Have post-2024 geopolitical shifts, new regulations, and cost pressures exposed weaknesses in your steel supply chain? Relying on old logistics and sourcing methods now poses a direct risk to your project timelines and budgets.

The marine steel plate supply chain after 2024 is transforming. Key changes include a stronger push for regionalization and dual-sourcing to mitigate geopolitical risk, mandatory adoption of digital tracking for emissions reporting (like CBAM), and a sharp focus on supply chain resilience over pure cost minimization, driven by lessons from recent global disruptions.

As a supplier at the heart of this network, I see these shifts not as abstract trends but as daily conversations with concerned buyers. To understand where we’re going, we must first grasp the fundamentals. Let’s start with the core concepts—what a supply chain is, how we handle and make steel—and then I’ll share what these processes look like in the new, more demanding post-2024 landscape.

What is the supply chain of steel?

Your steel plate arrives at the dock, but its journey began months earlier and involved dozens of players. A breakdown at any point means your project stops. Do you know all the links in your steel’s chain?

The steel supply chain1 is the complete network from raw material extraction2 (iron ore, coal) to the delivery of finished steel products. It includes mining, transportation, smelting in blast furnace3s or electric arc furnaces, rolling at mills, processing by service centers, and distribution to end-users like shipyards, connected by complex logistics and information systems.

Deconstructing the Chain: From Ore to Offshore Structure

The traditional steel supply chain is a global, linear monster. For marine plate, the chain has specific, high-stakes checkpoints. Post-2024, this chain is not just being optimized; it’s being re-examined for fragility. Let’s map the traditional path and identify the pressure points.

The classic marine steel plate chain follows these stages:

- Upstream (Raw Materials): Iron ore is mined (e.g., in Australia, Brazil). Coking coal is mined. These are shipped to steel-producing countries like China, Japan, or South Korea.

- Primary Production (Steelmaking): The raw materials are transformed into liquid steel in a blast furnace3 (BF) or an electric arc furnace (EAF). This is where the basic chemistry is set. For high-quality marine steel, this stage requires strict control.

- Secondary Production (Casting & Rolling): The liquid steel is cast into slabs. These slabs are reheated and rolled into plates in a heavy plate mill. This is the most critical stage for marine plate, where the Thermo-Mechanical Controlled Process4 (TMCP) is applied to achieve the required strength and toughness.

- Processing & Distribution: The mill may sell directly to large end-users or to distributors/stockists. For export, plates are often cut to size, treated (e.g., shot-blasted and primed), bundled, and prepared for shipping.

- Logistics & Delivery: Plates are loaded onto trucks, trains, or barges to a port, then onto ocean-going vessels for international shipment. This involves freight forwarding, customs clearance, and insurance.

- End-Use (Shipyard): The plates arrive, undergo inspection against Mill Test Certificates5 (MTCs), and are moved into storage or directly to the panel line for fabrication.

The post-2024 changes are injecting new requirements into each of these stages. The table below shows the traditional focus versus the emerging priority:

| Supply Chain Stage | Traditional Focus (Pre-2024) | Emerging Post-2024 Priority | Implication for Buyers |

|---|---|---|---|

| Sourcing (Mills) | Lowest cost per ton; large volume discounts. | Geopolitical safety and carbon footprint6 of the mill. Dual-sourcing from different regions. | You must now vet the mill’s location and environmental policies, not just its price. |

| Production | Meeting mechanical spec (yield strength, toughness). | Digital traceability of the production batch for ESG reporting and quality assurance. | You will need a digital record of the plate’s journey and CO2 data, not just a paper MTC. |

| Logistics | Cheapest freight route (often complex, multi-leg). | Resilient, transparent routes with backup options. Nearshoring where possible. | You may pay a premium for simpler, more reliable shipping lanes to avoid chokepoints. |

| Inventory | Just-In-Time (JIT) to minimize holding cost. | Strategic buffer stock of critical grades/sizes to absorb shocks (resilience over lean). | Your safety stock levels will need to increase, impacting working capital. |

My insight comes directly from the questions we now face. A European shipyard recently asked us not just for the MTC, but for the specific carbon emission data per ton of plate produced, aligned with the EU’s Carbon Border Adjustment Mechanism (CBAM). They also required proof that the slabs were not sourced from a specific region under sanction. The "supply chain" is no longer an invisible background process. It is now a source of compliance data and geopolitical risk assessment. A supplier’s value is shifting from just moving metal to providing this granular, verifiable chain of custody.

How to chain down steel plates?

You’ve received a shipment of valuable steel plates. Now you must move and store them without damage or safety incidents. Improper securing is a common, costly source of damage that happens before fabrication even begins.

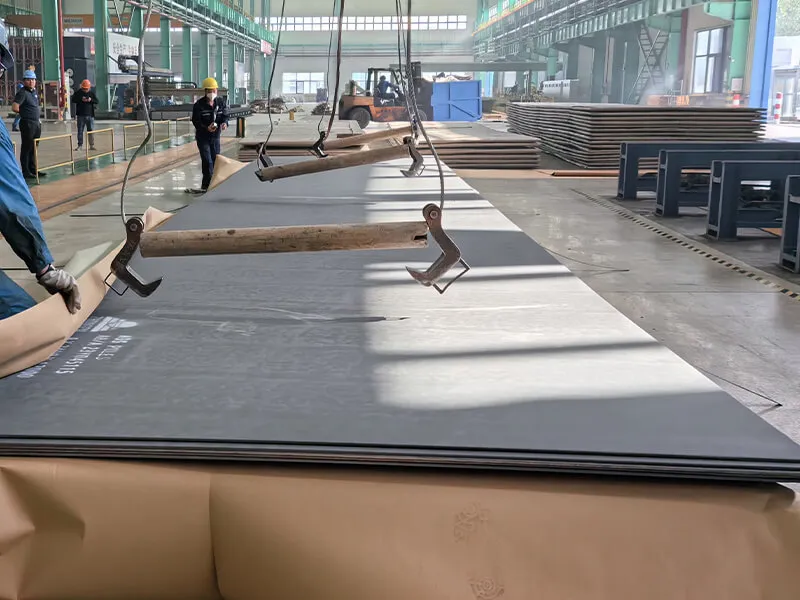

To chain down steel plates, use specialized lifting clamps1 or coil hooks designed for plate, not slings which can slip. For transport, place plates on flat, reinforced trailer beds with wooden dunnage2 to prevent contact. Secure them with heavy-duty chains3 and binders through dedicated lashing points, applying tension evenly to prevent movement during transit.

The Science of Safe Handling: Protecting Your Asset from Mill to Fabrication

"Chaining down" is a deceptively simple term for a critical engineering task. A single plate can weigh over 10 tons. If it shifts during ocean transport or yard handling, it can damage itself, other cargo, or cause a serious accident. Post-2024, with higher costs and tighter schedules, the tolerance for handling damage is zero.

Let’s break down the correct procedures for different stages:

1. Lifting from the Mill or Stockyard:

- Wrong Way: Using wire rope slings. These can slip, especially on shot-blasted plates, causing a sudden, dangerous drop.

- Right Way: Using vacuum lifters4 (for smaller plates) or lever-operated plate lifting clamps1. These clamps bite onto the edge of the plate with mechanical force. The clamp’s rating must exceed the plate’s weight. Always lift from dedicated lugs if the plate has them.

2. Securing for Land or Sea Transport:

The goal is to eliminate all movement. Steps include:

- Bed Preparation: Plates are stacked on wooden beams (dunnage2) on the trailer or ship hold. This allows forklift access and prevents moisture trapping.

- Lashing: High-strength steel chains are passed around the entire stack and through the trailer’s lashing points. Ratchet binders are used to apply immense tension.

- Angle of Lashing: Chains should be tensioned at an angle (ideally 30-60 degrees to the horizontal) to create both downward and sideways restraining force.

- Blocking: Timber or steel blocks are placed strategically to prevent longitudinal or lateral shift.

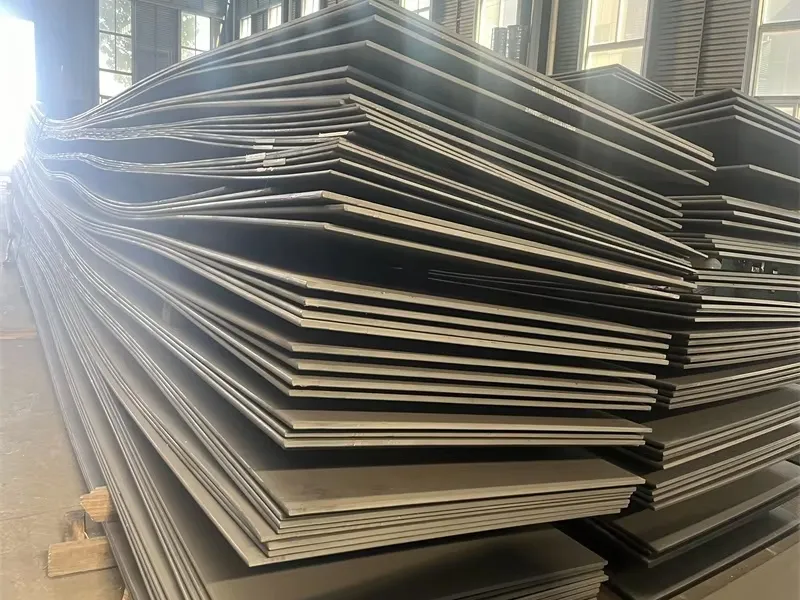

3. On-Site Storage at the Shipyard:

Plates should be stored flat on level, solid ground with ample dunnage2. Stacks should be stable and not too high. The storage area should be marked and organized by grade and thickness for easy retrieval.

Post-2024, we are seeing a trend towards digital monitoring of cargo integrity5. Some advanced logistics providers place IoT sensors on critical loads to monitor shock, tilt, and temperature in real-time during transit. This provides data to hold carriers accountable and predict potential damage before unpacking.

Here is a comparison of handling practices:

| Handling Aspect | Poor/Outdated Practice | Best Practice (Post-2024 Standard) | Consequence of Poor Practice |

|---|---|---|---|

| Lifting Equipment | Wire rope slings, unrated shackles. | Rated plate clamps or vacuum lifters4, with regular load testing certification. | Catastrophic drop, plate damage, worker injury, project delay. |

| Transport Securing | A few ropes or light chains; no dunnage2. | Engineered lashing plan using high-grade chains and binders; timber dunnage2. | Plate shift causing edge damage, coating scratches, or trailer overturn. |

| Packaging | Minimal protection; exposed edges. | Protective edge guards, waterproof wrapping, and robust steel frame packing for long sea voyages. | Cosmetic and corrosion damage that requires costly surface re-preparation before painting. |

| Documentation | Generic packing list. | Detailed packing & lashing certificate6, sometimes with photos/video of the secured load. | No proof of proper handling in case of damage claim; dispute with logistics provider. |

Our company made this a differentiator after client feedback. The testimonial from Gulf Metal Solutions specifically mentioned our packaging was "the best they had received." This wasn’t luck. We invested in steel frame packing for plates and proper edge protection7. We also started providing photographs of the properly lashed cargo inside the container before sealing. This gives the buyer proof and peace of mind. In the new environment, this attention to the "last mile" of the physical chain is a key part of supply chain resilience. Damaged goods are the ultimate disruption, and preventing them is a core supplier responsibility.

How are steel plates manufactured?

You specify thickness and grade, but do you know how a slab becomes a certified marine plate? The manufacturing process defines its quality, and understanding it is key to evaluating suppliers and troubleshooting future problems.

Steel plates are manufactured through a multi-stage process: Ironmaking (producing molten iron), Steelmaking (refining into liquid steel), Continuous Casting (forming slabs), Reheating, and Hot Rolling in a plate mill. For marine grades, the critical final step is often Thermo-Mechanical Controlled Processing (TMCP), which controls rolling temperatures and cooling rates to achieve high strength and superior toughness.

Inside the Mill: Where Chemistry Meets Physics to Create Marine Grade

The manufacturing process is the heart of the supply chain. Post-2024, the pressures of decarbonization and digitalization are hitting the mill floor directly, changing how plates are made and documented. Let’s walk through the journey of a slab becoming an AH36 plate.

1. Steelmaking and Continuous Casting:

The process starts with melting scrap in an Electric Arc Furnace (EAF)1 or reducing iron ore in a Blast Furnace (BF). The molten steel is refined to achieve the precise chemical composition for the ordered grade (low carbon, specific manganese, controlled impurities). It is then cast into a thick, rectangular slab. This slab is the blank canvas.

2. Reheating and Descaling:

The cold slab is reheated to around 1200°C in a furnace until it is uniformly plastic. It is then passed through a descaling unit where high-pressure water jets blast off the surface oxide layer (scale).

3. Hot Rolling:

This is the transformative stage. The slab passes back and forth through a set of massive rolling stands. Each pass reduces the thickness and increases the length, gradually forming a plate. The rolling is done in two phases:

- Roughing: Reduces the slab to an intermediate thickness.

- Finishing: Achieves the final target thickness with precise dimensional control.

4. The Game-Changer: Thermo-Mechanical Controlled Processing (TMCP)2:

For modern marine steels like AH36/DH36, TMCP is standard. It is not an extra step but a precise control of the entire finishing process.

- Controlled Rolling: The final rolling passes are done at a carefully controlled, lower temperature (often below 900°C). This prevents the steel grains from growing too large.

- Accelerated Cooling (ACC)3: Immediately after the final roll, the plate is rapidly cooled using high-pressure water jets. This "freezes" the fine grain structure and can create additional strengthening phases.

The result? Steel with higher strength and much better toughness without adding expensive, weldability-harming alloys. It’s a more energy-efficient process that yields a superior product.

Post-2024, two major trends are altering this manufacturing landscape:

- Green Steel Production4: Mills are investing in hydrogen-based direct reduction (H-DRI) coupled with EAFs to replace coal-intensive BF routes. The plates from these "green" mills will carry a premium but will be essential for yards building for eco-conscious owners or facing carbon taxes.

- Industry 4.0 and Digital Twins5: Sensors collect vast data during rolling (temperatures, forces, dimensions). This data creates a "digital twin" of each plate. Buyers may eventually access this data to verify the process was within optimal parameters, adding a new layer to quality assurance beyond the MTC.

| Manufacturing Stage | Key Parameter for Quality | Traditional Quality Check | Emerging Post-2024 Trend |

|---|---|---|---|

| Steelmaking | Chemical Composition6 | Sample analysis from the ladle. | Real-time spectroscopic analysis with data logging for full traceability. |

| Rolling | Finishing Temperature & Reduction Ratio | Manual logs and spot checks. | Fully automated, sensor-driven process control linked to the plate’s unique ID. |

| Cooling | Cooling Rate & Stop Temperature | Visual inspection and tempering if needed. | Precisely engineered ACC systems with digital records for each plate. |

| Certification | Mechanical Properties7 | Destructive testing of samples from the plate end. | Non-destructive testing8 (e.g., ultrasound) combined with predictive analytics from process data. |

I recently visited a partner mill in Shandong that supplies our marine plates. They showed me their new ACC system and the control room where every parameter is tracked. They explained that soon, each plate’s digital process record could be linked to its MTC via a QR code. This means a shipyard could scan a plate and see its full production history. This level of transparency is becoming a market expectation. It moves quality assurance from trusting a certificate to verifying a documented process. For buyers, this means your future suppliers must have deep, technologically advanced mill partnerships, not just a contact at a trading desk.

What are the 7 stages of supply chain management?

You manage procurement, but supply chain management (SCM) is the broader system that ensures the right material arrives at the right time and cost. Weakness in any of the seven stages creates risk for your entire operation.

The 7 stages of supply chain management are: 1. Planning (Demand Forecasting)1, 2. Sourcing (Supplier Selection)2, 3. Manufacturing (Production)3, 4. Delivery (Logistics)4, 5. Returns (Reverse Logistics)5, 6. Integration (System & Data Flow)6, and 7. Sustainability (ESG Compliance)7. For marine steel, planning, sourcing, and delivery are particularly critical and interconnected.

Applying the SCM Framework to Post-2024 Marine Steel Procurement

The classic seven-stage model provides a perfect lens to analyze how the marine steel supply chain is evolving. Each stage is being reconfigured by new technologies and new priorities. Let’s map these stages to our industry and see the changes.

1. Planning (Demand Forecasting)1:

- Traditional: Shipyards forecast based on firm orders. This is often short-term and reactive.

- Post-2024 Change: Advanced analytics and AI8 are used to model scenarios based on order books, commodity prices, and geopolitical events. Planning must now include carbon budget forecasting to comply with regulations like CBAM. The goal is a resilient plan, not just a lean one.

2. Sourcing (Supplier Selection)2:

- Traditional: Focus on unit cost, quality, and lead time.

- Post-2024 Change: Multi-criteria sourcing. Suppliers are now scored on: carbon footprint of their mills, geopolitical risk profile, financial health, digital capability (e.g., API integration), and ability to provide ESG data. Dual-sourcing from different regions is now a strategic imperative, not a luxury.

3. Manufacturing (Production)3:

- Traditional: The mill’s responsibility. The buyer cares only about the output spec.

- Post-2024 Change: The buyer is increasingly connected to the production process through demand for green steel and process transparency. Manufacturing data becomes part of the product’s value proposition.

- Traditional: Choose the cheapest freight option.

- Post-2024 Change: Resilient routing. Avoiding geopolitical chokepoints (e.g., specific canals or straits). Real-time tracking of shipments is standard. Logistics providers are chosen for their contingency planning ability. Speed and reliability often trump lowest cost.

5. Returns (Reverse Logistics)5:

- Traditional: Rarely considered for heavy steel; non-conforming material is a major dispute.

- Post-2024 Change: Circular economy principles9 are pushing for design that facilitates future recycling. Dispute resolution for rejected material is streamlined via digital evidence (photos, sensor data from transit) shared on common platforms.

6. Integration (System & Data Flow)6:

- Traditional: Communication via email, phone, and PDFs. Data silos are common.

- Post-2024 Change: Digital Supply Chain Platforms10. Buyers expect API integration where their ERP system can pull order status, documentation, and carbon data directly from the supplier’s system. Manual data entry is a red flag for inefficiency and error.

7. Sustainability (ESG Compliance)7:

- Traditional: An afterthought or a CSR report item.

- Post-2024 Change: A core, operational stage. It is embedded into planning (carbon budgets), sourcing (green suppliers), manufacturing (low-emission processes), and logistics (carbon-efficient shipping). Non-compliance can block a vessel’s registration or financing.

For a marine steel buyer, the new priorities reshape the SCM stages as follows:

| SCM Stage | Pre-2024 Priority for Marine Steel | Post-2024 Priority for Marine Steel | Required Supplier Capability |

|---|---|---|---|

| Planning | Match orders to mill lead times. | Model supply chain disruptions and carbon costs. | Provide accurate, long-term lead times and emission data for planning tools. |

| Sourcing | Find the lowest-cost certified mill. | Audit and select suppliers for resilience and ESG performance. | Offer transparent mill partnerships and verifiable ESG credentials. |

| Delivery | Get the cheapest freight quote. | Ensure secure, traceable, and reliable transit. | Provide robust logistics with real-time tracking and contingency plans. |

| Integration | Send PDF certificates via email. | Seamless digital data exchange for orders, certs, and tracking. | Have a modern IT system capable of EDI/API integration. |

My role has evolved with these stages. Clients no longer just ask for a quote. They ask: "Can your system integrate with our procurement portal?" "What is your mill’s specific CO2 emission per ton for this grade?" "What is your alternative shipping route if the main lane is congested?" We now have dedicated staff for digital integration and ESG data management. This is the new reality. The most successful buyers and suppliers after 2024 will be those who master this expanded, digitized, and responsible version of supply chain management across all seven stages.

Conclusion

The marine steel plate supply chain is undergoing a fundamental transformation. Success now depends on building resilient, transparent, and digitally integrated partnerships that can navigate geopolitical shifts, meet stringent ESG mandates, and guarantee material integrity from the mill floor to the shipyard.

-

Understanding demand forecasting is crucial for effective supply chain management, ensuring timely material availability. ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring sourcing strategies can enhance supplier relationships and improve overall supply chain performance. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learning about production practices can lead to better quality control and efficiency in supply chain operations. ↩ ↩ ↩ ↩ ↩ ↩

-

Staying updated on logistics trends can help optimize delivery processes and reduce costs. ↩ ↩ ↩ ↩ ↩ ↩

-

Understanding reverse logistics can improve customer satisfaction and reduce waste in the supply chain. ↩ ↩ ↩ ↩ ↩

-

Effective data integration is key to streamlining operations and improving decision-making in supply chains. ↩ ↩ ↩ ↩ ↩

-

Exploring ESG compliance practices can enhance brand reputation and meet regulatory requirements. ↩ ↩ ↩ ↩

-

Discovering AI applications can lead to smarter decision-making and improved forecasting accuracy. ↩ ↩

-

Understanding circular economy principles can drive innovation and sustainability in supply chain practices. ↩

-

Learning about digital platforms can enhance efficiency and connectivity in modern supply chain management. ↩