Selecting the wrong manufacturing process for your bulb flat steel can compromise an entire ship’s structural integrity. I’ve seen projects delayed because cold rolled sections couldn’t meet marine certification requirements.

Hot rolled bulb flat steel is formed above 1700°F, resulting in a scaled surface with good ductility and structural properties ideal for shipbuilding. Cold rolled bulb flat steel is processed at room temperature from hot rolled stock, offering precise dimensions and smooth finishes but limited ductility and certification options. For marine applications, hot rolled is the standard due to its superior mechanical properties and classification society approval.

From my experience supplying shipyards across Asia and the Middle East, I’ve learned that understanding these manufacturing differences is crucial for project success. Let me share practical insights that will help you make informed decisions for your marine projects.

What is the difference between cold rolled steel and hot rolled steel?

A shipyard in Thailand once ordered cold rolled bulb flats thinking they’d get better dimensional accuracy1, only to discover they couldn’t obtain ABS certification for their vessel. This costly mistake highlighted why understanding these processes matters.

Cold rolled steel2 is processed at room temperature from hot rolled stock, producing precise dimensions and smooth surfaces but reducing ductility. Hot rolled steel3 is shaped at high temperatures (over 1700°F), creating a scaled surface with better toughness and structural properties suitable for marine applications4. The temperature difference fundamentally changes the steel’s characteristics and certification possibilities5.

The Manufacturing Reality Behind Each Process

Having visited multiple mills and discussed processes with metallurgists, I’ve gained practical understanding of how these methods create different products.

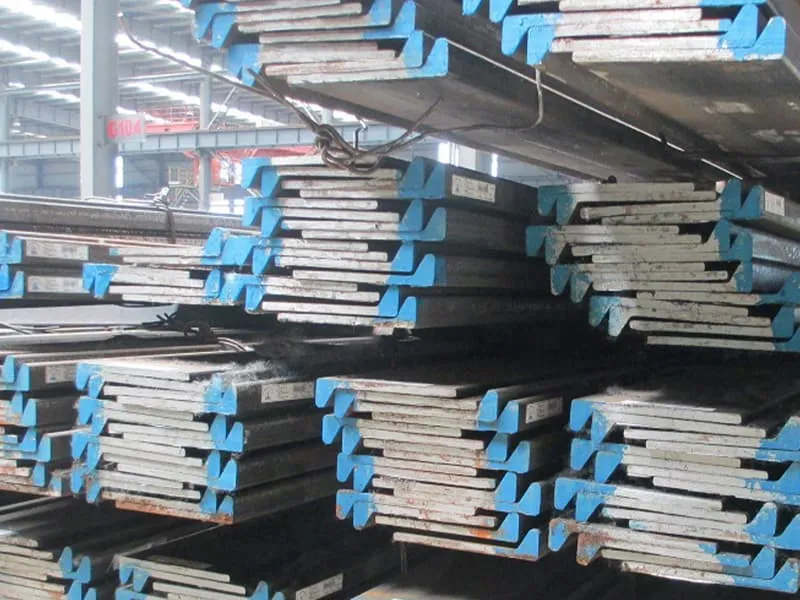

Hot Rolling: The Industrial Standard for Structural Steel

When I tour hot rolling mills, here’s what I observe:

- Material starts as slabs heated to orange-hot temperatures

- Multiple passes through rolling stands gradually shape the profile

- Natural cooling creates the characteristic mill scale

- Final straightening ensures usable lengths

For bulb flats specifically:

- The entire cross-section forms uniformly

- Grain structure remains consistent throughout

- Residual stresses are minimal

- Surface imperfections are acceptable within standards

Cold Rolling/Forming: Precision Over Structural Properties

Cold processing involves different equipment and considerations:

- Starts with cooled hot rolled material

- Pickling removes mill scale for clean surfaces

- Room temperature forming requires more force

- Work hardening occurs during deformation

What this means for bulb flats:

- Dimensions are tighter but ductility decreases

- Surface finish is superior but certification options shrink

- Production costs increase for structural applications

Practical Comparison from Daily Business

| Aspect | Hot Rolled Bulb Flats (Our Standard) | Cold Formed Bulb Flats (Special Order) |

|---|---|---|

| Surface Appearance | Blue-gray mill scale, natural finish | Clean, metallic, scale-free surface |

| Dimensional Tolerance | ±2-3mm typical, meets marine standards | ±0.5-1.5mm, architectural precision |

| Edge Condition | Rounded, as-rolled edges | Sharper, sometimes machined edges |

| Straightness | Meets ASTM A6/EN 10056 standards | Often exceeds structural requirements |

| Available Certifications | Full ABS, LR, DNV, BV, etc. | Limited, usually commercial only |

| Lead Time | Standard 2-4 weeks from mill | Longer, requires special production |

Why Marine Industry Prefers Hot Rolled

Based on conversations with classification society surveyors:

- Predictable Properties: Hot rolling provides consistent mechanical characteristics

- Welding Compatibility: Better weldability with established procedures

- Impact Toughness: Superior performance in cold environments

- Traceability: Complete manufacturing history from melt to product

I remember a project in Qatar where the engineer wanted cold formed sections for visible areas. We explained the certification limitations and ultimately supplied hot rolled sections with additional surface preparation instead. This met both aesthetic and regulatory requirements.

What is the difference between hot and cold steel1?

A fabricator in Vietnam asked if they could use "cold steel1" to save costs on a ship repair project. This confusion about terminology revealed a common misunderstanding—"cold steel1" isn’t a material type but a processing method that affects performance.

"Hot steel" refers to steel worked at temperatures above its recrystallization point (typically 1700°F+), allowing easy shaping with minimal work hardening2. "Cold steel" is processed at room temperature, increasing strength through work hardening2 but reducing ductility and impact resistance. For structural components like bulb flats, this temperature difference determines suitability for marine applications3.

How Temperature Affects Steel’s Fundamental Nature

Through technical discussions with mill engineers, I’ve learned that processing temperature changes steel at the microscopic level.

What Happens During Hot Working

When steel is hot rolled for bulb flats:

- Grains recrystallize: The crystal structure reforms during deformation

- Dislocations reduce: Internal defects that cause brittleness decrease

- Stress relief occurs: Thermal energy allows atoms to rearrange

- Scale forms naturally: Iron oxidizes creating protective mill scale

This results in:

- Consistent properties through the section thickness

- Good Charpy impact values at low temperatures

- Predictable response to welding heat

- Natural stress relief after forming

What Happens During Cold Working

When forming bulb flats at room temperature:

- Dislocations pile up: Crystal defects increase, raising strength

- Grains distort: They elongate without reforming

- Residual stresses remain: No thermal energy to relieve them

- Springback occurs: Material tries to return to original shape

The consequences for structural use:

- Higher yield strength4 but lower elongation

- Reduced impact toughness, especially in cold climates

- Potential for stress corrosion cracking

- Anisotropic properties (different in different directions)

Property Comparison from Actual Mill Test Data

| Test Parameter | Hot Rolled ABS Grade A | Cold Formed Equivalent | Why It Matters |

|---|---|---|---|

| Yield Strength | 235 MPa minimum | 275-350 MPa typical | Cold formed appears stronger on paper |

| Tensile Strength | 400-520 MPa | 450-550 MPa | Similar ultimate strength |

| Elongation | 22% minimum | 10-18% typical | Hot rolled bends without cracking |

| Impact @ -20°C | 27J minimum | Often not tested/specified | Critical for marine safety |

| Carbon Equivalent | Controlled for welding | May be higher due to work hardening2 | Affects weldability |

Practical Fabrication Differences

From client feedback across different countries:

- Cutting and Drilling: Cold formed steel requires more powerful equipment

- Welding Preparation: Hot rolled needs scale removal, cold formed needs stress relief consideration

- Bending and Forming: Hot rolled is more forgiving during fabrication

- Fatigue Performance: Hot rolled typically lasts longer under cyclic loading

Energy and Cost Perspective

Hot rolling consumes more energy upfront for heating but produces material better suited for structural applications. Cold forming uses less energy but creates material with limitations for demanding uses like shipbuilding. When clients in Saudi Arabia or Mexico choose between them, they’re really choosing between initial cost savings and long-term performance reliability.

What is CRC and HRC?

Reviewing an order from an Indian client, I noticed they specified "HRC bulb flats1" but their technical requirements described coil product characteristics. This common confusion between product categories can lead to receiving the wrong material entirely.

CRC means Cold Rolled Coil2 and HRC means Hot Rolled Coil3—both refer to flat steel products in coil form, not structural sections like bulb flats1. Using these terms for bulb flats1 is incorrect and leads to specification errors. Bulb flats are discrete structural sections produced on different equipment and governed by different standards than coil products. Proper terminology prevents procurement mistakes and ensures you get the right product for marine applications.

Clarifying Industry Terminology for Accurate Specification

Through daily communications with international clients, I’ve identified patterns of terminology confusion that affect purchasing outcomes.

Correct Definitions from Steel Industry Practice

In proper industry usage:

- HRC: Hot Rolled Coil3 – continuous coil of flat steel, thickness 1.5-25mm

- CRC: Cold Rolled Coil2 – cleaned and cold reduced coil, thickness 0.3-3.0mm

- Neither term applies to structural sections like:

- Bulb flats

- Angles

- Beams

- Channels

Why the Distinction Matters Practically

-

Different Production Lines:

- Coils: Continuous strip mills, kilometers long

- Sections: Reversing mills, producing discrete lengths

-

Different Quality Systems:

- Coils: Focus on thickness control and surface quality

- Sections: Focus on profile accuracy and mechanical properties

-

Different Certification:

Common Specification Errors We Correct

| What Clients Often Write | What They Usually Mean | Correct Specification |

|---|---|---|

| "HRC bulb flat 250×12" | Hot rolled bulb flat | Hot rolled bulb flat 250x12mm per JIS G31925 |

| "CRC steel beam" | Cold formed section | Cold formed steel beam |

| "HRC angle" | Hot rolled angle | Hot rolled steel angle L100x100x10 |

| "CRC profile" | Cold formed profile | Cold formed steel section |

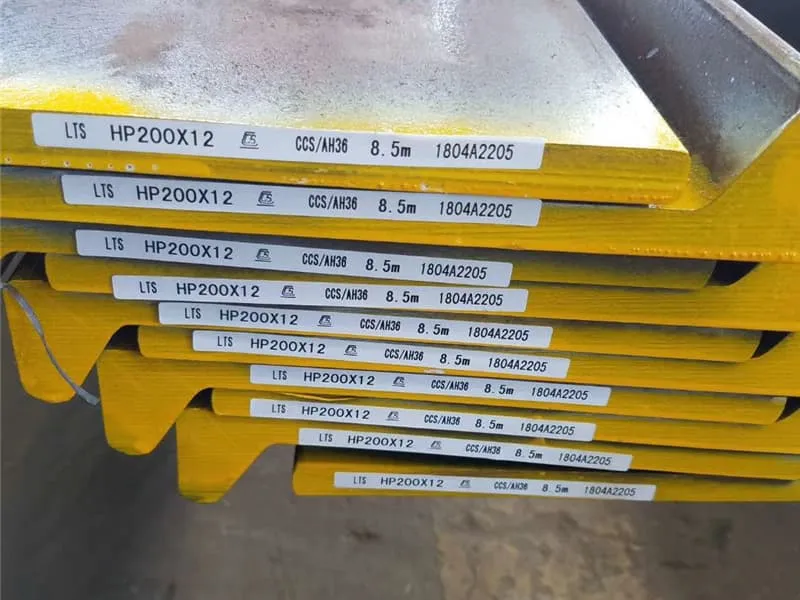

How to Specify Bulb Flats Accurately

Based on years of processing orders:

- Use descriptive names: "Hot rolled bulb flat steel sections"

- Reference standards: "To JIS G31925" or "to DIN 1025"

- Provide exact dimensions: "Bulb flat 200 x 10 mm"

- Include grade if needed: "Grade ABS AH36"

- Specify length: "Random 12 meters" or "Cut to length"

Documentation Differences in Practice

From handling thousands of shipments:

- Mill certificates for sections never mention "HRC" or "CRC"

- Shipping marks identify sections by profile code, not coil designations

- Quality documents reference section standards like ASTM A6

- Order confirmations use product codes specific to sections

Product Category Reference Guide

| Product Category | Industry Terms | Typical Form | Marine Applications |

|---|---|---|---|

| Coil Products | HRC, CRC, GI, PPGI | Continuous coils | Limited, mostly interior |

| Structural Sections | Beams, columns, angles, bulb flats1 | Discrete lengths | Primary structure, frames |

| Plate Products | Plate, sheet, floor plate | Flat sheets | Hull plating, decks |

| Bar Products | Round bar, flat bar, square bar | Straight lengths | Fasteners, fittings |

When Gulf Metal Solutions first inquired about materials, we spent time educating them on proper terminology. Now they specify "hot rolled bulb flats1 to ABS AH36" clearly, which ensures they receive exactly what their shipbuilding clients in Saudi Arabia require, without confusion or delays.

What is hot rolled flat steel1?

A Romanian shipyard ordered "hot rolled flat steel1" for hull stiffeners and received steel plates2 instead of bulb flats3. This specification error delayed their project by two weeks until we clarified the product categories and supplied the correct sections.

Hot rolled flat steel encompasses several product types rolled at high temperatures: plates (thicker than 3mm), sheets (thinner than 3mm), strips (narrow coils), and flat bars4 (rectangular sections). Bulb flats, however, are not flat steel—they’re structural sections with specific T-shaped profiles designed for stiffness, falling under different standards and manufacturing processes than flat products. Understanding these categories prevents ordering errors in marine projects.

Navigating Hot Rolled Product Categories Effectively

From managing thousands of shipments to diverse markets, I’ve developed a clear categorization system that helps clients specify exactly what they need.

The Four Categories of Hot Rolled Flat Products

-

Steel Plates (Our Major Product):

- Thickness: 3mm to 300mm+

- Width: 1500mm to 4000mm+

- Forms: Single plates, sometimes coils

- Marine Use: Hull plating, decks, bulkheads

-

Steel Sheets:

- Thickness: 0.4mm to 3mm

- Width: Various, usually in coils

- Forms: Primarily coils

- Marine Use: Interior partitions, furniture

-

Steel Strips:

- Thickness: Similar to sheets

- Width: Narrower than sheets (under 600mm)

- Forms: Coils

- Marine Use: Edge trim, specialized applications

-

Flat Bars:

- Thickness: 3mm to 50mm

- Width: 20mm to 300mm

- Forms: Straight lengths

- Marine Use: Brackets, supports, framing

Where Bulb Flats Actually Belong

Bulb flats are Structural Sections, a completely different category:

- Profile: Specific T-shape with bulb at one end

- Standards: JIS G3192, DIN 1025, etc.

- Manufacturing: Section mills, not plate mills

- Purpose: Stiffening structural members

Common Specification Confusions I Regularly Clarify

| What Clients Ask For | What They Usually Need | The Critical Difference |

|---|---|---|

| "Flat steel for stiffeners" | Bulb flats or angles | Function vs. form confusion |

| "HR plate for framing" | Structural sections | Framing requires sections, not plate |

| "Steel flats" | Could be flat bars4 or bulb flats3 | Imprecise terminology |

| "Profile steel" | Usually correct for sections | More accurate description |

Effective Procurement Communication Strategies

Based on helping hundreds of clients:

- Describe the application: "I need longitudinal stiffeners for a ship’s hull" is clearer than "I need flat steel"

- Use reference materials: "Similar to attached drawing" or "like photo example"

- Specify the standard: "To JIS G3192 for bulb flats3" removes ambiguity

- Provide context: "Replacement for existing bulb flats3 in attached specification"

Technical Specification Requirements by Product

| For Hot Rolled… | Key Specification Elements | Marine Certification Notes |

|---|---|---|

| Plates | Thickness x Width x Length, grade, condition | ABS, LR, DNV plates available |

| Sheets | Thickness x Width, grade, surface | Limited marine certification5 |

| Flat Bars | Thickness x Width x Length, grade, edges | Some certification available |

| Bulb Flats | Profile designation or dims, standard, grade | Full classification approval |

Industry Perspective on Product Segregation

In marine applications, these distinctions are critical because:

- Classification societies have separate rules for plates vs. sections

- Testing protocols differ between product types

- Welding procedures vary based on product category

- Design calculations use different parameters

I’ve found that taking a few extra minutes to clarify terminology during the inquiry phase saves days or weeks of corrective action later. When clients in Pakistan or Thailand contact us, we ask specific questions about their application to ensure we recommend the right product category. This proactive approach has significantly reduced ordering errors across all our export markets.

Conclusion

Understanding the manufacturing differences between hot and cold rolled processes, using correct industry terminology, and properly categorizing steel products ensures you select appropriate bulb flat steel for marine applications while avoiding specification errors and compliance issues.

-

Explore this link to understand the various applications and benefits of hot rolled flat steel in different industries. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the specifications and uses of steel plates, crucial for marine and construction applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the unique characteristics of bulb flats and their specific uses in structural applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Understand the various applications of flat bars in construction and marine engineering. ↩ ↩ ↩ ↩ ↩

-

Learn about the importance of marine certification for steel products and how it affects procurement. ↩ ↩ ↩ ↩ ↩