Your next big contract could be for an offshore wind farm, not a tanker. But the wrong steel choice can sink your profit and your reputation. The future of marine steel is being shaped right now by massive towers rising from the sea.

Marine steel remains irreplaceable for offshore wind foundations and structures. The future involves advanced grades with higher strength, better fatigue resistance, and superior corrosion protection to meet the extreme demands of deeper waters and larger turbines.

I talk with project contractors from Mexico to Saudi Arabia. Their questions are changing. They are less about traditional ship plates and more about the steel needed for the energy transition. Offshore wind is not just another market. It is a complete test for marine steel supply chains. To succeed, we must understand the forces shaping both the steel and the global market around it. Let’s look at the key questions every serious supplier and buyer is asking.

What will replace steel in the future?

A client asks if they should invest in composite material production instead of steel. They see headlines about "revolutionary" materials. The truth is, for the massive, load-bearing structures of offshore wind, nothing on the horizon can replace steel’s unique combination of strength, durability, and cost-effectiveness at scale.

For the primary structures of offshore wind projects—like monopiles, jackets, and towers—steel will not be replaced in the foreseeable future. The development is not about replacement, but about evolution: creating new, superior grades of marine steel and combining them with advanced coatings and hybrid designs.

The idea of replacing steel often comes from other industries like aerospace or automotive. People hear about carbon fiber or advanced composites. But the marine and offshore environment presents a different set of challenges. We should think about this in three ways: materials that compete, materials that complement, and the evolution of steel itself.

The Landscape of Materials for Offshore Wind Structures

| Material Category | Role in Offshore Wind | Advantages | Limitations for Primary Structure |

|---|---|---|---|

| Advanced Marine Steel1 (The Incumbent) | Primary material for foundations (monopiles, jackets), transition pieces, towers, and major fittings. | Proven performance, high strength-to-cost ratio, excellent fatigue life data, established fabrication and welding codes, recyclable. | Susceptible to corrosion without protection. Heavy, which impacts logistics and installation costs. |

| Composites (Carbon/Glass Fiber)2 | Used for non-critical parts: turbine blades, nacelle covers, some internal platforms, cable protection systems. | Very high strength-to-weight ratio, corrosion-resistant, good for complex aerodynamic shapes (blades). | Extremely high material cost. Limited database for long-term (25+ years) structural performance in marine environments. Difficult to inspect for internal damage. Not suitable for the massive, thick-walled primary load-bearing components. |

| Hybrid Designs3 (The Future Path) | Steel primary structure with composite elements or reinforced concrete sections for specific functions. | Optimizes material use. For example, a steel jacket with composite braces to reduce weight and wave load. | Increases design complexity. Creates challenging connection points between dissimilar materials. Still in R&D and early demonstration phases. |

| Concrete (A Complement)4 | Used for gravity-based foundations in some shallow-water projects. Also used in hybrid "suction bucket" designs. | Good compressive strength, corrosion resistant in mass, low maintenance. | Very heavy, complex logistics, limited to certain seabed conditions, can crack under tensile loads. |

The real story is the innovation happening within steel itself. Offshore wind is pushing mills to develop new grades. We are seeing a demand for steels with even higher yield strength5 (e.g., beyond 460 MPa) to reduce plate thickness and weight. There is a bigger demand for improved fatigue performance6. Every wave causes a tiny stress cycle in the steel. Over 25 years, this adds up to billions of cycles. New steel grades are being engineered at the microscopic level to resist crack initiation under this relentless loading.

My role as a supplier is to connect our certified mills with these new requirements. We are not waiting for steel to be replaced. We are actively sourcing the next generation of it. When a fabricator in the Philippines asks about steel for a new wind farm tender, we discuss specific grades like S460ML7 or similar, which offer higher strength and guaranteed impact properties at low temperatures. This is the practical future: better steel, not no steel.

What is the future of maritime trade1?

You might think maritime trade1 is only about container ships and bulk carriers. The future fleet will also include specialized installation vessels2, cable-laying ships, and floating wind platforms. This shift changes what kind of marine steel3 is in demand and where it needs to go.

The future of maritime trade is a dual transformation. It will continue to carry global goods, but it is also becoming the essential service arm for the offshore energy transition. This creates new routes, new vessel types, and new demands for specialized marine steel.

Traditional trade routes from Asia to Europe and North America will remain vital. But superimposed on this map is a new network. This network moves not just finished goods, but the gigantic components of the green economy. Let’s break down the two interconnected futures.

Two Intertwined Futures for Maritime Trade

| Trade Dimension | Traditional Maritime Trade (Evolving) | New Maritime Service & Installation Trade (Growing) |

|---|---|---|

| Primary Cargo | Containerized goods, dry bulk (ore, grain), liquid bulk (oil, LNG). | Oversized and heavy-lift cargo: Wind turbine blades, tower sections, foundation pieces, substation modules. |

| Key Vessel Types | Ultra-large container vessels (ULCVs), Capesize bulk carriers, VLCCs. | Specialized vessels: Heavy Lift Vessels (HLVs), Wind Turbine Installation Vessels (WTIVs), Cable-Laying Vessels, Feeder Barges. |

| Steel Demand Focus | High-strength hull steel for efficient, large hulls. | Specialized steel: Steel for dynamic positioning systems, strengthened decks for heavy loads, steel for complex jack-up legs and cranes on WTIVs. This often requires thicker plates and higher-specification grades. |

| New Trade Hubs | Established mega-ports (Shanghai, Rotterdam, Singapore). | Component manufacturing hubs & marshaling ports: Ports in Vietnam, the Philippines, the Middle East (like Dammam), and Europe are expanding to stage wind farm components. |

| Impact on Supply Chains | Demand for steel is steady, focused on shipbuilding in major yards. | Demand is project-based and localized. A wind farm off the UK may source steel from mills in Europe, but the components might be fabricated in the UAE, requiring marine steel3 to be shipped there first for fabrication. |

This shift has direct implications for our business at CN Marine Steel. Our clients are no longer just shipyards building tankers. They are fabrication shops in Qatar building transition pieces. They are yards in Romania converting vessels for offshore service. These clients have different needs. They might need extremely thick plates (80mm, 100mm+) for foundation collars. They need assurance that the steel has through-thickness properties (Z-direction quality) to prevent lamellar tearing in these heavy welds.

I remember a conversation with a project manager in Saudi Arabia. He was not just looking for steel for a ship. He was planning a fabrication facility to serve wind projects in the Red Sea. His questions were about our ability to supply large batches of certified plate with specific through-thickness requirements. This is the future. The trade is in the raw material (specialized steel) and the fabricated component. Our role is to be a reliable, technically informed partner in this new supply chain, ensuring fast delivery from Shandong to these emerging fabrication hubs4.

Is U.S. steel making a comeback?

A buyer in Mexico asks if they should wait for cheaper U.S. steel because of new policies. They think it might disrupt the market. The U.S. steel industry is focusing on specific, protected sectors, but for the global offshore wind market1, a full "comeback" as the primary supplier is unlikely due to cost and capacity.

U.S. steel production2 is increasing, driven by government investment and tariffs. However, this "comeback" is primarily focused on serving the domestic automotive, infrastructure, and energy markets. For cost-sensitive global projects like offshore wind, Asian and European mills will likely remain the dominant suppliers of marine-grade steel plate3.

The question of a U.S. comeback is really about geopolitics and economics, not just metallurgy. To understand it, we need to look at the drivers behind U.S. production and then compare its position to the established global supply chain4 for offshore wind steel.

Analyzing the U.S. Steel "Comeback" for the Marine Market

| Factor | The Case for a Comeback | The Reality for Global Offshore Wind |

|---|---|---|

| Government Policy & Investment | Laws like the Infrastructure Act and Inflation Reduction Act provide billions for projects using U.S. materials. "Buy America5" clauses are strong. | This stimulates domestic U.S. demand. It makes U.S. steel very competitive inside the USA for land-based wind, bridges, and pipes. It does little for a project in Vietnamese waters. |

| Production Capacity & Cost | New electric arc furnace6 (EAF) capacity is coming online. EAFs are flexible and use scrap metal. | EAF steel can be cost-effective. However, the very thick, high-quality plate required for monopiles often requires the integrated mill (BF-BOF) process. The U.S. has limited capacity for this specialty plate in the volumes needed for global export. |

| Logistics & Geography | Proximity to the growing U.S. offshore wind market1 (East Coast, Gulf Coast). | A major advantage for U.S. projects. It makes sense to source foundation steel from a U.S. mill if the price is right. But for projects in Asia, Europe, or the Middle East, shipping heavy steel plate across oceans from the U.S. adds massive cost. |

| Market Focus | U.S. mills are prioritizing high-margin products for automotive and strategic domestic infrastructure. | The marine and offshore plate market is specialized but very price-competitive. Asian mills, with their scale and integrated facilities, have built a decades-long advantage in producing cost-effective, certified marine plate. |

For international buyers and contractors, this situation creates a two-track market. If you are bidding on a U.S. offshore wind project, you must navigate "Buy America5" rules. You might need to source some steel locally. But for the vast majority of projects outside the U.S.—in Europe, Asia, or the Middle East—the supply chain will continue to revolve around established mills in China, Korea, Japan, and Europe.

Our value in this landscape is stability. While political tides shift, our long-term partnerships with major certified mills in Asia provide a consistent source of specification-grade steel. For a results-driven buyer like our client in Saudi Arabia, this predictability is key. They cannot base their project timelines and costs on unpredictable trade policies. They need a supplier who can deliver the right material at a stable price, with the right certification, directly to their port in Dammam. The U.S. comeback is an important trend, but for the global offshore wind steel business, it reinforces the need for reliable, existing supply chains.

Are steel prices going up or down in 2025?

You are preparing a bid for a wind farm foundation package. A 10% swing in steel plate prices can turn your profit into a loss. Guessing wrong is not an option. You need to understand the specific factors that move marine steel prices1, not just general market noise.

Predicting exact steel prices is difficult. However, for 2025, the balance of factors suggests prices for marine-grade steel plate will remain volatile but with a tendency to be firm or slightly elevated. Key drivers include sustained demand from energy transition projects2, high raw material costs3, and geopolitical uncertainties4 affecting supply.

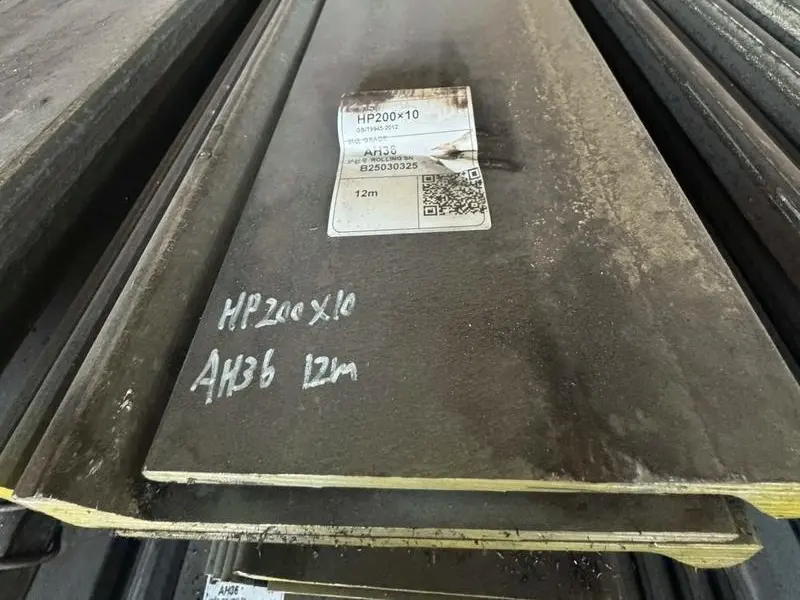

Headlines often talk about "steel prices" as one thing. But the price of hot-rolled coil for appliances is different from the price of 80mm thick AH36 plate with Z35 certification for a monopile. We must look at the specific market for marine and offshore plate. Let’s break down the major forces.

Key Factors Influencing Marine Steel Plate Prices in 2025

| Price Driver Category | Upward Pressure on Prices | Downward Pressure on Prices |

|---|---|---|

| Demand Side | Strong demand from offshore wind and LNG vessel construction. Global wind targets require millions of tons of steel. Government-backed projects are less sensitive to short-term economic cycles. | A significant slowdown in global shipbuilding for container ships or bulk carriers could free up mill capacity. A deep global recession could dampen all industrial demand. |

| Supply Side (Raw Materials) | Iron ore and coking coal prices remain high. Energy costs (for running mills) are unstable. Environmental compliance costs in China and Europe add to production expenses. | Increased use of scrap-based EAF production could lower costs for some products, but this is less relevant for thick plate. New mining capacity could eventually ease raw material costs. |

| Geopolitics & Trade Policy | Trade tensions and tariffs (like the EU’s CBAM) disrupt smooth trade flows and can create regional shortages, raising local prices. Conflicts can impact shipping routes and energy costs. | Diplomatic resolutions or trade agreements could stabilize flows. Policies that boost production in one region (like the U.S.) could create excess capacity there, affecting global balances. |

| Currency Fluctuations | A weaker Chinese Yuan (CNY) against the US Dollar makes Chinese exports cheaper, potentially supporting demand and allowing mills to hold prices. | A stronger CNY would make Chinese steel more expensive in dollar terms, potentially reducing export competitiveness and demand. |

For a B2B buyer, this volatility makes a trusted supplier relationship more important than ever. Locking in a price for a large project is risky for both the buyer and the supplier. More and more, we see contracts with price adjustment clauses linked to raw material indexes.

The practical strategy for 2025 is not about betting on up or down. It is about managing risk. This is where our business model helps. Our long-term cooperation with mills gives us stable access and priority in tight markets. We offer SGS inspection so you can be confident in quality on the first shipment, avoiding costly rejects. For clients like Gulf Metal Solutions, who value stable quality and clear communication, we provide transparent cost breakdowns and regular market updates. We cannot control the global price of iron ore. But we can offer the next best thing: a reliable partner5 who navigates the volatility for you, ensuring you get the material you need, when you need it, with no nasty surprises on quality or documentation. In an uncertain market, that reliability is the most valuable commodity.

Conclusion

The future of marine steel in offshore wind is not about replacement, but evolution. Success demands an understanding of advanced materials, shifting trade patterns, and smart strategies to navigate a volatile global market.

-

Understanding the factors influencing marine steel prices can help you make informed decisions in your bidding process. ↩ ↩ ↩ ↩ ↩ ↩

-

Explore how energy transition projects are driving demand for steel, impacting pricing and availability. ↩ ↩ ↩ ↩

-

Learn about the implications of raw material costs on steel pricing to better manage your project budgets. ↩ ↩ ↩ ↩ ↩

-

Discover how geopolitical factors can disrupt steel supply chains and influence market prices. ↩ ↩ ↩ ↩

-

Find out why a reliable partner is crucial for navigating the volatile steel market and ensuring quality. ↩ ↩ ↩ ↩

-

Learn about electric arc furnaces and their role in modern steel production, which is vital for understanding U.S. capabilities. ↩ ↩

-

Learn about S460ML steel and its benefits for offshore wind projects, including strength and impact resistance. ↩