An offshore platform is a city on the sea. It faces hurricanes, salt spray, and constant stress. If the steel in its legs fails, everything fails. I have talked to engineers who lost sleep over material specifications. The wrong steel choice is not a small mistake. It is a risk to the entire multi-million dollar investment and human safety. You need materials that do not just meet a standard. They must exceed expectations in the harshest environment on Earth.

Marine steel solutions for offshore platforms involve a specialized range of high-strength, low-alloy (HSLA) structural steels and corrosion-resistant alloys. These include primary structural plates (like grades A, D, E, F with yield strengths up to 690 MPa), heavy sections, and tubulars, all certified to stringent standards (API, ABS, DNV) for toughness, weldability, and resistance to seawater corrosion and hydrogen-induced cracking.

You know the stakes are high. The ocean does not forgive. So, building a resilient platform starts with understanding the very DNA of the materials you use. Let’s begin with the most fundamental question. What exactly makes steel "marine"?

What is marine steel?

Many people call any steel near water "marine steel." This is a dangerous oversimplification. Using ordinary structural steel in a splash zone is like building a house with cardboard in a flood zone. It might look fine at first, but it will not last. I have seen inventory lists from projects where "marine-grade" was just a label on a standard product. True marine steel is engineered with a specific purpose: to fight the sea and win.

Marine steel is a category of steel specifically designed and manufactured for use in seawater environments. Its key features include enhanced corrosion resistance1, high strength, excellent toughness (especially at low temperatures), and good weldability2. It follows strict international standards from classification societies like ABS, DNV, and LR.

Diving Deeper: The Engineering Behind "Marine-Grade"

Marine steel is not one single recipe. It is a family of alloys, each optimized for a specific challenge. The term applies to two broad categories: marine structural steel3 and marine stainless steel. For offshore platforms, we focus primarily on structural steel.

Core Design Principles for Offshore Structural Steel

The steel in a platform’s legs, jacket, and decks must solve several problems at once.

- Resist General and Localized Corrosion: Seawater is an electrolyte. It causes electrochemical corrosion. Marine steels often have small, controlled additions of elements like Copper (Cu), Chromium (Cr), and Nickel (Ni). These elements promote the formation of a dense, protective oxide layer (patina) that slows down rusting.

- Prevent Brittle Fracture: Offshore structures face impact loads and operate in cold waters. The steel must remain ductile. This is measured by Charpy V-Notch impact tests4 at temperatures like -20°C, -40°C, or even -60°C. Grades are designated by their toughness level: A (ambient), D (-20°C), E (-40°C), F (-60°C).

- Withstand Massive Static and Dynamic Loads: Platforms are heavy and face waves and wind. Steel grades have high yield strength (e.g., 355 MPa, 460 MPa). This allows for lighter, stronger designs.

- Be Weldable into Massive Structures: The steel’s chemical composition (Carbon Equivalent value) is controlled. This ensures it can be welded without forming hard, crack-prone microstructures in the heat-affected zone.

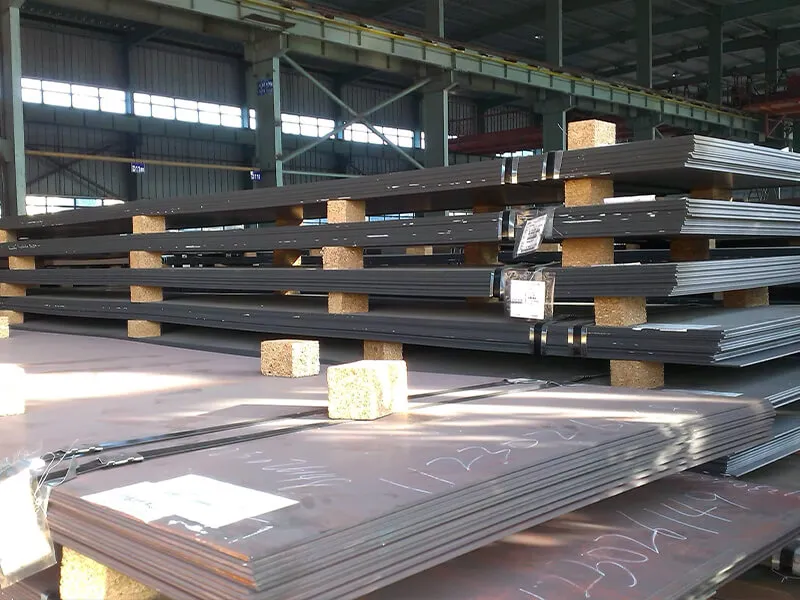

Common Marine Structural Steel Grades for Platforms

Here is a breakdown of typical grades we supply for offshore projects. Each has its place in the structure.

| Standard & Grade | Key Properties | Typical Application on Offshore Platforms |

|---|---|---|

| EN 10225 / API 2W Gr. 50 (Yield: 355 MPa) | Good all-round strength, moderate toughness. | General structural parts in non-critical zones, secondary deck supports, walkways. |

| EN 10225 S460 NL / API 2H Gr. 50 (Yield: 460 MPa) | Higher strength, excellent low-temperature toughness (NL = normalized, low temp). | Primary jacket legs, critical nodes, bracings in North Sea or Arctic environments. |

| ABS Grade EH36 / AH36 | Shipbuilding grade, also used offshore. Good strength and weldability2. | Module support frames, helideck structures, living quarters on the topsides. |

| ASTM A710 Gr. B5 | Age-hardenable, copper-precipitation strengthened. High strength-to-weight ratio. | Applications where weight savings are crucial, like deepwater platform components. |

Certification is Non-Negotiable

For offshore use, the mill test certificate (MTC)6 is as important as the steel. It must show compliance with the specified standard and often includes additional testing for:

- Hydrogen-Induced Cracking (HIC) Resistance: Critical for steels exposed to sour service (environments with H2S gas).

- Through-Thickness Properties (Z-direction): Ensures the steel resists lamellar tearing under heavy weld constraints.

Understanding marine structural steel3 is the first pillar. The second pillar involves the shiny, corrosion-resistant alloys used for critical equipment and fasteners. This leads us directly to the most common debate in that category.

Is 304 or 316 better for saltwater?

Walk onto any platform. Look at the handrails, valve bodies, or pump components. Many are made of shiny stainless steel. But not all that glitters is suitable. I once had a client who used standard 304 fasteners on a coastal project. They corroded within a year, causing maintenance headaches. The choice between 304 and 316 is a classic one, and for marine environments, there is a clear winner for a very specific reason.

For saltwater (marine) environments, 316 stainless steel1 is significantly better than 304. The key difference is the addition of Molybdenum2 (Mo) in 316 (2-3%). Molybdenum2 dramatically increases resistance to pitting and crevice corrosion3, which are the primary forms of attack by chloride ions4 in seawater.

Diving Deeper: The Chemistry of Survival in Chloride-Rich Water

To understand why 316 wins, we must look at the microscopic battle happening on the steel’s surface. Both 304 and 316 are "austenitic" stainless steels. They get their corrosion resistance from a thin, invisible layer of chromium oxide that forms on the surface. This layer is the shield.

The Threat: Pitting and Crevice Corrosion

Saltwater is full of chloride ions4 (Cl-). These ions are small and aggressive. They can attack the passive chromium oxide layer, especially in two situations:

- Pitting: A small local breakdown in the oxide layer becomes an anode. The surrounding area is the cathode. This creates an intense, localized galvanic cell that drills a hole ("pit") into the metal.

- Crevice Corrosion: This occurs in stagnant, shielded areas like under gaskets, bolts, or deposits. Oxygen levels drop inside the crevice, disrupting the passive layer and allowing chlorides to attack.

How Molybdenum2 Makes the Difference

Molybdenum2 (Mo) is the game-changer in 316 stainless steel1. It strengthens the passive oxide film. More importantly, when pitting starts, molybdenum ions (MoO4²⁻) form in the acidic pit environment. These ions help repassivate the pit—they help re-form the protective layer and stop the attack from progressing further.

A Direct Comparison: 304 vs. 316

Let’s put their compositions and performance side-by-side.

| Property / Element | AISI 3045 (Marine Use: Poor) | AISI 3166 (Marine Use: Good) | Why It Matters for Saltwater |

|---|---|---|---|

| Chromium (Cr) | 18-20% | 16-18% | Forms the primary passive oxide layer. Both have sufficient amounts. |

| Nickel (Ni) | 8-10.5% | 10-14% | Stabilizes the austenitic structure, improves ductility and toughness. |

| Molybdenum2 (Mo) | ~0% (Trace only) | 2-3% | The critical element. Provides massive resistance to chloride-induced pitting/crevice corrosion. |

| Carbon (C) | ≤0.08% | ≤0.08% | Low carbon minimizes sensitization (chromium carbide formation) during welding. |

| Marine Suitability | Not recommended for immersed or splash zones. May be okay for inland, coastal architectural uses with low salt exposure. | The standard choice for marine hardware, fasteners, and components exposed to salt spray or immersion. | |

| Typical Offshore Uses | Interior, dry cabinets, non-critical decorative parts. | Bolts, nuts, pump shafts, valve trim, exposed handrails, instrument housings in the splash zone. |

Important Caveat: Even 316 Has Limits

For fully immersed, critical components in seawater (like propeller shafts), even standard 316 may not be enough. In these cases, even higher grades are used:

- 316L7: The "L" means low carbon (≤0.03%), offering better weldability and resistance to sensitization.

- Duplex Stainless Steels8 (e.g., 2205): Have much higher strength and better chloride resistance than 316.

- Super Duplex & 6% Mo Austenitics (e.g., 254 SMO): For the most severe, hot, chlorinated seawater.

So, stainless steel excels at corrosion resistance. But when we talk about the main skeleton of an offshore rig, we use a different kind of strong steel. This leads to a common point of confusion.

Which is stronger, SS or MS?

A platform contractor once asked me: "If stainless steel is so good, why don’t we build the whole jacket from it? It must be stronger." This is a practical question. The answer lies in the fundamental difference between "strength" and "corrosion resistance1." They are not the same thing. Choosing the wrong one based on a simple label is a costly error. You need the right tool for the job.

For structural applications, high-strength marine steel (MS)2 is much stronger than standard austenitic stainless steel (SS)3. Common structural steels have yield strength4s of 355-690 MPa. Standard 304/316 stainless steel has a yield strength4 of around 205-310 MPa. However, some specialty stainless steels (like duplex grades) can match or exceed structural steel strength.

Diving Deeper: Defining and Comparing "Strength"

The word "stronger" is vague. We must compare specific mechanical properties and understand their economic and practical implications.

Breaking Down Mechanical Properties

-

Yield Strength (The Most Important for Design): This is the stress at which the material begins to deform permanently. For a skyscraper or a platform leg, you design so the stress never exceeds the yield strength4.

- Typical Marine Structural Steel (e.g., S355): ≥355 MPa

- High-Strength Marine Steel (e.g., S690): ≥690 MPa

- Austenitic Stainless Steel (304/316): ~205-310 MPa

This means a structural steel component can carry roughly 1.5 to 3 times more load before deforming than a same-sized stainless steel component.

-

Tensile Strength: The maximum stress the material can withstand while being stretched before breaking.

- Structural steels also generally have higher tensile strength5s than standard austenitic stainless steels.

-

Stiffness (Modulus of Elasticity): This measures how much a material bends under load. Both carbon steel and stainless steel have a similar Young’s Modulus (~200 GPa). A beam of the same size and shape will deflect the same amount under the same load, regardless of which material, if we ignore strength limits.

The Trade-Off: Strength vs. Cost vs. Corrosion

The choice between MS and SS is a classic engineering trade-off.

| Consideration | Marine Structural Steel (MS) | Austenitic Stainless Steel (SS like 316) |

|---|---|---|

| Yield Strength | High (355-690+ MPa) | Moderate (205-310 MPa) |

| Cost per Ton | Relatively Low | Very High (3-5x the cost of MS) |

| Corrosion Resistance | Moderate. Requires protective coatings (paint, galvanizing) for long life. | Excellent. Often used uncoated. |

| Weight for Given Strength | Low. You need less material to achieve the required strength. | High. You need thicker, heavier sections to match the strength of MS, increasing weight and cost further. |

| Best Use Case | Primary load-bearing structure: Jacket legs, deck beams, heavy bracings. Strength and cost efficiency are paramount. | Non-structural or lightly loaded components: Fasteners, handrails, cladding, equipment housings. Corrosion resistance is the top priority. |

The Exception: High-Strength Stainless Steels

It is important to know that not all stainless steel is weak. Newer grades bridge the gap:

- Duplex Stainless Steels6 (e.g., 2205): Yield strength is ≥450 MPa, rivaling structural steel, with far better corrosion resistance1 than 316. They are used for chemical tankers and highly corrosive areas on platforms, but at a premium price.

- Precipitation-Hardening Stainless Steels7: Can achieve even higher strengths.

For the main bones of an offshore platform, marine structural steel8 is the undisputed champion of strength and economy. Stainless steel serves a vital but different role. This distinction creates two separate product lines, which brings us to a final, crucial clarification.

What is the difference between marine stainless steel1 and stainless steel?

A procurement manager ordered "stainless steel bolts" for a rig upgrade. They got standard 304 bolts. They failed in the splash zone within months. The supplier said, "But it is stainless steel." This is the heart of the problem. "Stainless steel" is a huge family. "Marine stainless steel" is a specific member of that family built for a specific war. Using the general term in a marine spec is an invitation for failure.

Marine stainless steel is a subset of stainless steel specifically formulated to resist corrosion in saltwater environments. While all stainless steels resist rust, marine grades have higher alloy content—especially Molybdenum (Mo)2 and sometimes Nickel (Ni)—to combat pitting and crevice corrosion from chloride ions. Standard grades like 304 are not suitable for prolonged marine exposure.

Diving Deeper: Navigating the Stainless Steel Spectrum for Marine Duty

Think of it like this: All sports cars are cars, but not all cars are built for a racetrack. Marine stainless steel is the "race-ready" version for the chloride racetrack.

The Alloying Element Checklist for Marine Suitability

The suitability for marine service is not a yes/no question. It is a spectrum determined by composition. Key elements include:

- PREN (Pitting Resistance Equivalent Number)3: This is a formula that quantifies pitting resistance. PREN = %Cr + 3.3×%Mo + 16×%N. A higher PREN means better performance in chlorides.

- 304 Stainless: PREN ~18-20 (Not marine suitable).

- 316 Stainless: PREN ~24-28 (Minimum for marine splash/spray zones).

- Duplex 22054: PREN ~34-38 (Good for many immersed applications).

- Super Duplex/Super Austenitic: PREN >40 (For severe, hot, stagnant seawater).

A Detailed Comparison: Standard vs. Marine Grades

The following table shows why you must specify beyond just "stainless steel."

| Feature | Standard Stainless Steel (e.g., AISI 304, 430) | Marine Stainless Steel (e.g., AISI 3165/L, Duplex 22054, 6Mo Austenitic) |

|---|---|---|

| Primary Purpose | General corrosion resistance6 in mild environments (indoor, architectural, food service). | Resist chloride-induced pitting and crevice corrosion in seawater and salt spray. |

| Key Alloy Differentiator | Chromium (for basic passivity). May have no or little Molybdenum. | Must contain significant Molybdenum (Mo)2, and often higher Nickel (Ni) and Nitrogen (N). |

| Corrosion Mechanism in Sea Water | Prone to rapid pitting and crevice corrosion. The protective film breaks down easily. | The alloy-enhanced film is more stable. It can repassivate after minor chloride attacks. |

| Typical Applications (Offshore) | Interior ductwork, kitchen equipment, non-exposed hardware. | Bolts, nuts, pumps, valves, seawater piping, ladders, railings, instrument panels on exposed decks. |

| Cost Factor | Lower cost. | Significantly higher cost due to expensive alloying elements (Mo, Ni). |

| Mechanical Strength | 304: Moderate. 430: Lower. | Can be very high. Duplex grades have yield strengths double that of 304. |

| How to Specify | Simply stating "stainless steel" often results in 304 being supplied. | You must specify the exact grade: "AISI 3165L Stainless Steel per ASTM A276", or "Duplex 22054 per UNS S32205". |

Practical Implications for Procurement and Fabrication

- Specification is Everything: Engineering drawings and purchase orders must state the exact grade standard. "Marine-grade stainless" should be defined as 316 or better.

- Beware of Substitution: Some suppliers may propose 304 as a "similar, cheaper" alternative to 316. This must be rejected for marine applications.

- Fabrication Matters: Even marine stainless can be ruined by poor fabrication. Using carbon steel tools can embed iron particles, causing rust spots. Proper cleaning and passivation after welding are essential to restore the protective layer.

In short, for offshore platforms, "stainless steel" is not a safe spec. You need to be a detective and demand the right alloy for the right zone. Your material list should be a precise map of grades, from the high-strength S460 for the legs to the corrosion-fighting 316L for the bolts holding it all together.

Conclusion

Building offshore platforms demands a dual-material strategy: ultra-strong, tough marine structural steel for the skeleton, and precisely alloyed marine stainless steel for critical components. Knowing the difference is the foundation of safety and durability at sea.

-

Understanding marine stainless steel is crucial for applications in saltwater environments to prevent corrosion. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn how Molybdenum enhances the performance of stainless steel in corrosive environments. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover how PREN helps quantify the corrosion resistance of stainless steel in marine applications. ↩ ↩ ↩ ↩ ↩

-

Explore the benefits of Duplex 2205 for high-strength and corrosion resistance in marine settings. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

AISI 316 is essential for marine applications; understanding its properties can prevent costly failures. ↩ ↩ ↩ ↩ ↩

-

Explore the differences in corrosion resistance to ensure the right material is used for marine applications. ↩ ↩ ↩ ↩

-

Find out how Precipitation-Hardening Stainless Steels achieve high strengths and their applications in various fields. ↩ ↩

-

Understand the role of marine structural steel in construction and its advantages in strength and cost efficiency. ↩ ↩