Have you ever wondered what gives massive ships their incredible strength against powerful ocean forces? The secret lies in specialized steel sections that form the ship’s hidden skeleton.

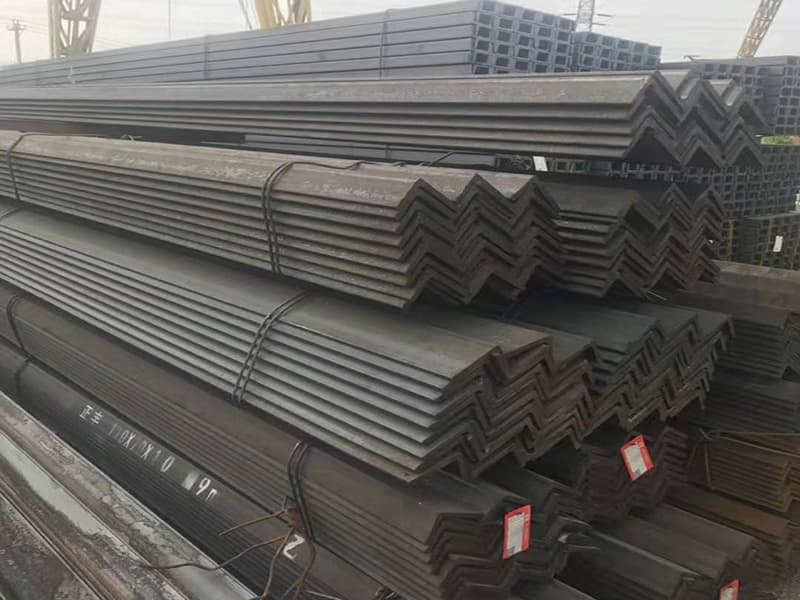

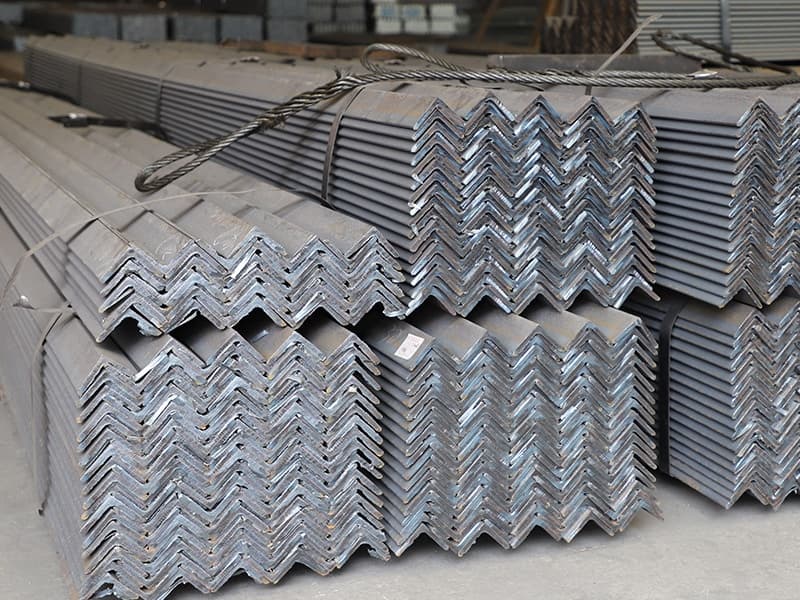

Marine angle steel is L-shaped structural steel specifically designed for shipbuilding applications. It provides critical stiffening to hull plates, supports deck structures, and creates the rigid framing system that maintains vessel integrity under extreme marine conditions and heavy loads.

This fundamental component works tirelessly behind the scenes. Let me show you why marine angle steel is indispensable in modern ship construction.

What type of steel is used in shipbuilding?

Walking through a busy shipyard, you see workers handling various steel components. But not all steel is suitable for shipbuilding – the marine environment demands specialized materials with exceptional properties.

Shipbuilding uses high-strength, low-alloy steels1 certified by classification societies2 like ABS, DNV, or LR. Common grades include AH36, DH36, and EH363, which provide excellent toughness, corrosion resistance, and weldability. These steels maintain structural integrity under dynamic loading in harsh marine environments.

Comprehensive Analysis of Shipbuilding Steel Requirements

The steel used in shipbuilding represents some of the most rigorously tested materials in the construction industry. These steels undergo strict quality control and certification processes to ensure they can withstand the unique challenges of marine service. The selection criteria go far beyond basic strength requirements.

Classification societies establish detailed specifications for shipbuilding steel. These organizations like ABS (American Bureau of Shipping), DNV (Det Norske Veritas), and LR (Lloyd’s Register) set the standards that ensure vessel safety and performance. Their certification means the steel has passed rigorous testing for chemical composition4, mechanical properties, and manufacturing quality.

The grading system follows a logical pattern that indicates key properties. Normal strength steels (Grades A, B, D, E) have a minimum yield strength of 235 MPa. High-strength steels (AH, DH, EH series) offer increased strength levels from 315 MPa to 390 MPa. The letters indicate impact test temperatures, with "A" representing room temperature testing and "E" indicating testing at -40°C.

Manufacturing processes significantly influence the steel’s performance characteristics. Hot rolling remains the primary production method, but additional treatments like normalizing or TMCP (Thermo-Mechanical Controlled Processing5) can enhance properties. Normalizing involves heating and controlled cooling to refine the grain structure, while TMCP provides optimal combination of strength and toughness through precise temperature control during rolling.

Chemical composition is carefully balanced to achieve the desired properties. Elements like carbon, manganese, and silicon provide strength, while micro-alloying elements like niobium and vanadium enhance toughness and weldability. Sulfur and phosphorus levels are kept low to ensure good impact properties and reduce the risk of cracking during fabrication.

Here’s a detailed breakdown of common shipbuilding steel applications:

| Steel Grade | Yield Strength | Impact Temperature | Typical Applications |

|---|---|---|---|

| AH36 | 355 MPa | 0°C | Main hull structures in tropical waters |

| DH36 | 355 MPa | -20°C | Vessels operating in temperate zones |

| EH36 | 355 MPa | -40°C | Ice-class vessels, cold climate operations |

| Normal Strength A-D | 235 MPa | Varies by grade | Secondary structures, interior framing |

We work with certified mills that produce shipbuilding steel under classification society supervision. Recently, we supplied EH36-grade materials for an ice-breaking vessel operating in Arctic waters. The steel required certified impact toughness6 at -60°C to ensure safety when encountering extreme cold temperatures during polar operations.

What is the purpose of the steel angle?

If you examine a ship’s internal structure, you’ll discover a network of L-shaped steel members supporting every major surface. These steel angles form the backbone that transforms flat plates into rigid structural systems.

Steel angle provides structural stiffening and support1 to ship components. It reinforces hull plates against water pressure, supports deck structures under cargo loads, frames bulkheads between compartments, and creates the skeletal framework that distributes loads throughout the vessel.

Detailed Examination of Steel Angle Functions in Shipbuilding

Steel angles serve multiple critical functions in ship construction, each contributing to the overall structural integrity and performance of the vessel. Understanding these purposes helps appreciate why angle selection is so crucial to ship design and safety.

The primary function of steel angles is providing stiffening to large plate areas. Ship hulls consist of extensive steel plates that would buckle under water pressure without adequate support. Steel angles attach perpendicular to these plates, creating T-sections that dramatically increase bending resistance. This stiffening prevents plate deformation and maintains the hull’s designed shape under operational loads.

Load distribution represents another essential purpose. Steel angles help transfer loads from local points to the overall hull structure. When cargo is placed on decks or water pressure acts on hull plating, the angles distribute these forces to stronger structural elements like girders and frames. This distribution prevents stress concentrations that could lead to structural failure.

Structural framing constitutes a fundamental application of steel angles. They form the basic framework for decks, bulkheads, and shell plating. This framing creates the cellular structure that provides torsional rigidity to the entire vessel. The arrangement follows specific patterns determined by classification society rules and naval architecture principles.

Connection and support functions make steel angles versatile components. They serve as connecting elements between different structural members, providing attachment points for equipment foundations, and supporting various ship systems. Their L-shape offers two surfaces for connections, simplifying fabrication and installation processes.

Different ship areas require specific angle applications:

- Hull Stiffening: Longitudinal and transverse angles prevent plate buckling

- Deck Support: Angles frame deck openings and support cargo loads

- Bulkhead Framing: Angles create watertight compartment boundaries2

- Foundation Structures: Angles support machinery and equipment

The table below shows specific angle purposes by location:

| Ship Area | Angle Purpose | Typical Size Range |

|---|---|---|

| Bottom Structure | Stiffen bottom plating against water pressure | L200×200×16 to L300×300×20 |

| Side Shell | Support side plating and transfer loads | L150×150×12 to L250×250×18 |

| Deck Structure | Frame deck plates and support cargo loads | L120×120×10 to L200×200×15 |

| Bulkheads | Create rigid partitions between compartments | L100×100×8 to L180×180×14 |

We recently supplied marine angles3 to a shipyard in Vietnam for a new container ship series. The angles served as primary stiffeners for the hull plating, with specific sizing determined by classification society rules for the vessel’s dimensions and service requirements.

What property is particularly important for shipbuilding steel to ensure it can withstand harsh marine environments?

When ships face violent storms and freezing Arctic waters, one material property becomes absolutely critical for survival. This property determines whether steel remains ductile or becomes dangerously brittle under stress.

Impact toughness1 is particularly important for shipbuilding steel in harsh marine environments. This property ensures the steel can absorb energy and resist brittle fracture2 at low temperatures, preventing catastrophic failure when vessels encounter ice, cold waters, or dynamic wave loading.

Comprehensive Analysis of Impact Toughness in Marine Applications

Impact toughness1 represents a steel’s ability to absorb energy and deform plastically before fracturing when subjected to sudden loading. In marine environments, this property becomes crucial because ships frequently encounter dynamic loads from waves, ice impact, and operational stresses that could cause brittle fracture2 in inadequate materials.

The transition from ductile to brittle behavior occurs as temperatures decrease. All steels have a temperature range where they change from absorbing large amounts of energy through plastic deformation (ductile behavior) to fracturing with minimal deformation (brittle behavior). Shipbuilding steels are specifically designed to maintain ductile behavior at the lowest expected service temperatures.

Charpy V-Notch testing3 provides the standard method for evaluating impact toughness. This test involves striking a notched sample with a pendulum hammer and measuring the energy absorbed during fracture. Classification societies mandate specific energy values at designated temperatures based on the vessel’s operational profile and structural location.

Several factors influence a steel’s impact toughness properties. Chemical composition plays a vital role, with elements like carbon increasing strength but reducing toughness. Manganese improves toughness, while elements like phosphorus and sulfur can create inclusions that initiate brittle fracture2. Manufacturing processes like normalizing or TMCP enhance toughness by refining the steel’s grain structure.

Service conditions determine the required toughness levels. Vessels operating in tropical waters may require impact testing at 0°C, while Arctic vessels need testing at -60°C or lower. The structural criticality also influences requirements, with highly stressed areas demanding higher toughness values than secondary structures.

Design considerations related to toughness include:

- Stress Concentrations: Avoiding sharp notches that initiate brittle fracture2

- Welding Procedures: Controlling heat input to maintain toughness in heat-affected zones

- Fabrication Quality: Ensuring proper workmanship to avoid defects

- Inspection Protocols: Regular monitoring to detect potential issues

Here’s how toughness requirements vary by application:

| Application | Minimum Test Temperature | Charpy Energy Requirement |

|---|---|---|

| Tropical Waters | 0°C | 34-41 Joules (depending on thickness) |

| Temperate Zones | -20°C | 34-41 Joules (depending on thickness) |

| Cold Climate | -40°C | 34-41 Joules (depending on thickness) |

| Arctic Operations | -60°C | 34-41 Joules (depending on thickness) |

We ensure all our marine angle steel supplies meet the required impact toughness specifications. For a recent project in Norway, we provided DH36-grade angles with certified impact values at -40°C to withstand the harsh North Sea conditions throughout the vessel’s operational life.

What are the properties of marine steel?

Marine steel possesses a unique combination of properties that distinguish it from ordinary structural steel. These properties work together to ensure reliable performance in the challenging marine environment.

Marine steel properties include high strength-to-weight ratio1, excellent impact toughness2 at service temperatures, superior corrosion resistance3, good weldability4, and classification society certification. These properties ensure structural integrity, durability, and safety in marine applications.

Detailed Examination of Marine Steel Characteristics

Marine steels are engineered with specific property combinations that address the unique demands of shipbuilding and offshore applications. These properties result from careful control of chemical composition, manufacturing processes, and quality assurance procedures throughout production.

The strength-to-weight ratio is a critical property for marine steels. Higher strength allows using thinner sections, reducing structural weight while maintaining load-bearing capacity. This weight reduction improves vessel stability, increases payload capacity, and enhances fuel efficiency. Marine steels typically offer yield strengths from 235 MPa for normal strength grades to 390 MPa for high-strength grades.

Corrosion resistance properties are essential for marine applications. Saltwater creates an extremely aggressive environment that attacks steel through multiple mechanisms including general corrosion, pitting, and crevice corrosion. Marine steels incorporate alloying elements and controlled manufacturing to enhance corrosion resistance, though additional protection through coatings and cathodic systems is still required.

Weldability properties ensure that marine steels can be efficiently joined using various welding processes without compromising performance. The carbon equivalent value is carefully controlled to prevent issues like cold cracking in heat-affected zones. Good weldability allows shipyards to use efficient fabrication methods while maintaining structural integrity throughout the welded connections.

Fatigue resistance is another important property for marine steels. Ships experience cyclic loading from waves, machinery vibrations, and operational stresses throughout their service life. Marine steels are designed to withstand these repeated loads without developing cracks that could lead to structural failure over time.

Dimensional consistency and surface quality are practical properties that affect fabrication. Marine steels must maintain consistent dimensions to ensure proper fit-up during construction. Surface quality requirements minimize defects that could initiate corrosion or cracking, ensuring long-term performance in marine service.

The table below summarizes key marine steel properties:

| Property | Importance | Typical Values |

|---|---|---|

| Yield Strength | Determines load-bearing capacity | 235-390 MPa |

| Impact Toughness | Prevents brittle fracture | 34-41 J at specified temperature |

| Elongation | Indicates ductility and formability | 21-24% |

| Carbon Equivalent | Measures weldability | 0.36-0.42% |

We verify all these properties through mill certificates and third-party inspection when required. Our clients in the Middle East particularly value the corrosion resistance properties of our marine steels, given the aggressive conditions in the Arabian Gulf with high salinity and temperatures.

Conclusion

Marine angle steel plays a vital role in shipbuilding, providing the structural framework that keeps vessels strong and seaworthy. Understanding its properties and applications ensures proper selection and usage.

-

Understanding this ratio is crucial for optimizing vessel design and performance in marine applications. ↩ ↩ ↩ ↩ ↩

-

Explore how impact toughness prevents brittle fractures, ensuring safety and reliability in marine environments. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the alloying elements and coatings that protect marine steel from aggressive saltwater environments. ↩ ↩ ↩ ↩

-

Discover the importance of weldability in ensuring structural integrity and efficient shipbuilding processes. ↩ ↩

-

Discover the benefits of TMCP in enhancing the strength and toughness of shipbuilding steel. ↩

-

Explore the significance of impact toughness for safety in extreme cold marine operations. ↩