a supporting member, you think "section" (long steel). L-shaped steel and bulb flat steel are both important types of long steel.

What are the 4 types of steel?

A client asks for "steel." I need to know what kind. The word "steel" alone is like saying "vehicle"—it could be a car, truck, ship, or plane. We classify steel into four main groups based on its composition.

The four main types of steel are Carbon Steel, Alloy Steel, Stainless Steel, and Tool Steel. Marine structural components like L-shaped steel and bulb flats are almost exclusively made from specific grades of High-Strength Low-Alloy (HSLA) Carbon Steel or Alloy Steel to meet classification society rules.

Each type has a different recipe and purpose. Knowing them helps you understand why marine steel is special.

A Guide to Steel’s Four Families

The type of steel is determined by the elements added to iron and their amounts.

1. Carbon Steel

This is the most common type, making up over 90% of all steel production. It is mostly iron with carbon as the main alloying element.

- Subtypes:

- Low Carbon (Mild Steel): <0.25% Carbon. Very ductile, easily welded. Used for car bodies, pipes, and general structures. Common "angle iron" is often mild steel.

- Medium Carbon: 0.25% – 0.60% Carbon. Stronger but less ductile. Used for machinery parts, gears.

- High Carbon: 0.60% – 1.25% Carbon. Very hard and strong, but brittle. Used for springs, cutting tools.

- Marine Relevance: Standard marine structural steel (Grades A, B, D, AH, DH) is a High-Strength Low-Alloy (HSLA) carbon steel. It is in the low-carbon range but has small, precise additions of other elements (like Manganese, Niobium, Vanadium) to increase strength and toughness without harming weldability.

2. Alloy Steel

This steel adds significant amounts of other elements (besides carbon) to achieve specific properties.

- Common Alloying Elements: Manganese, Silicon, Nickel, Chromium, Molybdenum, Boron.

- Purpose: To increase strength, toughness, wear resistance, or hardenability. For example, adding Chromium and Molybdenum creates strong, heat-resistant steels.

- Marine Relevance: Some higher-grade marine steels for extreme conditions (like Arctic grades) may have higher alloy content (more Nickel, for example) to achieve exceptional low-temperature toughness. They straddle the line between advanced HSLA carbon steel and alloy steel.

3. Stainless Steel

This steel is defined by a minimum of 10.5% Chromium, which forms a passive, protective oxide layer that resists rust.

- Key Feature: Excellent corrosion resistance.

- Types: Austenitic (most common, non-magnetic, e.g., 304, 316), Ferritic, Martensitic, Duplex.

- Marine Relevance: Used in specific marine applications where corrosion is a critical concern: chemical tanker lining, propeller shafts, high-grade fittings, exhaust systems, and offshore platform components exposed to splash zones. It is not typically used for primary hull structures due to its high cost and different welding/fabrication requirements.

4. Tool Steel

This is a family of very hard, wear-resistant steels designed for making tools.

- Key Feature: High hardness and resistance to deformation at high temperatures.

- Alloying: High carbon and significant amounts of Tungsten, Molybdenum, Cobalt, Vanadium.

- Marine Relevance: Essentially none for ship structures. It is used in the shipyard for cutting, drilling, and forming tools.

Why Marine Structures Use Specific Carbon/Alloy Steels

Shipbuilding chooses HSLA carbon steels for the perfect balance:

- Strength-to-Weight Ratio: High strength (AH36: 355 MPa yield) without excessive weight.

- Weldability: Low carbon equivalent allows for reliable welding without preheating in most thicknesses.

- Toughness: Controlled chemistry provides good impact resistance at low temperatures.

- Cost-Effectiveness: It is significantly more affordable than stainless steel while offering adequate corrosion resistance when combined with protective coatings.

When you order marine L-shaped steel or bulb flats, you are ordering a sophisticated, precisely engineered member of the Carbon Steel/Alloy Steel family, tailored for life at sea.

What are bulb flats used for?

You see a cross-section of a ship's hull. Behind the thick shell plate, there are vertical bars with a unique shape—a flat base and a rounded bulb at the top. These are bulb flats, and they have a very specific job.

Bulb flats are primarily used as longitudinal stiffeners on a ship's hull, deck, and bulkheads. The bulb provides high sectional modulus and moment of inertia, making them exceptionally efficient at resisting bending and buckling forces while minimizing weight and space.

%[bulb flat steel application ship hull stiffeners](https://cnmarinesteel.com/wp-content/uploads/2025/10/Marine-L-shaped-steel-8.webp "bulb flat steel application")

This specialized shape is not an accident. It is a brilliant engineering solution to a common marine problem.

The Engineering and Application of Bulb Flats

To understand their use, we must first understand the problem they solve.

The Problem: Stiffening Thin Plates

A ship's hull plate is strong but thin relative to its size. Under water pressure or global bending, an unstiffened plate would buckle easily (like pushing on an empty soda can). You need to support it with stiffeners welded to its back.

Why a Bulb Flat is the Solution

You could use a simple flat bar. But a bulb flat is much better.

- The Power of the Bulb: Adding mass (the bulb) away from the plate's neutral axis dramatically increases the section modulus. This is a geometric property that measures resistance to bending. A higher section modulus means the stiffener can resist more bending force with less material.

- Efficiency: For the same weight of steel, a bulb flat is much stiffer than a flat bar. For the same required stiffness, a bulb flat uses less steel and takes up less space than a larger flat bar or an angle. This saves weight (crucial for ship payload) and creates more usable space inside the hull.

- Stability: The bulb also improves the stiffener's resistance to lateral-torsional buckling (twisting under load).

Specific Locations on a Ship

Bulb flats are used as longitudinal stiffeners—they run along the length of the ship, parallel to the keel.

- Bottom Shell: They are welded vertically to the inside of the bottom hull plating to resist upward water pressure.

- Side Shell: They run vertically or horizontally to stiffen the sides against water pressure and docking impacts.

- Decks: They run transversely or longitudinally under the deck plating to support cargo and equipment loads.

- Bulkheads: They stiffen the large vertical walls inside the ship.

Types of Bulb Flats

There are two main profiles we supply:

- Standard Bulb Flat (BP): Has a symmetrical bulb. Common in European shipbuilding standards.

- HP Bulb (High Profile Bulb Flat): Has a larger, more pronounced bulb. It offers an even higher section modulus for the same web height, providing maximum strength efficiency. Common in Asian shipbuilding.

Comparison with Alternative Stiffeners:

| Stiffener Type | Typical Use Case | Key Advantage | Disadvantage |

|---|---|---|---|

| Bulb Flat | Primary longitudinal stiffeners on hull and decks. | Highest strength/weight ratio, space-efficient. | More complex to produce than flat bar. |

| Flat Bar | Light stiffening, non-critical applications, brackets. | Simple, low cost, easy to cut and weld. | Very inefficient for major loads; requires more steel for same stiffness. |

| L-shaped Angle | Transverse frames, brackets, general bracing. | Good for 90-degree connections, readily available. | Less efficient than bulb flat for pure stiffening; takes up more space. |

In summary, bulb flats are the high-performance choice for the critical job of keeping a ship's plating rigid and stable. When you see them on a material list, you know they are for the primary stiffening system.

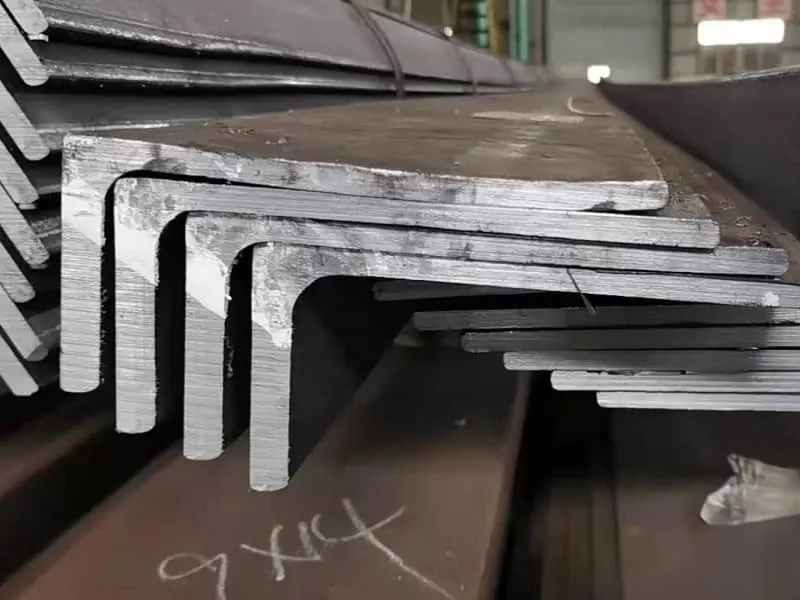

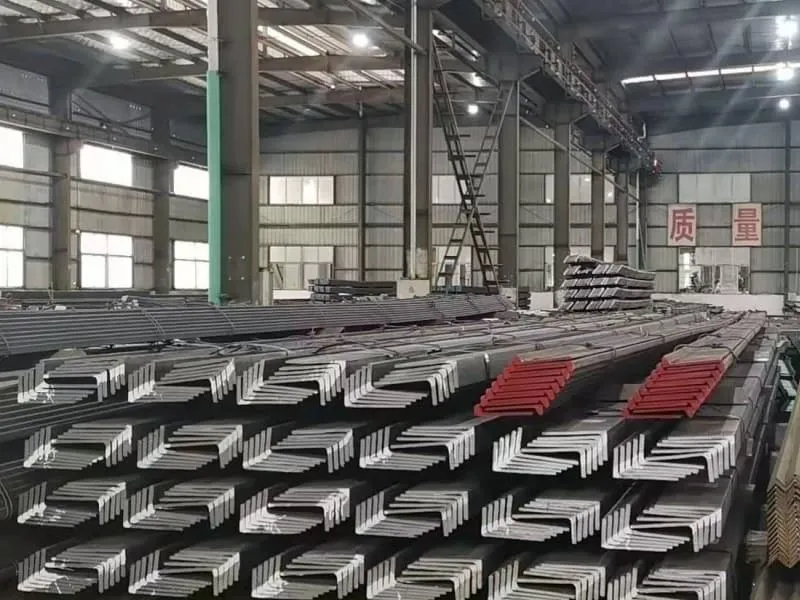

What do you call L-shaped steel?

In a shipyard, a foreman shouts, "Bring more 150x90x10!" Everyone knows he means an L-shaped section. This simple profile has many names around the world, and confusion can lead to ordering errors.

L-shaped steel is most accurately called "Angle Steel1" or "Angle Bar." In technical and shipping contexts, it is also referred to as "Equal Angle2" (legs same length) or "Unequal Angle3" (legs different lengths), with its size described by leg widths and thickness (e.g., 100x100x12mm).

%[L shaped steel angle bar dimensions](https://cnmarinesteel.com/wp-content/uploads/2025/10/Marine-L-shaped-steel-5.jpg "L shaped steel angle bar")

The name you use can tell people about your industry and your specific need.

The Many Names and Specifications of Angle Steel1

This common profile exists in every metalworking culture, leading to a variety of terms.

Common Global Names:

- Angle Steel1 / Angle Bar: This is the most universal professional term in engineering and construction. It is precise and unambiguous.

- L-Section / L-Shape: A descriptive name based on its geometry. Common in general fabrication.

- Angle Iron: A traditional term from the early days when it was made from wrought iron. It is still widely used, especially for lower-grade, non-marine applications. In marine contexts, we avoid "iron" and say "steel" to emphasize the material quality.

- Leg-Specific Terms:

- Equal Angle2: Both legs are the same length (e.g., 75x75x8mm).

- Unequal Angle3: The legs are different lengths (e.g., 150x90x10mm).

How to Specify and Order It Correctly

When you order marine angle steel, you must provide a complete specification to avoid mistakes. This specification has several parts:

- Material Grade4: This defines the quality. For marine use, this is essential. Examples: ABS Grade AH36, LR Grade DH36, CCS Grade D.

- Dimensions (Leg x Leg x Thickness)5: Always in millimeters for the global market.

- Example:

150 x 100 x 12 - This means: First leg = 150mm, Second leg = 100mm, Thickness = 12mm.

- For equal angles:

100 x 100 x 10.

- Example:

- Length: Standard lengths are usually 6 meters, 9 meters, or 12 meters. Custom lengths are available.

- Quantity: Usually in metric tons or by the number of pieces.

Example of a Clear Order:

"Please quote for 20 metric tons of ABS AH36 Unequal Angle3e Steel](https://cnmarinesteel.com/what-is-l-shaped-steel-and-how-its-used-in-shipbuilding/)[^1], size 200x150x16mm, in 12-meter random lengths."

Marine-Specific Applications of L-Shaped Steel

On a ship, angle steel is versatile but used differently than bulb flats.

- Transverse Frames6: The primary ribs of the ship that run across the width (athwartships). Their L-shape provides good strength in two directions.

- Brackets and Gussets7: Used to connect beams, frames, and stiffeners at joints. The 90-degree shape is ideal for creating strong triangular supports.

- Stiffeners for Bulkheads and Non-Critical Areas: Where buckling loads are lower, angle steel is a cost-effective stiffener.

- Deck Edge, Hatch Coamings, and Miscellaneous Steelwork: For edges, supports, and general fabrication.

Comparison of Terminology in Context:

| Term | Typical User | Context/Implication |

|---|---|---|

| Angle Steel1 / Angle Bar | Engineer, Shipbuilder, Professional Buyer. | Technical, precise. Implies a focus on specifications. |

| L-Shaped Steel | Designer, General Fabricator. | Descriptive, focused on geometry. |

| Angle Iron | Workshop, Traditional Trade, Non-Marine Construction. | Can imply generic, mild steel material. Less suitable for marine procurement. |

| ABS AH36 Angle 100x100x12 | Marine Procurement Specialist8 (Our Clients). | Complete specification. Defines quality, geometry, and standard. |

Using the correct term, "marine angle steel," along with the full grade and size, ensures you get the certified, high-performance material your project requires, not just a piece of bent metal.

Conclusion

Choosing between L-shaped steel and bulb flat steel depends on the structural role. Angles are versatile for framing and bracing, while bulb flats are superior for high-efficiency stiffening against buckling.

-

Explore this link to understand the applications and benefits of Angle Steel in various construction projects. ↩ ↩ ↩ ↩

-

Learn about Equal Angle specifications and their importance in structural integrity and design. ↩ ↩

-

Discover how Unequal Angle steel is utilized in different engineering applications for enhanced strength. ↩ ↩ ↩

-

Find out about the various Material Grades and their significance in marine applications for safety and durability. ↩

-

This resource will guide you on how to accurately specify steel dimensions to avoid ordering errors. ↩

-

Understand the role of Transverse Frames in ship design and their contribution to structural stability. ↩

-

Explore the importance of Brackets and Gussets in creating strong connections in structural frameworks. ↩

-

Learn about the role of a Marine Procurement Specialist and how they ensure quality in marine materials. ↩