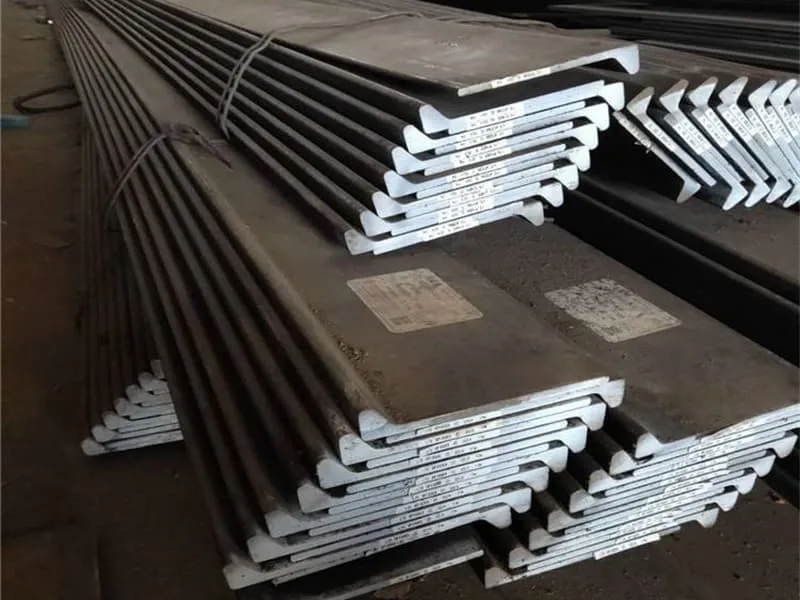

Finding reliable bulb flat steel suppliers in China can be challenging for international buyers. Many suppliers claim certification capabilities they don’t actually possess. This guide shares verified suppliers based on my industry experience.

The top bulb flat steel suppliers in China include Baowu Group, Ansteel Group, Shagang Group, Shougang Group, and specialized marine steel exporters like our company. These suppliers offer ABS, LR, DNV, and BV certified products with proper documentation and international shipping support.

Having worked with Chinese steel mills for over a decade, I’ve compiled this list based on actual project performance and client feedback. The following information will help you navigate China’s complex steel supply landscape effectively.

Who is the largest steel manufacturer in China?

Many international buyers assume China’s steel industry is fragmented and unreliable. This misconception causes them to miss opportunities with world-class manufacturers who produce superior quality marine steel1.

China Baowu Steel Group2 is the largest steel manufacturer in China and globally. They produce over 115 million tons annually and manufacture ABS, LR, and DNV certified bulb flat steel. Their extensive R&D capabilities3 ensure consistent quality for marine applications across all major classification societies.

Comprehensive Analysis of China’s Leading Steel Manufacturer

China Baowu Steel Group2 represents the pinnacle of Chinese steel manufacturing capability. Understanding their operations helps buyers appreciate the quality available from top-tier Chinese suppliers.

Baowu formed through the merger of Baosteel and Wuhan Iron and Steel in 2016. This consolidation created the world’s largest steel producer with massive economies of scale. Their production volume exceeds the total output of many countries’ entire steel industries.

Baowu Group Marine Steel Production Capabilities:

| Production Base | Location | Annual Capacity | Specialized Products | Certification Coverage |

|---|---|---|---|---|

| Baoshan Base | Shanghai | 25 million tons | High-grade marine steel1 | All major classifications |

| Wuhan Base | Hubei | 20 million tons | Shipbuilding plates | ABS, LR, DNV, BV |

| Zhanjiang Base | Guangdong | 15 million tons | Bulb flats, angles | Specialized marine sections |

| Xinjiang Bayi | Xinjiang | 10 million tons | Structural steel | General marine applications |

Research and development investments set Baowu apart from competitors. They operate multiple national-level laboratories and engineering research centers. Their technical staff includes over 15,000 R&D personnel focused on product development and process improvement.

Quality control systems meet international standards across all operations. Baowu implements comprehensive quality management from raw material sourcing to final product delivery. Their mills maintain ISO 9001 certification with additional classification society approvals for marine products.

Global presence and export experience make Baowu reliable for international buyers. They export to over 100 countries with established logistics networks. Their documentation processes accommodate various import requirements and customs procedures.

Environmental compliance and sustainability initiatives demonstrate world-class operations. Baowu invests heavily in emission reduction technologies and energy efficiency improvements. Their environmental standards often exceed local regulatory requirements.

How many steel plants1 are there in China?

International buyers often worry about supply consistency from China’s steel industry. Understanding the scale and distribution of production facilities reassures them about reliable supply chains.

China has approximately 400-500 significant steel plants1 with varying production capacities2. These include large integrated mills, specialized section mills3 producing bulb flats, and smaller electric arc furnace operations. The industry consolidation has reduced plant count while increasing average quality levels.

Detailed Overview of China’s Steel Plant Landscape and Capabilities

China’s steel plant network is both vast and sophisticated. The distribution reflects historical development patterns and modern industrial planning strategies.

Integrated steel mills represent the industry’s backbone. These large facilities typically produce 3-20 million tons annually using blast furnace and basic oxygen furnace technology. They offer complete production chains from iron making to finished products, including specialized sections like bulb flats.

Chinese Steel Plant Categories and Characteristics:

| Plant Type | Number Range | Typical Capacity | Product Focus | Marine Certification |

|---|---|---|---|---|

| Integrated Mills | 50-70 | 3-20 million tons | Comprehensive range | Full classification coverage |

| Special Section Mills | 80-100 | 0.5-3 million tons | Bulb flats, angles | Limited certification options |

| EAF Mini-Mills4 | 200-250 | 0.1-1 million tons | Rebar, merchant bars | Usually no marine certification5 |

| Stainless Specialists | 20-30 | 0.5-5 million tons | Stainless products | Selective certification |

| Coastal Export Hubs | 30-40 | 2-15 million tons | Export-oriented products | Full international certification |

Geographic distribution follows resource availability and logistics needs. Major production clusters exist in Hebei, Jiangsu, Shandong, and Liaoning provinces. Coastal locations like Shanghai, Tianjin, and Guangdong serve export markets efficiently with lower shipping costs.

Production technology varies significantly across different plant types. Modern integrated mills use world-class equipment and process controls. Some specialized section mills3 employ dedicated rolling lines for bulb flats and other marine sections with tight tolerance control.

Certification capabilities differ widely among plants. Only about 100 Chinese steel plants1 maintain classification society approvals for marine products. Even fewer have specific approvals for bulb flat production, typically requiring specialized rolling equipment and quality systems.

Industry consolidation continues to reshape the plant landscape. Government policies encourage mergers to eliminate excess capacity and improve environmental performance. This trend benefits buyers by ensuring suppliers have adequate scale and technical capability.

Is Chinese steel as good as US steel?

Many international buyers harbor doubts about Chinese steel quality compared to American products. These concerns often stem from outdated perceptions rather than current manufacturing realities.

Modern Chinese steel from certified mills equals or exceeds US steel quality for marine applications. Chinese mills produce bulb flat steel that meets all international classification society standards. The manufacturing processes, quality controls, and testing protocols match those used by American producers.

Objective Comparison of Chinese and American Steel Quality Standards

The quality comparison between Chinese and American steel requires understanding modern manufacturing realities rather than relying on historical perceptions.

Manufacturing technology and equipment are comparable between top Chinese and American mills. Chinese manufacturers have invested heavily in modern continuous casting machines, computerized rolling mills, and advanced heat treatment facilities. These investments ensure consistent product quality.

Quality Parameter Comparison Table:

| Quality Aspect | Top Chinese Mills | Top US Mills | International Standards |

|---|---|---|---|

| Chemical Composition Control | ±0.01% for key elements | ±0.01% for key elements | Within specified ranges |

| Mechanical Properties | Consistent within 5% variation | Consistent within 5% variation | Meet minimum requirements |

| Dimensional Tolerances | EN 10034/10056 standards | ASTM A6 standards | Classification society rules |

| Surface Quality | Scale-free, minimal defects | Scale-free, minimal defects | Commercial acceptance standards |

| Certification Documentation | Complete traceability | Complete traceability | Classification requirements |

Quality management systems implement international standards across Chinese mills. ISO 9001 certification is universal among major producers. Classification society surveys ensure continuous compliance with marine material specifications. Third-party inspection services provide additional verification.

Research and development investments in China have accelerated quality improvements. Chinese steel companies filed over 5,000 patents related to steel production in recent years. Their technical innovations focus on product consistency, property enhancement, and process efficiency.

Cost structure advantages don’t compromise quality in certified Chinese mills. Lower labor costs and efficient scale operations reduce prices while maintaining quality standards. International buyers benefit from competitive pricing without sacrificing performance requirements.

Real-world performance data supports Chinese steel quality claims. Ships built with Chinese bulb flat steel have operated successfully for decades in global service. Classification society records show no systematic quality issues with properly certified Chinese marine steel.

Which is a great iron and steel centre in China?

Buyers often struggle to identify the best sourcing locations within China’s vast steel industry. Understanding regional specializations helps target suppliers with the right capabilities for specific products.

The Tangshan region in Hebei province represents China’s largest and most comprehensive iron and steel center. It produces over 100 million tons annually with extensive bulb flat manufacturing capabilities. Other major centers include Shanghai, Wuhan, and Shandong’s Liaocheng region where our operations are based.

Analysis of China’s Major Steel Production Centers and Their Specializations

China’s steel production centers have evolved distinct characteristics and specializations. Understanding these regional differences helps buyers source more effectively.

The Tangshan cluster in Hebei dominates China’s steel output. This region produces approximately 13% of China’s total steel production. Its integrated mills and specialized plants manufacture everything from raw steel to finished bulb flats and other marine sections.

Major Chinese Steel Centers Comparison:

| Production Center | Annual Capacity | Key Specializations | Major Companies | Export Experience |

|---|---|---|---|---|

| Tangshan, Hebei | 100+ million tons | Comprehensive range | HBIS, Tangsteel | Extensive global exports |

| Shanghai/Jiangsu | 80+ million tons | High-grade marine steel | Baowu, Shagang | World-leading export volume |

| Shandong Province | 60+ million tons | Sections, bulb flats | Shandong Steel, local mills | Growing export focus |

| Liaoning Province | 50+ million tons | Plates, heavy sections | Ansteel, Benxi Steel | Established export channels |

| Hubei Province | 40+ million tons | Automotive, marine | Wuhan Steel, Hubei mills | Moderate export activity |

Shanghai and Jiangsu province form another critical steel hub. This region benefits from excellent port infrastructure and international business environment. Baowu’s massive Baoshan base leads this cluster with world-class technology and quality standards.

Shandong province has emerged as a specialized section production center. The Liaocheng region where we operate has developed particular expertise in marine sections like bulb flats. Local mills combine traditional craftsmanship with modern production technology.

Logistics infrastructure varies significantly between different steel centers. Coastal locations like Shanghai and Shandong ports offer direct shipping access. Inland centers like Tangshan and Wuhan rely on integrated rail and port networks for exports.

Supply chain maturity differs across production regions. Established export hubs have streamlined processes for international buyers. These include English documentation, familiar payment terms, and experienced freight forwarders specializing in steel exports.

Conclusion

China offers diverse, high-quality bulb flat steel suppliers capable of meeting international marine standards. Proper supplier selection ensures reliable quality and competitive pricing.

-

Explore this link to understand the scale and distribution of steel plants in China, ensuring reliable supply chains. ↩ ↩ ↩ ↩ ↩

-

Discover the varying production capacities of Chinese steel plants to gauge their output and reliability. ↩ ↩ ↩

-

Find out how specialized section mills contribute to the diversity of products in China’s steel market. ↩ ↩ ↩

-

Understand the role of EAF Mini-Mills in China’s steel production landscape and their environmental impact. ↩

-

Explore the significance of marine certification for steel products and how it affects quality and market access. ↩