Picture this: a massive hull section is ready for assembly, but the promised steel plates are stuck at customs. The entire project timeline is at risk. This is the harsh reality many shipbuilders face without a truly integrated supply solution. I’ve seen projects stall, budgets explode, and relationships sour over fragmented supply chains. The core issue isn’t just finding steel; it’s about securing a reliable flow of the right materials, with the right paperwork, at the right time. For marine contractors and shipyards, this seamless flow isn’t a luxury—it’s the foundation of their business. Every day a vessel isn’t in the water is a day of lost revenue.

Integrated steel supply is a complete service model that goes beyond selling metal. It provides shipyards with a single, reliable source for all their specialized steel needs—from marine-grade plates and structural sections to technical support and certified documentation. This model ensures material consistency, simplifies logistics, and mitigates project risks associated with multi-vendor sourcing.

You understand the stakes. A single material delay can ripple through an entire project, causing costly bottlenecks. So, how do you build a fortress against such unpredictability? The answer lies in mastering the details of the materials and the mechanisms that bring them to your yard. Let’s break down the essential pillars of shipbuilding steel, from the chemistry of the plates to the geography of the global supply chain.

What kind of steel is used in shipbuilding?

Imagine building the backbone of a 300-meter container ship with the same steel you’d use for a warehouse. It would be a disaster waiting to happen. The marine environment is one of the most corrosive on Earth, combining saltwater, changing pressures, and immense physical stress. The steel used here isn’t ordinary; it’s engineered for survival. When my team first consulted with Gulf Metal Solutions, their main pain point was quality inconsistency in surface finish from previous suppliers—a small flaw that can become a major corrosion point. This highlighted a critical truth: not all "marine steel" is created equal.

The primary steel used in shipbuilding is marine-grade structural steel1, most commonly grades like AH362, DH363, and EH364 per international standards. These steels are specially treated for high strength, good toughness at low temperatures, and superior resistance to corrosion from seawater. The exact grade selection depends on the ship’s design, the specific structural part (like hull or deck), and the sailing environment.

Diving Deeper: The Anatomy of Marine-Grade Steel

Choosing the right steel is a science. It’s about balancing strength, weldability, toughness, and corrosion resistance. Let’s look at the key properties that define marine-grade steel.

Key Properties and Their Impact

The performance of shipbuilding steel hinges on three interconnected properties:

- Strength and Yield Point: This is the steel’s ability to withstand immense loads without permanently deforming. A ship’s hull must bear the weight of the cargo and resist the dynamic forces of waves.

- Toughness and Impact Resistance: Perhaps the most critical property. Steel must remain ductile and resist cracking, especially in frigid waters. Grades with higher designations (like ‘D’ and ‘E’) guarantee excellent impact performance at temperatures as low as -20°C to -40°C.

- Weldability and Corrosion Resistance5: Ships are built by joining thousands of steel plates. The material must weld easily without developing cracks. Corrosion resistance, often enhanced by precise chemical composition (like controlled copper content), determines the vessel’s longevity and maintenance costs.

A Comparison of Common Shipbuilding Steel Grades

The following table breaks down the typical grades we supply and their primary applications. This is the kind of clarity we provide to clients like Gulf Metal Solutions, so they know exactly what they’re buying and why.

| Grade | Key Characteristics | Typical Application in Shipbuilding |

|---|---|---|

| AH362 | Good strength, moderate low-temperature toughness. The most commonly used grade for general hull structures. | Hull plating, bulkheads, decks in most commercial vessels. A versatile and cost-effective choice. |

| DH363 | Enhanced toughness compared to AH grade. Performs reliably at lower temperatures. | Critical structural members, areas subject to higher stress, vessels operating in cooler climates. |

| EH364 | Excellent toughness at very low temperatures. Highest grade among common structural steels. | Ice-class vessels, Arctic exploration ships, key stress points on large carriers and tankers. |

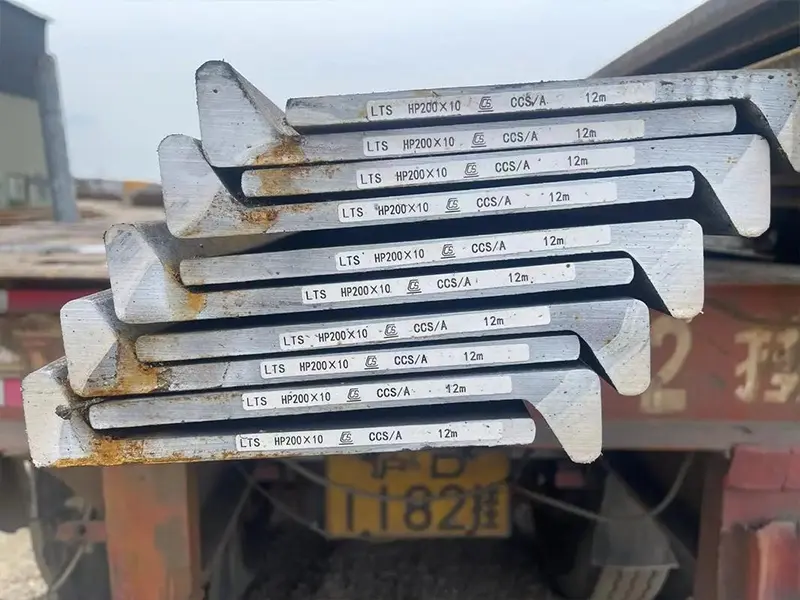

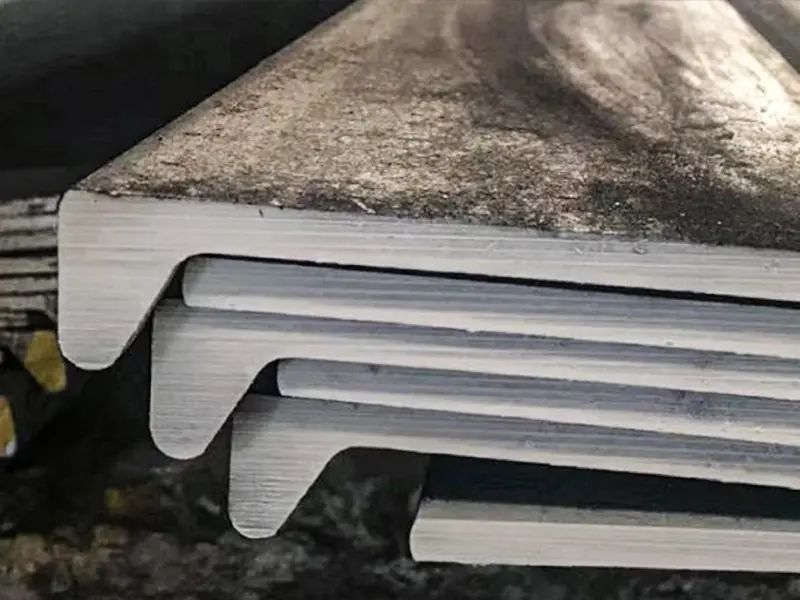

| Bulb Flat Steel6 | Unique "bulb" profile provides high section modulus and strength-to-weight ratio. | Stiffeners for decks, hulls, and bulkheads—replacing traditional angle bars for better efficiency. |

| Marine Angle Steel7 | L-shaped cross-section, fundamental for creating rigid frameworks and supports. | Brackets, frames, ribs, and reinforcement throughout the ship’s superstructure and internal skeleton. |

The choice isn’t arbitrary. For a bulk carrier, AH362 plates might form most of the hull. But for the critical transition zones and the ice belt on a vessel sailing northern routes, DH363 or EH364 becomes non-negotiable. Furthermore, the shape matters as much as the grade. While we supplied Gulf Metal Solutions with standard marine plates and angles, our upcoming shipment includes L-shaped section steel8 and bulb flat steel. Bulb flats, for instance, are a smarter alternative to angles for stiffeners. Their design offers greater strength with less weight, directly impacting the ship’s cargo capacity and fuel efficiency—a key selling point for our client’s end-users. Understanding this material science is the first step. The next is understanding how this specialized steel travels from the mill to your project.

What is the shipbuilding supply chain1?

Think of the supply chain as the vessel’s circulatory system. If it’s clogged or weak, the entire project suffers. A broken link doesn’t just mean a delayed part; it means idle cranes, waiting crews, and mounting penalties. I recall a project where a client’s previous supplier failed to provide the mill test certificates on time. The steel sat at the port for weeks, unable to be cleared. The lesson was clear: the chain is only as strong as its most unreliable link. For integrated supplier2s, our role is to be that strong, transparent link from start to finish.

The shipbuilding supply chain1 is the end-to-end network that moves raw materials into finished ships. It starts with certified steel mills3, moves through processors and distributors (like us), then to the shipyard for fabrication and assembly, and finally involves classification society inspectors who certify the materials and construction at every stage.

Diving Deeper: Navigating the Complex Network

The journey of a steel plate to a ship’s hull is a complex, multi-stage process involving technical, logistical, and compliance checks. Let’s trace the path.

The Major Stages from Mill to Hull

- Raw Material Production: It all begins at certified steel mills3 with the capability to produce thermo-mechanically controlled processed (TMCP) plates. These mills must have approvals from major classification societies4 like ABS, DNV, LR, or BV.

- Processing and Distribution: Plates are often cut to size, blasted, and primed. This is where integrated supplier2s add value. We don’t just sell raw plates; we coordinate cutting to your nest patterns, manage quality inspections (like SGS), and handle all export documentation. This stage transforms bulk material into a "kit" ready for the shipyard.

- Logistics and Delivery: This is the make-or-break phase. It involves inland transport, export customs, ocean freight, and delivery to the yard’s doorstep. Delays here are catastrophic. Our solution for clients in places like Dammam, Saudi Arabia, is to offer CFR or CIF terms, managing the entire voyage and providing customs clearance support.

- Shipyard Fabrication and Assembly: The steel is cut, shaped, welded, and assembled into blocks, which are then joined to form the vessel. Consistent material quality from a single supplier ensures uniform welding performance and simplifies quality control for the yard.

- Classification and Certification: At every stage, surveyors from classification societies4 inspect the materials and workmanship. This is why documentation—the Mill Test Certificate (MTC)5 that traces the steel’s chemical and mechanical properties back to its heat number—is as important as the steel itself.

The Role of an Integrated Supplier

In this chain, a traditional trader is just a middleman. An integrated supplier2, however, is a manager and guarantor. We become the single point of contact. When Gulf Metal Solutions praised our rapid response and stable quality, they were highlighting this integration. Our dedicated English-speaking sales rep wasn’t just taking orders; they were coordinating with the mill, the inspection agency, and the freight forwarder on behalf of the client. This model directly solves the classic pain points: delayed responses, quality inconsistency, and after-sales black holes. By consolidating these steps, we absorb complexity and deliver simplicity and reliability to the shipyard.

What is the main material used in shipbuilding?

We’ve talked about steel grades, but let’s be unequivocal: steel is the undisputed king of shipbuilding. While aluminum, composites, and even plastics find niches in superstructures or specialized vessels, over 90% of a typical large commercial ship’s weight is steel. Its dominance isn’t tradition; it’s a result of an unmatched balance of strength, durability, weldability, and cost-effectiveness. I’ve walked through yards where the air hums with the sound of steel meeting steel—it’s the literal and figurative framework of the industry. Trying to build a modern cargo ship or tanker without it would be like trying to build a skyscraper out of wood.

Steel is the fundamental and predominant material used in shipbuilding. Specifically, high-strength, low-alloy (HSLA) marine-grade steel1 plates and sections form the hull, deck, bulkheads, and skeleton of virtually all large commercial and naval vessels due to its structural integrity, economic feasibility, and adaptability to complex manufacturing processes like welding.

Diving Deeper: Why Steel Reigns Supreme

The question isn’t just "what" but "why." Why has steel remained the material of choice through centuries of technological advancement? The answer lies in a combination of physical properties, economic factors, and proven performance.

The Unbeatable Combination of Properties

No other material offers the same package for large-scale marine structures.

- Superior Strength-to-Weight Ratio2: Modern HSLA steels provide immense strength without excessive weight. This allows ships to carry more cargo (increasing revenue) while maintaining hull integrity against oceanic forces.

- Exceptional Toughness3: As discussed, grades like DH36/EH36 maintain ductility in impact-prone and low-temperature environments, preventing catastrophic brittle fracture—a non-negotiable safety requirement.

- Unmatched Weldability4: Ships are built by welding. Steel’s compatibility with advanced, automated welding techniques allows for efficient, strong, and reliable construction of massive structures. This manufacturability is a key economic driver.

- Proven Durability and Repairability: Steel’s behavior is well-understood. It withstands decades of service, and when maintenance is needed, repair protocols are standardized and straightforward. Damaged sections can be cut out and re-welded reliably anywhere in the world.

Economic and Logistical Reality

Beyond physics, steel wins on practicality.

- Cost-Effectiveness5: On a per-ton, per-strength-unit basis, steel is significantly more economical than alternatives like aluminum or specialized composites for primary structures. For cost-sensitive commercial projects, this is decisive.

- Global Supply Chain Maturity6: The global infrastructure for producing, processing, and transporting marine steel is deeply established. Integrated suppliers leverage this to ensure availability and competitive pricing, as we do from our base in Shandong, a major steel-producing region in China.

- Regulatory and Insurance Acceptance: Classification societies have over a century of data on steel performance. Designs, rules, and insurance models are built around it. Using the primary accepted material streamlines approval and reduces project risk.

While innovation continues, the core material remains constant. Our business focuses on supplying the evolved versions of this core material—ensuring it meets the latest standards for performance, safety, and environmental efficiency that modern shipyards demand.

Are there any shipyards in the US?

The image of bustling American shipyards from the World War II era is iconic, but the landscape today is different, more specialized. The answer is a definitive yes, but their focus has shifted. The US remains a major maritime nation with a diverse and technologically advanced shipbuilding sector1. However, it’s crucial for international suppliers like us to understand this landscape. Knowing whether a potential client is building a nuclear aircraft carrier, a luxury yacht, or an offshore wind vessel determines everything about the steel they need—the grade, the quantity, the certifications. Our engagement with global markets, from Mexico to Qatar, has taught us that every region has its own shipbuilding DNA.

Yes, the United States has a significant and active shipbuilding industry. It is primarily centered around naval and government vessel construction (like submarines and destroyers), with additional strong activity in commercial sectors such as cruise ships, offshore support vessels, ferries, and luxury yachts. Major shipbuilding hubs exist on the Gulf Coast, the East Coast, and the Great Lakes.

Diving Deeper: The Dual Tracks of American Shipbuilding

The US shipbuilding industry operates on two parallel, sometimes intersecting, tracks: the naval-industrial complex and the commercial market. Each has distinct drivers, customers, and material requirements.

The Naval Shipbuilding Dominance

This is the pillar of the industry, dominated by a few large, private yards with secure government contracts.

- Key Players and Locations: Huntington Ingalls Industries2 (HII) in Pascagoula, Mississippi, and Newport News, Virginia; General Dynamics’ Electric Boat in Groton, Connecticut; and Bath Iron Works in Maine. These yards build the US Navy’s most critical assets: aircraft carriers, nuclear submarines, guided-missile destroyers, and amphibious assault ships.

- Supply Chain Characteristics: This sector is highly insulated. It operates under strict "Buy American" regulations (like the Jones Act3 for certain components) and requires security clearances. The steel used is often specialty grades, including high-strength steels4 like HY-80/HY-100 for submarines, with certifications tied directly to Department of Defense standards. For most international suppliers, direct access to this tier is challenging due to these stringent national security and procurement rules.

The Commercial and Specialty Vessel Sector

This is a more diverse and accessible market for global material suppliers.

- Market Segments: It includes builders of cruise ships (like Meyer Werft’s US operations), offshore oil & gas support vessels, riverine casinos, fishing vessels, ferries, and high-end aluminum yachts. Yards are smaller and more scattered, found in places like Louisiana, Alabama, Wisconsin, and Washington State.

- Supply Chain Opportunities: This sector is more globalized. While the Jones Act3 mandates that vessels sailing between US ports must be US-built, owned, and crewed, it does not restrict the origin of raw materials. Therefore, yards building commercial vessels actively source competitively priced, high-quality steel from the global market, provided it meets the required classification society standards (ABS being the most common in the US). This is where integrated suppliers with a strong export focus, like ours, can provide real value. We offer the certified materials (ABS, BV, DNV, etc.), flexible MOQs suitable for smaller production runs, and the logistical support to deliver to US ports, just as we do to clients in Vietnam or the Philippines.

For an international steel supplier, the US commercial and specialty vessel market represents a significant opportunity. It demands the same reliability, certification support, and integrated service we provide to other global clients. Understanding this distinction—between the closed-loop naval sector and the open, competitive commercial sector—is key to engaging effectively with the American maritime industry.

Conclusion

In shipbuilding, your project’s success is welded to the reliability of your steel supply. Choosing an integrated partner who masters the material, the process, and the logistics isn’t just a procurement decision—it’s a strategic one for building on time, on budget, and to spec.

-

Explore insights on the evolution and current trends in the US shipbuilding sector. ↩ ↩ ↩ ↩ ↩

-

Discover the key projects and innovations from one of the largest shipbuilders in the US. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Gain clarity on the Jones Act’s impact on maritime commerce and shipbuilding in the US. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the types and applications of high-strength steels in modern shipbuilding. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Find out how steel’s economic advantages make it the preferred choice for cost-sensitive marine projects. ↩ ↩ ↩

-

Explore how a mature supply chain ensures competitive pricing and availability of steel for shipbuilding. ↩ ↩

-

Learn about marine angle steel’s applications in creating rigid frameworks, vital for ship stability and support. ↩

-

Discover the innovative uses of L-shaped section steel in shipbuilding, contributing to structural integrity and efficiency. ↩