L-shaped steel seems simple, but in marine projects, a weak or corroded angle can compromise an entire structure. Choosing the right one is not a minor detail.

Marine L-shaped steel, or angle bar, is commonly used for stiffening frames in ship hulls and decks, supporting walkways and ladders on offshore platforms, reinforcing sheet pile walls in ports, and constructing cargo holds and bulkheads due to its strength, ease of welding, and 90-degree form factor.

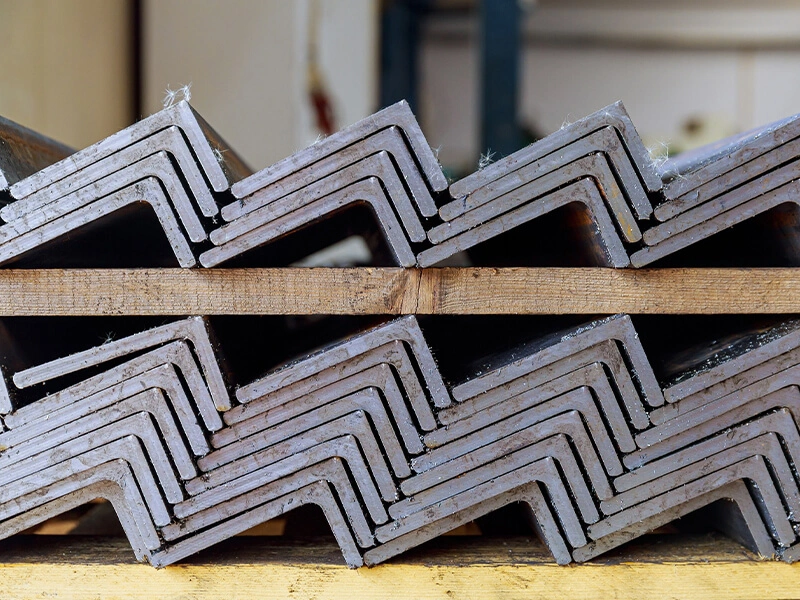

I supply these angles to shipyards and fabricators across Asia and the Middle East. They are the unsung heroes of marine construction. This article will show you where they are used and why the marine-grade specification matters so much.

What is the L angle used for?

An L-angle1 is a fundamental building block. Its 90-degree shape gives it inherent rigidity in two directions. In marine environments, this simple shape solves a wide range of structural challenges.

The L-angle1 is primarily used as a stiffener2 or bracket. It connects and reinforces flat plates (like hull plating or deck plates) to prevent buckling under load. It also forms lightweight frames for doors, hatches, and equipment supports, and acts as edge trim or reinforcement for cut-outs.

Imagine a large, flat steel plate. Under pressure from water or weight, it will bend and buckle easily. The L-angle1 is the perfect solution to stop this. Let’s explore its specific roles in detail.

The Multifunctional Role of the L-Angle in Marine Structures

The L-angle1 is a versatile component. Its applications can be grouped into three main functions: stiffening, framing, and connecting.

1. Primary Function: Stiffening

This is the most critical use. Thin steel plates are efficient for covering large areas, but they lack bending resistance.

- Hull Stiffening: On the bottom and sides of a ship’s hull (the shell plating), L-angle1s are welded vertically (called stiffener2s or frames) and horizontally (called stringers). They form a grid that breaks the large plate into smaller panels, dramatically increasing its resistance to water pressure and slamming loads.

- Deck Stiffening: On ship decks and offshore platform decks, L-angle1s are welded underneath as stiffener2s to support the weight of cargo, equipment, and vehicles. They prevent the deck plate from sagging.

- Bulkhead Stiffening: Walls inside a ship (bulkheads) also use L-angle1s as stiffener2s to resist water pressure in case of flooding in a compartment.

2. Secondary Function: Framing and Supports

The L-angle1‘s shape makes it ideal for creating three-dimensional frames.

- Door and Window Frames: Doors, hatches, and portholes on ships and offshore platforms are set into frames made of L-angle1s. The angle provides a surface to mount the door and a surface to weld to the surrounding structure.

- Equipment Mounting Brackets and Supports: Pumps, valves, cable trays, and pipe runs are often supported by brackets fabricated from L-angle1s. They are easy to cut and weld into custom shapes.

- Walkway and Staircase Edging: L-angle1s are used as the vertical risers on stair treads and as the side edging for grated walkways, providing a safe lip.

3. Tertiary Function: Connection and Reinforcement

- Edge Reinforcement: The edges of large cut-outs in plates (like for machinery access) are often reinforced by welding an L-angle1 around the perimeter. This restores the lost strength and prevents crack propagation.

- Connection Gussets: In structural nodes, L-angle1s are sometimes used as gusset plates to connect beams and columns, transferring loads effectively.

Why Marine-Grade Matters for L-Angles:

An L-angle1 doing these jobs cannot be made from common mild steel. It must be marine-grade3.

- Weldability: It will be extensively welded to the main plate. A high Carbon Equivalent (CEV) can cause weld cracks. Marine grades like S235JR, S275JR, or S355J2 have controlled chemistry for safe welding.

- Toughness: In cold waters, the angle must remain ductile. Grades with impact testing4 (J2, K2) are specified.

- Surface Quality: Good surface condition (free from heavy scale and defects) ensures better weld quality and coating adhesion. This was a key pain point for Gulf Metal Solutions that we solved by sourcing from certified mills.

| Application Area | Specific Use of L-Angle | Typical Size (mm) | Critical Property Needed | Common Marine Grade |

|---|---|---|---|---|

| Ship Hull | Vertical Stiffeners (Frames) | 150x90x10, 200x100x12 | High bending strength, Good weldability5 | AH36, DH36, S355J2 |

| Ship Deck | Under-deck stiffener2s | 100x75x8, 120x80x10 | Resistance to fatigue from cyclic loading | S355J2, S355K2 |

| Offshore Platform | Walkway support frames, Equipment brackets | 80x80x8, 100x100x10 | Corrosion resistance, Toughness | S355J2+N, S355G2 |

| Port Structure | Reinforcement for sheet pile caps, Bollard bases | 120x120x12, 150x150x15 | High strength, Corrosion resistance | S355J2, S355K2 (often galvanized) |

| Ship Interior | Bulkhead stiffener2s, Door frames | 75x75x6, 65x65x6 | Good formability, Weldability | S235JR, S275JR |

What is the L-shaped piece of metal1 used in construction?

In general construction, L-shaped metal is everywhere. But marine construction2 is a different beast. The principles are similar, but the demands are multiplied by salt water, dynamic loads, and the need for absolute reliability.

In marine construction2, the L-shaped piece of metal1 (angle bar) is used as a connecting bracket, a stiffening rib, and a framing member. It joins beams to columns, reinforces welded joints, forms the edges of platforms and stairways, and creates support structures for piping and electrical systems.

On land, you might use a standard angle. At sea, you need a certified marine angle. The difference is in the details of the material specification and the quality of its execution.

From Land to Sea: The Evolution of Angle Bar Application

The function transitions from "holding things up" to "surviving while holding things up under extreme conditions."

Land-Based Construction Applications (for context):

- Structural Bracing: Diagonal L-angles are used to brace building frames against wind and seismic loads.

- Support for Cladding and Sheeting: Angles form the substructure for attaching wall and roof panels.

- Stair Stringers and Handrail Posts: The basic frame for stairs.

- Equipment and Signage Supports: Simple, functional brackets.

Marine Construction Applications (Enhanced Requirements):

Here, every application from land construction exists, but with added layers of complexity.

- Heavy-Duty Bracing and Gussets: In port cranes, offshore jacket nodes, and shipyard gantries, L-angles are used as gusset plates3. These are thick, heavy angles that connect major load-bearing members. They must handle huge, fluctuating forces. The steel must have excellent through-thickness properties (Z-quality) if welded in a way that puts stress through the thickness, to prevent lamellar tearing.

- Composite Construction with Concrete: In pier and wharf construction, L-angles are often cast into concrete. They act as shear connectors4 or embedment plates to link the concrete deck to the steel piles or beams below. The angle must have good bond strength and its surface might be treated or have welded studs.

- Corrosion-Managed Framing: For control rooms, pump houses, and living quarters on offshore platforms, the entire steel frame might be made from L-angles and other sections. This frame is then fireproofed and coated with a multi-layer paint system. The steel’s surface preparation is critical.

- Modular Construction: Modern marine projects use modular design. Entire wall panels, ceiling sections, or equipment skids are pre-fabricated with L-angle frames in a shop. These modules are then shipped and bolted or welded together onsite. This requires angles with excellent dimensional tolerance so that everything fits together perfectly in the field.

The Critical Link: Fabrication and Tolerances

In marine construction2, fit-up is everything. A warped or twisted L-angle causes huge delays during assembly. We ensure our Marine Angle Steel5 is supplied with:

- Straightness and Flatness: Within strict tolerances per EN 10056 or ASTM A6.

- Consistent Leg Dimensions: So that when a fabricator cuts 100 pieces, they are all identical.

- Clean, Sharp Toes: The inside corner of the angle should be well-defined for proper fit-up against other members.

This level of quality turns the L-angle from a simple commodity into a precision component. It is what allows the large-scale, efficient fabrication that modern marine projects require. When Gulf Metal Solutions orders angles for their fabrication projects, they need this consistency to meet their own clients’ tight schedules.

What are the common applications of steel?

Steel is the skeleton of modern marine industry. But "steel" is too broad. We need to talk about specific product forms—plates, sections, profiles—and what each one is designed to do.

The common applications of steel in marine projects are: plates for hulls, decks, and shells; sections (I-beams, H-beams, angles, bulb flats) for frames, stiffeners, and girders; tubulars for offshore jacket legs and braces; and bar/rod for fasteners, shafts, and reinforcements. Each form is chosen for its structural efficiency.

As a supplier, we don’t just sell "steel." We sell solutions in specific shapes. Understanding this helps you specify the right product for the job and communicate effectively with mills and fabricators.

A Detailed Breakdown of Steel Product Forms and Their Marine Jobs

Each form of steel has a geometric property that makes it optimal for certain types of loads.

1. Steel Plates

These are the "skin" and primary load-bearing surfaces.

- Application: Ship hull plating, offshore deck plating, pressure vessels, large fabricated nodes.

- Why Plates? They provide a continuous, watertight surface and can be cut and welded into almost any shape. Thick plates (over 40mm) are used for high-stress areas.

- Marine Specifics: Supplied as Marine Steel Plate1 in grades like AH36, DH36, EH36 (shipbuilding) or S355G2/G3 (offshore). They often require ultrasonic testing (UT) and Z-direction testing.

2. Long Products / Sections

These are the "bones" that give structures their shape and rigidity.

- Angles (L-Shaped Steel): As discussed, for stiffening and framing.

- Bulb Flat Steel2: This is a specialized marine section. It looks like a flat bar with a bulb on one edge. It is the most common stiffener in shipbuilding. The bulb adds strength and stability without much extra weight, making it more efficient than a simple flat bar. We supply it in standard shipbuilding dimensions.

- I-Beams and H-Beams3: Used as primary girders and deck beams in large vessels and port structures. They carry massive bending loads over long spans.

- Channels (C-sections): Used for framing, especially where one side needs to be open for attachment.

3. Steel Tubulars4

These are hollow sections, efficient in compression and bending.

- Application: Offshore platform jackets (legs and braces), ship masts and columns, foundation piles.

- Why Tubulars? They offer a high strength-to-weight ratio and excellent resistance to buckling from all directions. They are also hydrodynamic, causing less drag in water currents.

- Round Bars: Used for shafts (propeller shafts, pump shafts), fasteners (high-strength bolts), and reinforcement in composite structures.

- Flat Bars: Simpler stiffeners, wear plates, and connection plates.

5. Special Profiles

- L-shaped section steel6: Sometimes this refers to an asymmetric angle or a special profile beyond the standard equal-leg angle. It is used where specific geometric needs arise in design.

The System in Action: A Ship’s Hull

Look at the cross-section of a ship. You will see:

- Bottom Shell: Made from thick steel plates.

- Keel and Longitudinal Stiffeners: Often Bulb Flat Steel2 running the length of the ship.

- Frames (Ribs): Usually made from L-shaped steel or bulb flats, welded vertically to the shell.

- Deck Girders: Large I-beams supporting the deck.

- Bulkheads: Steel plates stiffened with L-angles.

Each product form is engineered for its specific job in this system. Supplying the correct grade and dimension for each part is what we do for shipbuilders in Vietnam and the Philippines.

What is L-shaped steel called?

This seems like a simple question, but the answer reveals the importance of precise terminology in global trade and engineering. Using the wrong name can lead to misunderstandings, incorrect orders, and project delays.

L-shaped steel is most accurately called "Angle Bar1" or "Steel Angle." In technical and commercial contexts, it is referred to by standard names like "Equal Leg Angle2" or "Unequal Leg Angle," and is defined by specifications such as EN 10056, ASTM A363, or JIS G31924.

In my daily emails with clients from Mexico to Qatar, we must use the correct terms. Calling it just "L-bar" is not enough. We need the standard, the grade, and the dimensions.

The Official Nomenclature and Global Standards

To order or specify L-shaped steel correctly, you need to speak its formal language.

1. Common Names (Vary by Region):

- Angle Iron: An older, common term, especially for smaller, lighter angles. It implies a lower grade, often mild steel. Avoid this term for marine specifications.

- Angle Bar1 / Steel Angle: The most universally understood professional terms.

- L-Bar or L-Section: Also commonly used.

- Marine Angle Steel5: This is a term we use to specify angles that meet marine-grade requirements for chemistry, toughness, and surface quality.

2. Technical Description (How to Specify It):

A proper specification includes four parts:

[Leg Width 1] x [Leg Width 2] x [Thickness] x [Length] - [Standard] [Grade]

- Example 1 (Equal Angle):

100 x 100 x 10 x 12000 - EN 10056 S355J2- This is an equal leg angle, 100mm per leg, 10mm thick, 12 meters long, made to European standard, grade S355J2.

- Example 2 (Unequal Angle):

150 x 90 x 12 x 12000 - [ASTM A36](https://www.azom.com/article.aspx?ArticleID=6117)[^3]- This is an unequal leg angle, one leg 150mm, the other 90mm, 12mm thick.

3. Governing Standards:

The standard defines the dimensional tolerances, straightness, and sometimes the mechanical properties.

- EN 10056-16: The European standard for hot-rolled equal and unequal leg angles. It defines the "series" (e.g., dimensions).

- ASTM A6/A6M: The American standard for general requirements for rolled structural steel shapes. Angles are ordered by their dimensions.

- ASTM A363 / ASTM A992: Common material specifications for angles in the US.

- JIS G31924: Japanese standard for dimensions, weight, and tolerances for hot-rolled steel sections.

- GB/T 706: Chinese national standard for hot-rolled section steel.

4. The Importance of "Marine Grade" Designation:

When you need an angle for a marine application, the standard and grade become critical.

- You don’t just order "100x100x10 angle."

- You order "100x100x10 Angle Bar1 to EN 10056-16, Material Grade S355J2+N, with impact testing at -20°C (J2), with Mill Certificate 3.1."

- Or for shipbuilding: "Marine Angle Steel5, 150x90x12, Grade AH36, with ABS approval."

This precise specification tells the mill exactly what to produce and tells us, the supplier, what certification to provide. It eliminates the "quality inconsistency" that buyers like Gulf Metal Solutions experienced before. They now specify the exact standard and grade, and we ensure the mill’s production and our third-party inspection (SGS) validate it.

Other Related Terms:

- L-shaped Section Steel: Sometimes this can refer to a broader category that includes special, non-standard angles or other profiles with an L-shape.

- Leg: Each of the two sides of the angle.

- Toe: The tip of each leg.

- Root or Heel: The inside corner of the angle.

Using the correct, full name ensures you get the exact component your marine design requires, saving time, cost, and risk.

Conclusion

Marine L-shaped steel is a versatile stiffener, frame, and connector. Specify it precisely by its standard and marine grade to ensure strength, weldability, and longevity in harsh environments.

-

Understanding the term ‘Angle Bar’ is crucial for accurate specifications in steel construction. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about Equal Leg Angles to ensure proper usage in engineering and construction projects. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore ASTM A36 specifications to understand its applications and properties in structural steel. ↩ ↩ ↩ ↩ ↩

-

Learn about JIS G3192 to ensure proper dimensions and tolerances in steel section specifications. ↩ ↩ ↩ ↩ ↩

-

Discover the importance of Marine Angle Steel for marine applications and its specific standards. ↩ ↩ ↩ ↩ ↩

-

Understanding EN 10056-1 is essential for compliance in European steel angle specifications. ↩ ↩ ↩