Coastal defenses face a constant, brutal attack from waves, salt, and impact. Ordinary steel fails here, risking catastrophic collapse when communities depend on it most.

Marine structural steel is used in coastal defense for seawalls, breakwaters, sheet pile walls, and groynes. It must provide high strength to resist wave forces, excellent corrosion resistance for the splash zone, and good impact toughness. The right grade balances durability with project budget over decades.

I’ve supplied steel for flood barriers in Vietnam and revetments in the Philippines. The environment never rests, so the steel cannot have a weak point. This guide will explain the specific steels that survive at the water’s edge and why they are chosen.

What is marine grade structural steel1?

The term "marine grade" is used too loosely. For coastal defense, it doesn’t mean one special steel. It means a family of steels engineered to fight specific marine threats over a long lifespan.

Marine grade structural steel refers to high-strength, low-alloy (HSLA) steels2 manufactured to standards like EN 102253, ASTM A7104, or specific class society rules (e.g., DNV). They offer enhanced corrosion resistance5, guaranteed impact toughness at low temperatures, and excellent weldability for harsh marine environments.

Think of it as steel with a built-in defense system. It’s not just strong; it’s smart about how it resits the ocean. Let’s define exactly what sets it apart from ordinary construction steel.

Defining the Specifications and Properties

"Marine grade" is a performance requirement, not a single product. You identify it by the standard it meets and the properties it guarantees.

Key Distinguishing Features:

- Controlled Chemical Composition: The amounts of carbon, manganese, silicon, and micro-alloys (like niobium, vanadium, titanium) are tightly managed. This control achieves strength and toughness without making the steel hard to weld. A critical measure is the Carbon Equivalent Value (CEV)6. A lower CEV means better weldability. Marine grades have strict CEV limits.

- Enhanced Corrosion Resistance: This is achieved in two ways. First, some grades have added copper, chromium, and nickel (like in ASTM A588) to form a stable, protective rust layer that slows further corrosion. Second, and more commonly, the steel is designed to work as part of a protection system—it has a superior surface quality for coatings and is compatible with cathodic protection.

- Guaranteed Impact Toughness: Normal steel can become brittle in cold water. Marine grades are tested for Charpy V-Notch impact energy7 at low temperatures (e.g., -20°C, -40°C, or -60°C). The "J2", "K2", or "G3" in a grade name indicates this level of toughness. For coastal defenses in colder climates, this is non-negotiable.

- Strict Delivery Conditions: The steel is often supplied normalized (N) or thermomechanically rolled (M). These processes refine the grain structure, making the steel tougher and more uniform throughout its thickness, which is vital for thick plates used in defense projects.

Common Standards and Grades:

You specify marine grade by its standard. Here are the most relevant ones for coastal defense:

- EN 102253: This is a key European standard for weldable structural steel for offshore and marine applications. Grades like S355G2+M (for -20°C) and S355G3+N (for -40°C) are workhorses. The "G" denotes offshore/marine suitability.

- ASTM A7104 / A736: These are low-carbon, copper-nickel-chromium-molybdenum alloy steels with excellent atmospheric corrosion resistance5 and good weldability. They are sometimes used for above-splash zone structures.

- Class Society Grades: DNV, ABS, and Lloyd’s Register have their own material specifications (e.g., DNV GL NV 4208). These are common for major international projects.

- Sheet Piling Specific: Standards like EN 10248 cover hot-rolled sheet piling9 of non-alloy steels. Grades here focus on strength and interlock durability.

Application in Coastal Defense:

- Sheet Pile Walls: For seawalls and retaining walls. They need high bending strength and good interlock strength. Grades like AZ 46 or AS 500 are common.

- Breakwater Armor Units (Dolos, Tetrapods): While often concrete, large steel frames or core structures can use marine grades like S355J2G3 for their high impact toughness.

- Wave Wall Copings: The top cap of a seawall. It faces constant splash and impact. Normalized S355 or stainless steel clad options are used.

| Coastal Defense Component | Primary Threats | Key Steel Properties Needed | Typical Marine Grade Examples | Why These Properties Matter |

|---|---|---|---|---|

| Seawall Sheet Piles | Bending stress, corrosion, abrasion | High Section Modulus, Corrosion Resistance, Interlock Strength | AZ 46, AS 500, ASTM A572 Gr. 50 | Must retain shape under soil/water pressure; interlocks must not fail. |

| Breakwater Tie-Rods & Anchors | Tensile stress, corrosion, fatigue | High Tensile Strength, Good Fatigue Resistance | S460Q, S690QL, Hot-dip galvanized | Holds breakwater structure together under cyclic wave loading. |

| Bollards & Mooring Points | Impact, shear, corrosion | High Yield Strength, High Impact Toughness | S355K2+N, S460M | Must withstand sudden, massive loads from ships without breaking. |

| Access Walkways & Ladders | Corrosion, wear, safety | Corrosion Resistance, Good Surface Finish | S355J2+Z (galvanized), 316 Stainless | Requires minimal maintenance for long-term public safety. |

| Flood Gate Structures | Hydrostatic pressure, sealing, corrosion | Dimensional Stability, Weldability, Corrosion Resistance | S355G2+M, S355G3+N | Gates must seal perfectly; welding must not distort the frame. |

Is 316 steel marine grade?

This is a constant source of confusion. People hear "marine grade" and instantly think "316 stainless." For coastal defense1, this thinking can lead to a very expensive mistake or a surprising failure.

Yes, 316 stainless steel2 (and 316L) is a marine-grade alloy due to its 2-3% molybdenum content, which improves resistance to chloride pitting corrosion. However, it is not typically used for primary coastal defense1 structures due to cost and strength limitations, but rather for critical fasteners, fittings, and splash-zone cladding.

I’ve had clients in Saudi Arabia ask for 316 for entire sheet pile walls. We had to explain why that was not practical. Understanding its role is about knowing its strengths and its very real limits.

The Specific Niche of 316 in Coastal Engineering

316 is a specialist, not a general contractor. Let’s define exactly where it fits and where it does not in the harsh world of coastal defense1.

Where 316 Stainless Steel Excels:

These are applications where its corrosion resistance3 is worth the high cost, and its moderate strength is sufficient.

- Fasteners and Hardware: This is its most common and justified use. Bolts, nuts, washers, anchor rods, and shackles that connect carbon steel components. Using 316 here prevents these critical connection points from corroding away, which would cause the entire structure to fail. It eliminates a major maintenance headache.

- Splash Zone Cladding and Wear Plates: Thin plates of 316 can be welded or bolted over carbon steel at the most exposed tidal/splash zone areas of a structure, like the face of a wave wall. It acts as a sacrificial armor layer.

- Moving Parts and Hinges: For flood gates, lock gates, or movable barriers, 316 is excellent for pintles, bushings, and hinge pins because it resists seizing and corrosion in constantly wet, abrasive conditions.

- Instrumentation and Safety Features: Handrails, ladder rungs, light fixtures, and sensor mountings that are exposed to constant salt spray. Here, its low maintenance and good appearance are valuable.

Where 316 Stainless Steel is a Poor Choice:

- Primary Load-Bearing Structure: The yield strength of 316 is about 205 MPa. A common marine structural steel like S355 has a yield strength of 355 MPa. To achieve the same strength with 316, you would need a much thicker, heavier section. The material cost (5-8x higher per ton) and fabrication cost would be astronomical for a large seawall or breakwater.

- Fully Submerged, Stagnant Conditions: In low-oxygen environments (like behind a sheet pile wall), 316 can suffer from crevice corrosion. It is not a magic, corrosion-proof material.

- Galvanic Corrosion Risk: If 316 is directly connected to carbon steel in seawater, it creates a galvanic cell. The 316 becomes the cathode and the carbon steel becomes the anode, accelerating the corrosion of the carbon steel at the connection point. Insulation (e.g., plastic washers, sleeves) is mandatory.

- Abrasive Environments: In areas with high sand or silt content in the water, 316 can still suffer from erosion-corrosion.

The Verdict: Use it Strategically

The smart approach is a hybrid design4. For a flood defense project in Malaysia, we supplied S355G2+M plates for the main gate structure and 316 stainless steel2 round bars and plates for all the hinge assemblies, bolts, and wear strips on the sealing edges. This gave a 50-year design life for the moving parts without bankrupting the project on material costs. It’s about placing the right material in the right spot.

What is marine grade SS?

"Marine grade SS1" (Stainless Steel) is a broader category than just 316. It includes several alloys, each with a specific "superpower" for different levels of marine aggression. Choosing the wrong one is like sending a sailor to a deep-sea dive without the right suit.

"Marine grade SS1" encompasses austenitic (304, 316), duplex (2205), and super duplex (2507) stainless steels selected for marine use. 316/L is the baseline for general splash zones; duplex grades offer higher strength and better chloride resistance for critical applications like fasteners in warm seawater.

It’s a spectrum of performance and cost. For a coastal defense budget, you need to know where on this spectrum your project sits. Let’s map out the options.

Navigating the Spectrum of Marine Stainless Steels

All stainless steels have at least 10.5% Chromium for the passive layer. The "marine grade" variants add other elements to fight chloride attack.

1. Austenitic Stainless Steels (Non-magnetic)

- 304 (A2): Contains 18% Cr, 8% Ni. It has good corrosion resistance in mild atmospheres but is not suitable for coastal marine environments with salt spray. It will suffer pitting and crevice corrosion. Avoid it for coastal defense.

- 316 (A4) / 316L: The baseline marine grade. 316 has 16-18% Cr, 10-14% Ni, and 2-3% Molybdenum (Mo). The molybdenum is the key—it dramatically increases resistance to pitting from chloride ions. 316L is the low-carbon version; it is essential for anything that will be welded to prevent "weld decay" corrosion.

2. Duplex Stainless Steels2 (Mixed structure, magnetic)

These steels have a mix of austenite and ferrite. They are stronger and often more corrosion-resistant than 316.

- 2205 (Duplex): The most common duplex grade. It has about 22% Cr, 5% Ni, 3% Mo, and 0.15% N. It has roughly double the yield strength of 316 (around 450 MPa vs. 205 MPa). It offers much better resistance to stress corrosion cracking (SCC)3 and pitting in warm, chloride-rich waters. It is used for critical seawater piping, pump shafts, and high-strength fasteners in aggressive environments.

- 2507 (Super Duplex): Contains 25% Cr, 7% Ni, 4% Mo, 0.3% N. It is for the most extreme conditions: very warm seawater, high chloride, or presence of sour gas (H2S). Its cost is very high.

3. Precipitation-Hardening Stainless Steels

Grades like 17-4 PH offer very high strength combined with good corrosion resistance (better than 304, not as good as 316). They might be used for specialized, high-strength components like valve stems.

Selection Guide for Coastal Defense:

Use this as a simple rule of thumb:

- General Atmospheric/Splash Zone (Handrails, Bolts on above-water structure): 316/316L

- Critical Fasteners in Warm Seawater or Splash Zone (Tie-rod ends, Anchor systems): 2205 Duplex

- Seawater Piping Systems, Pump Components: 2205 Duplex or 2507 Super Duplex4

- High-Strength, Corrosion-Resistant Shafts or Pins: 17-4 PH or Duplex

A Critical Note on "Marine Grade" Fasteners:

Never just ask for "marine grade bolts." You must specify the material. A bolt marked A4-70 is a 316 stainless steel5 bolt with a 700 MPa tensile strength. A bolt marked A4-80 is higher strength. For the most critical connections, you might specify Duplex steel fasteners. The correct specification prevents undertorquing (bolt stretches) or brittle fracture.

Why is steel important in marine technology?

We have other materials like concrete, composites, and timber. But for the brutal, load-bearing heart of coastal defense, steel remains irreplaceable. Its importance comes from a unique combination of properties no other material can match in one package.

Steel is fundamental to marine technology because it offers an unmatched combination of high strength1, toughness, ductility, and fabricability at a viable cost. It can be formed into complex shapes (plates, sections, piles), welded into massive structures, and its properties can be precisely engineered for specific marine challenges.

Concrete is brittle in tension. Composites can’t yet handle the scale. Aluminum lacks strength. Steel is the backbone because it does everything well. Let’s break down its critical advantages.

The Multifaceted Role of Steel as the Marine Backbone

Steel’s importance isn’t about one feature; it’s about how all its features work together to solve marine engineering problems.

1. Unmatched Strength-to-Weight and Strength-to-Cost Ratio

This is the core economic and engineering reason. Steel provides enormous load-bearing capacity.

- High Strength: Grades like S690 have yield strengths over 690 MPa. This allows for lighter, more slender structures that still carry huge loads. For example, a steel sheet pile wall can be thinner and driven deeper than a concrete wall of equivalent strength, saving space and material.

- Cost-Effectiveness: Despite price fluctuations, steel remains the most cost-effective material for primary structure per unit of strength. This is crucial for large-scale, budget-conscious public infrastructure like coastal defenses.

2. Exceptional Toughness and Ductility

This is about safety and resilience, not just strength.

- Toughness: Marine-grade steels are tested to absorb impact energy (Charpy test). This means they resist brittle fracture. In a storm, a steel structure can deform and absorb energy rather than shatter like glass.

- Ductility: Steel can bend and stretch a significant amount before breaking. This gives warning signs (visible deformation) and allows for energy dissipation during extreme events like earthquakes or ship impacts. A ductile failure is always preferable to a sudden, brittle collapse.

3. Unparalleled Fabricability and Weldability

This is how we turn raw material into complex structures.

- Welding: This is steel’s superpower. We can join huge plates and sections into monolithic structures onsite or in a yard. The development of marine-grade steels2 with low CEV has made welding thick sections reliable and safe, preventing cold cracks.

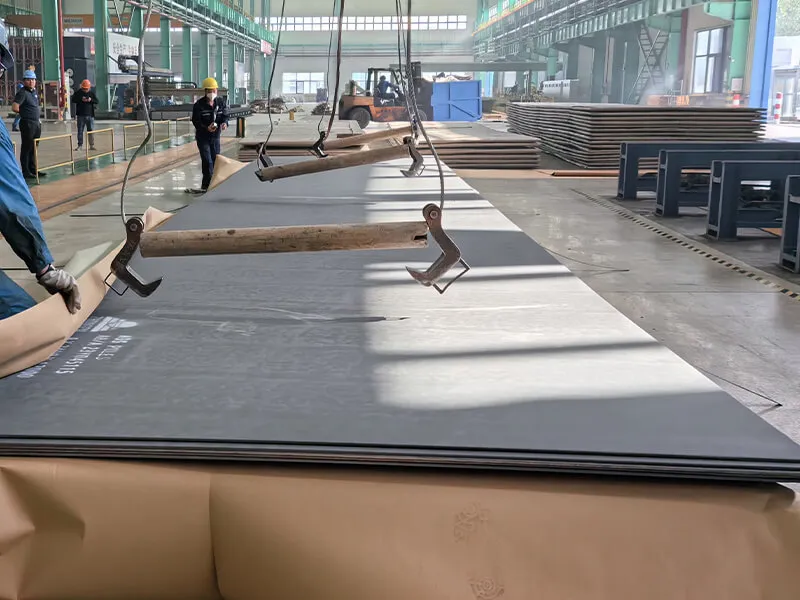

- Forming: Steel plates can be rolled into cylinders for piles, bent into angles, or cut into any shape. We supply Bulb Flat Steel and L-shaped section steel that come in precise, ready-to-use profiles for stiffening and framing, speeding up fabrication.

4. Predictable and Engineerable Behavior

Engineers can trust steel because its properties are well-known and consistent.

- Established Design Codes: The behavior of steel under load is thoroughly documented in codes like Eurocode 3, API, and ISO. Engineers can design with high confidence.

- Material Certification: As a supplier, we provide Mill Test Certificates (MTCs)3 and SGS reports. This gives the project engineer verified data on the exact yield strength, toughness, and chemistry of the steel they are building with. This traceability is a legal and safety requirement for major projects.

5. Adaptability to Corrosion Protection

Steel acknowledges its weakness to corrosion and provides excellent ways to manage it.

- It forms a perfect substrate for high-performance coating systems (epoxy, polyurethane).

- It works seamlessly with cathodic protection (sacrificial anodes or impressed current).

- It can be alloyed for better inherent resistance (e.g., weathering steels, ASTM A588).

- It can be clad with a more resistant material (e.g., stainless steel cladding on splash zones).

In short, steel is the only material that can be economically produced in the massive quantities needed, fabricated into the required shapes, welded together on-site, certified for its properties, and protected for a 50+ year life in the sea. It is the reliable, versatile, and proven choice for defending our coasts.

Conclusion

Coastal defense demands steel that is strong, tough, and corrosion-resistant. Specify marine-grade structural steel by its standard, use stainless steel strategically, and leverage steel’s unique advantages for durable, reliable protection.

-

Explore how high strength steel enhances marine structures with its load-bearing capacity and cost-effectiveness. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the unique properties and applications of marine-grade steels in coastal defense and marine technology. ↩ ↩ ↩ ↩ ↩

-

Learn about the significance of MTCs in ensuring the quality and safety of steel used in marine projects. ↩ ↩ ↩ ↩ ↩

-

Find out why 2507 Super Duplex is chosen for extreme marine conditions and its unique properties. ↩ ↩ ↩ ↩

-

Learn about the unique properties of 316 stainless steel, including its corrosion resistance and applications in marine settings. ↩ ↩ ↩

-

Understand the significance of CEV in determining the weldability and performance of marine grade steels. ↩

-

Find out how Charpy V-Notch testing ensures the toughness of steel in cold environments. ↩

-

Discover the applications and specifications of DNV GL NV 420 in marine and offshore projects. ↩

-

Explore the role of sheet piling in coastal defense and the types of marine grade steel used. ↩