You are designing a new vessel. The hull must be strong enough to withstand ocean forces, but light enough to maximize cargo capacity. You need stiffeners that offer exceptional strength without adding unnecessary weight. What is the solution that balances these competing demands perfectly?

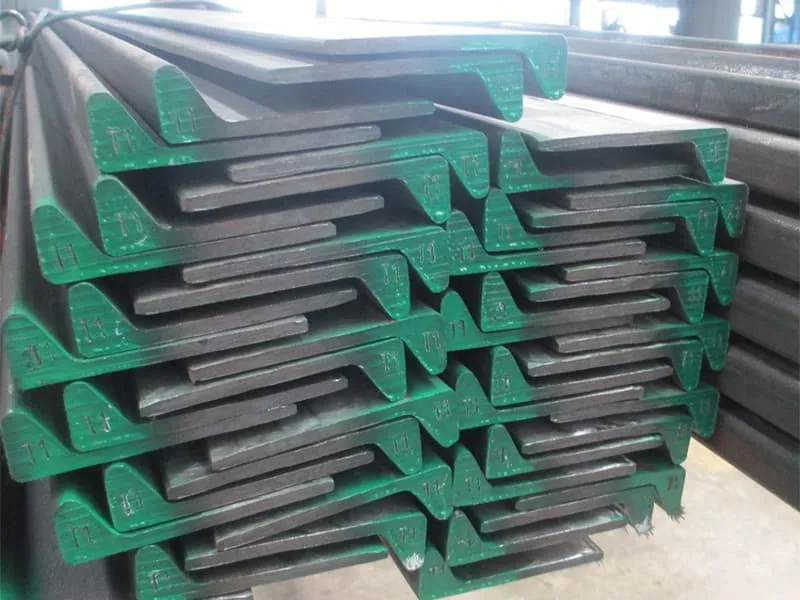

Ship designers prefer bulb flat steel because it provides the optimal strength-to-weight ratio for hull stiffening. The bulb’s unique shape adds critical strength at the edge, resisting buckling while minimizing steel use. This leads to lighter ships, increased cargo capacity, and easier welding, making it the most efficient choice for modern hull construction.

Choosing the right stiffener is not just a technical detail; it directly impacts the vessel’s profitability and safety. From my work with shipyards worldwide, I’ve seen how bulb flat steel transforms hull design. Let’s explore why this profile beats other options and how it fits into the broader picture of marine engineering.

What is the best steel for ship building?

There is no single “best” steel for all ship parts. The choice depends on the specific location and function on the vessel. Using the wrong grade in a critical area is a serious risk.

The best steel for shipbuilding is marine-grade steel1 certified by classification societies like ABS, LR, or DNV. For hull plates, high-strength AH/DH/EH grades2 are standard. For stiffeners like bulb flats, the steel must have excellent weldability3 and toughness to match the plates and withstand dynamic loads.

Selecting the Right Steel for Each Ship Part

Shipbuilding uses a family of steels, each engineered for a specific purpose. The table below breaks down the common types and their optimal applications.

| Steel Type / Grade | Key Properties & Purpose | Typical Applications in Shipbuilding | Why It’s Chosen |

|---|---|---|---|

| General Strength Steel (A Grades) | Good basic strength and toughness at low cost. | Internal, non-critical structures, secondary decking, some bulkheads. | Provides adequate performance for areas with lower stress, keeping overall cost down. |

| High-Strength Steel (AH/DH/EH Grades) | Higher yield strength (e.g., 32, 36, 40 kgf/mm²) with good low-temperature toughness. | Primary hull plating, decks, and critical longitudinal members. | Allows for thinner, lighter plates while maintaining strength, directly increasing cargo capacity. |

| Extra-High Toughness Steel4 (EH/FH Grades) | Exceptional impact resistance at very low temperatures (arctic conditions). | Ice-going vessels, Arctic offshore platforms, critical zones of LNG carriers. | Prevents brittle fracture in extremely cold environments, a vital safety feature. |

| Corrosion-Resistant Steel5 | Alloyed or treated to resist seawater corrosion better than standard grades. | Ballast tanks, waterline zones, cargo tanks for certain chemicals. | Extends the lifespan of structures in the most corrosive environments, reducing maintenance. |

| Steel for Stiffeners (Bulb Flats, Angles) | Must have excellent weldability3 and toughness compatible with the attached plate. | Hull stiffeners (bulb flats), frames, brackets. | Ensures strong, reliable connections that won’t crack under fatigue loading. The steel is often similar to the plate grade (e.g., AH36 plate with AH36 bulb flat). |

I worked with a shipyard in Thailand building a container ship. They initially considered using standard A-grade steel for all longitudinal bulb flats to save money. We had to explain the risk. The high-strength AH36 hull plates would be welded to these stiffeners. If the stiffener steel did not have matching toughness, the weld zone could become a weak point, prone to cracking under stress. They switched to AH36-grade bulb flats6. This example shows that the “best” steel is part of a system. The plate, the stiffener, and the weld must work together as one unit. The best choice always balances performance, safety, and total cost over the ship’s life.

Which type of steel is most commonly used in shipbuilding due to its strength and durability?

Walk through any major shipyard, and you will see one type of steel everywhere. It forms the backbone of the vast majority of oceangoing vessels. Its popularity comes from a proven balance of strength, durability, and cost.

Normal strength “A” grade steel and high-strength “AH” grade steel are the most commonly used types in shipbuilding. For hulls and primary structures, high-strength AH32/AH36 steel is the dominant choice because it offers superior strength and durability for less weight, which is crucial for modern efficient vessel design.

The Reign of High-Strength Steel in Modern Hulls

While many grades exist, shipbuilding has standardized around a few workhorses. The shift from normal strength to high-strength steel marks one of the biggest advancements in naval architecture.

| Steel Category | Typical Grades | Reason for Common Use | Impact on Ship Design & Bulb Flats |

|---|---|---|---|

| Normal Strength Steel | A, B, D, E (per ABS rules) | Lower cost, good general properties, and excellent weldability. It is very reliable for many applications. | Still used for internal structures, smaller vessels, or areas with low stress. Less common for primary hull longitudinals today. |

| High-Strength Steel | AH32, AH36, DH32, DH36 | Higher yield strength (315-355 MPa). This allows designers to reduce plate thickness by 15-20% for the same strength. This directly lowers steel weight and increases deadweight capacity. | This is the standard choice for hull plating and attached bulb flat stiffeners on container ships, tankers, and bulk carriers. |

| Comparison of Strength & Weight | AH36 vs. A Grade | AH36 has about 30% higher yield strength. To achieve the same strength, you can use thinner AH36 plate, saving significant weight. | When AH36 plate gets thinner, stiffeners (bulb flats) become even more critical to prevent buckling. The efficiency of bulb flats complements thin-plate design perfectly. |

| Durability Factors | Toughness & Weldability | These grades offer good toughness at low temperatures (especially D/EH grades). They are also designed for smooth welding, which is vital for hull integrity. | Bulb flats made of AH36 ensure the stiffening system does not become the weak link. The weld between plate and stiffener must be as strong as the base metal. |

| Economic Driver | Deadweight Optimization | For a large cargo ship, saving 1,000 tons of steel weight can mean 1,000 extra tons of paying cargo on every voyage. This is a massive financial advantage. | Using high-strength steel for both plate and bulb flats maximizes this weight-saving effect, making the ship more profitable. |

A naval architect from a European design firm once told me their standard spec for Panamax bulk carriers is now AH36 for the entire hull shell and longitudinals. A decade ago, a mix of A and AH grades was common. The change was driven entirely by economics. The saved weight translates directly into extra cargo revenue. For us as suppliers, this means demand for AH36-grade bulb flats is steady and growing. It also means quality control is non-negotiable. A batch of bulb flats with borderline toughness or incorrect chemistry doesn’t just fail a test; it compromises the entire design principle of the vessel. The most common steel is common for a good reason: it delivers proven, reliable performance that makes ships safer and more profitable.

What steel is used in ship hulls?

The hull is the ship’s most critical component. It is a complex steel structure designed as a single, watertight unit. The steel used here must meet the highest standards for strength, weldability, and resistance to the marine environment.

Modern ship hulls primarily use high-strength, low-alloy steel grades like AH32, AH36, DH36, and EH36. These steels are specifically rolled into hull plates and profiles like bulb flats. They must carry certification from classification societies (ABS, LR, DNV, etc.) confirming their toughness, weldability, and corrosion performance for marine service.

The Hull Material System: Plates and Profiles Working Together

The hull is not made from one piece of steel. It is a built-up system. Understanding the different roles of plates and profiles is key.

| Hull Component | Material Form & Key Grades | Function & Requirements | How Bulb Flats Integrate |

|---|---|---|---|

| Shell Plating | Heavy plates (e.g., 15-25mm thick). Grades: AH32-AH40/DH32-DH40. | Forms the watertight outer skin. Must resist water pressure, global bending, and local impact. | Bulb flats are welded perpendicular to the inner surface of these plates as stiffeners. They prevent the large, thin plates from buckling. |

| Deck Plating | Plates similar to shell plating. Often high-strength steel to resist tensile/compressive loads from hull bending. | Forms the top cover of the hull girder. Carries deck cargo and equipment. | Bulb flats run longitudinally under the deck as stiffeners, transferring loads into the main hull structure. |

| Longitudinal Stiffeners | Bulb flat steel bars are the most common choice today. Grades match the plate (e.g., AH36 plate with AH36 bulb flat). | Provide continuous support to plates. They are the primary defense against buckling and add to the hull’s longitudinal strength. | This is the primary application of bulb flats. They are aligned with the ship’s length and continuously welded to the plate. |

| Frames and Web Frames | Can be bulb flats, angles, or fabricated T-sections. Often standard strength steel in non-critical areas. | Provide transverse (side-to-side) support, dividing the hull into smaller, stronger panels. | Bulb flats can be used as web frames (deep frames) in some designs, especially in double bottoms. |

| Keel and Bottom Structure | The thickest plates and strongest grades. Subject to highest loads (slamming, grounding). | Forms the backbone of the ship. Requires extra toughness. | Bulb flats are densely arranged as bottom longitudinals to support the keel plates against intense water pressure. |

When we supply steel for a hull, we don’t just ship plates and bulb flats separately. We coordinate to ensure the heat numbers and grades are compatible. For a recent LNG carrier project, the shipyard required all bottom plate and stiffener steel for certain sections to be from the same melt heat. This ensures perfect chemical and mechanical property matching for the most critical welds. The hull is a masterpiece of engineering where every piece depends on another. The steel is not just a material; it is a precise component of a safety system. Bulb flats are a preferred choice for the stiffener role because their shape makes them an efficient and reliable partner to the high-strength hull plates.

What is the most seaworthy hull shape?

Seaworthiness is about how a hull moves through water. It affects speed, stability, fuel burn, and crew comfort. While shape is crucial, the strength of the hull structure—enabled by materials like bulb flat steel—is what allows these shapes to survive at sea.

No single hull shape is “most seaworthy” for all purposes. For large oceangoing cargo ships, the displacement hull with a bulbous bow is the most common and efficient design. Its seaworthiness depends fundamentally on the internal steel skeleton—frames and longitudinals like bulb flats—that maintain its shape and integrity under storm loads.

How Hull Shape and Internal Structure Work Together

Seaworthiness results from both external form and internal strength. The table connects classic hull shapes to the structural needs that bulb flats help address.

| Hull Shape & Purpose | Seaworthiness Characteristics | Key Structural Demands | Role of Bulb Flat Stiffeners |

|---|---|---|---|

| Displacement Hull (Bulbous Bow) | Used by tankers, bulk carriers, container ships. Cuts waves smoothly, has high cargo capacity, and is fuel-efficient at cruising speed. | Must withstand massive global hull girder bending (hogging/sagging) and constant water pressure. | Longitudinals (bulb flats) are continuous and numerous. They directly contribute to resisting the longitudinal bending that strains the hull the most. |

| V-Shaped Hull (Planing Craft) | Used by patrol boats, some ferries. Cuts through waves sharply for a smoother ride at high speed in rough water. | Experiences severe slamming impacts on the forward bottom. Structures must handle high, sudden local loads. | In these vessels, bulb flats may be used as closely spaced frames or longitudinals in the forward sections to distribute slam loads quickly. |

| Round-Bilge Hull | Common for fishing vessels, tugs. Good all-around stability and seakeeping at moderate speeds. | Handles twisting (torsional) forces and uneven loads well. | Bulb flats provide the stiffening for the curved shell plating, preventing “oil canning” or buckling of the curved surfaces. |

| Multi-Hull (Catamaran) | Offers exceptional stability and deck space. Used for ferries, offshore support. | The connection between hulls is highly stressed. The hulls themselves are long and slender. | In each slender hull, longitudinal strength is critical. Bulb flats are key stiffeners along the length to prevent flexing. |

| The Importance of Internal Framing | A hull’s shape is defined by its plating, but its strength comes from the hidden framework underneath. | Without adequate stiffening, even the best hull shape will flex, buckle, and fatigue quickly. | Bulb flats form the primary longitudinal framework. They are the “ribs” that give the hull its lasting shape and strength against crushing sea forces. |

A shipowner in Greece once asked me why we emphasize the straightness of our bulb flats. I explained it with a hull shape analogy. Imagine building the long, smooth curve of a ship’s side. If your longitudinal stiffeners have a slight bow or twist, they will pull the plate out of its fair, hydrodynamic shape. You will get a wavy hull surface. This increases drag (burning more fuel) and can be a point of structural weakness. The most seaworthy shape is not just drawn on paper; it is built in the shipyard with precise, straight, and strong components. Bulb flats, with their inherent stiffness and efficiency, are the ideal tool for translating a good hull design into a strong, durable, and efficient reality.

Conclusion

Bulb flat steel is the preferred choice because it turns design theory into practice. It delivers the strength, weight savings, and buildability that make modern, efficient, and seaworthy ships possible.

-

Explore the importance of marine-grade steel in shipbuilding for safety and durability. ↩

-

Learn about the benefits of high-strength steel grades for hull plating and structural integrity. ↩

-

Find out why weldability is crucial for the structural integrity of ship components. ↩ ↩

-

Discover how Extra-High Toughness Steel enhances safety in extreme conditions. ↩

-

Understand how corrosion-resistant steel extends the lifespan of marine structures. ↩

-

Learn about the role of AH36-grade bulb flats in ensuring strong ship structures. ↩