A shipbuilder in Vietnam recently asked me why their weight calculations kept failing. The problem was using wrong thickness measurements.

Marine steel plate weight calculation uses the formula: Weight = Length × Width × Thickness × Density. For marine steel with density of 7.85 g/cm³, this provides accurate weight estimates crucial for ship stability, transportation planning, and cost calculations in vessel construction projects.

Accurate weight calculation affects everything from shipping costs to structural integrity. Let me guide you through the essential formulas and practical applications.

How to calculate steel plate weight formula1?

Last month, a contractor in Qatar nearly ordered insufficient steel because of calculation errors. This could have delayed their entire shipbuilding project.

The basic steel plate weight formula1 is: Weight (kg) = Length (m) × Width (m) × Thickness (mm) × 7.85. This calculation uses the standard density of steel at 7.85 g/cm³ and converts all measurements to compatible units for accurate results.

Understanding the Weight Calculation Process

The weight formula seems simple, but each component requires careful attention. I’ll explain how to use this formula correctly in marine applications.

Breaking Down the Formula Components

Length and width must be in meters. Thickness must be in millimeters. The constant 7.85 represents steel density2. This combination gives weight in kilograms. Many people mix units and get wrong results.

Why Density Matters

Steel density varies slightly by grade. Marine steel typically has density of 7.85 g/cm³. Some special grades may have different densities. We always verify density for specific steel types. Using wrong density affects weight accuracy.

Practical Calculation Steps

First, measure the plate dimensions accurately. Convert all measurements to correct units. Multiply length by width by thickness. Multiply the result by 7.85. This gives the weight in kilograms.

Common Marine Steel Plate Specifications

| Plate Thickness (mm) | Typical Width (m) | Typical Length (m) | Weight Range (kg) |

|---|---|---|---|

| 6 | 1.5 | 6 | 424 |

| 8 | 2 | 8 | 1,005 |

| 10 | 2 | 12 | 1,884 |

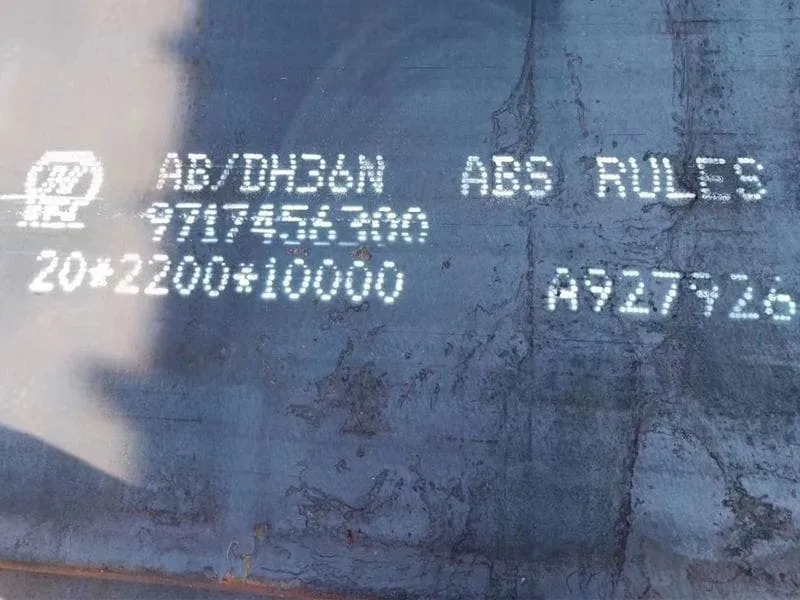

| 12 | 2.2 | 10 | 2,072 |

| 16 | 2.4 | 12 | 3,617 |

| 20 | 3 | 12 | 5,652 |

| 25 | 3 | 12 | 7,065 |

| 30 | 3.2 | 12 | 9,043 |

We provide detailed calculation sheets to all our clients. A shipyard in Philippines now uses our templates for all their projects. This prevents ordering mistakes and saves money.

How to calculate weight with length, width, and thickness?

A client in Saudi Arabia needed to calculate weight for irregular-shaped plates. The standard formula needed adjustments for their specific requirements.

To calculate steel weight using length, width, and thickness: Multiply all three dimensions, then multiply by steel density (7.85)1. Ensure consistent units: for metric calculations, use meters for length/width and millimeters for thickness, then apply the conversion factor for accurate kilogram results.

Mastering Dimension-Based Calculations

Using length, width, and thickness seems straightforward. However, marine applications present unique challenges that require special consideration.

Unit Conversion Essentials

The biggest mistake involves unit confusion2. Some people use centimeters instead of meters. Others use inches without proper conversion. I always recommend sticking to metric units. This avoids calculation errors.

Handling Real-World Variations

Marine steel plates often have slight dimension variations. Mills produce plates within tolerance limits. The actual thickness may differ from nominal thickness. We measure actual dimensions for precise calculations.

Accounting for Tolerances

Ship classification societies allow certain tolerances3. Plate thickness can vary by ±0.3mm for thinner plates. Heavier plates have larger tolerances3. These variations affect final weight calculations.

Practical Calculation Examples

For a 10m long, 2m wide, 15mm thick plate: 10 × 2 × 15 × 7.85 = 2,355 kg. For a 12m long, 2.5m wide, 20mm thick plate: 12 × 2.5 × 20 × 7.85 = 4,710 kg. These examples show the direct application.

Marine Plate Dimension Standards

| Application | Typical Thickness (mm) | Common Width (m) | Standard Length (m) |

|---|---|---|---|

| Hull Plating | 10-25 | 2-3 | 6-12 |

| Deck Plating | 8-20 | 2-2.5 | 8-12 |

| Bulkheads | 6-15 | 1.5-2.5 | 4-10 |

| Bottom Plating | 15-30 | 2.5-3.2 | 10-12 |

| Superstructure | 5-12 | 1.5-2 | 6-8 |

Our team in China helps clients with these calculations daily. We created a simple calculator that accounts for marine steel specifics. This tool helps buyers in Thailand and Malaysia plan their projects better.

What is the formula for plate weights?

A project manager in Mexico once used the wrong formula for ship plates. The error caused structural issues that required expensive corrections.

The standard formula for steel plate weights is: Weight = Length × Width × Thickness × Density1. For quick calculations, use the simplified version: Weight (kg) = Area (m²) × Thickness (mm) × 7.852. This formula works for all carbon steel plates including marine grades.

Comprehensive Formula Analysis

The weight formula has several variations for different situations. Understanding these variations helps in accurate marine steel planning and procurement.

Basic Formula Derivation

The formula comes from volume calculation. Steel volume equals length times width times thickness. Multiplying volume by density gives weight. The constant 7.85 combines density and unit conversions.

Alternative Formula Formats

Some people prefer using area directly. Weight equals area in square meters times thickness in millimeters times 7.85. This works well for multiple plates of same thickness. Other formats use different units for specific applications.

Marine Steel Considerations

Marine plates often have special coatings3. These coatings add slight weight. The formula calculates bare steel weight. For painted plates, add 1-2% for coating weight. This is important for precise ship weight calculations.

Formula Verification Methods

We always double-check calculations. Use multiple methods to verify results4. Compare with manufacturer’s certificates. Check against classification society requirements. This ensures accuracy in ship construction.

Weight Calculation Methods Comparison

| Method | Formula | Accuracy | Best Use |

|---|---|---|---|

| Basic Formula | L×W×T×7.85 | High | Single plates |

| Area Method | Area×T×7.85 | High | Multiple same-thickness plates |

| Per Square Meter | 1m²×T×7.85 | Medium | Quick estimates |

| Software Calculation | Automated | Very High | Large projects |

| Manufacturer Data | Certified | Highest | Final verification |

We provide formula sheets to all our clients. A shipbuilder in Romania uses our formulas for their monthly material planning. This improved their ordering accuracy by 15%.

How to calculate the thickness of a steel plate?

A naval architect from Pakistan asked about reverse calculations1. They needed to determine thickness based on weight requirements for a special vessel design.

To calculate steel plate thickness2 when weight is known: Thickness (mm) = Weight (kg) ÷ (Length (m) × Width (m) × 7.85). This reverse calculation helps select appropriate plate thickness during ship design phase based on weight constraints and structural requirements3.

Thickness Determination Methods

Calculating thickness from weight is common in ship design. Engineers often work backward from weight targets to determine required plate dimensions.

Reverse Calculation Process

Start with the known weight requirement. Divide by length and width dimensions. Divide again by density factor 7.85. The result is thickness in millimeters. Round up to nearest standard thickness available.

Standard Thickness Availability

Mills produce plates in standard thickness increments. Common marine plate thicknesses include 6,8,10,12,14,16,18,20,22,25,28,30,32,36,40mm. After calculation, choose the next available standard thickness.

Structural Requirements Consideration

Thickness affects structural strength. Classification societies specify minimum thickness for different ship areas. Bottom plates need more thickness than deck plates. The calculation must meet these rules.

Practical Application Examples

For a 3,000kg plate that is 10m long and 2m wide: 3,000 ÷ (10 × 2 × 7.85) = 19.1mm. Choose 20mm standard thickness. For a 5,000kg plate that is 12m long and 2.5m wide: 5,000 ÷ (12 × 2.5 × 7.85) = 21.2mm. Choose 22mm thickness.

Marine Steel Thickness Guidelines

| Ship Area | Minimum Thickness (mm) | Typical Thickness Range (mm) | Special Requirements |

|---|---|---|---|

| Bottom Shell | 14 | 16-30 | Increased corrosion allowance |

| Side Shell | 12 | 12-22 | Impact resistance |

| Main Deck | 10 | 10-20 | Weather protection |

| Bulkheads | 8 | 8-16 | Watertight integrity |

| Superstructure | 6 | 6-12 | Weight optimization |

| Stringers | 14 | 14-25 | Longitudinal strength |

Our technical team helps clients with these calculations regularly. We work with shipyards in Thailand and Vietnam to optimize plate selection. This ensures both structural safety and cost efficiency.

Conclusion

Accurate marine steel plate weight calculation ensures proper vessel design, cost control, and structural safety. Mastering these formulas is essential for successful shipbuilding and repair projects.

-

Exploring reverse calculations can enhance your understanding of engineering principles and their practical applications. ↩ ↩ ↩ ↩ ↩

-

Understanding how to measure steel plate thickness is crucial for ensuring structural integrity in ship design. ↩ ↩ ↩ ↩

-

Understanding structural requirements is essential for meeting safety standards in shipbuilding and design. ↩ ↩ ↩ ↩

-

Learning about verification methods enhances accuracy and reliability in critical engineering projects. ↩