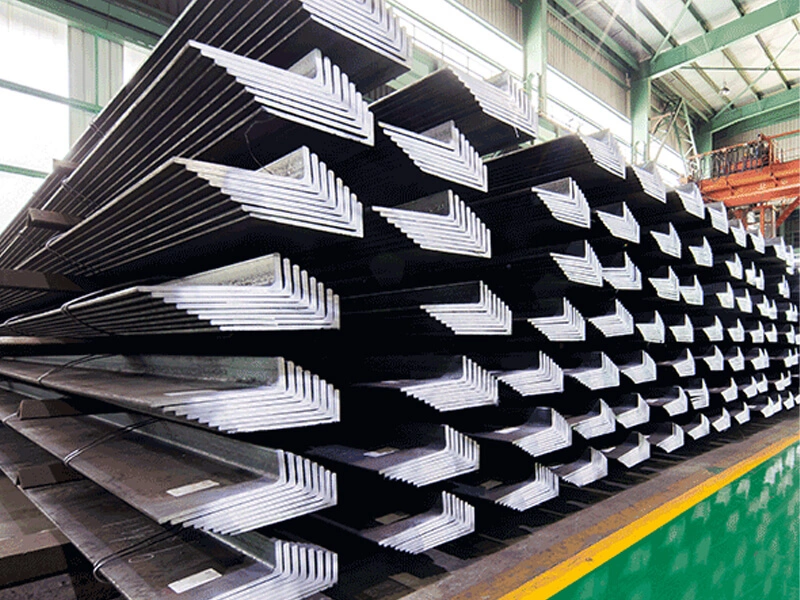

When shipbuilders and offshore fabricators need a reliable, high-strength material for frames and stiffeners, one grade consistently appears on their specifications: AH36. Its dominance isn’t by accident. I’ve supplied this steel for projects from Qatar to the Philippines, and its performance is proven.

AH36 L-shaped steel is widely used in marine engineering because it offers a high yield strength of 355 MPa, certified toughness for structural integrity, excellent weldability for fabrication, and a favorable strength-to-weight ratio that reduces hull weight and increases cargo capacity without compromising safety. It provides the optimal balance of performance, cost, and regulatory compliance for modern vessels.

For marine engineers, project contractors, and steel buyers, understanding AH36 is essential for making informed material decisions. This article will explain what makes this grade special, how it compares to alternatives, and why steel remains the undisputed king of marine construction. Let’s start by defining AH36 steel itself.

What is AH361 steel?

In the world of marine steel2, AH361 is more than just a code. It represents a specific set of guaranteed properties that engineers can design with confidence. A shipyard in Saudi Arabia recently rejected a shipment because the MTC showed it was AH32, not the specified AH361, highlighting the importance of precise grade identification.

AH361 is a high-strength shipbuilding steel3 grade certified by classification societies like ABS. The "A" indicates it meets basic impact test requirements, the "H" stands for High Strength, and the "36" denotes a minimum yield strength4 of 36 kgf/mm², which is 355 Megapascals (MPa). It is produced with controlled chemistry for weldability5 and is required to pass Charpy V-notch toughness tests6, making it suitable for critical hull structures.

The Detailed Breakdown of AH361 Properties

AH361 is not a single chemical recipe but a performance standard. Mills can achieve it through different processes, but the final product must meet strict criteria.

1. Mechanical Properties (The Strength Guarantee):

- Yield Strength (Rp0.2): Minimum 355 MPa. This is the stress at which the steel begins to deform permanently. It is the primary design strength.

- Tensile Strength (Rm): Typically 490-620 MPa. This is the maximum stress it can take before breaking.

- Elongation (A5): Minimum 21%. This measures ductility—how much it can stretch before fracture.

- These values are verified for each production heat (batch) and reported on the Mill Test Certificate (MTC).

2. Chemical Composition (The Recipe for Weldability and Toughness):

The chemistry is tightly controlled, especially for impurities.

- Carbon (C): Usually limited to a maximum around 0.18%. Low carbon is crucial for good weldability5.

- Manganese (Mn): Used to increase strength and toughness. Its content is balanced with carbon.

- Sulfur (S) & Phosphorus (P): Strictly limited (e.g., max 0.025% each). High levels of these impurities cause brittleness and weld cracking.

- Carbon Equivalent (CE): A calculated value (using C, Mn, Cr, etc.) that predicts weldability5. AH361 has a specified maximum CE (e.g., 0.41) to ensure it can be welded without pre-heat under normal conditions.

3. Toughness Requirements (The Safety Factor):

- Charpy V-Notch Impact Test: Samples from the steel must absorb a minimum amount of energy (e.g., 34 Joules) when struck at a specific low temperature (typically 0°C for Grade A toughness).

- This test proves the steel is ductile and resistant to brittle fracture, which is vital for a hull facing impact and cold seawater.

Why These Properties Matter for L-Shaped Steel:

When rolled into L angles, AH361 provides:

- Strong Frames: Angles used as ship frames must resist buckling from hull bending and water pressure. The 355 MPa yield strength4 provides this margin.

- Weldable Stiffeners: Thousands of meters of angles are welded to hull plates. The controlled chemistry prevents weld cracks.

- Reliable Performance: The certified toughness ensures that in the event of an impact, the angle will deform, not shatter.

| Property | Requirement (Typical per ABS Rules) | Importance for Marine L Angles |

|---|---|---|

| Yield Strength | ≥ 355 MPa | Allows for thinner, lighter sections in frames and stiffeners, reducing hull weight. |

| Tensile Strength | 490 – 620 MPa | Provides a reserve of strength beyond yield. |

| Elongation | ≥ 21% | Ensures ductility for forming and energy absorption. |

| Charpy Impact (0°C) | ≥ 34 J | Prevents brittle fracture, critical for safety in marine environments. |

| Max Carbon Equivalent | ~0.41 | Guarantees good weldability5 for efficient hull fabrication. |

For a supplier, providing genuine AH361 means sourcing from mills that can consistently meet these specs and provide the full MTC as proof. This traceability is what our clients demand. Now, a common question arises: how does it differ from the similar-sounding AH32?

What is the difference between AH32 and AH36?

Choosing between AH32 and AH36 is a classic engineering trade-off between cost and performance. A naval architect in Vietnam was optimizing a bulk carrier design and had to decide: could they save money with AH32, or did they need the extra strength of AH36? The answer lay in the numbers.

The key difference between AH32 and AH36 is the minimum yield strength1. AH32 has a yield strength of 315 MPa, while AH36 is stronger at 355 MPa. Both are high-strength marine grades with similar chemistry and toughness requirements, but AH36 allows for approximately 12% higher design stresses, leading to potential weight savings2 in the hull structure. The choice depends on the structural design’s stress levels and weight reduction goals.

A Technical and Economic Comparison

While the difference seems small on paper (40 MPa), it has significant implications for ship design, construction, and operation.

1. The Strength Difference in Practice:

Yield strength is the primary design value. A higher allowable stress3 means you can use a smaller cross-section to carry the same load.

- Example: A hull frame designed with AH36 might use a thinner angle or a shallower angle than one designed with AH32 for the same loading condition.

- Result: The AH36 structure will be lighter. For a large ship, saving hundreds of tons of steel weight translates directly to increased cargo capacity (deadweight) or improved fuel efficiency.

2. Chemical and Toughness Similarities:

Both grades share similar requirements for weldability and toughness4.

- Chemistry: The limits for Carbon, Sulfur, Phosphorus, and Carbon Equivalent are nearly identical. This means they are equally weldable.

- Impact Toughness: Both require Charpy V-notch testing, typically at 0°C for the ‘A’ grade toughness level. They must meet similar energy absorption minima.

- This is crucial: It means upgrading from AH32 to AH36 does not require changing welding procedures or sacrificing safety margins.

3. Cost and Availability:

- Cost: AH36 typically commands a premium of 5-10% over AH32 due to the tighter rolling process required to achieve the higher strength.

- Availability: Both are standard grades produced by all major marine steel mills. Availability is generally equal.

Decision Matrix: When to Use Which Grade?

| Design Scenario & Priority | Recommended Grade | Rationale |

|---|---|---|

| New-build large container ship or bulk carrier (maximizing cargo). | AH36 (or even AH40) | The weight saved by using higher-strength steel directly increases payload and revenue. The material premium is justified. |

| General cargo ship, tanker (standard design, moderate optimization). | AH32 or AH36 | AH32 is cost-effective. AH36 may be used in higher-stress areas (like the midship bottom) for a hybrid approach. |

| Ship repair or conversion where matching existing structure. | Match the original grade. | For structural continuity and consistent welding. |

| Offshore platform where weight is less critical than in a ship. | AH32 may be sufficient. | The primary goal is strength and fatigue life, not weight reduction for cargo. Cost savings can be significant. |

Procurement Note for Buyers:

You must specify the grade clearly. The MTC must state either "AH32" or "AH36." They are not interchangeable. We always confirm this detail with clients because using a lower grade than specified is a major compliance issue5. For rational buyers focused on results, the choice boils down to a cost-benefit analysis of the entire vessel’s lifecycle. Both, however, fall under the broader category of steel used to build ships.

What type of steel is used to build ships?

Imagine building a skyscraper that must also float, move, and withstand constant corrosion. That’s the challenge of shipbuilding, and it demands a special family of steels. Ordinary construction steel would fail quickly in this environment.

Ships are built with marine-grade steels1 certified by classification societies like ABS, LR, DNV, or BV. These are primarily carbon-manganese steels2 with tightly controlled chemistry. The types range from ordinary strength grades (A, B, D, E) to high-strength grades (AH32, AH36, DH36, FH40). They are selected for their combination of strength, toughness (especially at low temperatures), weldability, and corrosion resistance.

The Specialized World of Marine Structural Steels

Marine steel is a product of rigorous engineering and international standards. It is designed for the unique "load case" that is a ship’s life.

1. Classification Society Approval3:

This is the fundamental differentiator. A mill must be approved by the society (e.g., ABS) to produce steel under its rules. The society audits the mill’s processes. The steel is tested and certified (via MTC) to prove it meets the society’s published standards. This system provides global confidence and safety.

2. The Two Main Families, Revisited:

- Ordinary Strength Steel (Grades A, B, D, E):

- A & B: Standard grades for general hull structures. B has better toughness than A.

- D & E: Enhanced toughness grades for colder service. Used in the forward hull and for vessels operating in Arctic/Antarctic waters.

- High Strength Steel4 (H-grades: AH, DH, EH, FH):

- AH32/36, DH32/36: The workhorses of modern shipbuilding. They provide higher strength (315/355 MPa) with designated toughness levels (A or D).

- EH36, FH40: Even higher strength and toughness for the most demanding applications like icebreakers and offshore platforms.

3. Key Properties Tailored for the Marine Environment:

- Fatigue Resistance5: Ships flex in waves for decades. The steel must resist crack initiation under these cyclic loads. Clean steel with low inclusion content is important.

- Corrosion Performance: While not stainless, marine steels have controlled chemistry to work effectively with paint systems and sacrificial anodes (cathodic protection).

- Through-Thickness Properties (Z-direction): For thick plates used in highly stressed areas, the steel is tested to ensure it has strength through its thickness to resist lamellar tearing.

Application-Based Selection Guide:

| Ship Component & Environment | Typical Steel Type/Grade | Reason for Selection |

|---|---|---|

| Midship Bottom Shell | High-Strength Steel (AH36) | High global bending stresses; weight saving is key. |

| Forward Bottom & Side Shell | High-Toughness Steel (DH36 or EH36) | Subject to wave slamming and lower temperatures; requires superior impact resistance. |

| Deck in Cargo Area | High-Strength Steel (AH36) | To support heavy cargo loads with minimal structural weight. |

| Internal Bulkheads (non-critical) | Ordinary Strength Steel (Grade A or B) | Lower stress application; cost efficiency. |

| Superstructure | Lower strength grades or AH32 | Weight reduction high up improves stability; loads are lower. |

For a supplier exporting worldwide, we must stock and source this full range. When a shipyard in Romania needs DH36 for an ice-class vessel or a yard in Thailand needs AH36 for a container ship, we provide the correctly certified material. This specialization explains why steel, in general, is so prevalent in engineering.

Why steel is so commonly used in engineering applications?

From skyscrapers and bridges to ships and machinery, steel is everywhere. Its dominance is not a historical accident but the result of a nearly perfect balance of properties. A civil engineer in Mexico once explained to me that for his bridge project, no other material came close to steel’s combination of performance and constructability.

Steel is so common in engineering because it offers an unmatched combination of high strength1, ductility2 (ability to deform without breaking), excellent weldability3 and fabricability4, predictable behavior under load, 100% recyclability5, and competitive cost per unit of strength. This makes it the most versatile and reliable structural material for a vast range of applications, from buildings and infrastructure to vehicles and ships.

The Multifaceted Advantages That Cement Steel’s Dominance

Let’s break down these advantages to understand why alternatives struggle to compete for primary structural roles.

1. Mechanical Properties: The Performance Core

- High Strength: Modern steels like AH36 have yield strengths over 355 MPa. This allows structures to be strong yet lightweight.

- Ductility and Toughness: Steel can undergo significant plastic deformation before fracture. It absorbs energy (in impacts, earthquakes) and provides warning before failure. This is a critical safety feature that brittle materials like cast iron or unreinforced concrete lack.

- Elasticity: Steel follows Hooke’s Law predictably—it returns to its original shape after loading within its elastic limit. This makes structural analysis accurate and reliable.

2. Fabricability and Construction Efficiency

- Ease of Fabrication: Steel can be cut, drilled, punched, and bent with standard equipment. Complex shapes (like L angles, I-beams) are roll-formed efficiently.

- Weldability: This is revolutionary. It allows for the creation of monolithic, continuous structures from discrete parts. A ship’s hull is essentially one giant welded assembly. Bolting is also simple and reliable.

- Prefabrication: Components can be manufactured off-site under quality-controlled conditions, then quickly assembled on-site. This dramatically reduces project timelines.

3. Economic and Sustainability Factors

- Strength-to-Cost Ratio: While the raw material cost per kg might be higher than concrete, the cost per unit of strength and the speed of construction often make steel more economical overall.

- Recyclability: Steel is the most recycled material on Earth. It can be melted down and reused indefinitely without degradation of properties. This circular economy model is a major modern advantage.

- Adaptability: Steel structures can be easily modified, extended, or dismantled, giving them a long and flexible service life.

Comparison with Primary Competitors:

| Material | Key Advantages | Key Disadvantages vs. Steel |

|---|---|---|

| Reinforced Concrete | Good compressive strength, fire resistance, low material cost. | Heavy, slow to construct, poor tensile strength, difficult to modify, not recyclable in the same way. |

| Aluminum Alloys | Lightweight, corrosion resistant. | Cost is 3-5x higher, lower stiffness and strength, more complex welding, poor fire performance. |

| Timber | Renewable, good aesthetic, carbon sequestering. | Low strength, variable quality, flammable, not suitable for large spans or marine hulls. |

| Fiber-Reinforced Polymers | Lightweight, corrosion-free. | Very high cost, uncertain long-term durability, complex recycling, poor fire resistance. |

The Marine Engineering Context:

In shipbuilding, steel’s advantages are overwhelming. No other material can provide the necessary strength, toughness, and weldability3 at a scale of thousands of tons, all while being formable into complex hull shapes. The development of specialized marine grades like AH36 is a direct response to pushing the limits of these advantages for maximum efficiency and safety at sea.

For a results-driven business, choosing steel—and specifically the right grade like AH36—is a decision based on total value, risk management, and proven performance. It’s why our clients in shipbuilding and marine engineering6 continue to rely on it as their foundational material.

Conclusion

AH36 L-shaped steel is a cornerstone of marine engineering due to its optimal 355 MPa strength, certified toughness, and excellent weldability. It exemplifies why specialized steel remains the dominant, irreplaceable material for building safe, efficient, and durable ships and offshore structures.

-

Understanding high strength steel can enhance your knowledge of its applications and advantages in construction. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring ductility will reveal its critical role in safety and performance in engineering applications. ↩ ↩ ↩ ↩

-

Learning about weldability can provide insights into the efficiency and reliability of steel construction. ↩ ↩ ↩ ↩ ↩

-

Discovering fabricability can help you understand how steel is shaped and assembled in various projects. ↩ ↩ ↩ ↩ ↩

-

Understanding steel’s recyclability highlights its sustainability and environmental benefits in engineering. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Delving into marine engineering will showcase steel’s unique benefits in shipbuilding and offshore applications. ↩ ↩