You see a simple L-shaped bar on a ship. It looks basic. But its journey from raw material to a certified marine component is a story of precision engineering. This process defines its strength, quality, and reliability in harsh ocean environments.

Marine L-shaped steel is manufactured through a controlled process starting with steelmaking, followed by continuous casting into blooms. The key shaping step is hot rolling, where the red-hot bloom is passed through a series of grooved rollers in an angle mill to form the precise 90-degree L-shape, before final cooling, straightening, cutting, and inspection.

This journey ensures every piece meets strict standards. Let’s follow the material through the factory to understand how a trusted marine component is born.

What is the name of the process used to shape structural steel?

Structural steel gets its familiar shapes—beams, channels, and angles—through a powerful and precise method. This is not about casting molten metal into a mold. It is about using massive forces to deform solid steel into specific profiles.

The primary process used to shape structural steel is hot rolling1. In this process, heated steel billets or blooms are passed through a series of rollers with specially designed grooves. The rollers apply immense pressure, gradually squeezing and elongating the steel into the desired cross-sectional shape, such as an I-beam or L-angle.

The Heart of the Mill: How Hot Rolling Transforms Steel

Hot rolling is more than just squeezing metal. It is a carefully controlled thermomechanical event that refines the steel’s internal structure while forming its external shape. For marine L-shaped steel, this process is critical for achieving both the correct geometry and the required mechanical properties.

Why Heat is Essential:

Steel is heated to a temperature between 1100°C and 1300°C (about 2012°F to 2372°F). At this austenitizing2 temperature, the steel becomes ductile and malleable. Its crystalline structure changes, allowing it to deform under pressure without cracking. This means the mill can use less force to achieve significant shape changes.

The Rolling Sequence: Breakdown and Finishing

The process happens in two main stages within the rolling mill:

- Breakdown Rolling3: The starting block, called a bloom, is first reduced in cross-sectional area. It passes through large, smooth rollers that make it longer and thinner, preparing a uniform "stock" for the shaping stage.

- Shape or Profile Rolling4: This is where the L-shape is born. The stock enters the angle mill. This mill contains a series of roll stands. Each stand has two grooved rollers that meet to form a progressively deeper and sharper L-shaped groove. As the steel passes through each stand, the groove imprints the shape deeper into the material. The final stand gives the angle its precise 90-degree legs with sharp toes and specified thickness.

The Metallurgical Magic:

The rolling action does more than shape. The mechanical working at high temperature breaks down the coarse, as-cast grain structure of the bloom. It refines the grains into a finer, more uniform arrangement. Finer grains directly improve the steel’s strength and toughness, key requirements for marine applications5. The controlled cooling that follows (often on a cooling bed) locks in this improved microstructure.

Beyond Basic Hot Rolling:

For advanced marine grades, the process is often enhanced:

- Thermo-Mechanical Controlled Processing (TMCP)6: This is a sophisticated version of hot rolling1. It involves precise control over rolling temperatures, reduction amounts, and cooling rates. TMCP can produce steels with higher strength and better toughness without adding expensive alloying elements. This is common for grades like AH36 or DH36.

- Quenching and Self-Tempering (QST)7: Sometimes used for specific high-strength sections, this involves a rapid water quench immediately after the final rolling pass, followed by tempering using the steel’s own residual heat.

The table below contrasts the standard and advanced routes:

| Process | Key Control Parameters | Result for Marine Steel |

|---|---|---|

| Conventional Hot Rolling | Reheat temperature, finishing temperature. | Produces standard structural grades (e.g., S235, S355) with good properties. |

| Thermo-Mechanical Controlled Process (TMCP) | Precise control of rolling temp, strain, and accelerated cooling8 rate. | Produces higher-strength, tougher grades (e.g., AH/DH/EH series) with excellent weldability. |

Visiting our partner mills, the scale is breathtaking. Seeing a glowing red bloom, over ten meters long, snake through the roll stands and emerge as a perfectly formed, straight angle bar is a powerful reminder of the engineering behind every piece we supply.

What are the 4 types of steel?

Not all steel is the same. Its properties change dramatically based on its chemical recipe. Knowing these basic types helps you understand what you are buying and why certain grades are chosen for marine environments.

Steel is broadly categorized into four main types based on its chemical composition: Carbon Steel, Alloy Steel, Stainless Steel, and Tool Steel. Marine L-shaped structural steel typically falls under the category of High-Strength Low-Alloy (HSLA) steel, which is a specific sub-type of alloy steel designed for strength, weldability, and corrosion resistance.

From Chemistry to Application: Choosing the Right Steel

The "type" of steel is determined by the elements added to iron. Each element changes the steel’s behavior. For marine structures, the choice is a careful balance of strength, toughness, corrosion resistance, and cost.

1. Carbon Steels

These are the most common and economical steels. They are primarily iron and carbon, with only small amounts of other elements.

- Composition: Carbon content typically ranges from 0.05% to 1.0%.

- Properties: Strength increases with carbon content, but weldability and toughness decrease.

- Marine Use: Mild steel (low carbon) might be used for non-critical inland waterway barges. However, its poor corrosion resistance and low toughness make it unsuitable for most ocean-going ship hulls.

2. Alloy Steels

These steels add significant amounts of other elements (alloying elements) to achieve specific properties.

- Key Alloying Elements: Manganese (Mn), Silicon (Si), Chromium (Cr), Nickel (Ni), Molybdenum (Mo), Vanadium (V), Copper (Cu).

- Properties: Alloys can increase strength, hardness, toughness, wear resistance, and corrosion resistance.

- Marine Use: This is the critical category. High-Strength Low-Alloy (HSLA) steels are the workhorses of modern shipbuilding. They contain small, precise amounts of alloys (like Mn, Si, Cu, Cr, Ni) to boost strength and atmospheric corrosion resistance without making welding too difficult. Grades like ABS AH36 or EH36 are classic HSLA steels.

3. Stainless Steels

These steels contain a high percentage of Chromium (at least 10.5%) and often Nickel.

- Properties: They form a passive, self-healing chromium oxide layer that provides excellent corrosion resistance.

- Marine Use: Used for specific, highly corrosive applications on ships—handrails, kitchen equipment, pumps, and valves. They are generally not used for primary hull structures due to high cost, challenging welding requirements, and different mechanical properties.

4. Tool Steels

These are very hard, wear-resistant steels designed for cutting and forming other materials.

- Properties: High carbon and alloy content (like Tungsten, Cobalt).

- Marine Use: Not used in ship structures. They are for making tools used in the shipyard.

Why HSLA Steel is King for Marine L-Angles:

For L-shaped sections that form frames and stiffeners, HSLA steel offers the perfect balance:

| Requirement | How HSLA Steel Meets It | Example Alloying Element |

|---|---|---|

| High Strength | Solid solution strengthening from Manganese (Mn). Precipitation hardening from micro-alloys like Niobium (Nb). | Mn content around 1.0-1.6%. |

| Good Toughness | Fine grain structure achieved through controlled rolling (TMCP) and micro-alloys. | Niobium (Nb) helps pin grain boundaries during rolling. |

| Improved Corrosion Resistance | Addition of Copper (Cu), Chromium (Cr), and sometimes Nickel (Ni). | Cu content around 0.2-0.5% promotes protective rust layer formation. |

| Good Weldability | Low Carbon Equivalent (CE) value. Careful balance of alloys to prevent hard, crack-prone weld zones. | Controlled levels of Carbon (C), Manganese (Mn). |

When a client asks for "marine angle steel," they are implicitly asking for an HSLA steel with these optimized properties and the proper certifications to prove it.

How are steel angles manufactured?

The journey of an L-angle from a bloom to a finished product is a symphony of heat, pressure, and precision. Each step is designed to ensure the final bar is straight, dimensionally accurate, and possesses the right internal qualities.

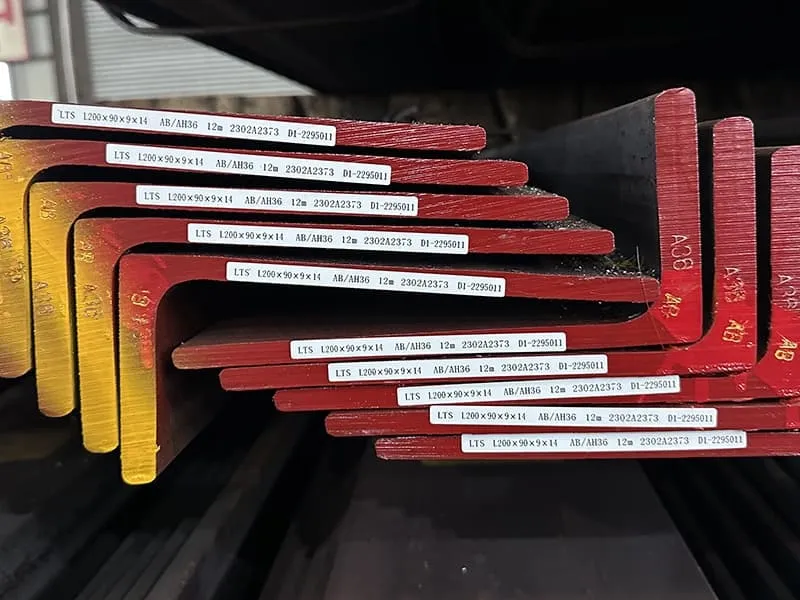

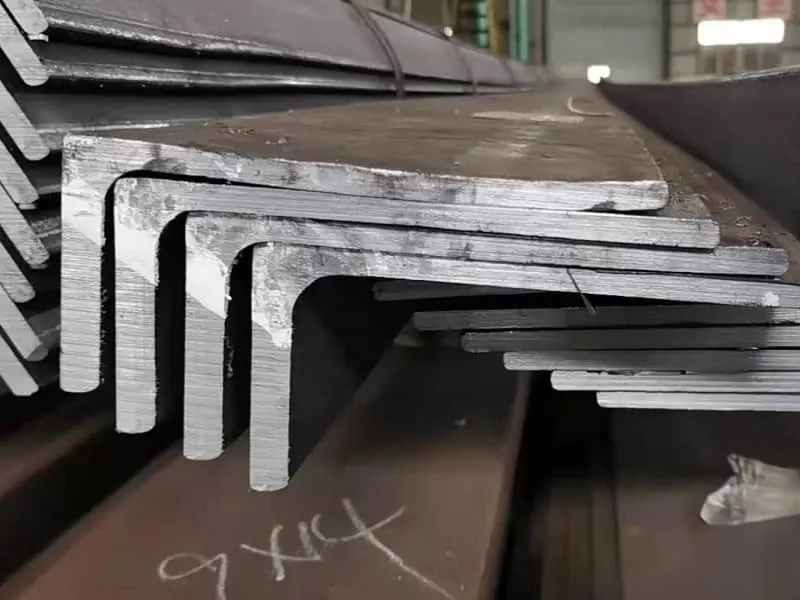

Steel angles are manufactured by hot rolling heated steel blooms through a series of grooved rollers in a specialized angle mill1. The process includes reheating the bloom, roughing and intermediate rolling to begin shaping, finishing rolling for precise dimensions, controlled cooling on a cooling bed2, and then straightening, cutting to length, and inspection.

A Step-by-Step Walk Through the Angle Mill

Let’s follow a single bloom as it becomes a bundle of finished L-shaped steel.

Step 1: Reheating

The process starts with a solid steel bloom from the continuous caster. This bloom is fed into a reheating furnace3, typically a walking beam or pusher type. It is heated uniformly to the optimal rolling temperature (around 1200°C). This ensures the steel is plastic and ready for deformation.

Step 2: Rolling the Shape

The red-hot bloom exits the furnace and enters the rolling mill train.

- Roughing Mill: The first few stands are the roughing mill. Here, large-diameter rollers with broad grooves begin to form the general "V" or shallow "L" profile. The bloom is reduced in size and elongated.

- Intermediate and Finishing Mills: The steel then passes through several more stands. Each stand has rollers with more precise and defined L-shaped grooves. With each pass, the legs become longer and the angle sharper. The finishing stand gives the angle its final exact dimensions—leg length, thickness, and the 90-degree angle (or other specified angle). Tolerances here are tight, often within a few millimeters.

Step 3: Cooling and Transformation

After the final rolling pass, the long, red-hot angle bar (now called a "strand") travels onto a cooling bed2. This is a critical phase. As it cools in air (or under controlled accelerated cooling for TMCP grades), the steel’s microstructure transforms from austenite to ferrite and pearlite, determining its final strength and toughness. The cooling bed2 is designed to let the bar cool evenly to prevent warping.

Step 4: Finishing Operations

Once cool, the long strand undergoes several finishing steps:

- Straightening: It passes through a series of staggered rollers in a straightening machine. These rollers apply corrective bends to remove any curvature or camber from rolling and cooling.

- Cutting to Length: The straight bar is fed into a flying shear or cold saw. It is cut into standard lengths (usually 6 meters, 12 meters, or as per customer order).

- Inspection and Bundling: Each piece is visually inspected for surface defects. Samples may be taken for mechanical testing. The angles are then stacked and tightly bundled with steel straps for shipment.

Quality Gates Throughout:

At multiple points, the mill’s quality control team4 takes samples. They check dimensions with calipers and gauges. They perform mechanical tests (tensile, Charpy impact) on samples from the front and back of the batch. For marine steel, a surveyor from the classification society (ABS, DNV, etc.) may witness these tests. Only after all checks pass does the mill issue the official Mill Test Certificate5.

This detailed, controlled process is why mill-direct material is reliable. When we ship to a fabricator in the Philippines, we know every bar in that container has passed through this rigorous system.

How are structural steel shapes produced?

Structural steel shapes—I-beams, H-beams, channels, and angles—share a common birth in the rolling mill. However, the specific equipment and roll designs change to create their unique profiles. Understanding this highlights the specialization within steelmaking.

Structural steel shapes are produced predominantly by the hot rolling process in universal mills (for wide-flange beams) and section mills (for angles, channels, tees). The process involves passing a heated bloom through a series of progressively shaped rollers that deform it into the final cross-section, followed by cooling, straightening, and cutting.

The Machinery Behind the Shapes: Universal Mills vs. Section Mills

While the core principle of hot rolling is the same, the type of mill dictates the family of shapes it can produce.

1. Universal Mill for Beams:

This mill is designed to produce wide-flange beams (H-beams or I-beams). It is called "universal" because it uses a combination of horizontal and vertical rollers simultaneously.

- Horizontal Rolls: These form the top and bottom flanges of the beam.

- Vertical Rolls: These are placed on the sides to form the web and control its thickness.

- Process: The bloom is shaped by this coordinated action. It allows for the production of very large, heavy beams with parallel flange surfaces.

2. Section Mill for "Standard" Sections:

This is where angles, channels, tees, and smaller beams are made. Our focus, the angle mill, is a type of section mill.

- Two-High or Three-High Rolling Stands: These mills primarily use pairs of grooved rolls.

- Roll Design: The key difference between an angle, a channel (U-shaped), and a tee (T-shaped) lies in the intricate design of the groove cut into the face of the rollers. A channel groove has a raised center to form the web, while an angle groove is a simple 90-degree cut.

- Flexibility: Section mills can be reconfigured by changing the roll sets, but this is time-consuming. Mills often specialize in a range of similar sections.

Comparing the Output and Use:

The choice of shape is an engineering decision based on load requirements.

| Structural Shape | Typical Production Mill | Key Characteristic | Common Marine Application |

|---|---|---|---|

| H-Beam / I-Beam | Universal Mill | Very high bending strength about its major axis. | Primary deck girders, large transverse frames. |

| Channel (U-Shape) | Section Mill | Good strength, provides a flat back for attachment. | Secondary deck beams, built-up sections. |

| Angle (L-Shape) | Section Mill (Angle Mill) | Good strength in two directions, excellent for connections and bracing. | Stiffeners on plates, brackets, secondary bracing, handrail supports. |

| Bulb Flat | Specialized Section Mill | Asymmetric profile; very efficient as a stiffener for hull plating. | Primary longitudinal and transverse stiffeners on hull and deck plates. |

The Importance of This for Buyers:

When you source L-shaped steel, you are tapping into the specialized production line of an angle mill. This specialization means the mill operators are experts in that specific product. It leads to higher quality, tighter tolerances, and more consistent output for that shape. We ensure our L-angle supply comes from mills with strong expertise in their section mills, guaranteeing the product performs exactly as expected in your fabrication.

Conclusion

The manufacturing of marine L-shaped steel is a precise, multi-stage hot rolling process. It transforms raw steel into a strong, reliable component that is essential for building safe and durable ships.

-

Gain insights into the specialized equipment used for manufacturing steel angles. ↩ ↩ ↩

-

Explore how cooling beds impact the quality and properties of steel angles during production. ↩ ↩ ↩ ↩

-

Understanding reheating furnaces is crucial for grasping the initial stages of steel angle production. ↩ ↩

-

Discover the importance of quality control in ensuring the reliability of steel products. ↩ ↩

-

Find out why Mill Test Certificates are essential for verifying the quality of steel products. ↩ ↩

-

Explore TMCP to see how it enhances steel properties and its advantages over conventional methods. ↩

-

Learn about QST and how it contributes to producing high-strength steel sections for demanding applications. ↩

-

Understand the role of accelerated cooling in improving steel’s mechanical properties and performance. ↩