Look at a modern container ship or cruise liner. Its vast scale and graceful lines are made possible by one material: structural steel. It is the literal and figurative backbone of the vessel. Without it, the age of global maritime trade would not exist.

Structural steel provides the essential skeleton and skin of a modern ship. Its primary functions are to create a watertight, buoyant hull that can withstand immense ocean forces, provide the strength to carry massive cargo loads, and offer the flexibility for complex, efficient designs. It is the enabling material that makes large, safe, and economical vessels possible. Its properties directly dictate a ship’s size, capability, and safety.

For naval architects, marine engineers, and anyone in shipbuilding, understanding steel’s role is fundamental. It’s not just a commodity; it’s the core engineering choice. This article will explore what structural steel does, how it’s used, the professionals who design with it, and its overarching role in construction, both on land and at sea. Let’s start with its basic function.

What is the function of structural steel1?

At its core, structural steel1 has one job: to carry load. But in a ship, this simple function manifests in complex and critical ways. I’ve seen designs where the choice of steel grade directly influenced the ship’s cargo capacity and operating costs.

The function of structural steel1 in a ship is to safely transfer and resist all applied loads—including the ship’s own weight, cargo weight, hydrostatic water pressure, wave-induced dynamic forces, and local impact loads—through a framework of plates, stiffeners, and frames, ensuring structural integrity, watertightness, and global strength throughout the vessel’s lifetime. It is the material that turns design concepts into floating, functional reality.

How Steel Performs Its Load-Bearing Role

To understand its function, we need to see how steel handles different types of forces in a ship’s environment.

1. Resisting Global Bending (Hogging and Sagging):

As a ship rides waves, its hull acts like a giant beam. The midsection is supported by wave crests at the bow and stern, causing the center to sag. Or it’s supported amidships, causing the ends to hog. The entire longitudinal structure—the keel, deck, and side shell—works together in tension and compression to resist this bending. High-strength steel plates are crucial here.

2. Resisting Local Pressures and Buckling:

Water pressure pushes inward on the hull. Cargo weight pushes down on the decks. Thin steel plates alone would buckle easily.

- Solution: A grid of smaller steel members—angles, bulb flats, and stiffeners—is welded to the plates. These members divide the large plate into smaller, stronger panels. The steel’s function here is to provide local stiffness and prevent deformation.

3. Providing Watertight Integrity:

The steel hull must not leak. This is a primary function. Continuous welds join steel plates to form a seamless barrier. The steel itself must be tough enough to resist crack propagation, especially at welded joints, to maintain this integrity under fatigue loads.

4. Creating Shape and Space:

The steel framework defines the ship’s form—the curved bow, the flat-bottomed cargo holds, the complex geometry of the engine room. Its ability to be cut, formed, and welded allows for this.

Functional Analysis by Ship Component:

| Ship Component | Made From Structural Steel… | Primary Function of the Steel in This Component |

|---|---|---|

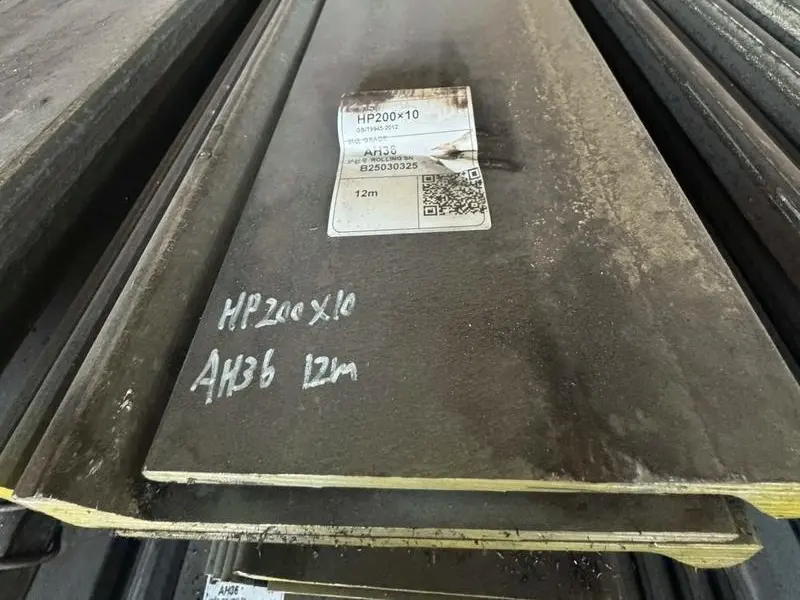

| Bottom Shell Plate | Thick plate (e.g., AH36) | Resists upward water pressure and global bending2 (in compression). |

| Deck Plate | High-strength plate (e.g., AH36) | Resists cargo loads and global bending2 (in tension/compression). |

| Side Frame (Transverse) | Rolled angle or built section | Provides transverse shape and strength; supports the side shell plating. |

| Longitudinal Stiffener | Bulb flat or angle | Prevents buckling of hull/deck plates under local pressure. |

| Bulkhead Plate & Stiffeners | Plate and angle grid | Creates watertight compartments; resists floodwater pressure. |

This multifaceted function is realized through specific, deliberate uses of steel in various forms, which is our next focus.

What is the use of structural steel1?

"We use steel" is too vague. In shipbuilding2, we use specific steel products in specific ways. A procurement manager needs to know the difference between a plate order and an angle order. Our business is built on supplying these distinct uses.

In shipbuilding2, structural steel1 is used as plates for the hull skin and decks, rolled sections3 (angles, bulb flats) for internal framing and stiffening, and fabricated shapes (girders, pillars) for major supports. These uses transform raw material into a ship’s watertight envelope, its internal skeleton for strength, and its platforms for equipment and cargo. Each use addresses a specific structural need.

A Detailed Breakdown of Applications

Let’s move from the abstract function to the tangible application on the shipyard floor.

1. Use as Plating (The Skin):

This is the largest use by weight. Steel plates are cut and welded to form:

- Shell Plating: The outer watertight skin. It is curved and shaped to form the hull.

- Deck Plating: The "floors" of the ship. They must be flat and strong.

- Bulkhead Plating: The vertical walls inside the hull, creating compartments.

- Key Point: Plating primarily resists in-plane forces (tension, compression, shear) and water pressure. It is almost always stiffened.

2. Use as Rolled Sections (The Skeleton):

These are the bones attached to the plating.

- Angle Bars (L-shapes): The most versatile section.

- As Frames: The transverse ribs of the ship.

- As Stiffeners: Welded to bulkheads and decks.

- As Brackets and Connections: Small pieces for joining members.

- Bulb Flats: Specialized sections used almost exclusively as longitudinals—members running fore-and-aft to stiffen the bottom, sides, and decks. Their shape offers maximum bending resistance for their weight.

- Flat Bars: Used for minor stiffening, edges, and small connections.

3. Use as Fabricated Sections (The Major Supports):

For very high loads, standard rolled sections3 may be insufficient.

- Built-up Girders: Welded from plates to create deep, strong beams for supporting heavy deck loads or as primary girders.

- Pillars and Stanchions: Vertical compression members supporting decks.

From Stock to Structure: The Transformation

| Raw Steel Product | Shipyard Process | Resulting Use on the Ship |

|---|---|---|

| AH36 Plate (from mill) | Cut to shape, curved. | Shell Plating for the midship hull. |

| Bulb Flat 250×12 (from mill) | Cut to length, welded. | Deck Longitudinal under container stacks. |

| L200x200x16 Angle (from mill) | Cut, sometimes bent. | Transverse Frame at station 45. |

| Assorted plates & angles | Welded into an assembly. | Engine Foundation or Hatch Coaming. |

For a supplier, understanding these uses is key. When a client asks for "ship L-shaped steel," we know they likely need angles for frames or stiffeners. This technical translation is the job of a specialized engineer.

What is the role of a structural steel engineer1?

The steel doesn’t design itself. Between the raw material and the finished ship is the structural engineer. They are the master planners who ensure the steel performs its functions safely and efficiently. I collaborate closely with these engineers to clarify material properties and availability for their designs.

A structural steel engineer1 in shipbuilding designs the arrangement, sizing, and connections of all steel members (plates, stiffeners, frames) to withstand design loads. They perform strength, stability, and fatigue calculations2, select appropriate steel grades, detail welds and connections, and ensure the design complies with classification society rules3 and safety standards. They are responsible for the vessel’s structural integrity from concept to completion.

The Multifaceted Responsibilities from Desk to Dock

The role spans analysis, specification, and oversight.

1. Design and Analysis:

- Global Strength Analysis: Using software to model the entire ship as a beam to check bending moments and shear forces.

- Local Strength Assessment: Calculating stresses in specific areas like hatch corners, openings, and connections.

- Fatigue Analysis: Predicting the life of welded details under millions of wave load cycles.

- Buckling Control: Designing the stiffener spacing and size to prevent plate buckling.

2. Material Specification and Selection:

This is a critical interface with procurement. The engineer:

- Specifies Steel Grades: Decides that the bottom shell needs AH36, the bow needs DH36, and an internal bulkhead needs Grade A. They base this on stress levels and required toughness.

- Defines Quality Requirements: May call for Z-quality steel for thick plates at nodes, or specify additional non-destructive testing (NDT).

- Creates the Material List: The definitive document that procurement uses to order steel.

3. Detailing and Compliance:

- Creates Detailed Drawings: Shows exact dimensions, weld sizes, and connections for the workshop.

- Ensures Rule Compliance: The design must satisfy all requirements of the chosen classification society (ABS, DNV, etc.). The engineer submits calculations and drawings for society approval.

How Their Work Affects the Supply Chain:

The engineer’s decisions directly impact what we supply.

- If they specify a special grade like EH40, we must source from a mill capable of producing it.

- If they require extensive NDT, we coordinate that service.

- A clear, accurate material list prevents errors in ordering. In contrast, vague specs lead to requests for clarification, causing delays.

Collaboration for Success:

A smooth project requires communication between the engineer and the material supplier. For example, if the engineer specifies a rare bulb flat size, we might advise on a more standard, readily available size that meets the same structural requirement, saving time and cost. This collaborative mindset highlights the broader role of steel in construction.

What is the role of steel in construction?

Steel’s role in shipbuilding is a specialized case of its universal role in construction. The principles are the same, but the application and demands are extreme. A civil engineer once told me that building a ship is like building a skyscraper that must also float and move.

In all construction, steel’s primary role is to provide a strong, durable, and versatile framework that efficiently carries loads over long spans, allows for fast assembly, and enables creative architectural forms. In marine construction, these roles are intensified: the "building" must withstand dynamic ocean forces, resist a corrosive environment, and be as light as possible to float efficiently. Steel is the default material where strength, speed, and reliability are paramount.

Comparing Land-Based and Marine Construction

Understanding the common principles makes the marine specialization clearer.

Universal Roles of Steel in Construction:

- Load-Bearing Skeleton1: It forms the columns, beams, and frames that transfer all loads (dead, live, wind, seismic) to the foundation (or, for a ship, to the buoyant hull).

- Design Flexibility2: It can be formed into an endless variety of shapes (I-beams, angles, tubes). This allows for innovative architecture and efficient structural forms.

- Speed of Erection3: Components are prefabricated off-site and quickly bolted or welded together on-site. This drastically reduces project time compared to cast-in-place concrete.

- High Strength-to-Weight Ratio4: It provides great strength without excessive weight, allowing for taller buildings and longer spans.

How These Roles Are Amplified in Shipbuilding:

| Construction Role | In a Building/Bridge | In a Ship (Amplified Challenge) |

|---|---|---|

| Load-Bearing | Static loads (weight, wind). | Dynamic, cyclic loads from waves for 25+ years (fatigue is critical). |

| Material Efficiency | Important for cost. | Crucial for performance. Every ton of steel saved is a ton of extra cargo (deadweight). High-strength grades (AH36) are essential. |

| Connection Integrity | Bolts and welds must be strong. | Welds are life-critical. A failed weld can lead to flooding. Weld quality and steel weldability are paramount. |

| Environmental Resistance | Protected from weather by cladding. | Constant exposure to corrosive saltwater. Requires coatings, cathodic protection, and corrosion allowances. |

| Formability | Beams are often straight. | Plates must be curved into complex hull shapes. Steel must be ductile enough for this. |

The Specialized Niche of Marine Structural Steel:

To fulfill its role in a ship, steel must have properties that go beyond standard construction steel:

- Certified Toughness5: Mandatory impact testing to prevent brittle fracture in cold water.

- Fatigue-Resistant Details6: Clean steel and careful weld design.

- Classification Society Approval: An added layer of quality assurance and traceability not required for most buildings.

For a supplier like us, our role is to provide the steel that fulfills these intensified construction requirements. We bridge the gap between the universal availability of steel and the specialized needs of shipbuilders, ensuring they get material that performs its role flawlessly in the most demanding construction environment on Earth.

Conclusion

Structural steel is the indispensable foundation of modern ship design, functioning as the load-bearing skeleton, enabling efficient and strong construction, and requiring specialized engineering to meet the unique challenges of the marine environment. Its role is both fundamental and highly refined.

-

Understanding the Load-Bearing Skeleton is crucial for grasping how structures support weight and ensure stability. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore how Design Flexibility allows architects to create unique and efficient structures, pushing the boundaries of design. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn how Speed of Erection can significantly reduce project timelines and costs, making construction more efficient. ↩ ↩ ↩ ↩

-

Discover why a High Strength-to-Weight Ratio is essential for modern construction, enabling taller and longer structures. ↩

-

Find out how Certified Toughness ensures safety and performance in marine environments, crucial for shipbuilding. ↩

-

Explore the importance of Fatigue-Resistant Details in ensuring the longevity and safety of marine structures. ↩