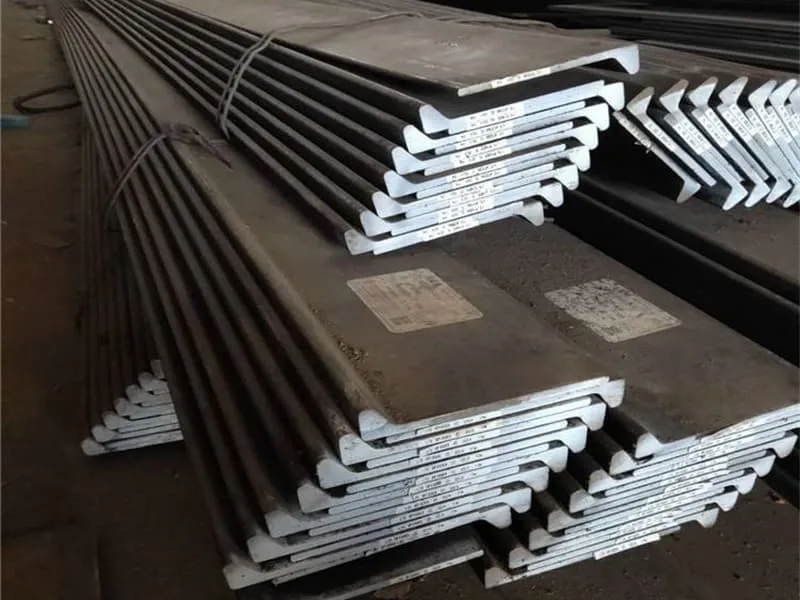

Walking through a shipyard in Vietnam, I noticed bulb flat steel forming the backbone of every vessel’s internal structure. This specialized profile provides unique advantages.

Bulb flat steel serves as longitudinal stiffeners in ship hulls, providing superior strength-to-weight ratio and efficient load distribution. Its unique bulb-tipped design offers enhanced section modulus compared to flat bars, making it ideal for hull reinforcement where space optimization and structural efficiency are critical.

Understanding bulb flat steel’s role helps appreciate modern ship design. Let me explain why this profile dominates hull reinforcement applications.

What kind of steel is used for ship hulls?

A naval architect from Saudi Arabia questioned our steel recommendations. The answer involves both material grades and specific profiles.

Ship hulls primarily use AH361, DH36, and EH36 marine grade steel plates2 combined with bulb flat steel stiffeners3. These materials offer 355 MPa yield strength with varying toughness levels, corrosion resistance, and excellent weldability to withstand ocean forces and ensure vessel structural integrity throughout its service life.

Comprehensive Hull Steel Selection

Ship hull steel selection involves multiple considerations that balance strength, toughness, fabrication needs, and lifecycle costs. Each component serves specific purposes.

Primary Hull Plating Materials

The main hull shell uses marine grade steel plates2. AH361 serves as the standard grade for most commercial vessels. DH36 provides enhanced toughness for colder waters. EH36 offers maximum toughness for arctic operations. The selection depends on operating routes and environmental conditions. All grades maintain 355 MPa minimum yield strength.

Bulb Flat Steel Applications

Bulb flats serve as longitudinal stiffeners throughout the hull. They reinforce the plating against water pressure. The bulb profile provides maximum section modulus with minimal weight. This efficiency reduces steel weight while maintaining strength. The design prevents buckling under compressive loads.

Chemical Composition Requirements

Marine steels maintain strict chemical controls. Carbon content typically ranges from 0.14% to 0.18%. Manganese levels vary from 0.90% to 1.60%. Silicon stays below 0.50% for deoxidation. Phosphorus and sulfur remain below 0.035% for toughness. These controls ensure good weldability and impact resistance.

Mechanical Property Specifications

Yield strength must meet 355 MPa minimum requirement. Tensile strength typically ranges from 490-620 MPa. Elongation exceeds 20% to ensure ductility. Impact toughness meets classification society standards. The properties provide adequate safety margins for marine service.

Classification Society Certification

All hull steels require society approval. ABS, DNV, LR, and BV set material standards. Certification involves mill audits and product testing. Regular surveillance ensures ongoing compliance. The process guarantees material quality and reliability.

Hull Steel Material Applications

| Component | Primary Material | Alternative Options | Key Requirements |

|---|---|---|---|

| Bottom Plating | AH361/DH36 plates | Higher strength grades | Impact resistance |

| Side Shell | AH361 plates | DH36 for cold waters | Corrosion resistance |

| Deck Plating | AH361 plates | Thinner with stiffeners | Fatigue strength |

| Longitudinal Stiffeners | Bulb flat steel | Angle bars, T-sections | Section modulus |

| Transverse Frames | Angle steel | Bulb flats, built sections | Bending strength |

We supply these materials to shipyards across Southeast Asia. Clients in Philippines and Thailand confirm their performance in actual service conditions.

Why common steel is used in shipbuilding?

A project manager from Mexico initially considered common steel for cost savings. Understanding the differences prevented a serious mistake.

Common steel lacks the specific properties required for marine environments. Shipbuilding demands controlled chemistry, guaranteed toughness, certified quality, and enhanced corrosion resistance that common structural steel cannot provide, making specialized marine grades essential for vessel safety and longevity.

Limitations of Common Steel in Marine Applications

Common structural steel serves many purposes but falls short in marine applications due to specific technical requirements and environmental challenges.

Chemical Composition Differences

Common steel has variable chemical content that affects marine performance. Carbon levels may be too high for good weldability. Sulfur and phosphorus contents often exceed marine grade limits. The lack of controlled alloys reduces corrosion resistance. These variations create unpredictable behavior in seawater environments.

Toughness and Impact Requirements

Marine structures face dynamic loading conditions. Common steel may become brittle at low temperatures. Impact resistance is not guaranteed or certified. The material cannot reliably withstand wave impacts and collision forces. This unpredictability creates safety risks in marine service.

Quality Certification Absence

Common steel lacks the certification framework of marine grades. No classification society oversight ensures quality. Mill test certificates may be incomplete or unavailable. Traceability from raw material to finished product is often missing. This lack of documentation prevents regulatory approval.

Corrosion Resistance Limitations

Seawater accelerates corrosion dramatically. Common steel lacks the composition for marine corrosion resistance. The material corrodes quickly without extensive protection systems. Maintenance requirements become excessive and costly. Service life falls short of marine expectations.

Fabrication Challenges

Welding common steel presents difficulties in marine applications. Cracking risks increase without controlled composition. Preheating requirements may be more extensive. Repair welding becomes more problematic. These issues increase construction costs and delays.

Regulatory Compliance Issues

Classification societies do not approve common steel for hull structures. Insurance companies may reject vessels built with improper materials. Port state control inspections can detain non-compliant vessels. Resale value suffers without proper certification. These regulatory hurdles make common steel impractical.

Performance Comparison Table

| Property | Common Steel | Marine Steel | Marine Significance |

|---|---|---|---|

| Impact Toughness | Variable | Guaranteed minimum | Safety in storms |

| Corrosion Rate | High | Controlled | Longer service life |

| Weldability | Problematic | Optimized | Construction efficiency |

| Certification | None | Full documentation | Regulatory approval |

| Traceability | Limited | Complete | Quality assurance |

Our clients in Qatar and Saudi Arabia understand these differences. Their vessels meet international standards using proper marine materials.

Which type of steel is most commonly used in shipbuilding due to its strength and durability?

A shipowner from Romania needed to standardize their fleet specifications. AH36 emerged as the optimal choice.

AH36 marine steel is the most commonly used type in shipbuilding due to its optimal balance of 355 MPa yield strength, good toughness, excellent weldability, and cost-effectiveness. It serves as the workhorse grade for hull plates, deck structures, and bulkheads in most commercial vessels operating in tropical and temperate waters.

AH36 Steel Dominance in Shipbuilding

AH36 has become the industry standard for commercial shipbuilding through its proven performance and economic advantages across multiple vessel types.

Strength and Durability Characteristics

AH36 offers 355 MPa minimum yield strength. This strength level meets most structural requirements. Tensile strength ranges from 490-620 MPa providing good safety margins. Elongation exceeds 20% ensuring adequate ductility. The balanced properties handle typical marine loads effectively.

Toughness Performance

AH36 undergoes Charpy V-notch testing at 0°C. The minimum impact energy is 34 joules. This toughness suits most commercial shipping routes. The material withstands normal wave impacts and dynamic loads. Enhanced toughness grades are available for special requirements.

Weldability Advantages

The chemical composition ensures excellent weldability. Carbon equivalent typically stays below 0.41%. Common welding methods work without special procedures. Preheating is rarely required for standard thicknesses. Repair welding performs reliably throughout the vessel’s life.

Cost-Effectiveness

AH36 provides the best cost-to-performance ratio. Production costs are lower than higher toughness grades. Availability is excellent from multiple mills worldwide. The competitive pricing supports economic vessel construction. Lifecycle costs remain reasonable with proper maintenance.

Application Versatility

AH36 serves in multiple hull areas. It works well for shell plating and deck structures. Bulkheads and internal structures use AH36 extensively. The grade suits various vessel types and sizes. This versatility simplifies material planning and procurement.

Classification Society Acceptance

All major classification societies approve AH36. ABS, BV, DNV, and LR have similar requirements. Certification processes are well-established and efficient. Mutual recognition between societies facilitates international operations. This acceptance supports global vessel trading.

AH36 Application Guide

| Vessel Type | AH36 Usage Percentage | Key Applications | Special Considerations |

|---|---|---|---|

| Bulk Carriers | 85-90% | Hull plating, decks | Corrosion allowance |

| Container Ships | 80-85% | Shell, bulkheads | Fatigue strength |

| Oil Tankers | 75-80% | Plating, structures | Crack resistance |

| General Cargo | 90-95% | Most components | Economic construction |

| Offshore Support | 70-75% | Hull, decks | Special areas upgrade |

We supply AH36 to shipyards in Malaysia and Myanmar. Their successful projects demonstrate the grade’s reliability and performance.

How do submarines not rust?

A naval engineer from Pakistan asked about submarine corrosion protection. The methods are sophisticated but follow similar principles to surface vessels.

Submarines employ multiple corrosion protection methods including cathodic protection systems, specialized coatings, corrosion-resistant alloys, controlled environments, and rigorous maintenance. These systems work together to prevent rust despite constant seawater immersion, with particular attention to welding integrity and material selection for pressure hull integrity.

Advanced Submarine Corrosion Control

Submarine corrosion protection represents the pinnacle of marine anti-corrosion technology. The systems are comprehensive and multi-layered for maximum reliability.

Cathodic Protection Systems

Submarines use sophisticated impressed current systems. Anodes distribute protective electrical currents. Reference electrodes monitor protection levels. The systems adjust automatically to changing conditions. This protection works throughout the hull’s submerged areas. The technology prevents electrochemical corrosion.

Advanced Coating Systems

Multiple coating layers provide barrier protection. Epoxy primers ensure excellent adhesion. Antifouling coatings prevent marine growth. Special elastomeric coatings accommodate hull flexing. The coating systems undergo rigorous quality control. Regular maintenance preserves coating integrity.

Corrosion-Resistant Materials

Pressure hulls use high-strength low-alloy steels. These steels contain copper, nickel, and chromium for corrosion resistance. Stainless steel serves in piping and mechanical systems. Copper-nickel alloys work in heat exchangers. Material selection minimizes corrosion risks.

Environmental Control

Internal atmospheres are carefully controlled. Dehumidification systems maintain low humidity. Air filtration removes corrosive contaminants. Temperature control prevents condensation. These measures protect internal structures from corrosion.

Welding and Fabrication Quality

Pressure hull welds receive special attention. Welding procedures ensure corrosion resistance. Post-weld heat treatment relieves stresses. Non-destructive testing verifies weld quality. This attention prevents corrosion initiation sites.

Maintenance and Inspection

Regular dry-docking allows thorough inspection. Coating repairs address any damage. Cathodic system maintenance ensures continuous protection. Internal systems receive periodic corrosion assessment. This proactive approach prevents serious corrosion issues.

Corrosion Protection Comparison

| Protection Method | Surface Ships | Submarines | Key Differences |

|---|---|---|---|

| Cathodic Protection | Sacrificial anodes | Impressed current | More sophisticated control |

| Coatings | Standard marine | Special systems | Higher performance requirements |

| Materials | Marine grades | Special alloys | Enhanced corrosion resistance |

| Inspection | Periodic dry-dock | More frequent | Higher safety criticality |

| Maintenance | Scheduled | Continuous | More intensive programs |

While we don’t supply submarine materials, the principles inform our marine steel recommendations. Clients appreciate understanding advanced corrosion protection concepts.

Conclusion

Bulb flat steel plays a crucial role in ship hull reinforcement, working with marine grade plates to create strong, durable vessels. Proper material selection ensures structural integrity and long service life.

-

Explore the significance of AH36 steel in shipbuilding and its properties that make it a preferred choice. ↩ ↩ ↩ ↩ ↩

-

Learn about marine grade steel plates and their critical role in ensuring ship hull durability and safety. ↩ ↩

-

Discover how bulb flat steel stiffeners improve the structural integrity of ship hulls under pressure. ↩