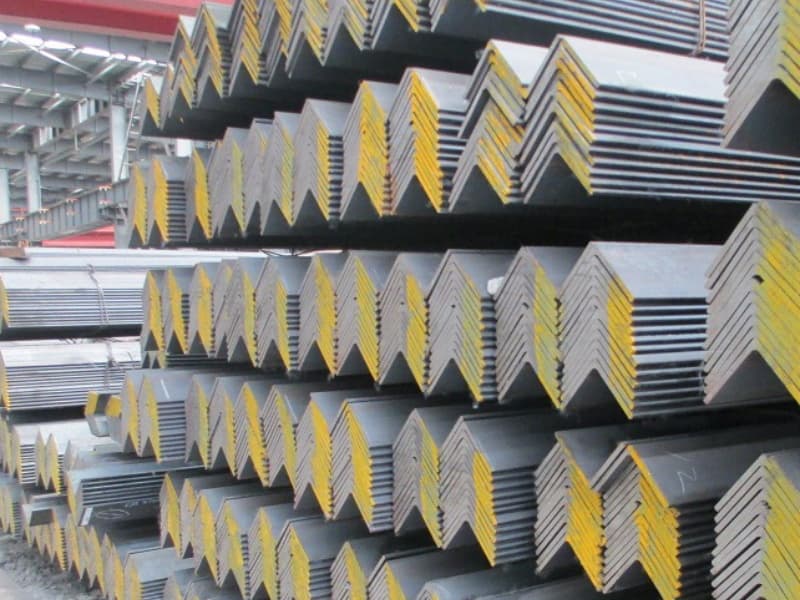

You have invested in high-quality marine angle steel. But without the right surface protection, seawater will attack it quickly. Corrosion can weaken your structure and lead to very expensive repairs or even failure.

Protecting marine angle steel requires a two-step approach: proper surface treatment followed by the correct coating system. The surface preparation, like abrasive blasting, creates a clean, rough profile for the coating to grip. The coating system, typically epoxy-based paints, then forms a barrier against water, oxygen, and salts.

I supply marine steel to shipyards and fabricators worldwide. I have seen projects succeed and fail based on their surface preparation choices. The difference is not just in the paint can; it starts the moment the steel leaves the mill. Let’s explore the critical steps that ensure your marine steel lasts for decades in harsh ocean environments.

What are the surface treatments for steel?

Many people think painting is the first step. This is wrong. Applying paint to unprepared steel is like building a house on sand. The coating will fail quickly because it has nothing to hold onto.

Surface treatments1 are the processes used to clean and prepare steel before painting or coating. The main goal is to remove contaminants like rust, mill scale, oil, and dirt. These treatments also create a specific surface profile or roughness to ensure strong mechanical adhesion of the coating.

A Deep Dive into Surface Preparation Methods

Surface treatment is not one single action. It is a sequence of steps chosen based on the steel’s condition and the final performance requirements. The quality of this step determines over 50% of the coating’s lifespan.

Common Surface Treatment Techniques

Each method has a specific purpose and result. The choice depends on the project stage and specifications.

| Treatment Method | Process Description | Typical Result & Use Case |

|---|---|---|

| Tool Cleaning (Hand/Power) | Using wire brushes, grinders, or needle guns to remove loose rust and scale. | ST2 or ST3 standard. It leaves adherent mill scale. Used for spot repairs or small areas where blasting is not possible. |

| Abrasive Blasting2 | Propelling abrasive media (sand, grit, shot) at high speed onto the steel surface. | Sa 2, Sa 2.5, or Sa 3 standard. It removes all contaminants and creates an anchor profile. This is the standard for new construction and major refurbishment. |

| Water Jetting | Using ultra-high-pressure water (with or without abrasives) to clean the surface. | WJ-1 to WJ-4 standard. It removes soluble salts effectively, which is critical for maintenance in salty environments. It does not create a profile unless abrasives are added. |

| Pickling | Immersing steel in an acid bath (usually hydrochloric or sulfuric) to dissolve mill scale and rust. | A very clean, slightly etched surface. Commonly used for steel tubes, profiles, and sometimes before hot-dip galvanizing. |

| Application of Shop Primer | Spraying a thin, fast-drying primer immediately after blasting to prevent flash rust. | Provides temporary protection (typically 3-9 months) during fabrication and storage before the full coating system is applied. |

The Critical Importance of Surface Profile and Cleanliness

Two concepts are non-negotiable for a successful coating: cleanliness and profile.

-

Cleanliness Standards (ISO 8501)3: This standard defines how clean the steel must be. The most common grades are:

- Sa 2 (Thorough Blast Cleaning): Removes nearly all rust, mill scale, and foreign matter. Some shadows or streaks may remain.

- Sa 2.5 (Very Thorough Blast Cleaning): Removes all rust, mill scale, and foreign matter. Only very light shadows or slight discolorations are allowed. This is the most commonly specified standard for marine new construction.

- Sa 3 (Blast Cleaning to Visually Clean Steel): A perfectly clean, uniform metallic surface. Used for critical immersion service or specific high-performance coatings.

-

Anchor Profile (Roughness)4: Blasting does not just clean; it also roughens the surface. This roughness is measured in microns (µm) and is called the anchor or profile. A typical profile for marine coatings is between 50µm and 100µm. This microscopic "mountain range" gives the liquid coating a massive surface area to grip onto mechanically. A smooth surface offers almost no grip.

The Connection to Our Supply Chain

When you order marine angle steel from us, you can specify the surface treatment you need ex-factory. We can supply steel with mill scale (as-rolled), which is the most common and cost-effective for projects that will do their own blasting. Alternatively, we can arrange for the steel to be blast-cleaned and primed with a shop primer before shipment. This option, often requested by clients like Gulf Metal Solutions, provides extra protection during ocean transit and saves time at the fabrication yard. The key is to communicate this need early in the RFQ process.

What is the best coating for steel in water?

There is no single "best" coating. The best coating is the one designed for the exact environment the steel will face. Steel fully submerged in seawater needs different protection than steel in the splash zone or in cargo holds.

For steel permanently immersed in seawater, the best protection is a multi-layer coating system based on high-build epoxy1. Epoxy coatings have excellent adhesion, resistance to water, and good overall chemical resistance. They are often combined with a final layer of anti-fouling paint2 to prevent marine growth.

Building a Defense System: The Multi-Layer Coating Approach

Think of coating for immersion service as putting on multiple layers of specialized clothing. Each layer has a specific job. Together, they create a robust defense.

The Standard Multi-Layer System for Immersion

A typical system for a ship’s hull or underwater structure involves three distinct layers.

| Coating Layer | Primary Function | Typical Product Type | Key Characteristics |

|---|---|---|---|

| Primer (1st Layer) | Adhesion and Corrosion Inhibition. This layer bonds to the blasted steel and provides active anti-corrosion properties. | Zinc-rich Epoxy Primer3 or Epoxy MIO (Micaceous Iron Oxide). | Zinc primer provides cathodic protection. Epoxy MIO creates a barrier with plate-like particles that hinder water path. |

| Intermediate/Barrier Coat (2nd Layer) | Build Film Thickness and Enhance Barrier Protection. This layer adds bulk and further blocks moisture and oxygen. | High-build Epoxy. Usually applied in multiple coats to achieve the required dry film thickness (DFT). | High solids content. Provides excellent resistance to water permeation. Links the primer to the topcoat. |

| Topcoat/Anti-fouling (3rd Layer) | Final Barrier and Functional Service. This layer faces the environment directly. In water, it must prevent marine organism growth. | Anti-fouling Paint (Self-polishing Copolymer – SPC, or Foul Release). | Contains biocides to deter barnacles and weeds (SPC). Or provides a very slick surface so organisms cannot attach (Foul Release). |

Factors That Determine "Best" Beyond the Product Name

Choosing a coating system involves more than picking brands. You must consider the entire application process and lifecycle.

-

Environmental Conditions: Is the water cold or tropical? Is there high abrasion from sand or ice? Is the structure static (like a platform) or moving (like a ship)? Moving ships can use self-polishing coatings. Static structures need harder, more resistant coatings.

-

Required Dry Film Thickness (DFT)4: More thickness generally means longer life. Specifications will state a required total DFT, often between 300 and 500 microns for immersion service. This thickness is achieved by applying multiple coats. Applying the coating correctly to meet this spec is as important as the coating itself.

-

Compatibility: All layers in the system must be chemically compatible. The best practice is to use a full system (primer, intermediate, topcoat) from a single manufacturer. This guarantees the products are designed to work together and the manufacturer will provide full technical support.

-

Inspection and Application Quality: The best coating in the world will fail if applied poorly. Critical factors include:

- Environmental Control: Coating must be applied within strict temperature and humidity ranges.

- Proper Curing: Each coat needs the correct time to cure before the next is applied.

- Holiday Detection: After application, the coating is checked for pinholes or voids (holidays) using a low-voltage or high-voltage spark tester.

Our clients in the shipbuilding industry, from Vietnam to Romania, follow strict coating specifications from classification societies like DNV or ABS. These specs define the exact system, surface preparation grade, and DFT required. As a steel supplier, our role is to provide material with a surface condition (either bare or primed) that is perfectly suited for their chosen coating protocol. A perfect coating starts with perfectly prepared steel from the very beginning.

Which coating type is most suitable for protecting underwater ship surfaces?

The underwater hull of a ship faces a unique combination of challenges. It is permanently wet, moving at high speed, and a target for biological growth. A coating that only fights corrosion is not enough here.

For protecting underwater ship surfaces, the most suitable coating system is a combination of a corrosion-resistant epoxy barrier system and a specialized anti-fouling topcoat. The epoxy layers (primer and intermediate) protect the steel. The anti-fouling topcoat, typically a Self-Polishing Copolymer (SPC), prevents marine growth that increases drag and fuel consumption.

The Dual Battle: Corrosion and Fouling

Underwater ship coatings have two main enemies: electrochemical corrosion and biological fouling. A successful system fights both simultaneously.

Breaking Down the Ideal Underwater Hull System

Let’s look at why this combined system is the industry standard for commercial vessels.

| System Component | Role in Underwater Protection | How It Works on a Ship |

|---|---|---|

| Epoxy Barrier System | Fights Corrosion. Creates an impermeable shield that blocks water, oxygen, and chloride ions from reaching the steel. | Applied in dry dock. It is the foundational protection. Its quality determines the hull’s basic integrity over 5-10 years between dry dockings. |

| Self-Polishing Copolymer (SPC) Anti-fouling | Fights Fouling. Prevents barnacles, weeds, and slime from attaching to the hull. | Applied over the epoxy. It contains biocides. As the ship moves, the coating surface slowly wears away (polishes), releasing fresh biocide and maintaining a smooth surface. This reduces drag. |

| Cathodic Protection (Sacrificial Anodes/Impressed Current) | Backup Corrosion Protection. Works alongside the coating to protect any small damaged areas (holidays). | Zinc or aluminum anodes are welded to the hull. They corrode instead of the steel. This is a mandatory backup system. |

Why Anti-Fouling is Non-Negotiable for Ships

For a shipowner, fuel is a huge cost. A fouled hull creates drag, like running with weights tied to your feet.

- The Fuel Cost Impact: Studies show that severe biofouling can increase fuel consumption by over 30%. Even a thin layer of slime can increase fuel use by 10-15%. Over a year, this means hundreds of thousands of dollars in extra fuel costs for a single large vessel.

- How SPC Coatings Work: The coating is designed to erode at a controlled rate. As it erodes, it constantly exposes a fresh layer with active biocides. This keeps the hull relatively clean between dry dock periods (typically 60 months). The polishing rate is tuned to match the ship’s trading pattern and speed.

Considerations for Different Vessel Types

The "most suitable" coating can vary.

- Container Ships & Bulk Carriers (High Speed, Regular Dry Docking): These vessels typically use modern SPC coatings. They benefit greatly from the fuel savings.

- Offshore Support Vessels (Slower Speed, Variable Operations): They might use a harder, more durable epoxy-based anti-fouling or a fouling-release coating.

- Fouling-Release Coatings (Silicone-based): An alternative technology. These coatings are very slick, so organisms have trouble sticking. They contain no biocides but require specific application and cleaning methods. They are popular on specialized vessels like naval ships or yachts.

When our clients order marine angle steel for hull frames, they know it will eventually be part of this sophisticated protection system. The steel’s surface condition when it arrives at the shipyard directly impacts how well the expensive epoxy and anti-fouling paints will perform. A poorly prepared surface leads to premature coating failure, higher fuel bills, and unscheduled dry docking—a cost no shipowner wants.

What is marine grade coating?

The term "marine grade" is used widely, but it is often misunderstood. It does not refer to a single paint. It describes a category of coating products and systems engineered to survive specific, harsh marine environments.

A marine grade coating is a high-performance paint system specifically formulated to protect steel structures from corrosion in marine atmospheres, splash zones, and full immersion. These coatings offer superior resistance to saltwater, UV radiation, abrasion, and cyclic wet/dry conditions. They are typically multi-component (like epoxy or polyurethane) and require strict surface preparation.

Demystifying "Marine Grade": Performance Over Product

Calling a coating "marine grade" is a promise of performance, not just a marketing label. This promise is backed by rigorous testing and formal approval processes.

The Key Characteristics of Marine Grade Coatings

All marine coatings share several high-performance traits that separate them from standard industrial paints.

| Characteristic | Why It’s Important in Marine Service | How It’s Achieved |

|---|---|---|

| High Resistance to Water & Salt Permeation | Seawater and salt spray are the primary causes of corrosion. The coating must act as a near-perfect barrier. | Formulations with high epoxy or polyurethane resin content create dense, cross-linked films that water molecules struggle to penetrate. |

| Excellent Adhesion | The coating must stick to the steel through thermal expansion, contraction, and flexing of the structure. | Requires perfect surface preparation (Sa 2.5) and the use of primers specifically designed for strong covalent bonding to steel. |

| Good Flexibility & Impact Resistance | Ship hulls and offshore structures flex and can be hit by debris. A brittle coating will crack. | Plasticizers and specific resin chemistries give the cured film some elasticity without losing toughness. |

| Resistance to UV Degradation (for topside coats) | Sunlight breaks down many polymers, causing chalking and loss of gloss. | Topside finishes use aliphatic polyurethane topcoats, which have much better UV stability than epoxy. |

Approvals and Specifications: The Proof of "Grade"

For professional use, a "marine grade" coating must have official approvals. This is critical for project specifications.

-

Classification Society Approvals: Organizations like Lloyd’s Register (LR), DNV, American Bureau of Shipping (ABS), and others test and approve specific coating systems for use on classed vessels. A coating with an LR or DNV approval has proven its performance in standardized tests.

-

Performance-Based Specifications (IMO PSPC): For ship hulls, the International Maritime Organization (IMO) has a mandatory Performance Standard for Protective Coatings (PSPC). This is not a product approval but a set of strict rules for coating selection, application, inspection, and documentation for dedicated seawater ballast tanks and double-hull spaces. Any coating system used in these areas must be applied in full compliance with PSPC. This regulation has drastically improved coating longevity.

-

Certified Inspectors (NACE, FROSIO): Applying marine grade coatings requires certified inspectors. These inspectors (holding NACE or FROSIO certifications) check the surface preparation, environmental conditions, film thickness, and final quality. Their sign-off is often required for the coating warranty to be valid.

Implications for Steel Buyers and Fabricators

As a buyer of marine angle steel, understanding marine grade coatings helps you plan better.

- Communication with Your Painter/Contractor: You can ask intelligent questions. You can ask if their proposed system has class approval or is PSPC-compliant for your application.

- Understanding Total Cost: Marine grade coatings and their application are expensive. But this cost is justified by the long-term protection of your multi-million dollar asset. Skipping on coating quality is the most expensive "saving" you can make.

- Our Role in Your Coating Success: We supply the blank canvas—the marine angle steel. Whether you need it bare, blast-cleaned, or shop-primed, we ensure it arrives in a condition that meets the stringent starting requirements of your chosen marine grade coating system. This foundational support is a key part of the value we offer to professional clients.

Conclusion

Protecting marine angle steel is a science, not an afterthought. Lasting defense requires impeccable surface preparation followed by a correctly specified, high-performance coating system.

-

Explore the advantages of high-build epoxy coatings, known for their excellent adhesion and chemical resistance, crucial for steel protection. ↩ ↩

-

Learn how anti-fouling paint prevents marine growth on ship hulls, ensuring longevity and efficiency in marine environments. ↩ ↩

-

Discover how Zinc-rich Epoxy Primer provides effective corrosion protection, enhancing the longevity of steel structures. ↩ ↩

-

Understand why achieving the right DFT is vital for coating durability and performance in various environments. ↩ ↩