Your ship’s structural bracket fails during a heavy storm. The investigation points to substandard angle steel. This is not a design flaw. It is a procurement failure. Using uncertified L-shaped steel is a hidden risk you cannot afford.

You should use BV certified marine L-shaped steel to guarantee the material’s strength, toughness, and weldability meet the rigorous standards of Bureau Veritas for marine structures. This certification ensures reliability, simplifies surveyor approval, and prevents costly structural failures at sea.

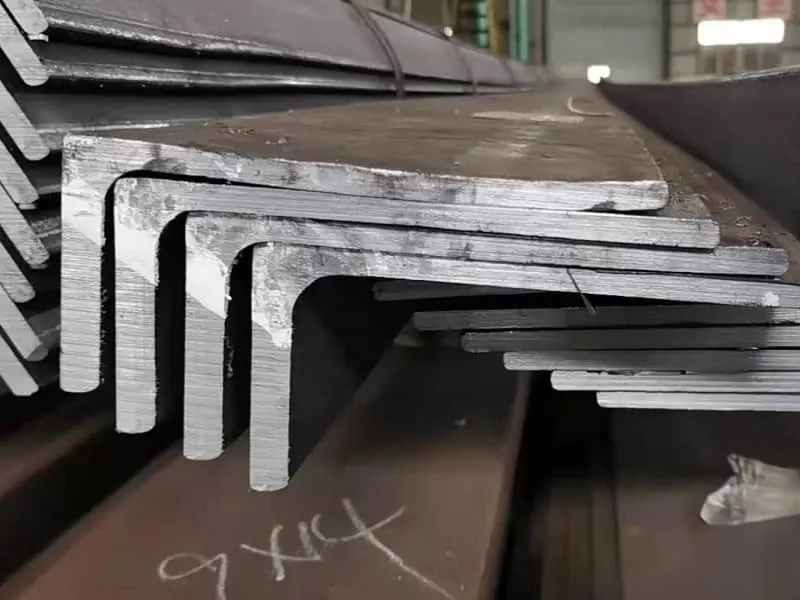

In my years supplying steel to global shipyards, I have seen too many projects use "commercial grade" angle steel for marine brackets and frames. This is a false economy. The L-shaped section is a critical component, and its quality must be guaranteed. Let’s examine the specific properties of BV steel, understand its place among marine grades, and address the real concerns about using angle steel.

What are the properties of BV grade steel1?

A fabricator substitutes a cheaper, uncertified angle bar for a BV grade. The weld looks good, but the heat-affected zone becomes brittle. Under load, a crack forms. This failure starts with not understanding the guaranteed properties in a BV certificate.

BV grade steel1 possesses a defined set of mechanical and chemical properties certified by Bureau Veritas. These include minimum yield and tensile strength, specific chemical composition limits, and crucially, verified impact toughness at low temperatures to prevent brittle fracture in marine environments.

When we talk about BV grade steel1, we are not talking about a single recipe. We are talking about a system of grades (like BV A, BV B, BV D, BV E, and high-strength grades like BV AH36) that each have a specific property profile. The certification is the guarantee that a particular batch of steel matches that profile.

Decoding the Key Properties of BV Certified Steel Grades

| Property Category | What It Means | BV Certification Guarantee | Why It’s Critical for L-Shaped Sections |

|---|---|---|---|

| Mechanical Strength2 | The steel’s ability to withstand force without deforming (Yield Strength) or breaking (Tensile Strength). | Each grade has a minimum value. E.g., BV A: Yield ≥ 235 MPa; BV AH36: Yield ≥ 355 MPa. | L-angles are used in brackets and frames that carry loads. They must have the strength to support decks, bulkheads, and equipment without bending. |

| Impact Toughness3 (KV) | The material’s ability to absorb energy and resist cracking at low temperatures, measured in Joules at specified temps (e.g., 0°C, -20°C, -40°C). | Grades BV D, E, and all high-strength grades (AH) require passing Charpy V-Notch tests at low temperatures. | Ships operate in cold waters. A bracket made of brittle steel can shatter from impact or fatigue, causing catastrophic structural failure. |

| Chemical Composition | The precise amounts of elements like Carbon, Manganese, Silicon, Sulfur, and Phosphorus, and alloying elements like Niobium. | Strict upper limits are set, especially for Sulfur and Phosphorus, which harm toughness and weldability. | The chemistry ensures good weldability and the right microstructure for strength and toughness. It is the foundation for all other properties. |

| Weldability4 | Ease of welding without causing cracks in the weld or the Heat-Affected Zone (HAZ). | Controlled through Carbon Equivalent (CE) value calculated from the chemical composition. A lower CE means better weldability. | L-shaped steel is almost always welded. Poor weldability leads to hidden defects that become failure points. |

For a buyer, the Mill Test Certificate5 (MTC) is the proof of these properties. A BV-certified MTC for a batch of L-shaped steel will list all the actual test results, the heat number, and the BV approval reference. This allows a shipyard surveyor to verify in minutes that the material is fit for its intended use in a specific hull zone.

This traceability solves a major pain point. Our client, Gulf Metal Solutions, faced quality inconsistency with previous suppliers. When they switched to us for BV-certified angle steel, they received the full, verifiable MTC with every shipment. Their rational, results-driven buyer could immediately confirm the properties matched the specification for their project in Saudi Arabia. This eliminated guesswork and risk, turning material procurement from a headache into a reliable process.

What is the best marine grade steel1?

A ship designer specifies the "best" steel as AH40 for the entire hull. The project goes over budget. The truth is, the "best" steel is the one that exactly meets the structural requirement2 at the lowest total cost. It is about precision, not prestige.

There is no single "best" marine grade steel1. The optimal choice depends on the ship’s structural location and classification society3 rules. For most hulls, high-strength grades4 like AH365 offer a great balance. For non-critical internal structures, normal strength Grade A is cost-effective and sufficient.

The quest for the "best" is often misguided. A better question is: "What is the most appropriate grade for this specific application?" We need to evaluate steel based on three factors: the structural demand, the classification society3‘s rules for that zone, and the total cost-in-use.

Selecting the Appropriate Marine Steel Grade

| Structural Zone & Application | Primary Requirements | Typical "Best Fit" BV Grades | Rationale: Why This is the Optimal Choice |

|---|---|---|---|

| Bottom Shell & Keel | Maximum strength, highest toughness, fatigue resistance. | BV AH365, DH36, EH36. For ice-going vessels: BV AH40. | These areas endure the highest loads and impacts. High-strength steel (HSS) allows for weight savings. The ‘H’ denotes high strength (36 for 355 MPa yield). The letter (D, E) indicates toughness testing temperature. |

| Side Shell & Main Deck | Good strength, good toughness, weldability. | Mix of BV A/B and BV AH32/AH365 for high-stress areas. | Not all areas need the highest strength. Using HSS only where needed (like deck edges) optimizes cost and weight. |

| Internal Structures (Frames, Bulkheads, Brackets) | Good weldability and formability. Strength is often secondary. | BV A or BV B grades are standard. | These parts are shielded from direct sea loads and extreme cold. Using expensive HSS here is wasteful. Normal strength steel is perfectly adequate and more economical. |

| L-Shaped Angle Steel for Brackets & Stiffeners | Must match or exceed the properties of the plate it supports. Good weldability is critical. | Typically BV A or BV AH32/AH365, specified to match the adjacent plate grade. | An angle bar bracket connecting AH365 plates should itself be AH365 grade. Using a weaker grade creates a weak link in the structure. |

Therefore, for L-shaped steel used in internal framing or bracketing, the "best" grade is the one specified on the ship’s structural drawings. It is often BV A or BV B. However, if that bracket is in a critical, high-stress location or supporting an HSS plate, the "best" grade becomes BV AH32 or AH365. The certification ensures the L-angle has the same guaranteed toughness and weldability as the plate, creating a uniform, reliable structure.

Our role is to supply the exact grade specified. We stock BV-certified L-shaped steel in common grades like A and AH365. This allows us to serve projects with different requirements. A yard in Vietnam building a bulk carrier might need BV A angles for most internal work. A yard in Romania working on an offshore module might need BV AH365 angles for critical connections. By having certified stock and mill access, we provide the "best" steel for each specific context, not a one-size-fits-all product.

What are the disadvantages of using angle steel?

A designer uses a thick, heavy angle bar for a simple bracket. It works, but it adds unnecessary weight and is difficult to fit in a tight space. The disadvantage is not angle steel itself, but its inefficient use compared to modern alternatives like bulb flats.

The main disadvantages of traditional angle steel (L-shaped) in marine construction are its lower structural efficiency compared to bulb flat steel, potential for higher corrosion in the inner corner, and the need for more complex welding and fitting in some assembly scenarios.

Angle steel is a classic and versatile profile. But in modern, optimized shipbuilding, we must acknowledge its limitations to use it correctly. The disadvantages become apparent when we compare it to more advanced rolled sections or when we consider specific applications.

Critical Evaluation: Limitations of Traditional Angle Steel

| Disadvantage | Detailed Explanation | Practical Implication in Shipbuilding |

|---|---|---|

| Lower Structural Efficiency1 | The material in an L-angle is not optimally distributed to resist bending. The neutral axis is close to one leg. | To achieve the same strength as a bulb flat, an L-angle often needs to be thicker and heavier. This adds unnecessary weight to the ship, reducing cargo capacity or increasing fuel consumption. |

| Corrosion Trap | The internal 90-degree corner can trap moisture, dirt, and salt, creating a perfect environment for crevice corrosion. | This requires more careful surface preparation, painting, and maintenance. If not properly protected, corrosion can start unseen in the corner, weakening the section. |

| Welding & Fit-up Challenges2 | Welding an L-angle to a plate often requires fillet welds on two sides. Achieving full penetration can be difficult. The fit-up must be precise to avoid gaps. | This increases welding time and cost. It requires higher skill from welders. Poor fit-up can lead to stress concentrations and potential weld defects. |

| Limited Standardization in Sizes3 | While common sizes exist, the range of optimized dimensions for marine use is smaller than for plates or bulb flats. | It can sometimes limit design flexibility or require custom cutting, adding cost. |

It is important to note that these disadvantages are context-dependent. For many secondary structures, brackets, and supports, angle steel remains perfectly suitable, cost-effective, and readily available. The key is to know when its use is optimal and when to consider an alternative like Bulb Flat Steel4.

Bulb flats are a superior alternative for primary stiffeners. The bulb at the tip provides excellent resistance to buckling. The flat web is easier to weld to the plate. The profile is more efficient, so you use less steel for the same strength. We supply both. When our client Gulf Metal Solutions mentioned their next order for "ship L-shaped steel and spherical flat steel," they were planning for different applications. The L-angles might be for miscellaneous brackets, while the bulb flats (spherical flat steel) would be for the main hull stiffeners. Understanding the disadvantages of each profile allows us to advise clients on the right material for the right job, ensuring their designs are both strong and cost-effective.

What grade is marine steel1?

A new shipyard buyer searches online for "marine steel1." He finds thousands of results with different numbers and letters. He feels confused. Marine steel is not one grade; it is a family of grades defined by classification society2 rules.

Marine steel refers to a range of grades defined by classification societies like BV, ABS, or DNV. These grades are categorized as Normal Strength (e.g., Grade A, B, D, E) and High Strength3 (e.g., AH32, AH36, DH40), where the letter indicates toughness and the number indicates minimum yield strength4 in ksi.

The question "What grade is marine steel?" is like asking "What model is a car?" It has many answers. To make sense of it, we need to understand the naming system. The system tells a story about the steel’s strength and toughness.

Understanding the Marine Steel Grade Coding System

| Grade Code (e.g., BV AH36) | Part of the Code | What It Signifies | Example & Meaning |

|---|---|---|---|

| Prefix (Optional) | "BV", "ABS", "DNV" | The classification society2 that certified the steel. | BV AH36 means the steel is certified to Bureau Veritas rules. |

| First Letter(s) | A, B, D, E (for Normal Strength) | Indicates the required impact test temperature5: A: Not required. B: Room temperature. D: 0°C. E: -10°C to -40°C (depends on thickness). |

BV D steel is Normal Strength and must pass impact tests at 0°C. |

| AH, DH, EH (for High Strength3) | The first letter (A, D, E) still indicates impact test temperature5. The ‘H’ stands for High strength. | BV AH36 is High Strength3 steel with impact tests at a temperature defined for grade A (not required by default, but often specified). BV EH36 is High Strength3 with impact tests at very low temperatures (e.g., -40°C). | |

| Number | 32, 36, 40 | The minimum yield strength4 of the steel in kilo-pounds per square inch (ksi). 36 means 36 ksi, which equals approximately 355 Megapascals (MPa). | BV AH36 has a minimum yield strength4 of 355 MPa. BV AH40 has a minimum yield strength4 of 390 MPa. |

So, when you specify "marine steel1," you must specify the exact grade. A ship’s structural plan will say "BV AH36 Plate" or "BV A Angle." This code gives the fabricator and the supplier all the information needed.

For us as a supplier, this clarity is essential. When a client from the Philippines emails an inquiry for "marine angle steel," our first question is always: "What is the required grade and certification (BV, ABS)?" This ensures we quote the correct material. We stock and source BV-certified L-shaped steel in common grades like A, B, and AH36. This systemized approach prevents costly mistakes. It ensures that the steel we deliver to a port in Thailand or Mexico will be exactly what the shipyard’s welding procedures and classification surveyor require. This precision, backed by certification, is what builds long-term trust with rational, project-focused buyers around the world.

Conclusion

Choosing BV certified L-shaped steel is a decision for guaranteed performance and project security. It turns a simple component into a reliable link in your vessel’s structural integrity.

-

Explore this link to understand the various grades of marine steel and their significance in shipbuilding. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Understanding classification societies is crucial for ensuring compliance and quality in marine steel procurement. ↩ ↩ ↩ ↩ ↩

-

Discover the properties of High Strength marine steel grades and how they impact ship design and safety. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

This resource will clarify the importance of minimum yield strength in selecting the right marine steel for your project. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the significance of impact test temperatures in marine steel to ensure safety and performance in harsh conditions. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩