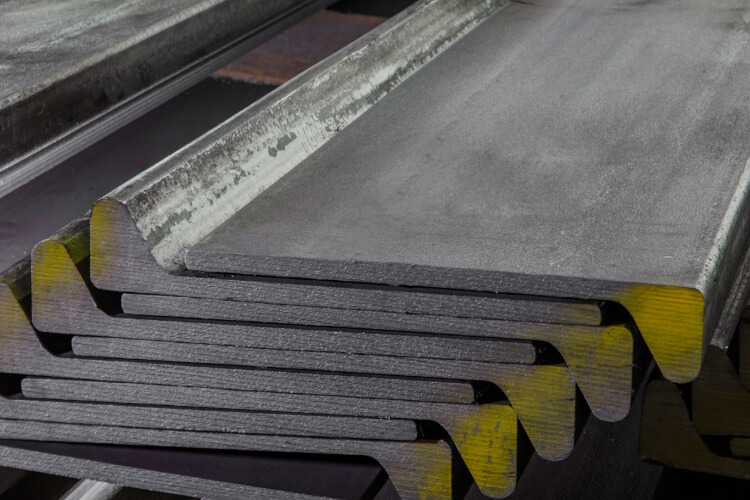

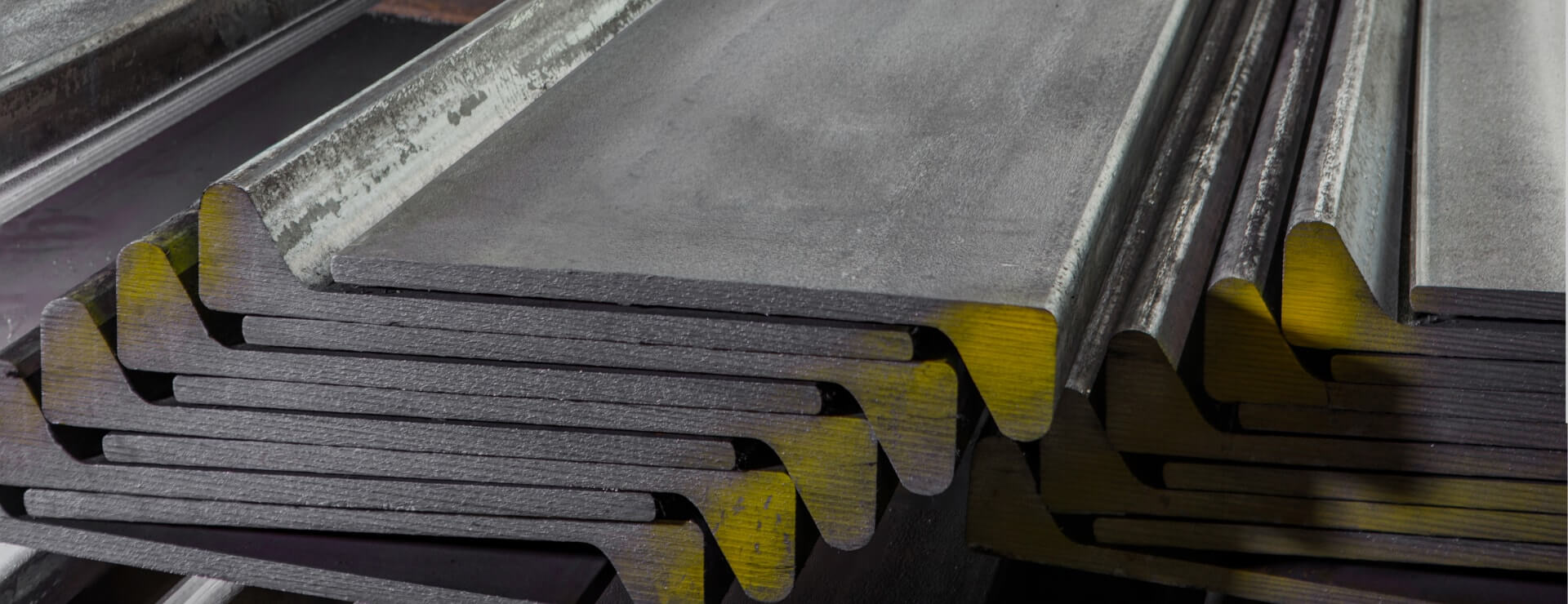

Walking through a bustling shipyard, I often notice the unique L-shaped steel beams supporting massive hulls. These aren’t ordinary steel bars—they are bulb flat steels, and they play a critical role in keeping vessels strong and seaworthy.

Bulb flat steel is a specialized profile with a bulb-like thickening at one end, providing superior strength and stiffness. It’s primarily used in shipbuilding for framing, hull reinforcement, and deck support because it offers excellent load-bearing capacity and corrosion resistance, making ships safer and more durable.

As someone who has worked closely with shipbuilders and steel fabricators, I’ve seen how the right steel choice can make or break a project. Let’s explore why materials matter in shipbuilding and where bulb flat steel fits in.

What materials are commonly used in shipbuilding and why?

Shipbuilders face harsh marine environments daily. Saltwater, heavy loads, and constant motion demand materials that won’t fail under pressure. Choosing the wrong steel can lead to costly repairs or even catastrophic failures.

The most common materials in shipbuilding are marine-grade steels1, aluminum alloys2, and composites. Marine-grade steels dominate because they offer high strength, good weldability, and excellent corrosion resistance. Aluminum is lighter but less durable, while composites suit smaller boats but lack the strength for large vessels.

Breaking Down Shipbuilding Materials

Shipbuilding isn’t just about picking the strongest material—it’s about balancing strength, weight, cost, and longevity. Let’s look at the key materials and their roles.

Material Comparison Table

| Material Type | Strength | Corrosion Resistance | Cost | Best Use Cases |

|---|---|---|---|---|

| Marine Steel Plate | Very High | High | Moderate | Hull construction, bulkheads |

| Aluminum Alloy | Medium | Medium | High | Small boats, superstructures |

| Fiberglass Composite | Low to Medium | Very High | Low to High | Recreational boats, decks |

| Bulb Flat Steel | High | High | Moderate | Ship frames, stiffeners |

Marine steel plates form the backbone of most large ships. They are designed to resist saltwater corrosion, which ordinary steels cannot handle. The secret lies in their chemical composition—adding elements like copper, chromium, and nickel creates a protective layer against rust.

Aluminum alloys are popular for smaller vessels or upper structures where weight matters. They are lighter than steel, which helps with fuel efficiency. However, aluminum is more expensive and less durable over time. I’ve seen clients choose aluminum for fishing boats but switch to steel for cargo ships because strength matters more.

Fiberglass and other composites work well for yachts and pleasure craft. They don’t rust at all, but they can crack under heavy impact. For large commercial vessels, composites simply aren’t strong enough to handle ocean forces.

Bulb flat steel sits in a unique spot. Its bulb-shaped edge adds stiffness without much extra weight. This makes it perfect for longitudinal frames—the ribs that run along a ship’s hull. Without these, the hull would flex too much in rough seas, leading to fatigue cracks.

From my experience supplying Gulf Metal Solutions in Saudi Arabia, they initially used standard angles for frames. After switching to bulb flats, they reported fewer structural issues and longer service life. The bulb distributes stress more evenly, reducing weak points.

What are the 4 types of steel?

Steel isn’t a single material—it’s a family of alloys with different properties. Many people get confused between carbon steel, alloy steel, stainless steel, and tool steel. Each serves distinct purposes.

The four main types of steel are carbon steel, alloy steel, stainless steel, and tool steel. Carbon steel is most common in construction for its strength and affordability. Alloy steel adds other elements for special properties. Stainless steel resists corrosion well. Tool steel is hardened for cutting tools.

Understanding Steel Classifications

Knowing steel types helps you choose the right grade for your project. Let’s dive deeper into what makes each type unique.

Steel Types Breakdown Table

| Steel Type | Carbon Content | Key Elements | Typical Uses | Marine Suitability |

|---|---|---|---|---|

| Carbon Steel | 0.05%-2.1% | Iron, Carbon | Structural beams, pipes | Good (with coatings) |

| Alloy Steel | Varies | Manganese, Silicon | Gears, axles | Moderate |

| Stainless Steel | Low | Chromium, Nickel | Kitchenware, medical tools | Excellent |

| Tool Steel | High | Tungsten, Molybdenum | Drills, blades | Poor |

Carbon steel is the workhorse of industry. It’s strong, cheap, and easy to work with. Most ship hulls use carbon steel plates because they provide the backbone strength needed. However, carbon steel rusts easily unless protected by coatings or paints.

Alloy steel includes extra elements like manganese or silicon to enhance specific properties. For example, high-strength low-alloy (HSLA) steels are common in shipbuilding for their toughness. They handle dynamic loads better than plain carbon steel, which is vital for parts like keels and decks.

Stainless steel contains chromium, which forms a passive oxide layer that prevents rust. While not used for entire hulls due to cost, stainless steel appears in critical areas like propeller shafts or railings. I always recommend it for components exposed to splash zones.

Tool steel is hardened to resist abrasion and heat. It’s useless for ship structures because it’s too brittle and expensive. But it’s perfect for the tools that build the ships—cutting torches, drills, and bending machines.

In our production, we focus on carbon and alloy steels tailored for marine use. We add micro-alloying elements like niobium or vanadium to improve weldability and impact resistance. This attention to detail ensures our clients get steel that lasts in saltwater environments.

What is the best material for boat building?

"Best" depends on the boat’s size, purpose, and budget. A material perfect for a cargo ship might be terrible for a speedboat. Through years of supplying shipbuilders, I’ve learned there’s no one-size-fits-all answer.

The best material for boat building is marine-grade steel for large commercial vessels due to its strength and durability. For smaller boats, aluminum or fiberglass may be better for their light weight and corrosion resistance. The choice ultimately depends on the vessel’s intended use and operating conditions.

Evaluating Materials for Different Vessels

Let’s break down material selection by vessel type. Each material shines in specific scenarios.

Boat Material Selection Guide

| Vessel Type | Ideal Material | Why It Works | Limitations |

|---|---|---|---|

| Oil Tankers | Marine Steel Plate | Handles heavy loads, resists corrosion | Heavy, requires maintenance |

| Container Ships | Bulb Flat Steel | Provides stiff framing, durable | Higher cost than standard angles |

| Fishing Boats | Aluminum Alloy | Light, fuel-efficient | Less durable than steel |

| Yachts | Fiberglass | Smooth finish, low maintenance | Not for heavy commercial use |

| Bulk Carriers | High-Strength Steel | Supports massive cargo weight | Needs skilled welding |

For large ships like oil tankers and bulk carriers, marine steel plate is unbeatable. Its tensile strength prevents the hull from deforming under thousands of tons of cargo. I’ve seen 300-meter tankers built entirely from steel plates up to 40mm thick.

Container ships benefit greatly from bulb flat steel in their framing. The bulb adds stiffness along the ship’s length, preventing hogging and sagging when containers are stacked high. One of our clients in Vietnam reported 15% better structural integrity after switching to bulb flats.

Fishing boats and patrol vessels often use aluminum to save weight. Lighter boats use less fuel, which cuts operating costs. But aluminum wears out faster in abrasive environments, so it’s not ideal for decades-long service.

Fiberglass suits yachts and pleasure craft where appearance matters. It can be molded into sleek shapes and requires little upkeep. However, it lacks the impact resistance for commercial use—a collision that would dent steel might shatter fiberglass.

High-strength steels offer the best balance for heavy-duty applications. They allow thinner plates without sacrificing strength, reducing weight slightly. Our mills produce these grades with tight control over chemistry and rolling processes to ensure consistency.

What is the strongest material in build a boat?

Strength in boat building isn’t just about raw hardness—it’s about yield strength, toughness, and fatigue resistance. A material can be hard but brittle, shattering on impact. The strongest materials combine multiple properties.

The strongest material commonly used in boat building is high-tensile steel, specifically grades like AH36 or DH36. These steels offer yield strengths over 355 MPa, excellent impact resistance at low temperatures, and good weldability. They outperform aluminum and composites in load-bearing capacity and durability.

Analyzing Strength in Marine Contexts

Strength means different things in different parts of a boat. Let’s explore how high-tensile steel compares to other options.

Strength Comparison Table

| Material | Yield Strength (MPa) | Impact Resistance | Fatigue Life | Relative Cost |

|---|---|---|---|---|

| Mild Steel | 235 | Moderate | Good | Low |

| AH36 Steel | 355 | High | Very Good | Medium |

| Aluminum 5083 | 215 | Low | Moderate | High |

| Fiberglass | Varies | Very Low | Poor | Medium |

| Bulb Flat Steel | 315-355 | High | Excellent | Medium |

High-tensile steels like AH36 are the gold standard for critical structural parts. The "AH" stands for "A" grade with high strength, and "36" means 36 kgf/mm² yield strength. This steel can withstand huge forces without permanent deformation, which is crucial in stormy seas.

Aluminum alloys simply can’t match steel’s strength. Even the best marine aluminum has about 60% of steel’s yield strength. That’s why aluminum boats need thicker plates, which negates some weight savings. For heavy cargo ships, steel is the only practical choice.

Fiberglass has high tensile strength in some directions but poor impact resistance. A sharp hit can cause delamination—where layers separate—leading to hidden damage. Steel, by contrast, dents but rarely fails catastrophically.

Bulb flat steel made from high-tensile grades offers exceptional strength-to-weight ratios. The bulb adds stiffness precisely where needed, allowing lighter overall structures. In one project with a Philippine client, using bulb flats reduced frame weight by 10% while increasing strength.

Beyond yield strength, toughness matters immensely. Tough materials absorb energy before breaking—vital for iceberg collisions or groundings. High-tensile steels maintain toughness down to -20°C, ensuring they don’t become brittle in cold waters.

Conclusion

Choosing the right steel makes ships safer and longer-lasting. Bulb flat steel stands out for its unique strength and stiffness in ship framing.