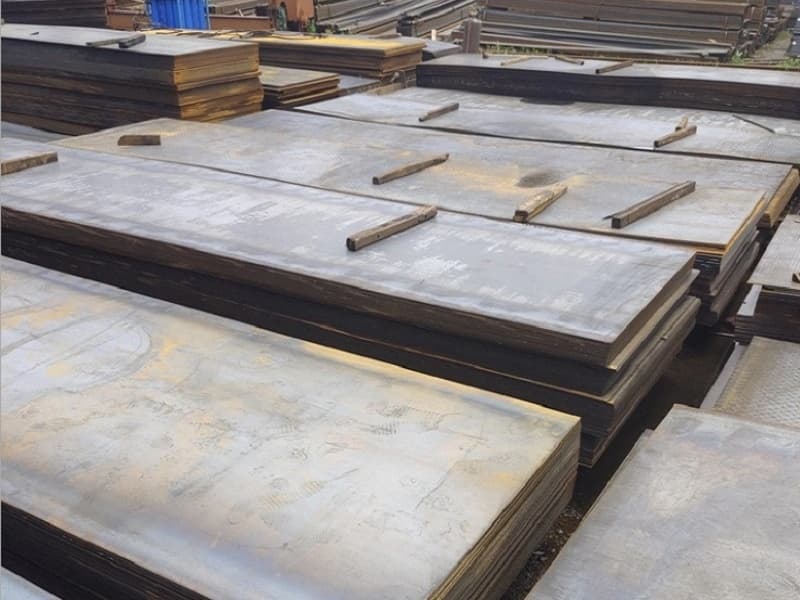

Walking through a shipyard in Vietnam, I notice AH36 stamped on most steel plates. This grade has become the industry standard for good reasons.

AH36 marine steel plate dominates shipbuilding due to its optimal balance of strength, weldability, and toughness. With 355 MPa yield strength and excellent impact resistance at -20°C, it meets classification society requirements while offering cost-effectiveness for commercial vessel construction worldwide.

Understanding why AH36 remains the top choice helps shipbuilders make informed material decisions. Let me break down its advantages and applications.

What makes A36 steel1 so popular?

A contractor from Saudi Arabia once asked why A36 appears in both construction and marine projects. The answer lies in its versatile properties and reliable performance.

A36 steel1‘s popularity stems from its excellent weldability, good strength-to-cost ratio, and widespread availability. It serves as a general-purpose structural steel that performs reliably across various applications while maintaining consistent quality from different mills worldwide.

The Universal Appeal of A36 Steel

A36 has maintained its position as the most commonly used structural steel for decades. Its popularity crosses multiple industries and applications for several key reasons.

Balanced Mechanical Properties

A36 offers 250 MPa yield strength and 400-550 MPa tensile strength. These values meet most structural requirements without being excessive. The steel has good ductility with 20% minimum elongation. This combination works well for buildings, bridges, and general fabrication.

Excellent Weldability Characteristics2

The carbon content in A36 stays below 0.25%. This low carbon level makes welding straightforward. Preheating is rarely necessary for most thicknesses. Common welding methods like SMAW, GMAW, and FCAW all work effectively. This reduces fabrication time and costs.

Cost-Effective Production3

A36 uses a simple chemical composition. Mills can produce it efficiently in large quantities. The manufacturing process is well-established and optimized. This results in competitive pricing and reliable supply chain availability.

Availability and Standardization4

A36 is produced by mills worldwide. The specifications are clearly defined in ASTM A36 standards. This standardization ensures consistent quality regardless of the source. Buyers can easily compare prices and specifications from different suppliers.

A36 Steel Key Properties and Applications

| Property | Specification | Practical Benefit |

|---|---|---|

| Yield Strength | 250 MPa | Adequate for most structures |

| Tensile Strength | 400-550 MPa | Good load-bearing capacity |

| Elongation | 20% minimum | Good formability |

| Carbon Content | 0.25% max | Easy welding |

| Availability | Worldwide | Supply chain reliability |

We supply A36 to clients in Philippines and Thailand for various structural projects. While it’s not marine-grade, its reliable performance in terrestrial applications demonstrates why similar principles make AH36 successful in shipbuilding.

What grade of steel is used in shipbuilding?

A shipowner in Mexico initially confused regular structural steel with marine grades. This misunderstanding could have led to serious safety issues in their new vessel construction.

Shipbuilding primarily uses AH36, DH36, and EH36 grade steels1 for hull construction. These grades offer increasing levels of toughness, with AH36 being the standard for most commercial vessels, while DH36 and EH36 serve colder environment operations with enhanced impact resistance2.

Marine Steel Grade Selection Criteria

Shipbuilding requires specialized steels that withstand unique marine environment challenges3. The grade selection depends on vessel type, operating routes, and classification society rules.

AH36 – The Workhorse Grade

AH36 serves as the baseline for most commercial shipbuilding. It offers 355 MPa yield strength with adequate toughness for normal marine conditions. The "A" indicates it’s tested at ambient temperature. This grade works well for tropical and temperate waters.

DH36 – Enhanced Toughness

DH36 provides better impact resistance2 than AH36. The "D" indicates testing at -20°C. This grade suits vessels operating in colder waters. It offers the same strength as AH36 but with improved low-temperature performance.

EH36 – Maximum Toughness

EH36 represents the highest toughness level among these grades. Testing occurs at -40°C, making it suitable for arctic operations. While strength remains at 355 MPa, the enhanced toughness comes from tighter composition control and special processing.

Specialized Marine Grades

Beyond the standard grades, shipbuilding uses specialized steels for specific applications4. These include higher strength steels for weight reduction5, stainless steels for chemical tankers, and extra corrosion-resistant grades for ballast tanks.

Classification Society Approvals6

All marine steels require certification from classification societies like ABS, DNV, LR, or BV. These organizations verify that the steel meets their specific rules and requirements. The certification process ensures quality and safety standards.

Shipbuilding Steel Grade Applications

| Grade | Impact Test Temperature | Typical Applications | Classification Societies |

|---|---|---|---|

| AH36 | 0°C | Tropical waters, commercial vessels | ABS, DNV, BV, LR |

| DH36 | -20°C | Temperate waters, general trading | ABS, DNV, BV, LR |

| EH36 | -40°C | Arctic waters, ice-class vessels | ABS, DNV, BV, LR |

| AH40 | 0°C | Higher strength requirements | ABS, DNV, BV, LR |

| DH40 | -20°C | Cold environment, high strength | ABS, DNV, BV, LR |

Our mills in Shandong produce all these grades with full classification society approval. We supply to shipyards in Qatar and Saudi Arabia where environmental conditions dictate specific grade requirements.

What is material grade AH36?

A project manager in Romania needed to understand AH36 specifications for their new container ship project. The detailed explanation helped them optimize their material selection.

AH36 is a high-strength marine structural steel1 with minimum yield strength of 355 MPa. The ‘A’ indicates ambient temperature impact testing, while ‘H’ signifies high strength and ’36’ represents 36 kgf/mm² yield strength. It offers excellent weldability and toughness for ship hull construction.

Comprehensive AH36 Grade Analysis

AH36 represents a specific category within marine steels designed to balance multiple performance characteristics essential for ship construction and operation.

Chemical Composition Requirements

AH36 maintains strict chemical limits to ensure consistent performance. Carbon content typically ranges between 0.14-0.20% depending on thickness. Manganese content varies from 0.90-1.60% to enhance strength and toughness. Silicon usually stays below 0.50% for deoxidation purposes. Phosphorus and sulfur maintain low levels below 0.035% each to ensure good weldability and toughness.

Mechanical Property Specifications

The yield strength must reach minimum 355 MPa across all thickness ranges. Tensile strength typically falls between 490-620 MPa. Elongation varies with thickness but generally exceeds 20% in 50mm gauge length. Impact energy requirements demand minimum 34 joules at 0°C test temperature.

Manufacturing Process Control

AH36 production involves controlled rolling and normalizing treatments. These processes refine the grain structure and enhance mechanical properties. Mills conduct rigorous testing including tensile tests, impact tests, and bend tests. Each plate receives individual certification documenting its properties and test results.

Thickness Considerations

Mechanical properties vary with plate thickness. Thicker plates generally show slightly lower yield and tensile values. Impact properties may also decrease in heavier sections. The specifications account for these variations through thickness-dependent requirements.

AH36 Detailed Specification Breakdown

| Property | Requirement | Test Standard | Notes |

|---|---|---|---|

| Yield Strength | ≥355 MPa | ASTM A370 | All thicknesses |

| Tensile Strength | 490-620 MPa | ASTM A370 | Thickness dependent |

| Elongation | ≥20% | ASTM A370 | 50mm gauge length |

| Impact Energy | ≥34J @ 0°C | ASTM A370 | Charpy V-notch |

| Carbon Equivalent | ≤0.41 | Calculated | Weldability indicator |

We provide complete material certification with every AH36 shipment. Our clients in Malaysia and Pakistan appreciate the detailed documentation for their quality control and regulatory compliance needs.

What is ASTM A36 steel1 used for?

A fabricator in Thailand initially used ASTM A36 for marine applications until we explained the crucial differences between structural and marine grades.

ASTM A36 steel1 serves primarily in building construction2, bridge components3, and general structural applications. It functions well in bolted and welded structures for buildings, warehouse frames, industrial plants, and construction equipment where marine environment corrosion resistance4 isn’t required.

ASTM A36 Application Spectrum

ASTM A36 finds widespread use across multiple industries due to its reliable performance and cost-effectiveness in non-marine environments.

Construction Industry Applications

A36 forms the backbone of structural steel frameworks in commercial and industrial buildings. It serves as columns, beams, and girders in building construction2. The steel works well in bolted connections for structural frames. Its weldability5 allows flexible design and fabrication approaches. Construction equipment manufacturers use A36 for frames and supports.

Bridge and Infrastructure Uses

Bridge construction utilizes A36 for various components including girders, cross-bracing, and support structures. The steel’s proven performance in static load applications makes it suitable for infrastructure projects. Highway construction employs A36 for guard rails and support poles. Its consistent quality ensures long-term reliability in these critical applications.

Industrial and Manufacturing Applications

Manufacturing plants use A36 for equipment supports, platforms, and walkways. The steel serves in machine bases and frames where vibration resistance matters. Industrial stairs and ladders frequently use A36 for its combination of strength and formability. Storage rack systems utilize A36 for their structural components.

Comparison with Marine Steels

While A36 works well in dry environments, it lacks the corrosion resistance needed for marine applications. Marine grades like AH36 include enhanced corrosion protection and tougher impact requirements. The chemical composition differs significantly, particularly in elements affecting corrosion resistance and low-temperature performance.

ASTM A36 vs AH36 Application Guide

| Application | Recommended Grade | Reason |

|---|---|---|

| Building Frames | ASTM A36 | Cost-effective, adequate strength |

| Bridge Components | ASTM A36 | Proven performance |

| Ship Hulls | AH36 | Corrosion resistance, toughness |

| Offshore Platforms | AH36/DH36 | Marine environment durability |

| Industrial Equipment | ASTM A36 | General purpose reliability |

We help clients understand these application differences to prevent material selection errors. Our technical support team guides customers in choosing the right grade for their specific project requirements and environmental conditions.

Conclusion

AH36 marine steel plate remains the shipbuilding industry preferred choice due to its optimal strength, proven reliability, and cost-effectiveness. Understanding its properties ensures proper material selection for vessel construction and maintenance.

-

Explore this link to understand the versatile applications and benefits of ASTM A36 steel in various industries. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn how ASTM A36 plays a crucial role in structural frameworks and its advantages in building projects. ↩ ↩ ↩ ↩ ↩

-

Discover the reliability and performance of ASTM A36 in bridge construction and its critical applications. ↩ ↩ ↩

-

Understand the importance of corrosion resistance in marine applications and how it differs from structural grades. ↩ ↩ ↩

-

Explore the significance of weldability in steel fabrication and how it enhances design flexibility. ↩ ↩

-

Discover the role of classification societies in ensuring the safety and quality of shipbuilding materials. ↩